dhkr123

Expert

It *IS* necessary.

It is necessary on ALL sleds.

Smoke will come from when the INSULATION ON THE WIRES MELT AND MAYBE CATCH ON FIRE. You could burn your whole sled to the ground!

It MUST be close to the battery (edit: or connected to another fused circuit, like the main)... because ANY distance between the fuse and the battery is an OPPORTUNITY FOR CHAFING AND SHORT CIRCUIT/SMOKE/FIRE.

It is necessary on ALL sleds.

Smoke will come from when the INSULATION ON THE WIRES MELT AND MAYBE CATCH ON FIRE. You could burn your whole sled to the ground!

It MUST be close to the battery (edit: or connected to another fused circuit, like the main)... because ANY distance between the fuse and the battery is an OPPORTUNITY FOR CHAFING AND SHORT CIRCUIT/SMOKE/FIRE.

dhkr123

Expert

You will note that the MAIN FUSE is right down at the battery. From there, a big red wire runs to the secondary fuse box right above the chain case. There are FOUR fuses in there, running HEADLIGHT, SIGNAL (brake light, not tail), CARB HEATER, and IGNITION. (or something like that since your sled may differ slightly from the wiring diagrams I'm looking at....)

With a blown main fuse (withOUT short present), the machine will still RUN, but will neither START, nor CHARGE. It is not important for the charge wire from the voltage regulator to be protected by a fuse, since a short that takes out the main fuse will be enough to guarantee that the ignition fails. Without a short, the ignition can run straight off the voltage regulator.

I suggest that you remove your wires from the battery, hook the BLACK to chassis NEAR the secondary fuse box, and attach a fuse to the SOURCE side of the secondary fuse box with one of these: http://www.cooperbussmann.com/images/3c ... d13aad.JPG

--- that thing is called a fuse tap. You need "ATM" size.

With a blown main fuse (withOUT short present), the machine will still RUN, but will neither START, nor CHARGE. It is not important for the charge wire from the voltage regulator to be protected by a fuse, since a short that takes out the main fuse will be enough to guarantee that the ignition fails. Without a short, the ignition can run straight off the voltage regulator.

I suggest that you remove your wires from the battery, hook the BLACK to chassis NEAR the secondary fuse box, and attach a fuse to the SOURCE side of the secondary fuse box with one of these: http://www.cooperbussmann.com/images/3c ... d13aad.JPG

--- that thing is called a fuse tap. You need "ATM" size.

Irv

TY 4 Stroke God

- Joined

- Mar 23, 2005

- Messages

- 3,778

- Reaction score

- 44

- Points

- 1,233

- Location

- ONT. Canada

- Country

- Canada

- Snowmobile

- 2008 40th Anniversary Vector.

1995 XLT SP (Son's)

dhkr123 said:You will note that the MAIN FUSE is right down at the battery. From there, a big red wire runs to the secondary fuse box right above the chain case. There are FOUR fuses in there, running HEADLIGHT, SIGNAL (brake light, not tail), CARB HEATER, and IGNITION. (or something like that since your sled may differ slightly from the wiring diagrams I'm looking at....)

With a blown main fuse (withOUT short present), the machine will still RUN, but will neither START, nor CHARGE. It is not important for the charge wire from the voltage regulator to be protected by a fuse, since a short that takes out the main fuse will be enough to guarantee that the ignition fails. Without a short, the ignition can run straight off the voltage regulator.

I suggest that you remove your wires from the battery, hook the BLACK to chassis NEAR the secondary fuse box, and attach a fuse to the SOURCE side of the secondary fuse box with one of these: http://www.cooperbussmann.com/images/3c ... d13aad.JPG

--- that thing is called a fuse tap. You need "ATM" size.

Thanks for the info and link, guess I had better get it torn back down and get this done.

Out of curiousity, what are the main reasons for the fuse, is it a heat(amp) issue, wire chafing issue or something else?

With the fuse in there, does it help with the heat issue or is it there just in case the wire does gets hot?

