Some back ground:

I have 2500 miles on my tuned Winder all on the stock primary with TPI rollers and Dalton tuning components.

-when the sled was brand new I removed the primary and found it difficult to get off although I got it with my quality puller.

-when I reinstalled the clutch and torqueing it to the spec of 108 ft lbs I thought the bolt was going to twist off as it felt very spongey

-I ran the sled 2500 miles before removing the clutch again and this time I could not get it off without reverting to the teflon tape and grease method.

-it appeared as though the clutch had turned slightly on the stub shaft as there was scarring on both surfaces.

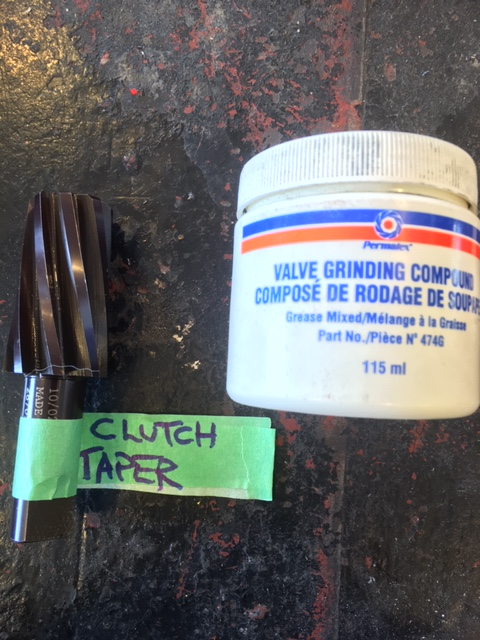

Before reinstalling my primary I ran a reamer, that I had from my old Polaris clutch days, in the clutch taper. I was amazed how poorly the reamer initially worked as it was only cleaning up random spots in the taper. I hesitantly kept reaming until it was actually cutting the complete taper surface.

I then lapped the clutch on the shaft with valve grinding compound, cleaned everything with brake clean and torqued the clutch back on the stubshaft.

This time the clutch torqued up with a very solid feel, no feeling of twisting off the bolt, like a bolt is supposed to torque and like all my other Yamahas clutches install.

I am now thinking the taper on my stock clutch was inconsistent and reaming it allowed it to seat up properly...just like all my other Yamahas. I am a bit concerned that the clutch may spin again on the stub shaft...I guess time will tell.

I have 2500 miles on my tuned Winder all on the stock primary with TPI rollers and Dalton tuning components.

-when the sled was brand new I removed the primary and found it difficult to get off although I got it with my quality puller.

-when I reinstalled the clutch and torqueing it to the spec of 108 ft lbs I thought the bolt was going to twist off as it felt very spongey

-I ran the sled 2500 miles before removing the clutch again and this time I could not get it off without reverting to the teflon tape and grease method.

-it appeared as though the clutch had turned slightly on the stub shaft as there was scarring on both surfaces.

Before reinstalling my primary I ran a reamer, that I had from my old Polaris clutch days, in the clutch taper. I was amazed how poorly the reamer initially worked as it was only cleaning up random spots in the taper. I hesitantly kept reaming until it was actually cutting the complete taper surface.

I then lapped the clutch on the shaft with valve grinding compound, cleaned everything with brake clean and torqued the clutch back on the stubshaft.

This time the clutch torqued up with a very solid feel, no feeling of twisting off the bolt, like a bolt is supposed to torque and like all my other Yamahas clutches install.

I am now thinking the taper on my stock clutch was inconsistent and reaming it allowed it to seat up properly...just like all my other Yamahas. I am a bit concerned that the clutch may spin again on the stub shaft...I guess time will tell.

snowcaine

VIP Member

- Joined

- Dec 23, 2019

- Messages

- 307

- Location

- Indiana

- Country

- USA

- Snowmobile

- 20 Sidewinder

21 ZR 9000

23 SRX

Some back ground:

I have 2500 miles on my tuned Winder all on the stock primary with TPI rollers and Dalton tuning components.

-when the sled was brand new I removed the primary and found it difficult to get off although I got it with my quality puller.

-when I reinstalled the clutch and torqueing it to the spec of 108 ft lbs I thought the bolt was going to twist off as it felt very spongey

-I ran the sled 2500 miles before removing the clutch again and this time I could not get it off without reverting to the teflon tape and grease method.

