Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Here are the current clutch and gearing configurations of each sled. CV Tech lists their primary springs in Newton's, so I converted the rates to both pounds and kilograms:

APEX:

Primary spring:

700 / 1600 Newton's

157 / 360 lbs

71 / 163 kg

Current weights per puck:

(2) 5.7 gram weights

(1) 54.5 gram slug

Secondary, stock:

51/43 helix, pink spring.

Gearing, stock:

24/37

Track:

136 x 1.5 Intense

VECTOR:

Primary spring:

800 / 1300 Newton's

180 / 292 lb

81 / 132 kg

Current weights per puck:

(8) 5.7 gram weights

Secondary:

Team TSS-04 roller

Helix:

58-40-38

Spring:

140 / 220 lbs (Red/Blue)

Gearing:

21 / 39

Track:

136 x 1.5 Intense

APEX:

Primary spring:

700 / 1600 Newton's

157 / 360 lbs

71 / 163 kg

Current weights per puck:

(2) 5.7 gram weights

(1) 54.5 gram slug

Secondary, stock:

51/43 helix, pink spring.

Gearing, stock:

24/37

Track:

136 x 1.5 Intense

VECTOR:

Primary spring:

800 / 1300 Newton's

180 / 292 lb

81 / 132 kg

Current weights per puck:

(8) 5.7 gram weights

Secondary:

Team TSS-04 roller

Helix:

58-40-38

Spring:

140 / 220 lbs (Red/Blue)

Gearing:

21 / 39

Track:

136 x 1.5 Intense

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I just completed a week long trip of riding in the UP. I rode an additional 1,100 miles on my PB 80 equipped Apex with no issues!

As stated in my earlier posts, there wasn't enough weight in the pucks on the first trip. Adding three slugs to each puck, however, brought this clutch right in line. It now grabs the belt and pulls hard. There is a minimal black smudge from down low, the drive belt still looks great and I've maintained stock-like performance and top speed!

At this time, I am officially giving this clutch my approval! They're a suitable, alternative clutch that's cheaper to purchase, easy to tune and performs like stock with very little maintenance required...perfect for me! I could not be happier!

As stated in my earlier posts, there wasn't enough weight in the pucks on the first trip. Adding three slugs to each puck, however, brought this clutch right in line. It now grabs the belt and pulls hard. There is a minimal black smudge from down low, the drive belt still looks great and I've maintained stock-like performance and top speed!

At this time, I am officially giving this clutch my approval! They're a suitable, alternative clutch that's cheaper to purchase, easy to tune and performs like stock with very little maintenance required...perfect for me! I could not be happier!

Last edited:

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Reaction score

- 486

- Points

- 1,328

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

Thanks for the Follow up Northernsledder

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

You're welcome!Thanks for the Follow up Northernsledder

If anyone reading this decides to try a PB 80, I would at least buy the clutch holding tool to keep from turning the engine over when torquing the retaining fasteners. The tool is about $25.

For the way I ride, these clutches work...plain and simple!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I removed the PB 80 from my Vector for a post-season inspection. The pucks and sheaves all look great! The PB 80 clutch puller works as it should. I see no need to remove and inspect the PB on my Apex. I'm very satisfied!

You can tell by the sheaves that I'm a trail rider and spend the bulk of my time in the 50 - 70 mph range!

You can tell by the sheaves that I'm a trail rider and spend the bulk of my time in the 50 - 70 mph range!

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,420

- Reaction score

- 1,556

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

I like simple. Nice follow through!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I'm going to experiment with different weights in the pucks for my Apex this winter. Unfortunately, there was no room left for additional weight; maxed out.