I remember seeing that secondary fuse box, it made me wonder but I was uncertain as some electric hardware has been added to this sled(Yamaheater and an extra 12 volt outlet) so I stayed away from it.

Thanks again, I appreciate your help and the fact that you may have saved my sled from burning to the ground!

grizztracks

TY Advertiser

- Joined

- Feb 24, 2005

- Messages

- 3,118

- Reaction score

- 975

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

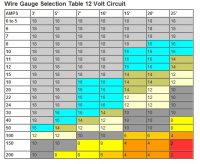

You need to fuse a circuit according to the length and gauge of the wire feeding the load. A fuse is installed to protect the wire not the load. If you overload the wire the fuse needs to blow before damage is done.

I added a heat shield and DC outlet to my 08 Nytro and ran the wires back to the fuse box. I picked up power off of the white/black wire which is feed by the load control relay (pink wires come directly from the main fuse) I picked up a couple off inserts at a local parts store that push up into the block allowing me to add a fuse to an empty position. The inserts where a little to big for the fuse box so I filed one side down to make them fit. This is a much cleaner install and the fuse is protected by the box. I also considered adding a Dual ATM Mini Fuse Holder to the fuse box which would be an easier route and should work but not as clean of an install. If you decide to add the dual holder I'd place it in the "SIG" fuse position which powers down when the sled is not running. Auto Zone carries the fuse holders.

I added a heat shield and DC outlet to my 08 Nytro and ran the wires back to the fuse box. I picked up power off of the white/black wire which is feed by the load control relay (pink wires come directly from the main fuse) I picked up a couple off inserts at a local parts store that push up into the block allowing me to add a fuse to an empty position. The inserts where a little to big for the fuse box so I filed one side down to make them fit. This is a much cleaner install and the fuse is protected by the box. I also considered adding a Dual ATM Mini Fuse Holder to the fuse box which would be an easier route and should work but not as clean of an install. If you decide to add the dual holder I'd place it in the "SIG" fuse position which powers down when the sled is not running. Auto Zone carries the fuse holders.

Attachments

dhkr123

Expert

It is because the battery is capable of delivering FAR more current (amps) than the wire you're installing. Without a secondary source of resistance (your heated shield), the FULL current of the battery will run through that tiny wire, instantly driving its temperature up to Chernobyl levels. You can get this zero resistance condition either by the wire chafing against the frame, or by some low resistance load (broken heated shield, kid plugging in a big speaker...) being connected to the TERMINAL you install on your handle bar. The wire in the fuse is designed to melt and fall away safely when the current exceeds a predetermined amount, which is significantly less than the load the WIRE is capable of carrying. See the chart posted by grizztracksIrv said:Out of curiousity, what are the main reasons for the fuse, is it a heat(amp) issue, wire chafing issue or something else?

I'm pretty sure I covered that above, but to summarize... current = heat. The fuse melts away before the wire gets *too* hot.With the fuse in there, does it help with the heat issue or is it there just in case the wire does gets hot?

I guess someone else installed it. Wouldn't be a bad idea to check it all over to ensure that it has been properly fusedI remember seeing that secondary fuse box, it made me wonder but I was uncertain as some electric hardware has been added to this sled(Yamaheater and an extra 12 volt outlet) so I stayed away from it.

Sled + fire = bad.Thanks again, I appreciate your help and the fact that you may have saved my sled from burning to the ground!

Irv

TY 4 Stroke God

- Joined

- Mar 23, 2005

- Messages

- 3,778

- Reaction score

- 44

- Points

- 1,233

- Location

- ONT. Canada

- Country

- Canada

- Snowmobile

- 2008 40th Anniversary Vector.

1995 XLT SP (Son's)

Awesome info guy's, appreciate it

When saying the fuse should be located as close to the battery as possible, in your opinion would approx 4-5 inches be close enough?

I am hoping to install a fused joiner wire I had made up today but I am hoping I don't have to take everything apart again to get as close to the battery as possible?