-it appeared as though the clutch had turned slightly on the stub shaft as there was scarring on both surfaces.

Before reinstalling my primary I ran a reamer, that I had from my old Polaris clutch days, in the clutch taper. I was amazed how poorly the reamer initially worked as it was only cleaning up random spots in the taper. I hesitantly kept reaming until it was actually cutting the complete taper surface.

I then lapped the clutch on the shaft with valve grinding compound, cleaned everything with brake clean and torqued the clutch back on the stubshaft.

This time the clutch torqued up with a very solid feel, no feeling of twisting off the bolt, like a bolt is supposed to torque and like all my other Yamahas clutches install.

I am now thinking the taper on my stock clutch was inconsistent and reaming it allowed it to seat up properly...just like all my other Yamahas. I am a bit concerned that the clutch may spin again on the stub shaft...I guess time will tell.

View attachment 154853

Nice write up Bob. You may want to grab a new primary bolt just in case. They’re cheap and, under the right circumstances, can shear off. I know from first-hand experience!

Macheater

VIP Member

- Joined

- Feb 7, 2006

- Messages

- 731

- Age

- 58

- Location

- Niles, Ohio

- Country

- USA

- Snowmobile

- 2006 Apex GT, 2002 SRX700

- LOCATION

- Niles, Oh

I would see if there is an aftermarket substitute. Like an ARP or equivalent.Nice write up Bob. You may want to grab a new primary bolt just in case. They’re cheap and, under the right circumstances, can shear off. I know from first-hand experience!

Turboflash

TY 4 Stroke God

- Joined

- Mar 18, 2019

- Messages

- 2,442

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

Hard to understand the difference between Yamaha and Cat torque specs on primary. Yamaha is 108 ftlbs., back off and re-tighten to ???

Cat is torque to 51 ft.lbs, run engine 5 minutes, re-torque to 51 ft.lbs. As far as crank snub is concerned, a clutch is a clutch. IF the tapers are correct and match each other, torque specs should be the same whether it's Winder primary or a Team primary.

What am I missing here?

Cat is torque to 51 ft.lbs, run engine 5 minutes, re-torque to 51 ft.lbs. As far as crank snub is concerned, a clutch is a clutch. IF the tapers are correct and match each other, torque specs should be the same whether it's Winder primary or a Team primary.

What am I missing here?

snowcaine

VIP Member

- Joined

- Dec 23, 2019

- Messages

- 307

- Location

- Indiana

- Country

- USA

- Snowmobile

- 20 Sidewinder

21 ZR 9000

23 SRX

Hard to understand the difference between Yamaha and Cat torque specs on primary. Yamaha is 108 ftlbs., back off and re-tighten to ???

Cat is torque to 51 ft.lbs, run engine 5 minutes, re-torque to 51 ft.lbs. As far as crank snub is concerned, a clutch is a clutch. IF the tapers are correct and match each other, torque specs should be the same whether it's Winder primary or a Team primary.

What am I missing here?

I’ve been wondering this too. I have a stub shaft and primary bolt from a Cat 998 that J&J Racing loaned me. Stub shaft is the same as a Winder, but the Cat primary bolt is a much smaller diameter compared to the Winder primary clutch bolt. No way in hell would I ever put 108 ft-lbs on a Cat primary bolt! Thing would snap in a second or at least be significantly weakened.

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,164

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

I thought the same thing when I first pulled my winder primary back in 2018. Why did it need this amount of torque when the Apex only required 55 lbs? I set mine at 65lbs. It spun on the shaft ever so slightly. I wonder if the taper is inconsistent on the clutch as stated earlier in this thread by Sideshow?

Turboflash

TY 4 Stroke God

- Joined

- Mar 18, 2019

- Messages

- 2,442

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

Interesting.

It does make one wonder.

The Apex's spec 85 ft lbs initial torque on the same taper. SC and Turbo Apexs run up over 300hp at that torque with no issues.

Why does Yamaha spec 108 ft lbs on the Sidewinder?

What are people running an Apex clutch on the Sidewinder using for torque specs?

The Apex's spec 85 ft lbs initial torque on the same taper. SC and Turbo Apexs run up over 300hp at that torque with no issues.