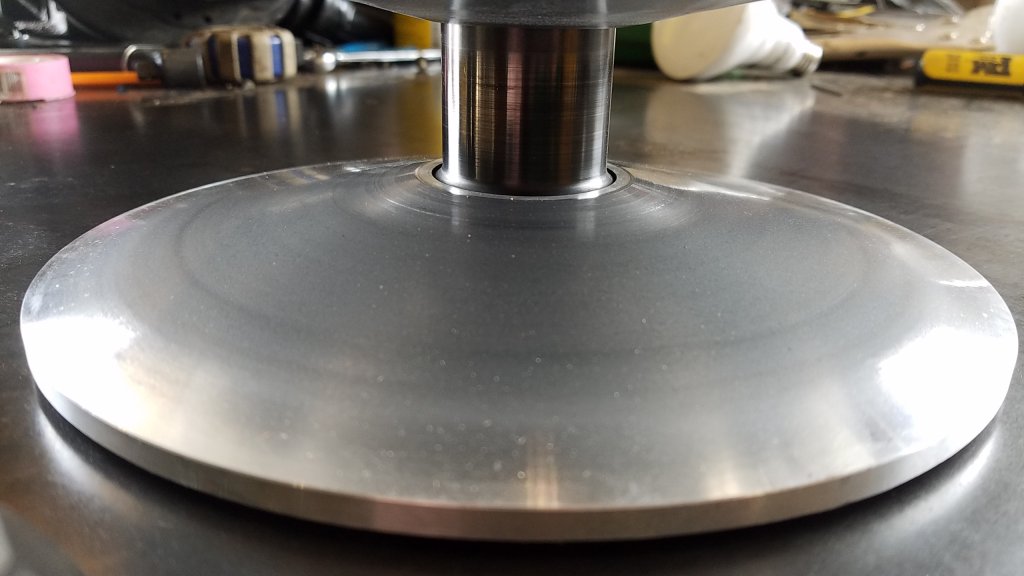

I contacted CV Tech and they sent me the pictured heavy slugs. They are machined to fit inside the hole on the face of the puck and extend beyond the normal slug bearing area, giving me the extra weight capacity.

I updated the current calibration figures, for both sleds, in post 17 above.

I contacted CV Tech and they sent me the pictured heavy slugs. They are machined to fit inside the hole on the face of the puck and extend beyond the normal slug bearing area, giving me the extra weight capacity.

I updated the current calibration figures, for both sleds, in post 17 above.

Last edited:

Great information,write up, and pics.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

After spending all of last week in the UP, I decided to follow up on my experiment with the heavy slug weights mentioned in post #23 above. These weights were used in my Apex.

Rewind:

When I originally purchased this clutch in 2017, it came pre-calibrated with (11) 5.7 gram slugs, which added up to 62.7 grams of weight inside each puck. That wasn't enough, as the sled over-revved and the sheaves wouldn't fully shift out on top. In addition, there was a black smudge from the belt slipping at takeoff. I then added (3) more 5.7 gram slugs, which brought the total up to 79.8 grams of weight inside each puck. BINGO! This brought my revs down to 10,800 rpm, and the sled pulled hard. I rode an entire season this way, but my clutches were always HOT, and I still had a slight smudge down low at takeoff.

Fast forward:

Winter of 18-19, I installed the heavy slug weights pictured above, weighing 54.5 grams each. In addition, I adjusted the number of 5.7 gram slugs to closely match the total of 79.8 grams I used in each puck the previous year. Wow! The sheaves really grabbed the belt, so I rode the entire day this way. There was no belt smudge, but my overall performance was down due to my max revs only topping at 10,400 RPM'S. This didn't make sense to me, as I was running almost the exact same weight as before, at least within 1.5 grams. The other thing I noticed was that the sheaves were warm, not HOT. I don't have a temp gun, but I could tell the sheaves were noticeably cooler just by feeling them bare handed. Unfortunately, this was the only day I got to run my Apex that year...a whopping 150 miles...

Winter 19-20:

I took notes, so I started subtracting the individual 5.7 gram slugs from each puck until my revs came back up to 10,800. I'm now at (1) 54.5 & (2) 5.7 gram slugs, which brings the total weight inside each puck down to 65.9 grams. The sled just runs great, so I rode the entire day this way. I stopped several times, and upon inspection, there was no black smudge and the sheaves were warm, not HOT. Again, this doesn't make sense to me! Here my sled pulls hard, runs at the proper RPM, and does it with almost the exact same weigh per puck that it was shipped with, which wasn't even close! (scratching my head)

My uneducated conclusion:

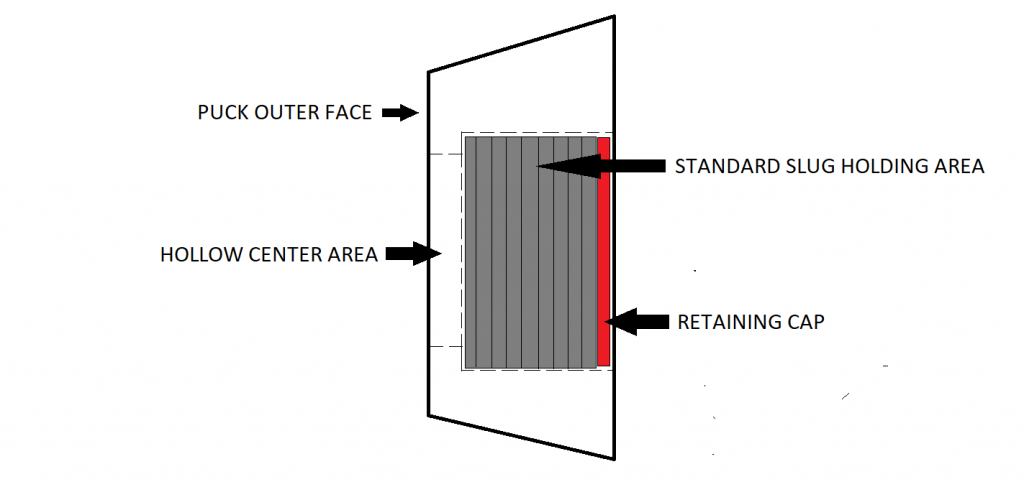

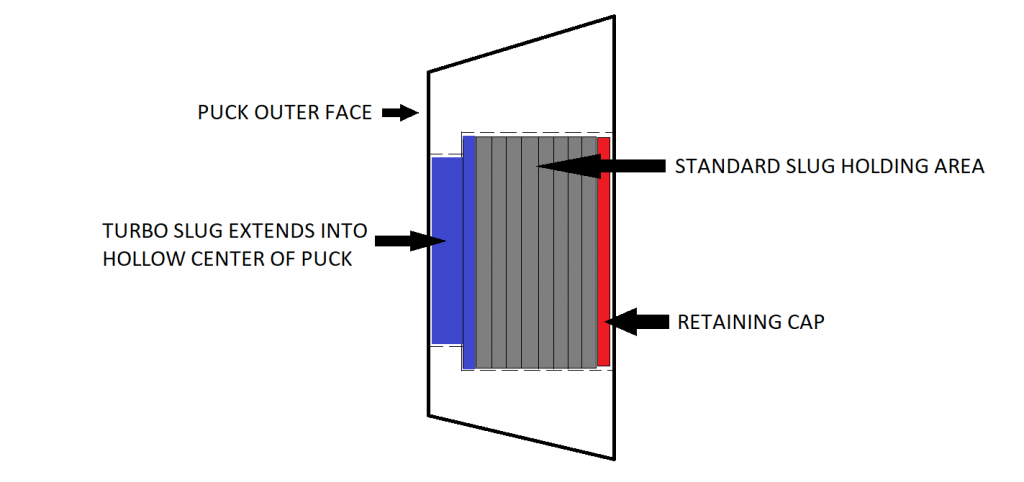

The only thing that makes sense to me as to why this combination works so well, is WEIGHT PLACEMENT. The heavy 54.5 gram slug has a stepped shape. About half of its mass fits inside the hollow puck face, whereas the standard slugs do not. I'm speculating that moving weight into this void, farther from the center of rotation, allows the weight to come on sooner, all the way from engagement to full shift. I believe that's why the low end smudge disappeared and the reason for retaining top performance with less finish weight.

As mentioned early in this thread, I'm not a clutch expert. Call me silly or whatever, but these clutches work, and they're easy to tune. I truly believe the weight placement made all the difference in my sled for the way I ride - trail!

Here are a few home drawn diagrams to display how both the standard and heavy weight turbo slugs are placed inside each puck. Again, refer to post #23 above for turbo slug pictures.

Cheers my friends!

Rewind:

When I originally purchased this clutch in 2017, it came pre-calibrated with (11) 5.7 gram slugs, which added up to 62.7 grams of weight inside each puck. That wasn't enough, as the sled over-revved and the sheaves wouldn't fully shift out on top. In addition, there was a black smudge from the belt slipping at takeoff. I then added (3) more 5.7 gram slugs, which brought the total up to 79.8 grams of weight inside each puck. BINGO! This brought my revs down to 10,800 rpm, and the sled pulled hard. I rode an entire season this way, but my clutches were always HOT, and I still had a slight smudge down low at takeoff.

Fast forward:

Winter of 18-19, I installed the heavy slug weights pictured above, weighing 54.5 grams each. In addition, I adjusted the number of 5.7 gram slugs to closely match the total of 79.8 grams I used in each puck the previous year. Wow! The sheaves really grabbed the belt, so I rode the entire day this way. There was no belt smudge, but my overall performance was down due to my max revs only topping at 10,400 RPM'S. This didn't make sense to me, as I was running almost the exact same weight as before, at least within 1.5 grams. The other thing I noticed was that the sheaves were warm, not HOT. I don't have a temp gun, but I could tell the sheaves were noticeably cooler just by feeling them bare handed. Unfortunately, this was the only day I got to run my Apex that year...a whopping 150 miles...

