Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Current clutch calibrations are listed on page 2, post 17.

VECTOR:

My 2008 Vector LTX hit the 10,000 mile mark this past season. I've owned this sled since new and it's been bullet proof with NO issues, except the original primary clutch is showing its age (worn sheaves, pins and bushings). Since day one, however, my only complaint has been the rattle...rattle...rattle sound the clutch produces. This past winter had me considering a replacement before this upcoming season. I actually have two, like new, spare Yamaha clutches sitting on the shelf for such an occasion, but I wanted to try and find a way to get away from the rattle, and the only way I know to explore that option is with the aftermarket.

I searched and read all internet forums this summer, and one name that kept popping up was the CV Tech Power Bloc 80. There's very little information about these clutches being used on Yamaha, but CV Tech does offer the PB 80 pre-calibrated for the Vector; for most Yamaha 4-stoke in fact. Reports of this clutch used on other brands have been mostly positive; some even swearing by it. Reports also indicate this isn't a suitable clutch for drag racing, but I'm long distance trail rider, not a racer.

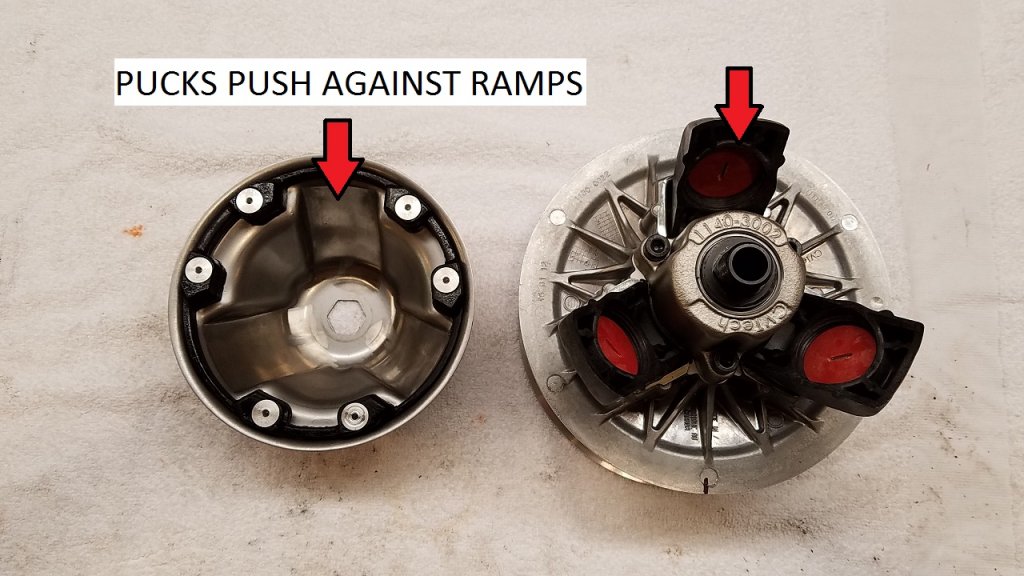

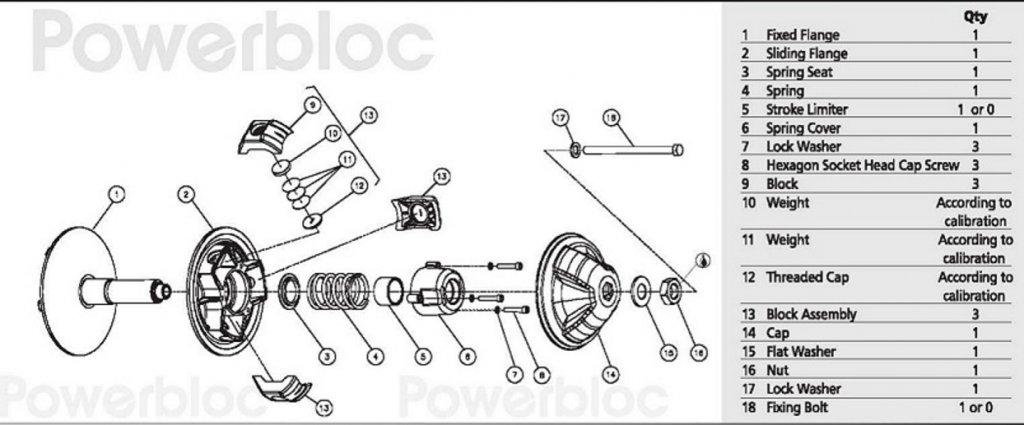

Like stock, the PB 80 has a primary spring, but that's where the similarities end. It has no arms, pins, rollers or bushings, with the exception of bushings on the sliding half of the sheaves. There are three large pucks that contain interchangeable weight discs, commonly referred to as, "slugs!" As RPM increases, centrifugal force causes the pucks to tip outward and press on the clutch cover, which overcomes the primary spring and engages the sheaves on the belt. To change engine RPM, you simply add or subtract weight discs in each puck. There are different weights of discs available, even heavy slug weights for turbo applications. An assortment of primary springs are also available for custom tailoring. The clutch appears to be well built with plenty of meat in all the right areas.

