Motorhead

TY 4 Stroke God

- Joined

- Apr 20, 2003

- Messages

- 2,090

- Location

- Augusta, Maine

- Country

- USA

- Snowmobile

- 2017 SW LTX-LE

- LOCATION

- Augusta ME

Looking at the pic on the bottom, you see a .065” gap between the roller nut and the clutch tower side. This has been like this since new, problem is there aren’t any Allen screws holding the collar in place on the rollers much like the clutch weights. The roller bolt head is recessed into the other side clutch tower, and allowed to move back and forth easily, thus causing it to make more noise and also causing the bolt head to deepen itself into the clutch tower side.

My thought was to either shorten the collar length, or add a shim over that collar, to help stop some of the noise and not allow that amount of side to side free play.

I decided to play with home made shims for now and found that all three are different thicknesses, probably from 8K miles of being able to clatter back and forth since new. I left a few thousands play as to not allow the bolt to squeeze the roller assembly, thinking that must be why it was left loose from the factory. Had they just copied the weight set up, it would have been a non issue.

So I am interested in your thoughts on this.

Should I have shortened the collar?

Used shims as I did?

Or add the needed Allen set screw to stop that movement?

Or none because it is futile?

Rebuilding both rollers and weights which were needed!

FYI: It did quiet it down a lot, but it is not quiet like past sled clutches. And if the bolt heads are wearing into the clutch recessed side, no telling how long it will last?

Shim thickness varied. .064, .057, .040

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,103

- Age

- 49

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

I prefer to have the bolts going the opposite way then what yours are on the first pic. Nuts should be on the right side not the left in first pic.

Not sure doing what your doing with the shims will matter much.

I would NOT be adding Allen holes/screws.. This will weaken the area around the hole you tap.

Not sure doing what your doing with the shims will matter much.

I would NOT be adding Allen holes/screws.. This will weaken the area around the hole you tap.

Last edited:

Motorhead

TY 4 Stroke God

- Joined

- Apr 20, 2003

- Messages

- 2,090

- Location

- Augusta, Maine

- Country

- USA

- Snowmobile

- 2017 SW LTX-LE

- LOCATION

- Augusta ME

I prefer to have the bolts going the opposite way then what yours are on the first pic. Nuts should be on the right side not the left in first pic.

Not sure doing what your doing with the shims will matter much.

I would NOT be adding Allen holes/screws.. This will weaken the area around the hole you tap.

It did make it noticeably quieter for now anyways. Instead of sounding like an old style Detroit Diesel, it now sounds like the more modern less noisy Diesels.

I see your point about drilling holes to accept set screw Allen’s. That must be why Yamaha made the collars longer then the clutch, so that one can’t squeeze and crack those!

That bolt and nut orientation is the way it came from the factory, and just on the roller right side that hole is indented, so it will accept both the bolt head and the nut? They must be exact diameter.

possessed

Veteran

- Joined

- Apr 18, 2003

- Messages

- 45

- Age

- 62

- Location

- Sidney ME

- Country

- USA

- Snowmobile

- 2017 Sidewinder LE RTX 129 Curve Skis 1.0 track header tune 280 hp

08 Apex LTX Yamachager

1998 SRX Bender 835

03RX1/ 1993 Thunder Cat

- YAHOO

- rx11000@yahoo.com

Hopefully this works they all sound like a little Diesel 3 cly machine haha Apex clutch sounds like the way to go !!

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,103

- Age

- 49

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

The holes for the set screws on the weights is a area to watch VERY closely.. This is a weak design area.. many have cracked in this area.. Use blue lock tight and don't OVER torque screws.. snug is plenty.. IMO this is a design that needs to be changed.. to thin in the area around the set screw hole.. If they beef this area up it would be fine

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,103

- Age

- 49

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

ssgzag15

Extreme

For some reason they want the roller pins to rotate, and not the weight pins

Motorhead

TY 4 Stroke God

- Joined

- Apr 20, 2003

- Messages

- 2,090

- Location

- Augusta, Maine

- Country

- USA

- Snowmobile

- 2017 SW LTX-LE

- LOCATION

- Augusta ME

Yes exactly, and they don’t just rotate they pound back and forth because they are tight against the collar (pin as you call it), and leave a lot of back and forth movement for the bolt and nut against the clutch!For some reason they want the roller pins to rotate, and not the weight pins

Motorhead

TY 4 Stroke God

- Joined

- Apr 20, 2003

- Messages

- 2,090

- Location

- Augusta, Maine

- Country

- USA

- Snowmobile

- 2017 SW LTX-LE

- LOCATION

- Augusta ME

Hopefully this works they all sound like a little Diesel 3 cly machine haha Apex clutch sounds like the way to go !!