Winter 19-20:

I took notes, so I started subtracting the individual 5.7 gram slugs from each puck until my revs came back up to 10,800. I'm now at (1) 54.5 & (2) 5.7 gram slugs, which brings the total weight inside each puck down to 65.9 grams. The sled just runs great, so I rode the entire day this way. I stopped several times, and upon inspection, there was no black smudge and the sheaves were warm, not HOT. Again, this doesn't make sense to me! Here my sled pulls hard, runs at the proper RPM, and does it with almost the exact same weigh per puck that it was shipped with, which wasn't even close! (scratching my head)

My uneducated conclusion:

The only thing that makes sense to me as to why this combination works so well, is WEIGHT PLACEMENT. The heavy 54.5 gram slug has a stepped shape. About half of its mass fits inside the hollow puck face, whereas the standard slugs do not. I'm speculating that moving weight into this void, farther from the center of rotation, allows the weight to come on sooner, all the way from engagement to full shift. I believe that's why the low end smudge disappeared and the reason for retaining top performance with less finish weight.

As mentioned early in this thread, I'm not a clutch expert. Call me silly or whatever, but these clutches work, and they're easy to tune. I truly believe the weight placement made all the difference in my sled for the way I ride - trail!

Here are a few home drawn diagrams to display how both the standard and heavy weight turbo slugs are placed inside each puck. Again, refer to post #23 above for turbo slug pictures.

Cheers my friends!

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I forgot to mention that I ran my 2012 Apex against my buddy's 2011 Apex with an identical 136" M20 suspension, and indentical 136 x 1.5" Intense track. Both sleds had a new drive belt. His sled has Pilot 5.7 ski's, mine has USI Triple Threats. His has stock clutching, mine has the PB80. Both sleds had about the same amount of fuel, and rider weight varied less than 20 lbs.

Single run conclusion:

My sled pulled harder out of the hole, but his slowly caught me until about 80 MPH when they basically ran neck-to-neck, with him inching me slightly. I have no idea how for we ran? No GPS or timers, just seat of the pants trail race. The snow was very sugary, so I know there was a lot of track spin. Too many variables running an air skid, as air pressure has a huge impact on weight transfer. What I do know is; my PB80 equipped sled is good enough! The PB80 is a suitable alternative that's cheaper to purchase and is basically maintenance free with no traditional weights, rollers or pins. Easy to tune and perfect for me! Honestly, people that ride my sled would have never guessed there's a primary clutch with 40+ yr old technology under the hood!

Single run conclusion:

My sled pulled harder out of the hole, but his slowly caught me until about 80 MPH when they basically ran neck-to-neck, with him inching me slightly. I have no idea how for we ran? No GPS or timers, just seat of the pants trail race. The snow was very sugary, so I know there was a lot of track spin. Too many variables running an air skid, as air pressure has a huge impact on weight transfer. What I do know is; my PB80 equipped sled is good enough! The PB80 is a suitable alternative that's cheaper to purchase and is basically maintenance free with no traditional weights, rollers or pins. Easy to tune and perfect for me! Honestly, people that ride my sled would have never guessed there's a primary clutch with 40+ yr old technology under the hood!

Last edited:

Stubbs

TY 4 Stroke Master

- Joined

- Nov 7, 2006

- Messages

- 1,189

- Reaction score

- 695

- Points

- 1,378

- Location

- Uxbridge, On, Can.

- Country

- Canada

- Snowmobile

- ‘16 Apex XTX with 137” Mono II

+ other gooodies

- LOCATION

- Uxbridge ON

Just like with a standard flyweight type clutch, the placement of mass is going to be critical to the way it shifts. Great update and post! I’m still going to stick with my 20 y/o tech vs. 40.

Fast

TY 4 Stroke Master

- Joined

- Sep 25, 2018

- Messages

- 1,015

- Reaction score

- 232

- Points

- 758

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

Doesn't the apex make its most power at 10400, nice postAfter spending all of last week in the UP, I decided to follow up on my experiment with the heavy slug weights mentioned in post #23 above. These weights were used in my Apex.

Rewind:

When I originally purchased this clutch in 2017, it came pre-calibrated with (11) 5.7 gram slugs, which added up to 62.7 grams of weight inside each puck. That wasn't enough, as the sled over-revved and the sheaves wouldn't fully shift out on top. In addition, there was a black smudge from the belt slipping at takeoff. I then added (3) more 5.7 gram slugs, which brought the total up to 79.8 grams of weight inside each puck. BINGO! This brought my revs down to 10,800 rpm, and the sled pulled hard. I rode an entire season this way, but my clutches were always HOT, and I still had a slight smudge down low at takeoff.

