LazyBastard

TY 4 Stroke God

There is something nagging at me about that symptom... I've heard of it before... I think you need to take a look at the wiring.

Two places;

1) remove the nose cone under the front bumper and/or the beer can holder from inside the nose and inspect the wiring there. There are two very thin white wires in there running to the rectifier/regulator assembly. These wires are known to sit against the frame in that area and sometimes will wear through and ground out. Inspect those wires VERY CAREFULLY, seal them up very well, and tie them so they don't rub against the frame.

2) around the steering stops on the steering column, there may be a grey or beige wire that may be damaged. Take a look at it.

My money is on #1. Both of these problems are VERY common, but ONLY on 2003 RX1, which I notice is what you have.

And could you do us one favor... fill out the location section in your profile. Its forum rules.

Two places;

1) remove the nose cone under the front bumper and/or the beer can holder from inside the nose and inspect the wiring there. There are two very thin white wires in there running to the rectifier/regulator assembly. These wires are known to sit against the frame in that area and sometimes will wear through and ground out. Inspect those wires VERY CAREFULLY, seal them up very well, and tie them so they don't rub against the frame.

2) around the steering stops on the steering column, there may be a grey or beige wire that may be damaged. Take a look at it.

My money is on #1. Both of these problems are VERY common, but ONLY on 2003 RX1, which I notice is what you have.

And could you do us one favor... fill out the location section in your profile. Its forum rules.

Len Todd

TY 4 Stroke God

I need to make sure I still got this right; The Tach is NOT working but the rest of the Gage is. Is that correct?

Did the sled go under with the Key on or off?

You have checked all fuses.

Was there any water visible in the gage? You may want to consider taking the gage out and opening it up and baking it in the oven on very low with the oven door partially open. Do not touch the inside of the "glass." It has a anti-fog coating. My gage has some really tiny vent holes in it.

I am pretty sure the CDI is sealed. The connectors are not. There could be water in the harness running down into the connector.

Did you double check the connector to the gage? Maybe it might not be fully seated or the pins not lined up.

Did the sled go under with the Key on or off?

You have checked all fuses.

Was there any water visible in the gage? You may want to consider taking the gage out and opening it up and baking it in the oven on very low with the oven door partially open. Do not touch the inside of the "glass." It has a anti-fog coating. My gage has some really tiny vent holes in it.

I am pretty sure the CDI is sealed. The connectors are not. There could be water in the harness running down into the connector.

Did you double check the connector to the gage? Maybe it might not be fully seated or the pins not lined up.

Jerimiah Johnson

Newbie

I'm Back

Thank you all for the help and advice you have given me.I have been away at for the last 2 weeks(I work in the oil fields in Pruhdoe Bay Alaska...2wks on 2wks off).And have just gotten back home tonight.Can't wait till tomorrow morning so I can get back to working on the sled.

In regards to the tach....heres what I got going on.....I have taken the gauge apart,drained it and dried it.I have sprayed the connection where the harness goes into the tach and where it goes into the ecu with contact cleaner.When I first start the sled the tach cycles all the way up,and then back to zero where it stays.Everything else on the instrument cluster works however I did gain 2000 miles on the odometer!!Guess it would have been asking to much to have it read 2000 miles less!!

Thank you all for the help and advice you have given me.I have been away at for the last 2 weeks(I work in the oil fields in Pruhdoe Bay Alaska...2wks on 2wks off).And have just gotten back home tonight.Can't wait till tomorrow morning so I can get back to working on the sled.

In regards to the tach....heres what I got going on.....I have taken the gauge apart,drained it and dried it.I have sprayed the connection where the harness goes into the tach and where it goes into the ecu with contact cleaner.When I first start the sled the tach cycles all the way up,and then back to zero where it stays.Everything else on the instrument cluster works however I did gain 2000 miles on the odometer!!Guess it would have been asking to much to have it read 2000 miles less!!