More to come as I gear up to install this clutch. I will also update this winter as I get some miles on and form a real-world opinion. Stay tuned!

EDIT - I have since purchased a PB 80 for my 2012 Apex as well.

VECTOR:

My 2008 Vector LTX hit the 10,000 mile mark this past season. I've owned this sled since new and it's been bullet proof with NO issues, except the original primary clutch is showing its age (worn sheaves, pins and bushings). Since day one, however, my only complaint has been the rattle...rattle...rattle sound the clutch produces. This past winter had me considering a replacement before this upcoming season. I actually have two, like new, spare Yamaha clutches sitting on the shelf for such an occasion, but I wanted to try and find a way to get away from the rattle, and the only way I know to explore that option is with the aftermarket.

I searched and read all internet forums this summer, and one name that kept popping up was the CV Tech Power Bloc 80. There's very little information about these clutches being used on Yamaha, but CV Tech does offer the PB 80 pre-calibrated for the Vector; for most Yamaha 4-stoke in fact. Reports of this clutch used on other brands have been mostly positive; some even swearing by it. Reports also indicate this isn't a suitable clutch for drag racing, but I'm long distance trail rider, not a racer.

Like stock, the PB 80 has a primary spring, but that's where the similarities end. It has no arms, pins, rollers or bushings, with the exception of bushings on the sliding half of the sheaves. There are three large pucks that contain interchangeable weight discs, commonly referred to as, "slugs!" As RPM increases, centrifugal force causes the pucks to tip outward and press on the clutch cover, which overcomes the primary spring and engages the sheaves on the belt. To change engine RPM, you simply add or subtract weight discs in each puck. There are different weights of discs available, even heavy slug weights for turbo applications. An assortment of primary springs are also available for custom tailoring. The clutch appears to be well built with plenty of meat in all the right areas.

More to come as I gear up to install this clutch. I will also update this winter as I get some miles on and form a real-world opinion. Stay tuned!

EDIT - I have since purchased a PB 80 for my 2012 Apex as well.

Last edited:

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

I'll be watching this one ! I have a Vector that's pushing 12000 miles. I'm about done adding upgrades but if this works good for you I might have to invest...

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

VECTOR:

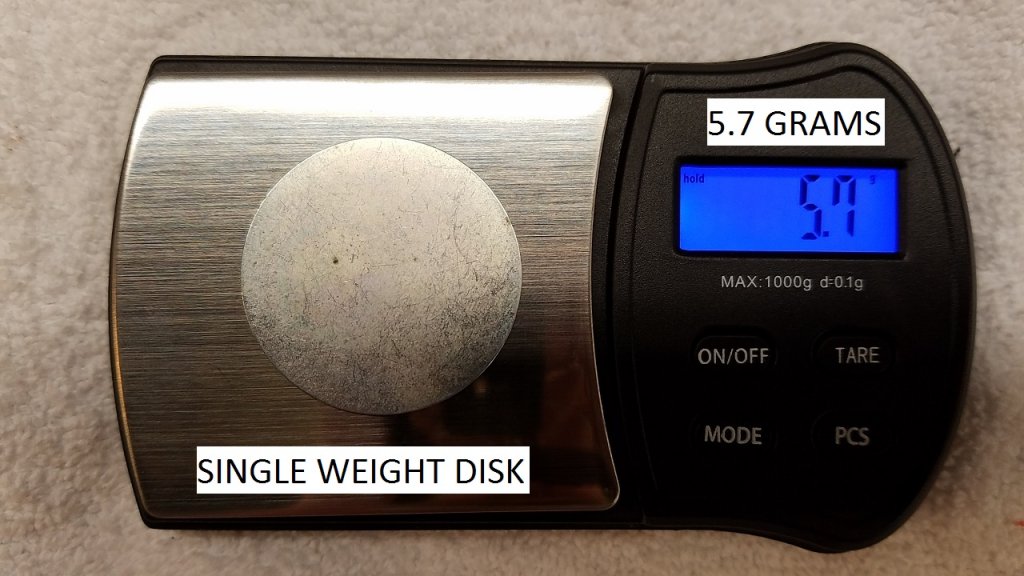

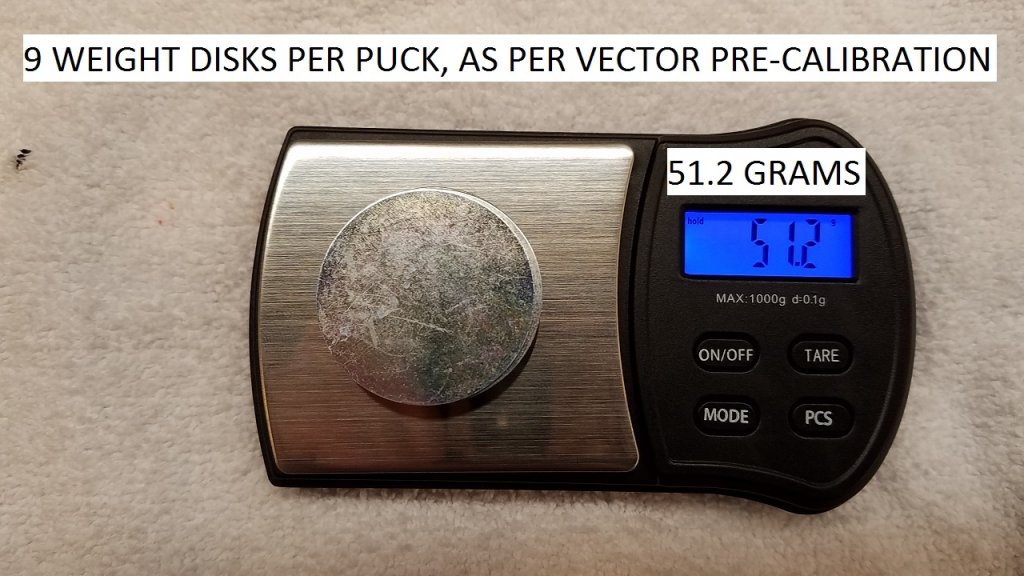

Using a U.S. postage scale, I weighed the PB 80 and compared it to the stock Yamaha clutch weight. The PB is actually heavier than stock by 5.6 oz. I assumed the extra weight was from the steel cover, but I wasn't sure? I disassembled the clutch and started weighing all the internal components and discovered each puck, contains 9 disks and weighs right at 100+ grams. Wow! That tells me the extra weight is likely from the heavy pucks and the steel cover combined. Again, this clutch was shipped pre-calibrated for a Vector. More to come later on the spring.

Here is a breakdown of all the weights:

Using a U.S. postage scale, I weighed the PB 80 and compared it to the stock Yamaha clutch weight. The PB is actually heavier than stock by 5.6 oz. I assumed the extra weight was from the steel cover, but I wasn't sure? I disassembled the clutch and started weighing all the internal components and discovered each puck, contains 9 disks and weighs right at 100+ grams. Wow! That tells me the extra weight is likely from the heavy pucks and the steel cover combined. Again, this clutch was shipped pre-calibrated for a Vector. More to come later on the spring.

Here is a breakdown of all the weights:

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I'm anxious to give this clutch a shot!I'll be watching this one ! I have a Vector that's pushing 12000 miles. I'm about done adding upgrades but if this works good for you I might have to invest...

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

I have never seen this clutch torn apart . Good Info. So all you do is unscrew retaining clip from the puck and add or subtract pucks to get the desired engagement ? Did they pre set this up for how you ride ? Ulmer asked me a lot of questions then set it up from how I answered. It has been a great kit from him. This looks way to simple..

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Yes and No.I have never seen this clutch torn apart . Good Info. So all you do is unscrew retaining clip from the puck and add or subtract pucks to get the desired engagement ? Did they pre set this up for how you ride ? Ulmer asked me a lot of questions then set it up from how I answered. It has been a great kit from him. This looks way to simple..

First, I want to mention that I'm not discrediting a stock Yamaha clutch by any means. They're noisy on a triple 4-stroke, but that's just me being picky.

Yes, this particular PB 80 was shipped pre-calibrated for the Vector triple, but I'm guessing it's a base line calibration; in the ballpark, so to speak.

I'm not a clutch specialist by any means, but I would think that altitude, track length, lug height, riding style and rider weight would all come in to play with this clutch as well. I plan to install the clutch "as is" and see how it runs before I make any changes.