Sorry for all the stupid questions.

When saying the fuse should be located as close to the battery as possible, in your opinion would approx 4-5 inches be close enough?

I am hoping to install a fused joiner wire I had made up today but I am hoping I don't have to take everything apart again to get as close to the battery as possible?

Sorry for all the stupid questions.

Crewchief47

Lifetime Member

- Joined

- Jan 16, 2006

- Messages

- 2,830

- Reaction score

- 32

- Points

- 1,333

- Location

- McGregor, ON Canada

- Country

- Canada

- Snowmobile

- 2008 Nytro MTX 45th

As close to the battery as reasonable is fine.

dhkr123

Expert

Irv said:Awesome info guy's, appreciate it

When saying the fuse should be located as close to the battery as possible, in your opinion would approx 4-5 inches be close enough?

I am hoping to install a fused joiner wire I had made up today but I am hoping I don't have to take everything apart again to get as close to the battery as possible?

Sorry for all the stupid questions.

As close to the battery as possible, or as close to the nearest FUSED MAIN as possible... as in 1" or less.

ecopter

TY 4 Stroke Guru

In my opinion, it's easier to tap into the headlight wire near your handlebar. A simple solder job and it's all good. I've had mine like that for years with no issues. And, no fuse necessary.

jf

jf

dhkr123

Expert

Except that if your shield shorts out, it'll blow your headlight circuit and you'll be driving home without headlights.

woolyviper

TY 4 Stroke Master

- Joined

- Mar 24, 2006

- Messages

- 1,151

- Reaction score

- 2

- Points

- 841

- Location

- hibbing,mn

- Country

- USA

- Snowmobile

- 2009 Yamaha Phazer RTX

i always go straight to the battery with my plug - that way if i take my helmet off i leave it hooked up and the shield stays warm.

Irv

TY 4 Stroke God

- Joined

- Mar 23, 2005

- Messages

- 3,778

- Reaction score

- 44

- Points

- 1,233

- Location

- ONT. Canada

- Country

- Canada

- Snowmobile

- 2008 40th Anniversary Vector.

1995 XLT SP (Son's)

dhkr123 said:Irv said:Awesome info guy's, appreciate it

When saying the fuse should be located as close to the battery as possible, in your opinion would approx 4-5 inches be close enough?

I am hoping to install a fused joiner wire I had made up today but I am hoping I don't have to take everything apart again to get as close to the battery as possible?

Sorry for all the stupid questions.

As close to the battery as possible, or as close to the nearest FUSED MAIN as possible... as in 1" or less.

Just finished hooking it up, put the fuseable link with 3 amp fuse as close to the battery as possible, heat shrunk and tie wrapped everything up so I should be good to go I think. Thoughts??

Attachments

grizztracks

TY Advertiser

- Joined

- Feb 24, 2005

- Messages

- 3,118

- Reaction score

- 975

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Irv

TY 4 Stroke God

- Joined

- Mar 23, 2005

- Messages

- 3,778

- Reaction score

- 44

- Points

- 1,233

- Location

- ONT. Canada

- Country

- Canada

- Snowmobile

- 2008 40th Anniversary Vector.

1995 XLT SP (Son's)

grizztracks said:Irv, they sell fuse holder with caps to protect them from the weather for a few dollars at most any auto parts store. I wouldn't trust those connectors. Get yourself the proper holder.

Wish I had of known about those but I am not going to take my sled apart a 3rd time lol.

I think I will be alright, everything is heat shrunk, dielectric grease was added and I taped and secured the fuse you see in the picture.

One thing that struck me was the size of the wires that went to + and - , they must be a 22-24 guage, they are that small!!

Would it have hurt HJC to make them at least a 18 or are they that small for a reason?

ecopter

TY 4 Stroke Guru

dhkr123 said:Except that if your shield shorts out, it'll blow your headlight circuit and you'll be driving home without headlights.

I believe the headlight circuit is fused.

jf

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.