Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I've been hammering the ol' Vector this week. I'm still in love with this snowmobile! The M20 made this sled a perfect touring machine.

I stopped in to visit my friends at the dealership in which I purchased this sled new in 2008!

Snow is nothing short of awesome in the Keweenaw right now!

I stopped in to visit my friends at the dealership in which I purchased this sled new in 2008!

Snow is nothing short of awesome in the Keweenaw right now!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Team Fast now has a new suspension out called, "King Air!"

This may be a potential M20 replacement?? Time will tell??

This may be a potential M20 replacement?? Time will tell??

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Reaction score

- 92

- Points

- 753

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

Yes, I saw that a couple of weeks ago. Interesting indeed.Team Fast now has a new suspension out called, "King Air!"

This may be a potential M20 replacement?? Time will tell??

MarkAttack

Pro

- Joined

- Feb 15, 2007

- Messages

- 161

- Reaction score

- 26

- Points

- 698

- Location

- South West MI in the Mud

- Website

- haywardlime.com

All solenoids, switches and electrical connectors were sourced from eBay.

All fittings and lines were sourced from my local hydraulic shop.

When I decided on the type of air lines to use, I wanted something that would take a beating and be easy to work on in frigid weather if an issue were to arise. Standard DOT lines with compression fittings would work, but I just don't trust their durability, no to mention the little ferrules needed to keep from crushing the line. In addition, my old farm semi's use compression fittings, and they ALL leak.

I ultimately decided on stainless braided poly air lines with stainless #4 JIC fittings that are crimped on in a hydraulic powered machine. All the lines tighten/loosen with a 9/16 wrench and they will never rust. I have yet to have a line fail. I've even had a large chunk of ice hanging from the air line that goes through the tunnel to the rear spring. The line kinked, but never broke or lost air pressure. I do keep a spare line in the trunk in case it does happen some day.

I make my own Hydraulic lines.. I also have the dies to make 1/4" Teflon Braided Stainless lines. The fitting you are using are Hydraulic fittings as opposed to pipe fittings .. and you are are using the 37 Degree JIC ends.. Those Hydraulic fittings in 1/4" are rated for like 6,000 PSI where pipe fittings are rated for like 250 PSI.. It does not matter for air fittings .. I have seen many times people use water pipe fittings in a hydraulic system not a good idea. I have even seen Fertilizer spreaders from the South come from the factory with pipe fittings say 3/4" on the Pressure side.. A total no no .. My 2011 M-20 system has no Solenoids and I am very happy that it does not ..Purchased in 2011.. I have not installed it yet in a 2006 Attak.. near as I can tell there is a 3 way switch goes on the dash .. that is neutral add air or exhaust air.. It's the same switch that many class 8 trucks use that have air bag suspension ..

MarkAttack

Pro

- Joined

- Feb 15, 2007

- Messages

- 161

- Reaction score

- 26

- Points

- 698

- Location

- South West MI in the Mud

- Website

- haywardlime.com

Yes, I saw that a couple of weeks ago. Interesting indeed.

I saw that and asked Brian at Team Fast .. his answer was confusing.. He said it's better in rare situations.. He said the M-20 is better for long mile days? I am an aggressive rider that normally likes rough trails .. I competed in Mogul Competition on Snow Skis.. I have skied the Steep and Deep and done extreme skiing.. that's why I never owned a Snowmobile in the past.. Skiing in Michigan is no challenge to me.. where as a snowmobile can go uphill down hill or on the Level if you have snow.. I hope to try the UP next winter never been up there.. Have been to the Cadillac area three times I guess.. Here in SW MI if you get enough snow to ride .. you better ride cause it may rain and be melting in three days.. Last winter had two weeks of around 0 weather with bear ground..

I thought Maybe I could trade up to the King Air while my M-20 is stall brand new but I did not get a very informative answer..

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Back in early December, I finally got around to changing the original idler wheel bearings on the Vector M20. The skid had 3 seasons under its belt, so I felt some preventive maintenance was in order. Out came the skid and ALL bearings were replaced. None were out, but a handful were over the hill.

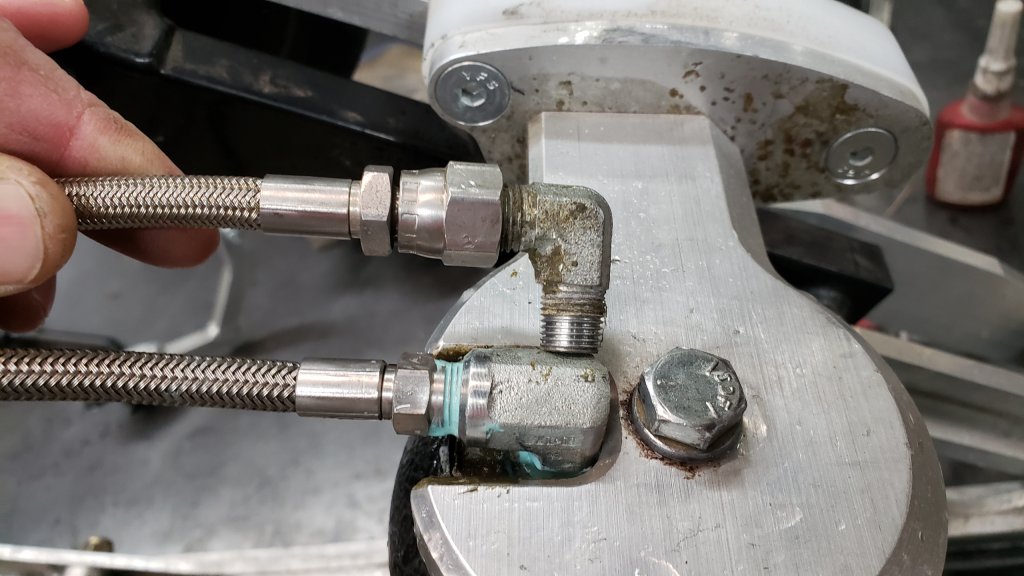

While the skid was out, I made one engineering change to the way the air line connects from inside the tunnel to the rear air spring. One end of the line is 1/8" pipe, which threads into a pipe coupling that passes through the tunnel. The other end is a #4 JIC swivel that connects to an elbow on top of the air spring. This configuration has always worked, and never once caused a problem, except when removing the skid for service; just a nuisance really.