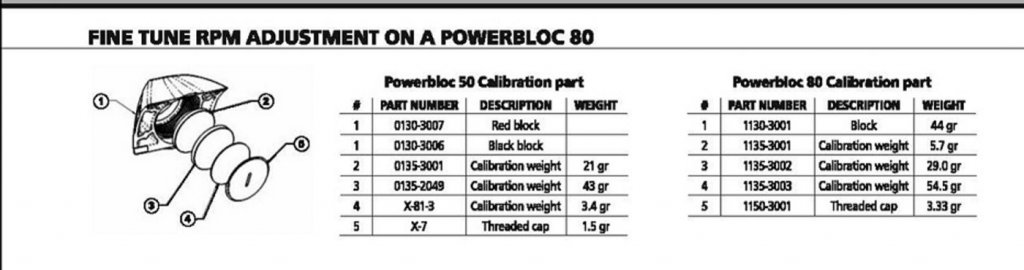

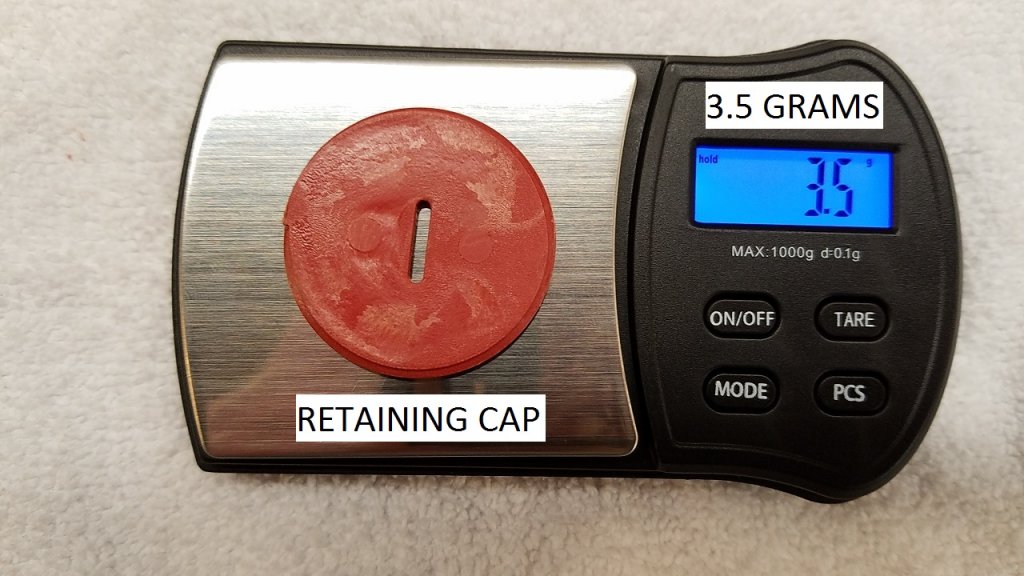

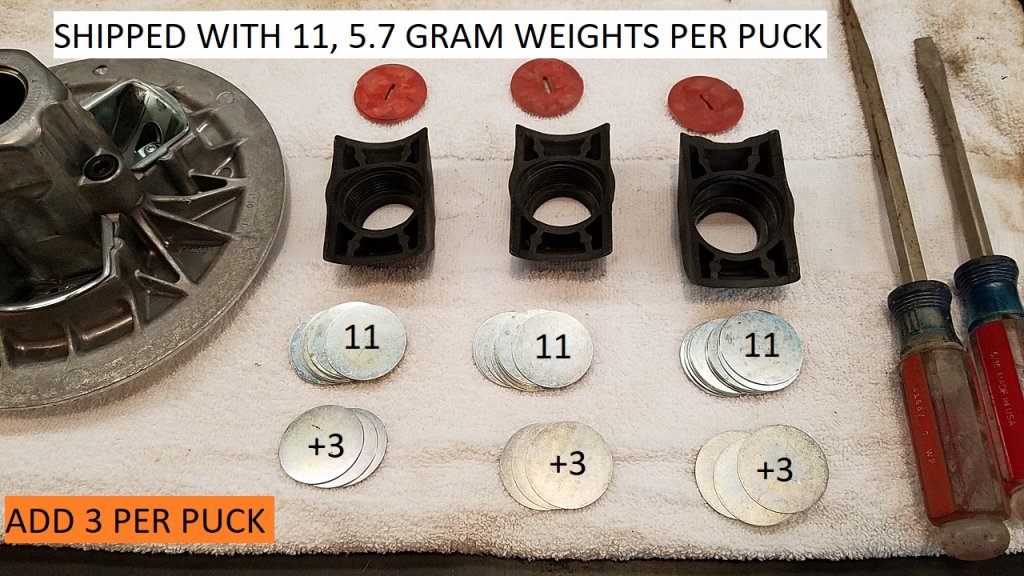

As mentioned, all you do is add or subtract slugs, equally, inside each puck, to adjust rpm. I believe you'd lean towards a spring change to adjust engagement, but changes in slug mass will effect engagement as well.

