Omega_5

Extreme

It is a Pro-Ride bulkhead.What is the front bulkhead from (Nytro). Looks cool and should be light what ever you are building.

I'm hoping for light, but being realistic. I'm aiming for about 460lbs dry; which would be the dry weight of a 2012 turbo pro 163.

Thanks! Although I've had some professional training on machining, it's not hard to learn. Honestly, anyone can pick up a hobby lathe and learn it by watching the youtube pros, like Fenner.great to see the talents you have there. wish i knew how to turn a lathe even on, guess will have to stick to turning wrenches. front end looks to be a polaris.

Thanks! Some times I find I get more enjoyment out of fabbing, then the riding.Definitely interested, you have some awesome fab skills! It's really cool to see all the talent that's on this forum customizing sleds, can't wait to get my shop interior finished so I can get to work on my own sled. I'll have a bit to pick up on the welding side!

If you don't mind me asking, how are you tuning your custom setups? I'm assuming you have some sort of software to log runs and have a couple different sensors for feedback?

For tuning, I'm using RapidBike Racing as the fuel / ignition controller. Despite the terrible support for the product, it is a far superior unit to anything else out there. However, I'd suggest the PCV to others.

As far as the tuning process, I actually own a small tune shop on the side. So, I have access to an entire array of data acquisition hardware and software.

Thank you! It's just a matter of getting out to the shop and doing. Only a few years ago, I felt like a total noobie, dipping the tungsten every few inches, now I feel totally confident in doing aluminum work. It's all about the practice.Wish I had your skills..

Omega_5

Extreme

On to the progress.

Monday;

