Yank it out of there and run the wire over top of tunnel. Would be easy to do. Probably could use a section of original at back so it looks decent.

**sj**

Lifetime Member

- Joined

- Mar 2, 2004

- Messages

- 6,064

- Reaction score

- 970

- Points

- 1,983

- Location

- southeastern Mich

- Country

- USA

- Snowmobile

- 2019 SRX

It's not the wire mold anymore that's the biggest concern..like the viper..there's a vent..but on the sw it hangs down ..eyeballing it 1/2-5/8" ! !

That surely reduces the maximum stud length..

That surely reduces the maximum stud length..

Oh the Louvers. Ceramic coat the exhaust manifold and pound the louvre flat. Yes that might be a issue.

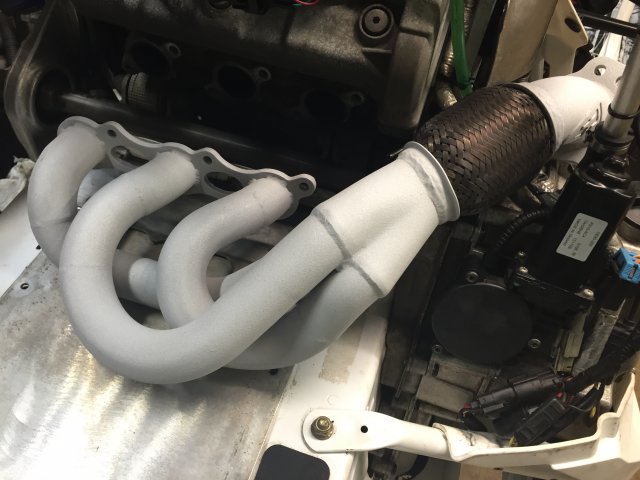

I had that issue with the Evo header which hung in hole a little to far! Pretty good pattern eh?

So I did this. Notice this header is short like yours on Sidewinder. Just be careful. Gets real hot in there!

So I did this. Notice this header is short like yours on Sidewinder. Just be careful. Gets real hot in there!

monte1214

TY 4 Stroke Guru

- Joined

- Apr 20, 2005

- Messages

- 752

- Reaction score

- 46

- Points

- 1,028

- Location

- Durham Region, ON

- Website

- www.portperrysnowmobileclub.com

- Country

- Canada

- Snowmobile

- 2017 Sidewinder LTX-SE

Has anyone on here thought about an Ice Ripper Track instead of Studding?

WVTurboLTX

TY 4 Stroke Guru

- Joined

- Nov 9, 2014

- Messages

- 878

- Reaction score

- 465

- Points

- 978

- Country

- USA

- Snowmobile

- 2009 Nytro XTX

2017 Sidewinder LTX LE

68gmc

Extreme

Protectors are approximately 1.02" or 26mm and louvers in tunnel protrude approximately 0.315" or 8mm. I have W85 Warthog studs that extend Approximately 0.59" or 15mm past the lug. That leaves 0.118" or 3mm of tolerance which with a bit of lug deflection hopefully will be just barely enough hopefully. I wouldn't recommend running anything longer as there would be interference issues for sure!

Attachments

**sj**

Lifetime Member

- Joined

- Mar 2, 2004

- Messages

- 6,064

- Reaction score

- 970

- Points

- 1,983

- Location

- southeastern Mich

- Country

- USA

- Snowmobile

- 2019 SRX

there we go...basically .60 is maxed out net protrusion and Im going to try and stay out of the center approx 3 inches thanks again..

WVTurboLTX

TY 4 Stroke Guru

- Joined

- Nov 9, 2014

- Messages

- 878

- Reaction score

- 465

- Points

- 978

- Country

- USA

- Snowmobile

- 2009 Nytro XTX

2017 Sidewinder LTX LE

Saved me some time. Those are some serious studs! I should have plenty of space.Protectors are approximately 1.02" or 26mm and louvers in tunnel protrude approximately 0.315" or 8mm. I have W85 Warthog studs that extend Approximately 0.59" or 15mm past the lug. That leaves 0.118" or 3mm of tolerance which with a bit of lug deflection hopefully will be just barely enough hopefully. I wouldn't recommend running anything longer as there would be interference issues for sure!

actionjack

TY 4 Stroke God

- Joined

- Apr 9, 2005

- Messages

- 2,519

- Reaction score

- 623

- Points

- 1,483

- Location

- Westminster, Maryland

- Website

- www.inspectorjack.com

- Country

- USA

- Snowmobile

- 2017 SideWinder LTX-LE

I will be running the Ice CobraHas anyone on here thought about an Ice Ripper Track instead of Studding?

WINDER1987

TY 4 Stroke Guru

What's everyone using for a pattern is there anything that keeps it off the center

I just quickly came up with this pattern which avoids the center 2" of the track. You can use this in combination with our studding template. It has 144 studs down the center and 48 on the outside for a 137" long track. A similar design can be used/created for a 129" track.

Attachments

Does anyone think if the studs do hit the louvers it will be a light enough kiss to basicly machine clearance without damaging the stud? They did a number on that header and its stainless. Didnt hurt the studs one bit. It would happen under hard braking

WINDER1987

TY 4 Stroke Guru

I just quickly came up with this pattern which avoids the center 2" of the track. You can use this in combination with our studding template. It has 144 studs down the center and 48 on the outside for a 137" long track. A similar design can be used/created for a 129" track.

Is there a 192 pattern for it I see a PDF below the picture but nothing comes up

View attachment 122432

**sj**

Lifetime Member

- Joined

- Mar 2, 2004

- Messages

- 6,064

- Reaction score

- 970

- Points

- 1,983

- Location

- southeastern Mich

- Country

- USA

- Snowmobile

- 2019 SRX

I just quickly came up with this pattern which avoids the center 2" of the track. You can use this in combination with our studding template. It has 144 studs down the center and 48 on the outside for a 137" long track. A similar design can be used/created for a 129" track.

View attachment 122432

nice pattern tool...guessing its going to be the middle 3" that needs to be avoided....

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.