Fast forward:

Winter of 18-19, I installed the heavy slug weights pictured above, weighing 54.5 grams each. In addition, I adjusted the number of 5.7 gram slugs to closely match the total of 79.8 grams I used in each puck the previous year. Wow! The sheaves really grabbed the belt, so I rode the entire day this way. There was no belt smudge, but my overall performance was down due to my max revs only topping at 10,400 RPM'S. This didn't make sense to me, as I was running almost the exact same weight as before, at least within 1.5 grams. The other thing I noticed was that the sheaves were warm, not HOT. I don't have a temp gun, but I could tell the sheaves were noticeably cooler just by feeling them bare handed. Unfortunately, this was the only day I got to run my Apex that year...a whopping 150 miles...

Winter 19-20:

I took notes, so I started subtracting the individual 5.7 gram slugs from each puck until my revs came back up to 10,800. I'm now at (1) 54.5 & (2) 5.7 gram slugs, which brings the total weight inside each puck down to 65.9 grams. The sled just runs great, so I rode the entire day this way. I stopped several times, and upon inspection, there was no black smudge and the sheaves were warm, not HOT. Again, this doesn't make sense to me! Here my sled pulls hard, runs at the proper RPM, and does it with almost the exact same weigh per puck that it was shipped with, which wasn't even close! (scratching my head)

My uneducated conclusion:

The only thing that makes sense to me as to why this combination works so well, is WEIGHT PLACEMENT. The heavy 54.5 gram slug has a stepped shape. About half of its mass fits inside the hollow puck face, whereas the standard slugs do not. I'm speculating that moving weight into this void, farther from the center of rotation, allows the weight to come on sooner, all the way from engagement to full shift. I believe that's why the low end smudge disappeared and the reason for retaining top performance with less finish weight.

As mentioned early in this thread, I'm not a clutch expert. Call me silly or whatever, but these clutches work, and they're easy to tune. I truly believe the weight placement made all the difference in my sled for the way I ride - trail!

Here are a few home drawn diagrams to display how both the standard and heavy weight turbo slugs are placed inside each puck. Again, refer to post #23 above for turbo slug pictures.

Cheers my friends!

View attachment 152443 View attachment 152444

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Perhaps?? In all honesty, I really don't know?Doesn't the apex make its most power at 10400

Not disagreeing whatsoever, but my overall performance, at WOT, "seems" better when she winds out to 10,800. I've read through a handful of old posts, and a few guys maintain that their 2011+ Apex ran better when removing a little tip weight and spinning them up to the 10,600 -10,800 range. I addition, I know I'm getting more track spin from the M20 suspension, but NO WAY am I giving up that suspension. I bet that if I had hookup like my stock CK144 skid had, or a mono; my top RPM'S would be lower.

Finally, please remember that I'm a novice. I'm not a knowledgeable clutch tuner, but I am learning and having fun doing it.

I really like how simple these clutches are, for me at least.

Maybe Stubby, or someone else, can chime in on the HP vs RPM question.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

From what I've gathered, regarding proper clutching, is that EACH sled should be dynoed to see where they make the MOST power, and clutch from there. Otherwise, we're all kinda shooting in the dark. Then it's a matter of what you're clutching for: drag race, corner to corner, trail, etc. All I have, however, is the butt dyno...lol. I know I'm just guessing, but I have found a combination for trail riding that closely matches an identical stock clutched sled. In addition, my belt and sheaves now run warm, whereas they always ran HOT, even with stock clutching.

Last edited:

Stubbs

TY 4 Stroke Master

- Joined

- Nov 7, 2006

- Messages

- 1,189

- Reaction score

- 695

- Points

- 1,378

- Location

- Uxbridge, On, Can.

- Country

- Canada

- Snowmobile

- ‘16 Apex XTX with 137” Mono II

+ other gooodies

- LOCATION

- Uxbridge ON

Bang on Redbeard! Without a dyno run of YOUR motor, you really have no idea where it’s gonna make the most power RPM wise. Conditions like temp, both air and coolant/engine, along with baro pressure that day, also have an effect. What I’m saying here is shoot for a known good number from either the manufacturer or a tuner you trust. Clutch your sled to run that RPM consistently in the conditions you ride in most often. For a trail sled, this will give you the best performance on most days.

If you’ve got the time/patience/space/conditions and keep very detailed notes, nothing beats testing your own sled, over and over and over again to create a viable database of results from changes made, and under what conditions you were testing in that day. Most trail guys will never do this, I know I don’t. Lol

If you’ve got the time/patience/space/conditions and keep very detailed notes, nothing beats testing your own sled, over and over and over again to create a viable database of results from changes made, and under what conditions you were testing in that day. Most trail guys will never do this, I know I don’t. Lol

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.