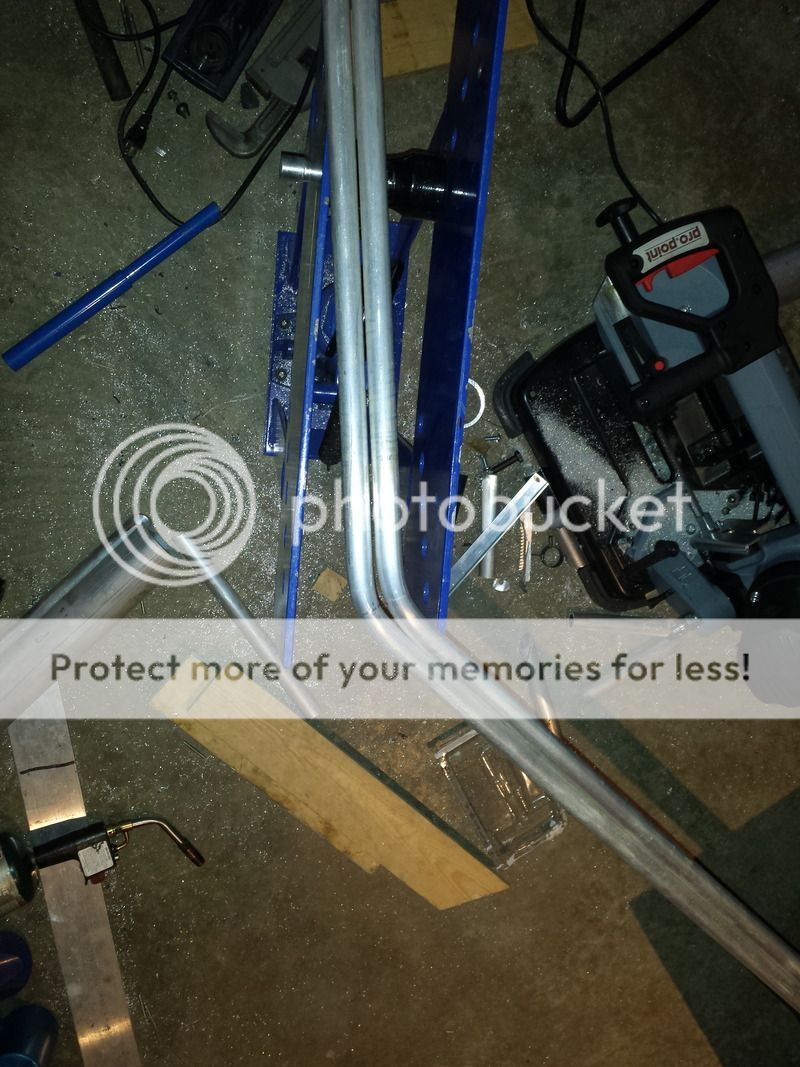

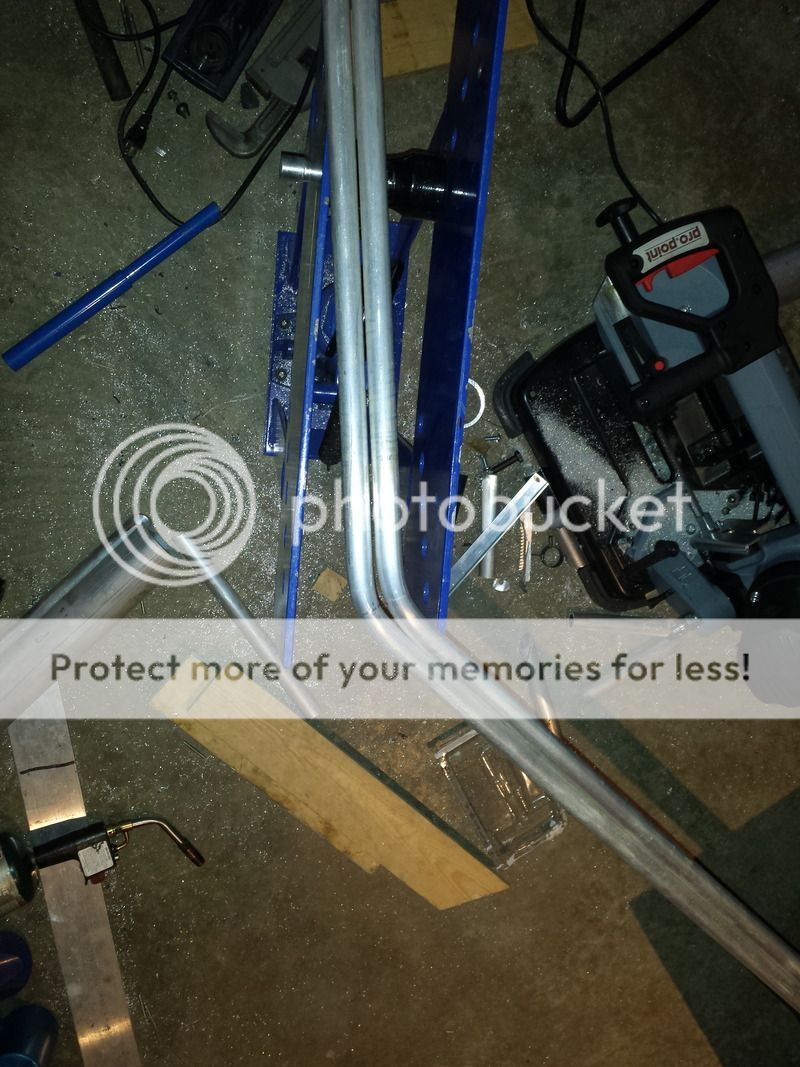

I bent up the outer rails for the running boards.

I again utilized the local laser table, to cut the board inserts.

With the assistance of my wife (again) I tacked up the basic layout on both sides.

And with that, the evening was spent. It's the finicky work that chews up the time.

Tuesday;

Not much, just tacked the entire array of board inserts.

Monday;

I bent up the outer rails for the running boards.

I again utilized the local laser table, to cut the board inserts.

With the assistance of my wife (again) I tacked up the basic layout on both sides.