Len Todd

TY 4 Stroke God

There is a Yellow/Black wire that comes from the CDI unit directly to the Tach. The CDI drives the tach. If all the connections are good, then I would say the Tach is bad. The reason for picking the tach is that you say all the other Gage functions are working (ie all indications work (except the tach) and you are getting no alarms.) You could test the CDI unit, possibly buy puncturing the Yellow/Black wire and looking for a change in voltage as you rev the Sled. If you see a change in voltage, you know the CDI is sending some form of signal. Got a fiend who will let you either test his Yellow/Black wire for comparison or maybe even let you try his Gage?

I would have to rule out any of the inputs (and outputs for that matter) to the CDI unit for shorting. You are getting no gage alarms and if I recall correctly, the sled is running smoothly.

I would have to rule out any of the inputs (and outputs for that matter) to the CDI unit for shorting. You are getting no gage alarms and if I recall correctly, the sled is running smoothly.

papi

Newbie

- Joined

- Jan 10, 2008

- Messages

- 12

another thing I would do is dissassemble the diaphragm part of the carbs and make sure there is no water in this area and also blow out every small vacumm hoses to make sure no water is trapped anywhere, very important to keep this part of the carbs clean also, not only what is in the bowls is important on those carbs.

papi

Newbie

- Joined

- Jan 10, 2008

- Messages

- 12

also the seat cover, if it is easily removable to get the foam out, do it, them put foam between two sheets of plywood and drive over it with heavy equipement(tractor or heavy truck) otherwise it wont dry, happened to us in 81 in March last ride of season, seat spent all summer hooked standing up from ceilling on a wire to drip and dry, guess what, the next winter as soon as it got freezing outside the seat was hard as a brick, thats when we had to take it inside in the heat and take it apart to dry properly 2 days behind wood stove.

Len Todd

TY 4 Stroke God

How is it comming, Jerimiah Johnson?

Jerimiah Johnson

Newbie

Not going so good today.Did manage to get the seat back together and on(I took it apart and dried out the foam while I was up at work).The sled fired right up and ran good in the garage.Aside from a mid range stutter it ran good outside.....for about 5min!!Then it went right back to running through the rev limiter when I would try to give it any fuel.Leads me to believe I still have a problem with TORS.And it is about-15 out today.

Not going so good today.Did manage to get the seat back together and on(I took it apart and dried out the foam while I was up at work).The sled fired right up and ran good in the garage.Aside from a mid range stutter it ran good outside.....for about 5min!!Then it went right back to running through the rev limiter when I would try to give it any fuel.Leads me to believe I still have a problem with TORS.And it is about-15 out today.Thinking I will probably bite the bullet and run it into a dealer.

Rockmeister

TY Advertiser

- Joined

- Feb 7, 2007

- Messages

- 2,188

- Location

- NE Indiana

- Website

- www.yamaheater.com

- Country

- USA

- Snowmobile

- 2007 Attak - LOVE my sled!!!

Jeremiah Johnson said:Not going so good today.Did manage to get the seat back together and on(I took it apart and dried out the foam while I was up at work).The sled fired right up and ran good in the garage.Aside from a mid range stutter it ran good outside.....for about 5min!!Then it went right back to running through the rev limiter when I would try to give it any fuel.Leads me to believe I still have a problem with TORS.And it is about-15 out today.

Thinking I will probably bite the bullet and run it into a dealer.

This may cost you quite a bit.

It will most likely take alot of time to find and fix, IF they find it.

Sounds like you still have water in one of the TORS switches and it is freezing when you take it outside.

Did you spray everything while warm with warm 100% silicone spray?

For example, spray all around and INTO the TORS switches?

This will force the water out of them.

Again, everything MUST be warm to get the moisture out.

Would be surprised if the foam dried out in one day, it usually takes about a week over a furnace vent with the furnace fan running 24/7.

Would suggest trying all the information you have been given before racking up a possibly very large repair bill.

Hope this helps!

Jerimiah Johnson

Newbie

I just pulled the 2 contacts in the wiring harness and sprayed with yamaha contact cleaner.Do I need to unplug from each individual carb and spray?Is the Yamaha contact cleaner good enough or do I need to use silicone spray?As for the seat....I pulled out the foam,put it in between 2 pieces of plywood and ran over it about 20 times with my truck,then put it in front of my furnace for 2 weeks(I work 2 wks on 2wks off)I know,sounds harsh but it worked.