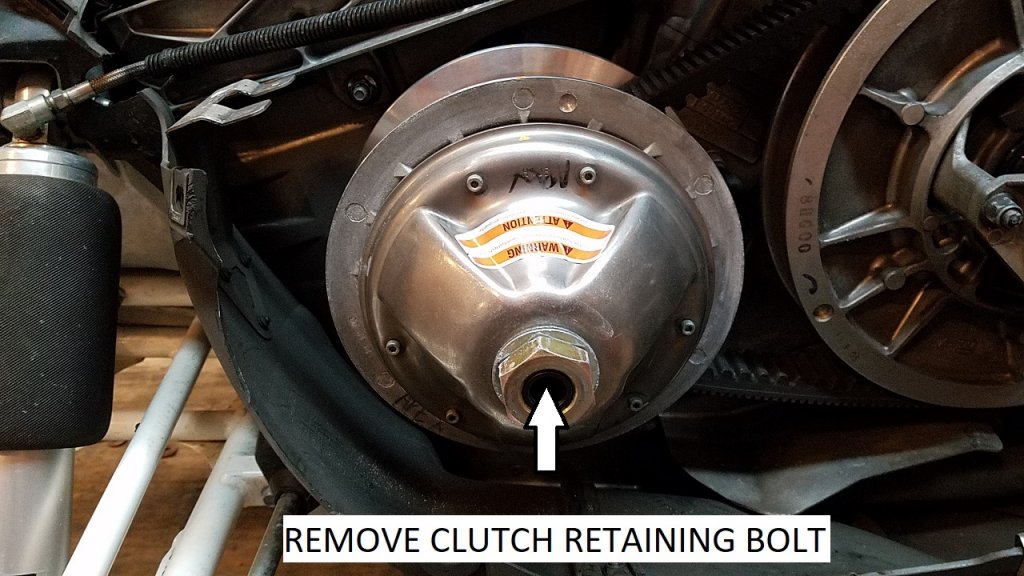

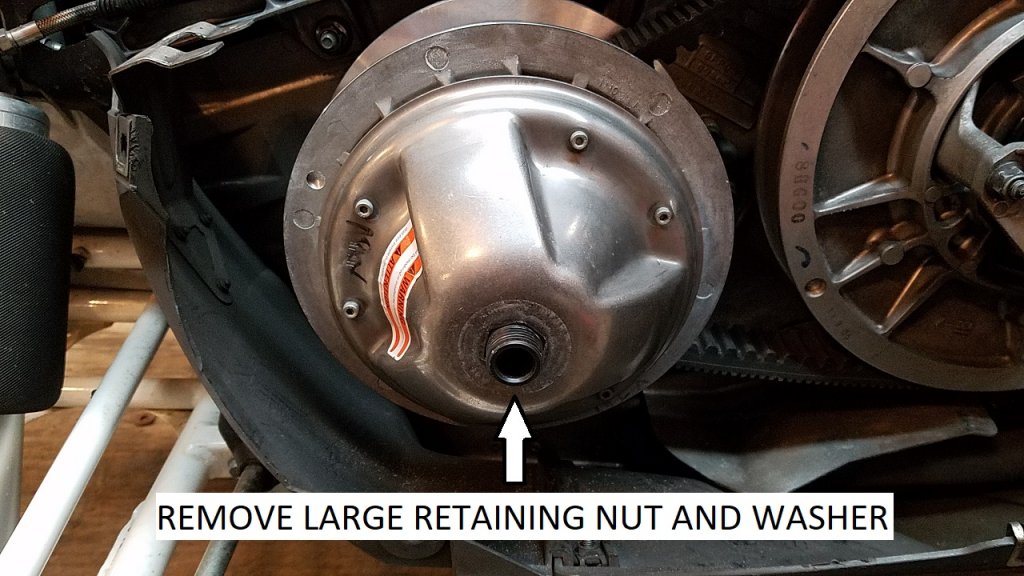

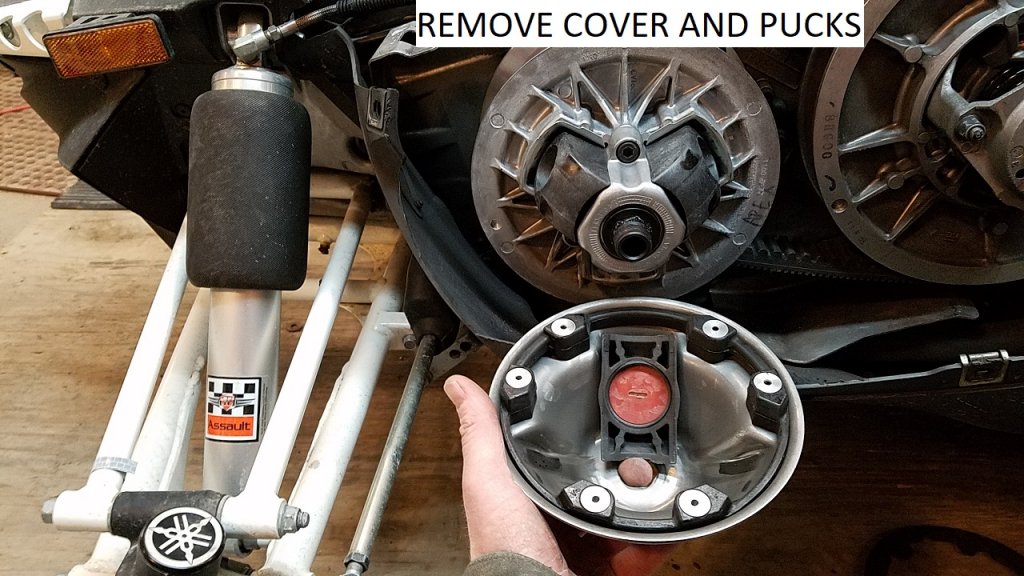

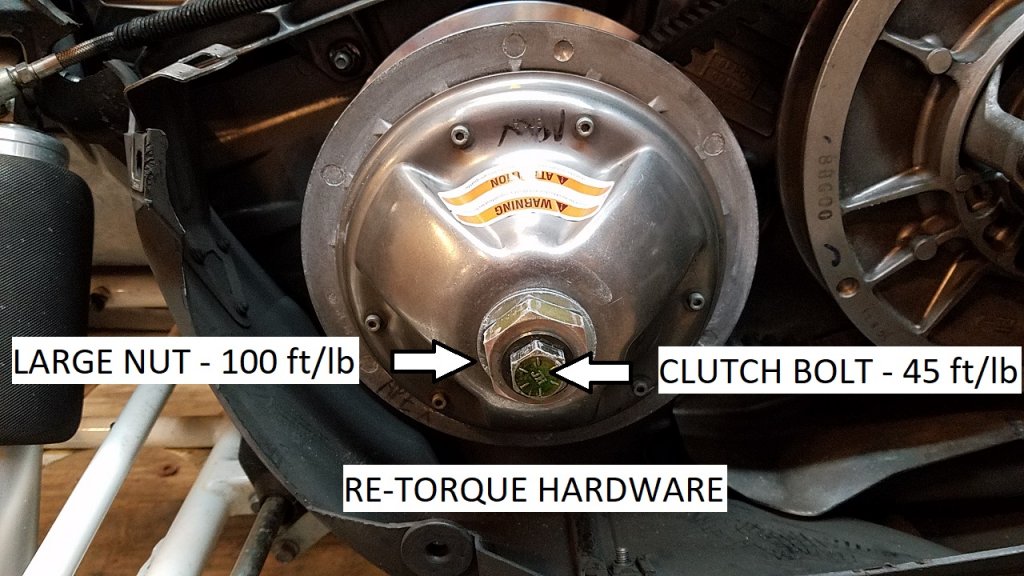

To access the pucks and change weight, you remove the clutch mounting bolt, a large 1-7/16" nut on the cover, and the pucks are right there! Adjust your weight, retorque hardware and you're good for the next run. Should only take 10 minutes or less to adjust.

Time will tell my friend, but I can't wait to try 'er out.

Last edited:

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

You must have a field of clover and some dish soap ! I'm thinking some grass drags !

Stubbs

TY 4 Stroke Master

- Joined

- Nov 7, 2006

- Messages

- 1,110

- Age

- 43

- Location

- Uxbridge, On, Can.

- Country

- Canada

- Snowmobile

- ‘16 Apex XTX with 137” Mono II

+ other gooodies

- LOCATION

- Uxbridge ON

The 1970's called, they'd like their clutch technology back. Lol

I've had a rattling triple, so I get it, but the super old school tech makes me laugh a little. I'll be keeping an eye on this to see how it ends up.

I've had a rattling triple, so I get it, but the super old school tech makes me laugh a little. I'll be keeping an eye on this to see how it ends up.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Ok....

My son and I just hammered out 70 miles on my Apex and Vector. No trails yet, just fields and ditches.

Apex:

Whack the throttle and straight to 11,000! That's too high, and it seemed soft out of the hole. It pulled hard once moving, and felt smooth overall, but the belt and sheaves were HOT to the touch. I'm going to leave this clutch alone and run it "as-is " until I get some trail time, as I know the heavy snow is working things pretty hard. I need to get it on the trail and open it up.

Vector:

Whack the throttle and straight to 8700. It felt strong out of the hole and pulled hard, but my top RPM'S were down slightly. Belt and sheaves were warm to the touch, not HOT. Again, we were in heavy snow, so I'm leaving it alone until I get some trail time.

Stay tuned and I'll post more feedback when I have it.

My son and I just hammered out 70 miles on my Apex and Vector. No trails yet, just fields and ditches.

Apex:

Whack the throttle and straight to 11,000! That's too high, and it seemed soft out of the hole. It pulled hard once moving, and felt smooth overall, but the belt and sheaves were HOT to the touch. I'm going to leave this clutch alone and run it "as-is " until I get some trail time, as I know the heavy snow is working things pretty hard. I need to get it on the trail and open it up.