And with that, the evening was spent. It's the finicky work that chews up the time.

Tuesday;

Not much, just tacked the entire array of board inserts.

Omega_5

Extreme

Wednesday;

I mocked up the pyramid structure, and began tack welding the support brackets in place.

Thursday;

Finished up the pyramid structure, and mocked up the handlebars.

And the hood fits nice!

Friday;

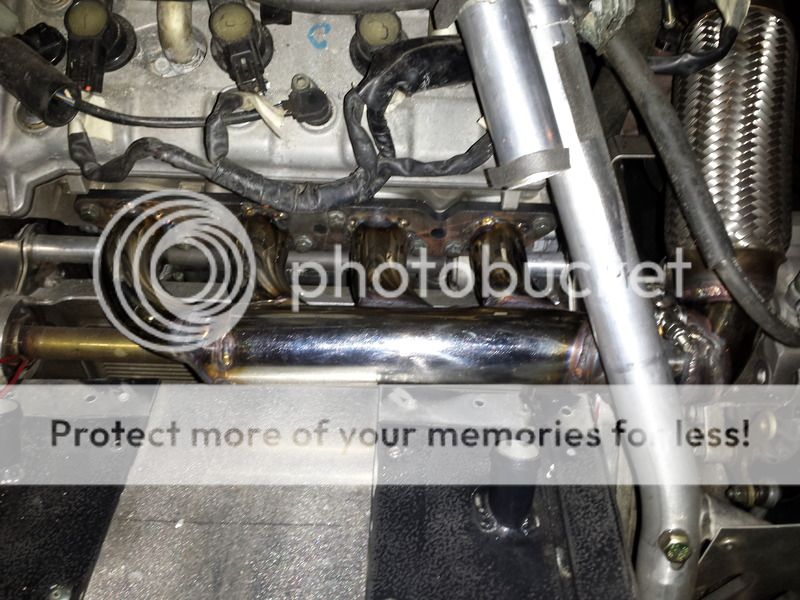

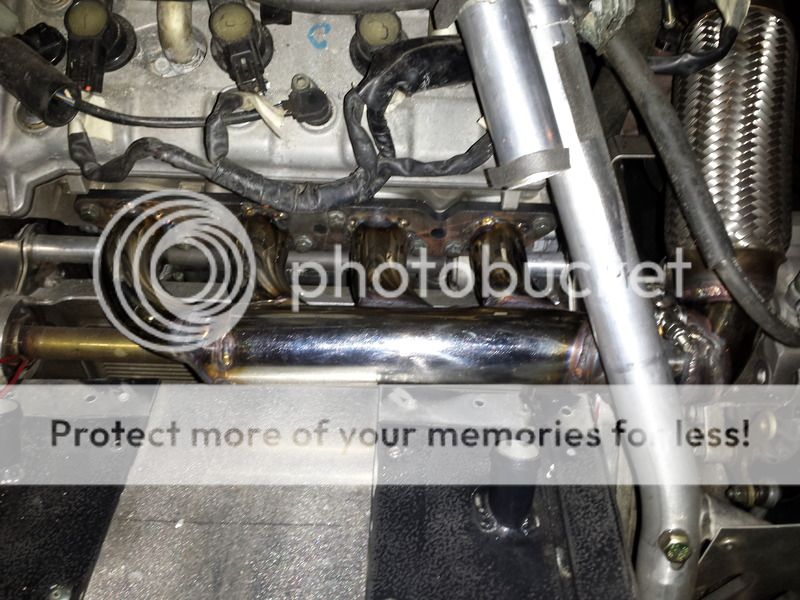

I picked up the exhaust flanges I had laser cut.

Volvo spec TD04 Turbo's have a step for additional sealing, so I had to run it on the lathe to cut the recess.