Yes for sure. After hearing what Knapp and others have said about that older style Yamaha clutch, when it comes time for a replacement, that’s where I am going!

possessed

Veteran

- Joined

- Apr 18, 2003

- Messages

- 45

- Age

- 62

- Location

- Sidney ME

- Country

- USA

- Snowmobile

- 2017 Sidewinder LE RTX 129 Curve Skis 1.0 track header tune 280 hp

08 Apex LTX Yamachager

1998 SRX Bender 835

03RX1/ 1993 Thunder Cat

- YAHOO

- rx11000@yahoo.com

I don't understand why they would want the roller pins collar to rotate this will in time wreck the aluminum in the clutch ??? 13,000 miles on mine header tune 280 Hp bought new clutch wish I would of know back then that the Apex clutch would of worked !! But I have only like 1500 miles on my new clutch now but a lot of up keep on these sleds !! But if you want to be fast !! Maintenance !! Maintenance!! is an all summer long thing haha it's all fun thou !!!For some reason they want the roller pins to rotate, and not the weight pins

Motorhead

TY 4 Stroke God

- Joined

- Apr 20, 2003

- Messages

- 2,090

- Location

- Augusta, Maine

- Country

- USA

- Snowmobile

- 2017 SW LTX-LE

- LOCATION

- Augusta ME

I don't understand why they would want the roller pins collar to rotate this will in time wreck the aluminum in the clutch ??? 13,000 miles on mine header tune 280 Hp bought new clutch wish I would of know back then that the Apex clutch would of worked !! But I have only like 1500 miles on my new clutch now but a lot of up keep on these sleds !! But if you want to be fast !! Maintenance !! Maintenance!! is an all summer long thing haha it's all fun thou !!!

Yeah don’t know why they want them with that much play as shown in the pic.

I do enjoy doing the maintenance on my sled most of the times!!

- Joined

- Nov 11, 2016

- Messages

- 546

- Location

- Cedarville, MI

- Country

- USA

- Snowmobile

- Yamaha, Polaris, AC and Ski-Doo

- LOCATION

- Cedarville, MI

- WEBSITE

- www.thunderproductsclutching.com

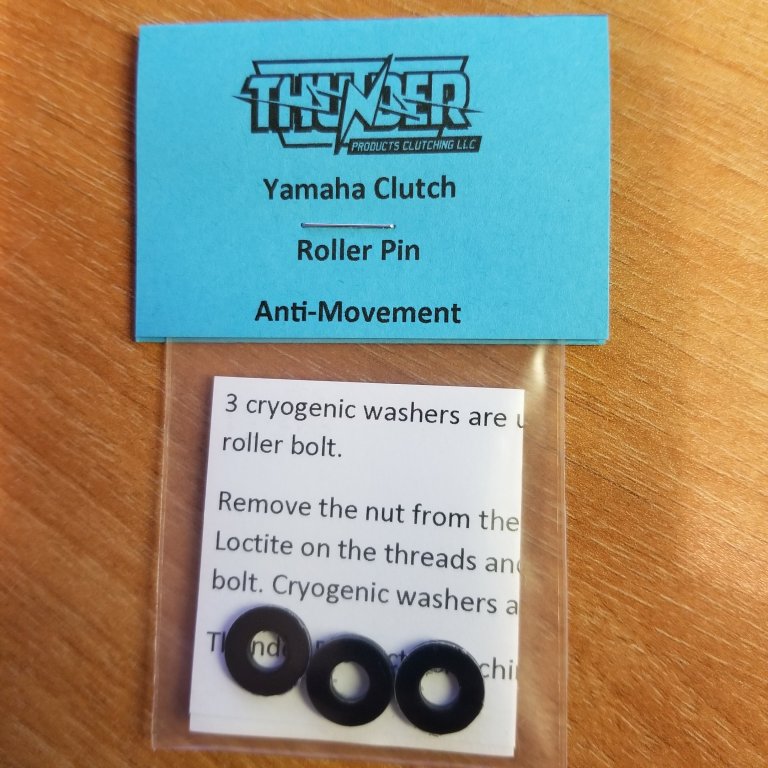

Thunder Products Clutching has these for this very issue. It is to lock the pin and bolt in place. These are reusable. I will find the original post on these.

TSK-545

TSK-545

- Joined

- Nov 11, 2016

- Messages

- 546

- Location

- Cedarville, MI

- Country

- USA

- Snowmobile

- Yamaha, Polaris, AC and Ski-Doo

- LOCATION

- Cedarville, MI

- WEBSITE

- www.thunderproductsclutching.com

Motorhead

TY 4 Stroke God

- Joined

- Apr 20, 2003

- Messages

- 2,090

- Location

- Augusta, Maine

- Country

- USA

- Snowmobile

- 2017 SW LTX-LE

- LOCATION

- Augusta ME

Thunder Products Clutching has these for this very issue. It is to lock the pin and bolt in place. These are reusable. I will find the original post on these.

TSK-545

View attachment 161554

Dam I should have been paying attention. Not sure how that got by me because my shims do quiet my clutch down quite a bit, and it’s been like this since day one! I left .002-.005” play, but yours would work much better and of course so much easier whereas they are made to just order and just install!

Will have to buy a set of these!

I do not have a Head Bump emoji otherwise, yep that would be me.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,228

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

I'd like to tap one side and put a set screw in there. You guys really think that would weaken it too much?

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 21

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.