Vector:

Whack the throttle and straight to 8700. It felt strong out of the hole and pulled hard, but my top RPM'S were down slightly. Belt and sheaves were warm to the touch, not HOT. Again, we were in heavy snow, so I'm leaving it alone until I get some trail time.

Stay tuned and I'll post more feedback when I have it.

Last edited:

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

Good follow up! Please keep letting us know how they are working

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

We just returned home from a 3 day rip in the UP. This trip was my first run using these clutches on the trail. Unfortunately, my buddy with a stock '11 Apex had to cancel, so I didn't have a constant to compare against. Keep in mind that I'm a novice trail rider, not a racer. A.K.A. Clutch Dummy!

Note* Both clutches were shipped pre-calibrated.

APEX:

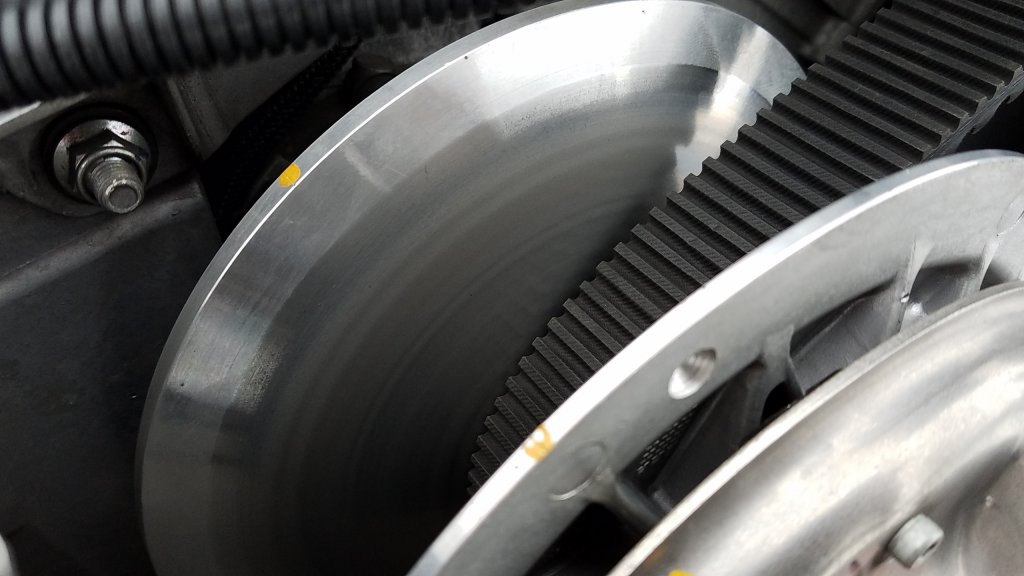

Engagement is a little higher than I'd like @ 3,500 - 3,800. Backshift is instant! It pulls hard from 0 - 70 mph on hard pack. It's a hoot in the twisties, but it tops out at only 85 mph in the straights, running @ 11,000 RPM. That's too many RPM'S, and it should be faster. I know this sled is capable of 100 mph, even with the stock 23/37 gearing.

