Gone Blue

VIP Member

- Joined

- Oct 11, 2006

- Messages

- 1,628

- Age

- 62

- Location

- Howell, Michigan

- Country

- USA

- Snowmobile

- 08' Nytro RTX 40th Anniversary - Stretched

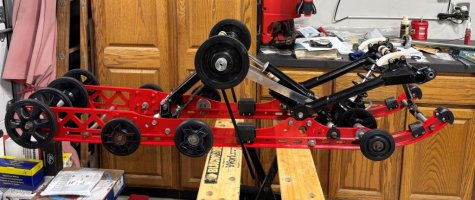

So I am finishing up a complete skid rebuild, replacing all bearings and oil seals in the chaincase and drive line, and will install a new 1" 3/8" x 144" Cobra track. While taking apart the chaincase, I found the broken driveshaft bolt. The last thing I need to do is remove the broken bolt from the driveshaft. Using a blind bearing puller to remove the chaincase upper inner bearing was easy with a little heat around the bearing on the chaincase. I used plumbers putty and the driveshaft spacer to remove the outer driveshaft bearing in the case cover. It worked great but took time while keep having to add more putty.

QUESTION: Is there a different torque spec for the new higher strength driveshaft bolt? I believe the torque spec for this bolt according to my Yamaha service manual is 20 ft/lbs (28Nm)?

Thanks, GB

QUESTION: Is there a different torque spec for the new higher strength driveshaft bolt? I believe the torque spec for this bolt according to my Yamaha service manual is 20 ft/lbs (28Nm)?

Thanks, GB

Attachments

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,316

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

The bolt breaks because the driveshaft was too short and didn't slide into the collar far enough. Yamaha made the correct fix with a longer driveshaft and collar to go with it on later models. I would think the torque spec will be the same.

Stubbs

TY 4 Stroke Master

- Joined

- Nov 7, 2006

- Messages

- 1,150

- Age

- 44

- Location

- Uxbridge, On, Can.

- Country

- Canada

- Snowmobile

- ‘16 Apex XTX with 137” Mono II

+ other gooodies

- LOCATION

- Uxbridge ON

I put a fair number of k’s on my ‘13 Nytro with no issues in terms of that lower bolt, Yammy’s update seemed to do the trick.

Gone Blue

VIP Member

- Joined

- Oct 11, 2006

- Messages

- 1,628

- Age

- 62

- Location

- Howell, Michigan

- Country

- USA

- Snowmobile

- 08' Nytro RTX 40th Anniversary - Stretched

Thanks Nitro. I read some threads on here about the length change with the driveshaft. I found a XTX driveshaft for sale cheap I am thinking of looking at. Want to see if there is a length difference and it would save time drilling out my broken bolt?The bolt breaks because the driveshaft was too short and didn't slide into the collar far enough. Yamaha made the correct fix with a longer driveshaft and collar to go with it on later models. I would think the torque spec will be the same.

Anyone have an idea when the longer driveshaft change was made?I put a fair number of k’s on my ‘13 Nytro with no issues in terms of that lower bolt, Yammy’s update seemed to do the trick.

Stubbs

TY 4 Stroke Master

- Joined

- Nov 7, 2006

- Messages

- 1,150

- Age

- 44

- Location

- Uxbridge, On, Can.

- Country

- Canada

- Snowmobile

- ‘16 Apex XTX with 137” Mono II

+ other gooodies

- LOCATION

- Uxbridge ON

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,316

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

It may have been 2010. Look at the online parts diagrams and see when the part numbers change. The collar that goes on the end is also needed.

I think the shaft was also a little bigger diameter which means the plastic sprockets are different.

The 2.86 drivers were only used on the 13 and 14 RTX if I remember correctly.

I think the shaft was also a little bigger diameter which means the plastic sprockets are different.

The 2.86 drivers were only used on the 13 and 14 RTX if I remember correctly.

Gone Blue

VIP Member

- Joined

- Oct 11, 2006

- Messages

- 1,628

- Age

- 62

- Location

- Howell, Michigan

- Country

- USA

- Snowmobile

- 08' Nytro RTX 40th Anniversary - Stretched

Thanks guys, dont worry about it now. I was only looking for other drive shaft options if I had trouble removing the broken bolt. I used some cheap HF bolt extractors today and the bolt easily came out. So I am good. Thanks to all for your help!It may have been 2010. Look at the online parts diagrams and see when the part numbers change. The collar that goes on the end is also needed.

I think the shaft was also a little bigger diameter which means the plastic sprockets are different.

The 2.86 drivers were only used on the 13 and 14 RTX if I remember correctly.

Attachments

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,316

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

The new bolt will likely break again at some point, but it's not a real big deal as the machine still works even with broken bolt.

Gone Blue

VIP Member

- Joined

- Oct 11, 2006

- Messages

- 1,628

- Age

- 62

- Location

- Howell, Michigan

- Country

- USA

- Snowmobile

- 08' Nytro RTX 40th Anniversary - Stretched

Yeah sounds like it. My broken bolt was riding around in the chain case cover for a while. It lasted some 12,000 miles so if I get that or more with higher strength bolt, I can live with that.The new bolt will likely break again at some point, but it's not a real big deal as the machine still works even with broken bolt.

Dynomax666

Extreme

my 2010 did this, I think 2010 was the year they added a clip to old the bolt in. it still bored a hole in my chaincase cover, I JB Welded it. it drilled a perfectly circular hole before I noticed it. Never lost a drop of oil, but was full of filings, I cleaned it out good, ran it and changed oil againYeah sounds like it. My broken bolt was riding around in the chain case cover for a while. It lasted some 12,000 miles so if I get that or more with higher strength bolt, I can live with that.

old iron

Newbie

I have a question. Why would Yamaha put a sealed bearing in the cover if it's inside and oil bath?

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,316

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Because there is a lot of metal filings always coming off the gear teeth and chain links.I have a question. Why would Yamaha put a sealed bearing in the cover if it's inside and oil bath?

Gone Blue

VIP Member

- Joined

- Oct 11, 2006

- Messages

- 1,628

- Age

- 62

- Location

- Howell, Michigan

- Country

- USA

- Snowmobile

- 08' Nytro RTX 40th Anniversary - Stretched

My 08' was long tracked by its previous owner. So someone has been the chaincase before? So I am not confident what bearings in the chaincase should have seals and which ones dont? That lower bearing in my chaincase cover had only one seal on the inboard side. It is open on the backside. So that is what I put back in it. G.B.Because there is a lot of metal filings always coming off the gear teeth and chain links.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,316

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

That's factory.My 08' was long tracked by its previous owner. So someone has been the chaincase before? So I am not confident what bearings in the chaincase should have seals and which ones dont? That lower bearing in my chaincase cover had only one seal on the inboard side. It is open on the backside. So that is what I put back in it. G.B.

Similar threads

- Replies

- 36

- Views

- 6K

- Replies

- 22

- Views

- 2K

- Replies

- 8

- Views

- 1K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.