Rockmeister

TY Advertiser

- Joined

- Feb 7, 2007

- Messages

- 2,188

- Location

- NE Indiana

- Website

- www.yamaheater.com

- Country

- USA

- Snowmobile

- 2007 Attak - LOVE my sled!!!

Jerimiah Johnson said:I just pulled the 2 contacts in the wiring harness and sprayed with yamaha contact cleaner.Do I need to unplug from each individual carb and spray?Is the Yamaha contact cleaner good enough or do I need to use silicone spray?As for the seat....I pulled out the foam,put it in between 2 pieces of plywood and ran over it about 20 times with my truck,then put it in front of my furnace for 2 weeks(I work 2 wks on 2wks off)I know,sounds harsh but it worked.

Lol, that should work for the seat foam!

Been there, done that.

Contact cleaner is more of a cleaning solvent, it doesn't repel moisture nearly as well.

You need 100% silicone spray, it isn't conductive and will repel moisture very well.

Unless an emergency, do NOT use WD-40, it has oil in it that is conductive and will attract dirt.

Can get 100% silicone spray at most hardware stores and NAPA.

You have to spray the outside AND the inside of each switch with the silicone.

Can usually get the little spray straw past the rubber seal and saturate the switch with it.

The switches should drip the silicone out of them when you are done.

You are forcing the silicone spray in and the water out.

Take apart and lightly spray all connectors inside.

Silicone spray is clear and looks like water.

(Watch your eyes, I wear safety glasses when I use it.)

Wipe the drips and the excess off.

If you plan on using the area to paint in the next year, use a different area, silicone will make paint "fisheye".

The machine and the silicone MUST be warm for this to work.

Had a friend submarine his and we had to do the same thing.

Hope this helps!

PS There is a TORS switch at each carb and one at the throttle, I would suggest focusing on these and the wiring connectors to them.

(I agree with LB, Would bet its water inside one of the switches.)

Jerimiah Johnson

Newbie

Thanks for your help! I will try re hitting them all again with the silicone tomorrow am.Sure hope this works.How bout my mid range stumble?Do you think this could still be water in the fuel?I have added Red Heet to the fuel.When I have ridden it and Tors didnt act up I would get about a 2 sec stumble/stutter when opening the throttle up all the way.After the stumble the motor would come right to life.

Crewchief47

Lifetime Member

- Joined

- Jan 16, 2006

- Messages

- 2,830

- Location

- McGregor, ON Canada

- Country

- Canada

- Snowmobile

- 2008 Nytro MTX 45th

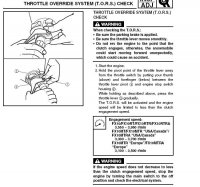

Don't overlook the throttle cable having water in it. If it has enough water to 'slow' the cable down when it starts to freeze outside, it will cause TORS issues. The esiest way to figure out if whats happening is TORS related is to test the TORS in the garage.

Attachments

Rockmeister

TY Advertiser

- Joined

- Feb 7, 2007

- Messages

- 2,188

- Location

- NE Indiana

- Website

- www.yamaheater.com

- Country

- USA

- Snowmobile

- 2007 Attak - LOVE my sled!!!

Crewchief47 said:Don't overlook the throttle cable having water in it. If it has enough water to 'slow' the cable down when it starts to freeze outside, it will cause TORS issues. The esiest way to figure out if whats happening is TORS related is to test the TORS in the garage.

Great idea with the cable crew!

Not too sure about checking it in the garage, as it may thaw again before testing.

Would assume there is water in everything, or at least just the parts that were underwater...

As I suggested in my first post, spray everything that moves with silicone.

It is easiest to tackle one problem at a time, spray everything, especially the TORS see what works then.

hypertxer

Expert

it sounds like the throttle cable is binding up. i had the same problem the sled would run fine and then go nuts hitting the rev limiter. check where it goes in the carbs and try to spray silicone in it if you can.

Similar threads

- Replies

- 24

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.