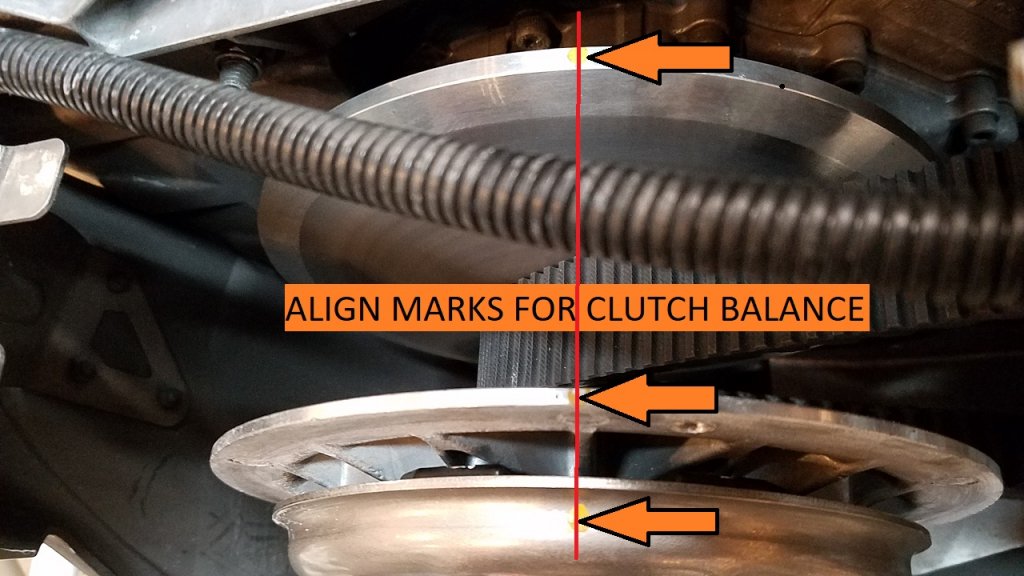

I opened the side panel and noticed the sheaves weren't fully shifting out (pic below). The belt was very HOT to the touch, and there was a black smudge down low on the sheaves at the engagement point. That tells me the belt is slipping and more weight needs thrown at the pucks. When I went to the truck for my tools, however, I discovered that I left ALL my extra slugs at home on the bench. That was the end of my Apex tuning for this trip. I took my stock primary clutch in case it was needed, but decided to just wait until I got home for a recalibration of the PB. I feel like some weight will really bring this clutch in line for the way I ride - trail.

That was the end of my Apex tuning for this trip. I took my stock primary clutch in case it was needed, but decided to just wait until I got home for a recalibration of the PB. I feel like some weight will really bring this clutch in line for the way I ride - trail.

VECTOR:

I put almost 500 miles on this sled in two days. Clutch engagement is nice @ 2500 - 2800. The sled pulls hard and I actually got it to top out at 94 mph on a hard-packed trail. I didn't have a Garmin, so I'd say the sled was actually running 85+. RPM's were a tad low @ 8500.

Upon inspection, I noticed the belt was getting all the way to the edge @ WOT. The belt and sheaves were warm to the touch, not HOT. I think one slug could be removed from each puck, which would slightly raise RPM, but I'm very satisfied with the current configuration. My only disappointment is the infamous PTO rattle-rattle is still there. Oh well...it's not the clutches fault. It's the PTO spline design.

Stay tuned for the next rip once I get the Apex recalibrated.

Note* Both clutches were shipped pre-calibrated.

APEX:

Engagement is a little higher than I'd like @ 3,500 - 3,800. Backshift is instant! It pulls hard from 0 - 70 mph on hard pack. It's a hoot in the twisties, but it tops out at only 85 mph in the straights, running @ 11,000 RPM. That's too many RPM'S, and it should be faster. I know this sled is capable of 100 mph, even with the stock 23/37 gearing.

I opened the side panel and noticed the sheaves weren't fully shifting out (pic below). The belt was very HOT to the touch, and there was a black smudge down low on the sheaves at the engagement point. That tells me the belt is slipping and more weight needs thrown at the pucks. When I went to the truck for my tools, however, I discovered that I left ALL my extra slugs at home on the bench.

That was the end of my Apex tuning for this trip. I took my stock primary clutch in case it was needed, but decided to just wait until I got home for a recalibration of the PB. I feel like some weight will really bring this clutch in line for the way I ride - trail.

That was the end of my Apex tuning for this trip. I took my stock primary clutch in case it was needed, but decided to just wait until I got home for a recalibration of the PB. I feel like some weight will really bring this clutch in line for the way I ride - trail.VECTOR:

I put almost 500 miles on this sled in two days. Clutch engagement is nice @ 2500 - 2800. The sled pulls hard and I actually got it to top out at 94 mph on a hard-packed trail. I didn't have a Garmin, so I'd say the sled was actually running 85+. RPM's were a tad low @ 8500.

Upon inspection, I noticed the belt was getting all the way to the edge @ WOT. The belt and sheaves were warm to the touch, not HOT. I think one slug could be removed from each puck, which would slightly raise RPM, but I'm very satisfied with the current configuration. My only disappointment is the infamous PTO rattle-rattle is still there. Oh well...it's not the clutches fault. It's the PTO spline design.

Stay tuned for the next rip once I get the Apex recalibrated.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

APEX:

I finally got the Apex into the shop for a recalibration. As stated earlier, the RPM's are too high, top speed is down, and the belt is slipping.

For now, I'm going to add one slug at a time and see what changes take place.

I finally got the Apex into the shop for a recalibration. As stated earlier, the RPM's are too high, top speed is down, and the belt is slipping.

For now, I'm going to add one slug at a time and see what changes take place.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I ended up adding (3) 5.7 gram slugs to each puck on the Apex. We don't have enough snow for a good run, so the only thing to do now is head back north for a true run on the trail...and take all the appropriate items for a parking lot recalibration if needed.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Working on sleds and burning corn at home today. Other than riding, it doesn't get much better my friends!

Vector LTX GT 08

Expert

- Joined

- Aug 3, 2016

- Messages

- 416

- Age

- 26

- Location

- Rockwood, Maine

- Country

- USA

- Snowmobile

- 2008 Yamaha Vector LTX GT.

- WEBSITE

- www. Moosehead Lawn Care.com

- YAHOO

- colemanbodemer@yahoo.com

Good to know about the clutch rattle on the vector clutch. I will be following conversation.

Similar threads

- Replies

- 6

- Views

- 3K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.