Saturday & Sunday;

I messed around getting the wiring installed, first. Then I mocked up the turbo, notched the exhaust tube, and tacked up the exhaust manifold. I then started building the up-pipe into the turbo. Once everything was fitting nice, I started to weld it out.

I mocked up the pyramid structure, and began tack welding the support brackets in place.

Thursday;

Finished up the pyramid structure, and mocked up the handlebars.

And the hood fits nice!

Friday;

I picked up the exhaust flanges I had laser cut.

Volvo spec TD04 Turbo's have a step for additional sealing, so I had to run it on the lathe to cut the recess.

Saturday & Sunday;

I messed around getting the wiring installed, first. Then I mocked up the turbo, notched the exhaust tube, and tacked up the exhaust manifold. I then started building the up-pipe into the turbo. Once everything was fitting nice, I started to weld it out.

Snowman871

Lifetime Member

- Joined

- Feb 9, 2010

- Messages

- 278

- Reaction score

- 67

- Points

- 1,028

- Location

- Woodville, WI

- Country

- USA

- Snowmobile

- 2024 Polaris Assault 850

Like the look of the boards!

kennyspec

Expert

- Joined

- Sep 30, 2009

- Messages

- 327

- Reaction score

- 88

- Points

- 738

- Location

- stonewall, manitoba

- Country

- Canada

- Snowmobile

- nytro

Awesome build. Where will you be mounting the oil tank?

Omega_5

Extreme

Thanks! I'm super happy with how they turned out, so far.Like the look of the boards!

Awesome build. Where will you be mounting the oil tank?

Thanks.

And what a coincidence, I was building oil tank brackets last night.

Monday;

Built the oil tank brackets, the bracket for the ECU & RBR.

BTW, the hot side charge tube in the picture; from an old DSM. I love being able to go shopping for turbo parts in my own shop!

I also built a bracket to re-locate the IAC. I knew earlier on that it would interfere at full lock, and didn't want it any higher. As well, I started the backplate for the intake manifold. That will be a long thinking job, as the steering rod just barely clears it.

I also managed to get the header full welded out last night. My mill is in storage, so I arranged to have it surfaced on a big-boy mill at work.

I'm getting up to a time crunch now. I've arranged to have the bulkhead and tunnel coated next Monday, so I have one weekend to get the pyramid structure finished off, the bumper built, and the IC & pump mounted. Then pull it all apart again to prep it.

Omega_5

Extreme

Started on the bumper;

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,422

- Reaction score

- 1,556

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

Awesome!!!! I want to make a 'plate' tunnel similar to what you did. I have been scheming it for years maybe I will get it done this summer!

Omega_5

Extreme

Awesome!!!! I want to make a 'plate' tunnel similar to what you did. I have been scheming it for years maybe I will get it done this summer!

Thanks!

Honestly, picking up a set of IQ or Pro coolers makes the job so simple. Everything just slides together perfect, and there is no bending required.

Past few days have have been busy.

Built lower bumper support (with pump mount), bent up the IC mounts, fab'd cold side piping, and tacked together the plenum.

mcamzr

TY 4 Stroke Guru

I have to reply to follow this. Great work!!

Omega_5

Extreme

Thanks! It's been quite the project so far.I have to reply to follow this. Great work!!

Another busy weekend;

Built the rear braces. Basically a piece of flat bar, milled to accept the tunnel profile. I turned down a piece of round stock to fit inside the tube I'll be using for the main brace, then slash cut it to fit the angle I want.

And built the upper bracket to hold the brace tubes;

Then time for disassembly;

And prep for coating;

So, it's going to the powdercoating shop today. They figure a day for two. In that time, I'm hoping to have the boards welded out, and painted.

Omega_5

Extreme

Took off from work early to finish up some parts.

Welded out the boards, pyramid mount and intake manifold.

Painted / coated some parts.

Because I wanted to be able to repair the coating on the boards, I used an etching primer and high temp satin paint, as a base. I coated the running board section with bed liner. From past experience, it holds up pretty decent, and can be easily touched up.