Why does Yamaha spec 108 ft lbs on the Sidewinder?

What are people running an Apex clutch on the Sidewinder using for torque specs?

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,673

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

It does make one wonder.

The Apex's spec 85 ft lbs initial torque on the same taper. SC and Turbo Apexs run up over 300hp at that torque with no issues.

Why does Yamaha spec 108 ft lbs on the Sidewinder?

What are people running an Apex clutch on the Sidewinder using for torque specs?

I use 108 ft. lbs. on a RX-1 clutch after I use lapping compound on it, then loosen and TQ to 45 ft. lbs. Tightens right up unlike the Winder primary that you'd swear you're going to break the bolt on. Comes off and goes on just fine.

The Winder primary uses that new mush steel that stretches then breaks, but not before it binds up the movable, blows belts and eats rollers. LOL!

Seriously though, there is something about the Winder primary that makes it crap, and I believe it to be crap china steel and alum.

Hard to understand the difference between Yamaha and Cat torque specs on primary. Yamaha is 108 ftlbs., back off and re-tighten to ???

Cat is torque to 51 ft.lbs, run engine 5 minutes, re-torque to 51 ft.lbs. As far as crank snub is concerned, a clutch is a clutch. IF the tapers are correct and match each other, torque specs should be the same whether it's Winder primary or a Team primary.

What am I missing here?

I agree with TF here. Whenever I torqued mine to 108lbs, I would cringe. Removable required heat everytime and the end of the puller would bend. This was ridiculous.

The last few years I've gone 90lbs, loosen, re-torque to 60lbs. Clutch pops off easy and has never spun or had any issues.

My 5 cents....

Once the stubshaft and primary are are marred from the clutch slipping, the next step would be new stubshaft and and clutch? Nothing you can really do to fix it?Seriously though, there is something about the Winder primary that makes it crap, and I believe it to be crap china steel and alum.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,673

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Once the stubshaft and primary are are marred from the clutch slipping, the next step would be new stubshaft and and clutch? Nothing you can really do to fix it?

My Winder primary is going to sit on the shelf as I'm using the old RX-1 primary, but I always lap them together using valve lapping compound so they match up perfect and fit nicely together. If you use lapping compound, you can see if they are mating properly. I've not seen a clutch spin on the shaft and it shouldn't if it is torqued properly with the proper drive clutch taper installed.

The OP used a reamer he said to cleanup the clutch, which IMO is not needed. If he'd have used the valve lapping prior to reaming it would have showed the same effect. Myself, I wouldn't ream the taper, it's just going to make the clutch sit that much further on the shaft and inward. Polishing with valve lapping compound is going to provide the fit needed to mate it to the shaft. I've been doing the lapping since the late 80's and its never failed me for the shaft to grip clutch.

Lap it to the shaft always and there shouldn't be an issue.

swampcat

TY 4 Stroke Junkie

One MORE thing to add to the LIST.

swampcat

TY 4 Stroke Junkie

When lapping, should clutch be spun only CCW, or both ways to get a good grind ? Know not to spin crank CW, but what about clutch, just spin it back and forth. Will clutch not grab with compound in there ? Thanks.My Winder primary is going to sit on the shelf as I'm using the old RX-1 primary, but I always lap them together using valve lapping compound so they match up perfect and fit nicely together. If you use lapping compound, you can see if they are mating properly. I've not seen a clutch spin on the shaft and it shouldn't if it is torqued properly with the proper drive clutch taper installed.

The OP used a reamer he said to cleanup the clutch, which IMO is not needed. If he'd have used the valve lapping prior to reaming it would have showed the same effect. Myself, I wouldn't ream the taper, it's just going to make the clutch sit that much further on the shaft and inward. Polishing with valve lapping compound is going to provide the fit needed to mate it to the shaft. I've been doing the lapping since the late 80's and its never failed me for the shaft to grip clutch.

Lap it to the shaft always and there shouldn't be an issue.

When I did mine I rotated the clutch back and forth just like you do when lapping a valve...it doesn't take much at all...less is better.

Similar threads

- Replies

- 2

- Views

- 620

- Replies

- 4

- Views

- 2K

- Replies

- 0

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.