KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,876

- Reaction score

- 6,174

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

I know I have mentioned, and many others have mentioned as well, that its fine to remove the snap-ring behind the secondary to line up our secondary clutches.

I have removed, many, many snap rings without an issue or having the jackshaft move, but I helped a fella Saturday that was throwing a bunch of belts, so we moved his PTO stub shaft back into place and loctited it back into position, it had moved in quite a bit, we then used the Hurricane bar to line the clutches up and found we needed to remove the washers and snap-ring from behind the secondary. This allowed it to line up perfectly, so I sent him on his way to break in a new belt. He was going to return the machine to me for some more work after he rode it Sunday.

Well he brought it back and I noticed the deflection on the belt was quite extreme. Upon inspection, it's plain to see the shaft has moved inward about 2mm, and the bearing has moved out of its place in the housing about .5mm. This makes for a secondary that also no longer lines up, and because the jackshaft moved inward, his deflection loosened. He is still using the washers on the end of the jackshaft for adjustment, just like the stock setup.

So this is the first machine I've ever seen move the jackshaft or the secondary bearing in the mount without a snap-ring.

It is possible the jackshaft is bent and vibrating from so many blown belts. We know for certain the machine vibrates from a plastic drive sprocket that is way out of whack because he hit a rock under the snow, it hit hard enough it ruined the belly pan and ripped it off too. So Is the vibration bad enough to move the jackshaft? I'd have no way of knowing, but possibly.

None the less, the jackshaft has moved in and the bearing has started to come out of the alum mount. I will update further when I get the shafts out of it for inspection, which will be a while as the owner has gone on a trip West. We have ordered up a new jackshaft, driveshaft and bearing to replace.

I just wanted people who removed the snap-ring to double check alignment and make sure the shaft and bearing is staying put and not moving. It typically takes a press to move both the shaft and the bearing, so I'm surprised to see this happen at all. No other machine has moved the jackshaft like this I have removed the snap-ring on, just this one in particular.

Sorry for a long post, I just wanted to get the info out there.

I have removed, many, many snap rings without an issue or having the jackshaft move, but I helped a fella Saturday that was throwing a bunch of belts, so we moved his PTO stub shaft back into place and loctited it back into position, it had moved in quite a bit, we then used the Hurricane bar to line the clutches up and found we needed to remove the washers and snap-ring from behind the secondary. This allowed it to line up perfectly, so I sent him on his way to break in a new belt. He was going to return the machine to me for some more work after he rode it Sunday.

Well he brought it back and I noticed the deflection on the belt was quite extreme. Upon inspection, it's plain to see the shaft has moved inward about 2mm, and the bearing has moved out of its place in the housing about .5mm. This makes for a secondary that also no longer lines up, and because the jackshaft moved inward, his deflection loosened. He is still using the washers on the end of the jackshaft for adjustment, just like the stock setup.

So this is the first machine I've ever seen move the jackshaft or the secondary bearing in the mount without a snap-ring.

It is possible the jackshaft is bent and vibrating from so many blown belts. We know for certain the machine vibrates from a plastic drive sprocket that is way out of whack because he hit a rock under the snow, it hit hard enough it ruined the belly pan and ripped it off too. So Is the vibration bad enough to move the jackshaft? I'd have no way of knowing, but possibly.

None the less, the jackshaft has moved in and the bearing has started to come out of the alum mount. I will update further when I get the shafts out of it for inspection, which will be a while as the owner has gone on a trip West. We have ordered up a new jackshaft, driveshaft and bearing to replace.

I just wanted people who removed the snap-ring to double check alignment and make sure the shaft and bearing is staying put and not moving. It typically takes a press to move both the shaft and the bearing, so I'm surprised to see this happen at all. No other machine has moved the jackshaft like this I have removed the snap-ring on, just this one in particular.

Sorry for a long post, I just wanted to get the info out there.

Good info Mike, It really baffles me to think that with all that we know now about the alignment on this sled that Yami missed the boat here. It seems more evident that all of these secondary shafts need at least 2mm milled off of them to achieve proper offset while retaining the circlip.

yamamarc

TY 4 Stroke God

- Joined

- Sep 29, 2013

- Messages

- 3,051

- Reaction score

- 2,848

- Points

- 1,583

- Location

- Massey Ontario

- Country

- Canada

- Snowmobile

- 2019 zr9000 Ltd

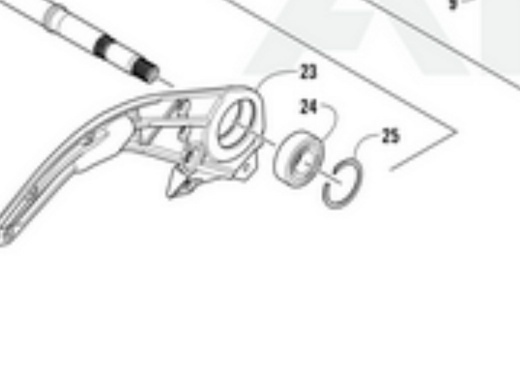

You can buy the clip for the outer race of the jackshaft bearing from cat!!