To remove the skid, you had to loosen and tip the top of the air spring forward just to loosen the air line swivel. Then you had to remove the clamp that secures the line to the rear arm. Finally the 1/8" pipe end of the air line had to be threaded out of the tunnel, all to remove the skid... I'm really splitting hairs, but it didn't have to be this way.

I'm really splitting hairs, but it didn't have to be this way.

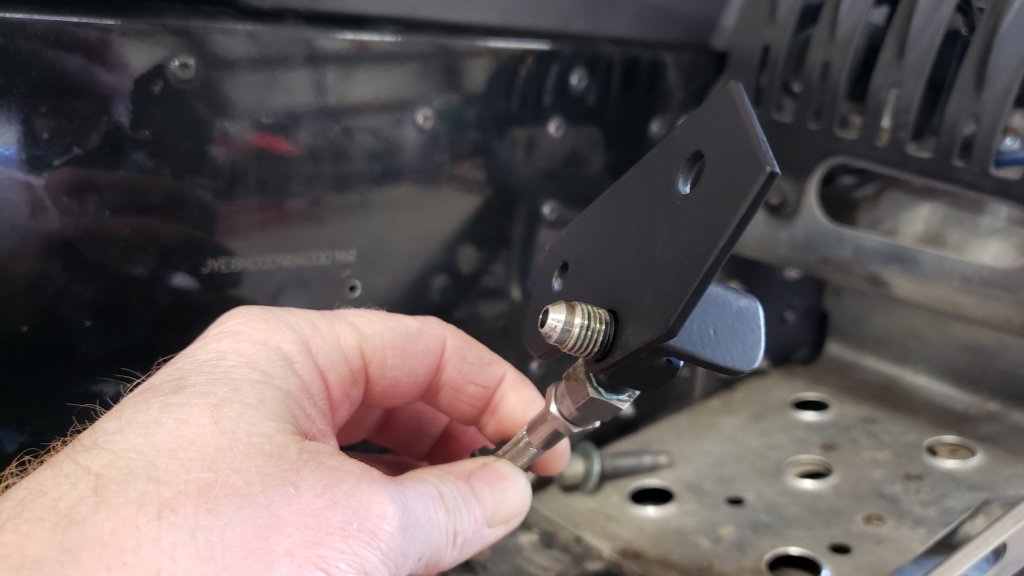

As suggested by Viper Dave, I simply reversed the order in which the air line is connected. Now the 1/8" pipe end connects to the air spring, and the #4 JIC end connects to the tunnel. The air line can simply be unhooked from the tunnel while the rest of the line stays fastened in place on the skid. Remove 4 bolts, and out comes the skid...much simpler!

To make this come together, I made a new outer tunnel bracket with a #4 JIC elbow welded to it. The only other thing that had to be changed was the elbow on top of the air spring. I originally feared that the movement of the rear arm might loosen the JIC swivel, but 900+ miles proved otherwise. I just didn't tell the guys taking turns riding this sled that they were riding an experiment...

Now to reconfigure my Apex and Viper Dave's as well this summer.

Shop is messy, as I had just completed harvest.

Stay tuned...

While the skid was out, I made one engineering change to the way the air line connects from inside the tunnel to the rear air spring. One end of the line is 1/8" pipe, which threads into a pipe coupling that passes through the tunnel. The other end is a #4 JIC swivel that connects to an elbow on top of the air spring. This configuration has always worked, and never once caused a problem, except when removing the skid for service; just a nuisance really.

To remove the skid, you had to loosen and tip the top of the air spring forward just to loosen the air line swivel. Then you had to remove the clamp that secures the line to the rear arm. Finally the 1/8" pipe end of the air line had to be threaded out of the tunnel, all to remove the skid...

As suggested by Viper Dave, I simply reversed the order in which the air line is connected. Now the 1/8" pipe end connects to the air spring, and the #4 JIC end connects to the tunnel. The air line can simply be unhooked from the tunnel while the rest of the line stays fastened in place on the skid. Remove 4 bolts, and out comes the skid...much simpler!

To make this come together, I made a new outer tunnel bracket with a #4 JIC elbow welded to it. The only other thing that had to be changed was the elbow on top of the air spring. I originally feared that the movement of the rear arm might loosen the JIC swivel, but 900+ miles proved otherwise. I just didn't tell the guys taking turns riding this sled that they were riding an experiment...

Now to reconfigure my Apex and Viper Dave's as well this summer.

Shop is messy, as I had just completed harvest.

Stay tuned...

Last edited:

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,424

- Reaction score

- 1,558

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

Nice solution!!

Similar threads

- Replies

- 124

- Views

- 22K

- Replies

- 385

- Views

- 78K

- Replies

- 16

- Views

- 8K

- Replies

- 28

- Views

- 4K