I also took the opportunity to catch up on some things that I had been lagging behind on.

Test fitted the vents on the hood.

Built a few misc. fittings for plumbing the coolant in.

And I got the manifold back from the machinist a work, at coffee this morning.

Welded out the boards, pyramid mount and intake manifold.

Painted / coated some parts.

Because I wanted to be able to repair the coating on the boards, I used an etching primer and high temp satin paint, as a base. I coated the running board section with bed liner. From past experience, it holds up pretty decent, and can be easily touched up.

I also took the opportunity to catch up on some things that I had been lagging behind on.

Test fitted the vents on the hood.

Built a few misc. fittings for plumbing the coolant in.

And I got the manifold back from the machinist a work, at coffee this morning.

Last edited:

Omega_5

Extreme

Got a call from the powdercoaters right before I left work last night, letting me know the tunnel and bulkhead were done.

So, I spent the night putting the boards and bulkhead on the tunnel, as well as assembling the pyramid structure.

Tonights plan is to try and get the motor / drivetrain back in it.

So, I spent the night putting the boards and bulkhead on the tunnel, as well as assembling the pyramid structure.

Tonights plan is to try and get the motor / drivetrain back in it.

moab11

Lifetime Member

- Joined

- Feb 4, 2010

- Messages

- 424

- Reaction score

- 29

- Points

- 878

- Location

- Thunder Bay, Ontario

- Country

- Canada

- Snowmobile

- 2016 SKS 155

Wow, can't believe I missed this! Awesome work!!!

Omega_5

Extreme

Thanks!Wow, can't believe I missed this! Awesome work!!!

It's getting closer.

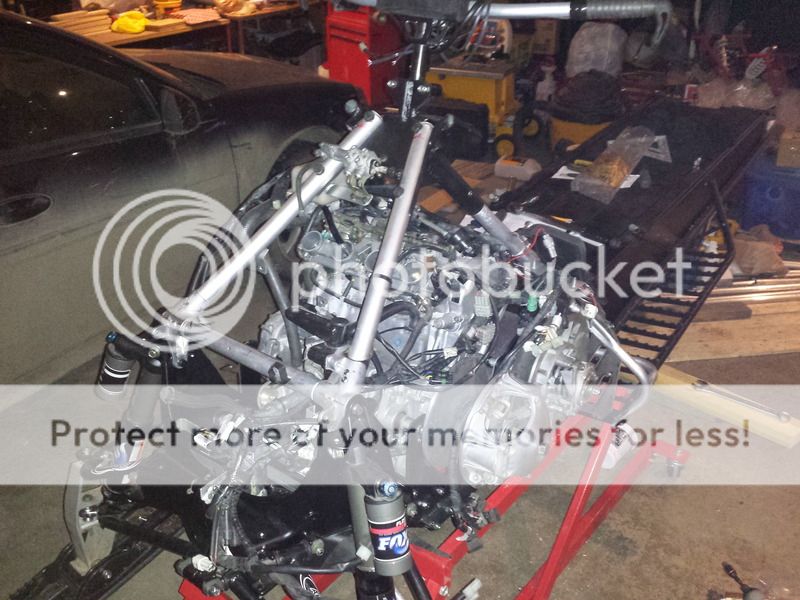

Suspension & steering in. Engine mounted. Pyramid on. Drivetrain mocked up.

We just got a decent bit of snow these past few days, so I might actually be able to get it out to test / tune before spring.

The plan for this weekend, is to get it most of the way.

What is left; exhaust, turbo, piping, intercooler, plenum, IAC tubing. Track & Skid. Chaincase, fuel tank & lines, panels, battery box, aux wiring. It will be a busy few days.

Similar threads

- Replies

- 10

- Views

- 3K

- Replies

- 24

- Views

- 16K

- Replies

- 386

- Views

- 181K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.