The groove is there for it on all winders

The groove is there for it on all winders

DMCTurbo

VIP Member

- Joined

- Nov 12, 2005

- Messages

- 2,837

- Reaction score

- 2,583

- Points

- 1,623

- Location

- Val Caron, Ontario

- Country

- Canada

- Snowmobile

- 2017 Sidewinder XTX LE 137

You can buy the clip for the outer race of the jackshaft bearing from cat!!

The groove is there for it on all winders

View attachment 159386 View attachment 159387

When I replaced my jackshaft I wondered if I was missing that clip! I'm surprised yamaha doesn't use it.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,876

- Reaction score

- 6,174

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

You can buy the clip for the outer race of the jackshaft bearing from cat!!

The groove is there for it on all winders

View attachment 159386 View attachment 159387

Yes Mark, but does not stop the shaft from moving in. Typically nothing ever moves when removing the snap-ring. For whatever reason, this one sled did and its the only one I've ever seen do it.

yamamarc

TY 4 Stroke God

- Joined

- Sep 29, 2013

- Messages

- 3,051

- Reaction score

- 2,848

- Points

- 1,583

- Location

- Massey Ontario

- Country

- Canada

- Snowmobile

- 2019 zr9000 Ltd

D

yamamarc

TY 4 Stroke God

- Joined

- Sep 29, 2013

- Messages

- 3,051

- Reaction score

- 2,848

- Points

- 1,583

- Location

- Massey Ontario

- Country

- Canada

- Snowmobile

- 2019 zr9000 Ltd

Sorry I misunderstood I thought you said the bearing moved also!!Yes Mark, but does not stop the shaft from moving in. Typically nothing ever moves when removing the snap-ring. For whatever reason, this one sled did and its the only one I've ever seen do it.

Do you think the locking collar on the chaincase might be loose?

Last edited:

NYTurbo

TY 4 Stroke God

- Joined

- Sep 26, 2017

- Messages

- 1,582

- Reaction score

- 1,386

- Points

- 1,038

- Location

- Ottawa

- Country

- Canada

- Snowmobile

- Sidewinder

I highly doubt the jack shaft has moved inwards, if it has any your buddy will not have a good trip. I would never leave the bearing on the secondary side without a circlip either on the shaft or in the housing, preferred would be in the housing.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,876

- Reaction score

- 6,174

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

I highly doubt the jack shaft has moved inwards, if it has any your buddy will not have a good trip. I would never leave the bearing on the secondary side without a circlip either on the shaft or in the housing, preferred would be in the housing.

Oh with absolute certainty it moved inward, the jackshaft shoulder has moved towards the chain case and is about 2-3 mm away from the bearing and you can no longer see the snap-ring slot. It moved inward! And the bearing has moved out of the housing by about 1/2MM. I will get picture when the machine comes back in here.

He didn't take this sled to ride to ride the mountains, so its just sitting. There is no way its getting ridden until I tear into it when he gets back. We ordered up a jackshaft to replace it because were afraid it has a bend to it and the reason it's moved like it has.

We have run many sled with no snap-ring or circlip in the bearing housing without an issue, tens of thousands of miles ridden, but its because of this one machine that has moved the shaft and bearing that I'm reporting it here for all to know. Because of this one machine I'm not sure I'm going to remove the snap-ring anymore.

I'll know more when I the owner gets back from out west and we get the shafts out of it to check everything over.

I'd hate to see this happen to anyone else and ruin a trip, thus the reason for posting this info.

sledheadgeorge

TY 4 Stroke God

- Joined

- Apr 28, 2003

- Messages

- 1,620

- Reaction score

- 54

- Points

- 1,008

- Location

- Ontario

- Country

- Canada

- Snowmobile

- Which one? I have 6

Good to know. I removed my citclip as well and ran it that way last season. Did not have any issues but wasn't comfortable with that, so I had the secondary cut and put the clip back on for the proper offset.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,876

- Reaction score

- 6,174

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

I have this machine back in the shop and dug into it today. The shaft indeed moved inward just over 2mm on the bearing, and the bearing moved out of the housing just over .5mm. The jackshaft is straight and not bent or tweaked whatsoever. It's quite possible the vibration from the owner hitting a rock and bending a plastic drive sprocket on the front drive caused the jackshaft to move, but the press fit was not very tight on either the shaft or the housing. So its getting the circlip put back into place and the secondary machined to get to the proper offset.

As you can see, the shoulder on the inside of the jack shaft has moved well over 2mm away from the bearing and the bearing has moved out from the housing by about .5mm

This pic is the inside of the PTO side jackshaft housing prior to pressing it back into place and re-installing the snap-ring back on the outside.

As you can see, the shoulder on the inside of the jack shaft has moved well over 2mm away from the bearing and the bearing has moved out from the housing by about .5mm

This pic is the inside of the PTO side jackshaft housing prior to pressing it back into place and re-installing the snap-ring back on the outside.

johan

Pro

- Joined

- Jan 19, 2015

- Messages

- 157

- Reaction score

- 103

- Points

- 713

- Location

- sweden

- Country

- Sweden

- Snowmobile

- Viper Xtx mcx 270

Was the secondary fixated or did it had float?

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,876

- Reaction score

- 6,174

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Was the secondary fixated or did it had float?

Float just like stock with washer and shims on the end.

Similar threads

- Replies

- 19

- Views

- 7K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.