Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Spring 2017, Apex XTX M20 Version 2.0

Hello again my friends! This thread covers the installation of a 136” M20 Airwave into a friend’s Apex XTX. I absolutely love these suspensions and I'd recommend them to anyone who is seeking for a way to improve their snowmobile! TF has done a great job with the engineering and it shows the second you open the box!

Since my first M20 project in 2013, I’ve spent many hours refining the installation of these suspensions and their respective components. My top three priorities have always been: safety, reliability and functionality. In addition, I try very hard to make these components look like they’re supposed to be there.

This will be my third M20 project and I have some new ideas to set in motion, so stay tuned as this project gets started!

Spring 2013: Apex XTX M20 Version 1.0

http://ty4stroke.com/threads/team-fast-m20-apex-xtx-version-1-0.119161/

Summer 2016: Vector LTX M20:

http://ty4stroke.com/threads/team-fast-m20-vector-ltx.141902/

Hello again my friends! This thread covers the installation of a 136” M20 Airwave into a friend’s Apex XTX. I absolutely love these suspensions and I'd recommend them to anyone who is seeking for a way to improve their snowmobile! TF has done a great job with the engineering and it shows the second you open the box!

Since my first M20 project in 2013, I’ve spent many hours refining the installation of these suspensions and their respective components. My top three priorities have always been: safety, reliability and functionality. In addition, I try very hard to make these components look like they’re supposed to be there.

This will be my third M20 project and I have some new ideas to set in motion, so stay tuned as this project gets started!

Spring 2013: Apex XTX M20 Version 1.0

http://ty4stroke.com/threads/team-fast-m20-apex-xtx-version-1-0.119161/

Summer 2016: Vector LTX M20:

http://ty4stroke.com/threads/team-fast-m20-vector-ltx.141902/

Last edited:

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Reaction score

- 1,501

- Points

- 1,753

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

Great Joe, love to read and review these posts of your great work

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

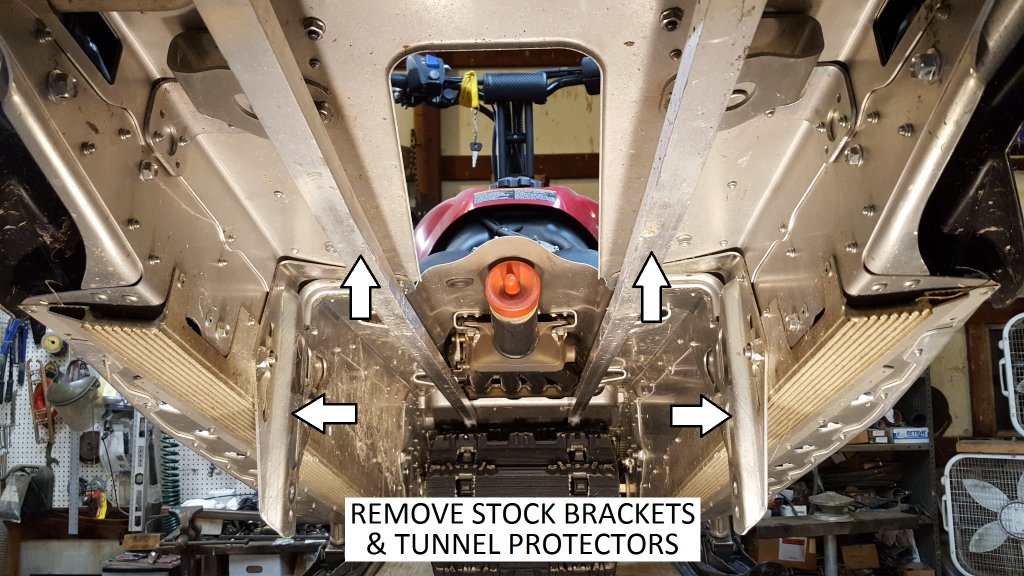

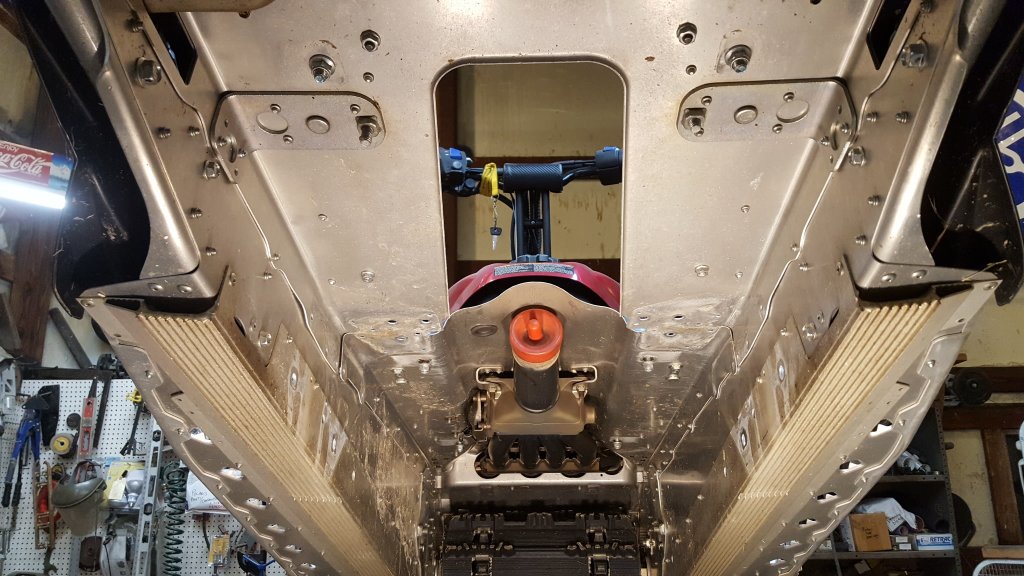

At this point, I'd like to mention that this installation will be a custom departure from the instructions included with the skid. This will involve altering some chassis features that are not represented by TF. The only items I use are the suspension and the dimensions to mount it.

For those interested in an M20, please follow the instructions included for your particular sled.

First thing is to strip the sled and make room for working on all the various parts. This project will include a track change, so all the front panels need to come off as well.

Note* Removing the tunnel protectors and drop brackets are for this application only.

For those interested in an M20, please follow the instructions included for your particular sled.

First thing is to strip the sled and make room for working on all the various parts. This project will include a track change, so all the front panels need to come off as well.

Note* Removing the tunnel protectors and drop brackets are for this application only.

Last edited:

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Reaction score

- 92

- Points

- 753

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

Great stuff, I look forward to every post.At this point, I'd like to mention that this installation will be a custom departure from the instructions included with the skid. This will involve altering some chassis features, which is not represented by TF. The only items I use from TF are the suspension and the dimensions to mount it.

For those interested in an M20, please follow the instructions included for your particular sled.

First thing is to strip the sled and make room for working on all the various parts. This project will include a track change, so all the front panels need to come off as well.

View attachment 128635 View attachment 128636 View attachment 128637 View attachment 128638 View attachment 128639 View attachment 128640

Note* Removing the tunnel protectors and drop brackets are for this application only.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I unpacked the new skid today and started laying out all the parts. I noticed the air spring looked different, so I took it out and laid it on the bench next to the air spring from my Apex. I inflated both to discover the new spring is 1.5" shorter. I'm not sure if this will affect ride quality, but there is definitely less air volume in the shorter spring.

FYI: The part number for this style of Firestone air spring is stamped on the band that crimps the sleeve to the upper cap.

FYI: The part number for this style of Firestone air spring is stamped on the band that crimps the sleeve to the upper cap.

Last edited:

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Reaction score

- 486

- Points

- 1,328

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

You are one of the best at providing great pictures and information in your builds !!!!

Keep up the great work, it helps the summer to pass ....

Keep up the great work, it helps the summer to pass ....

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

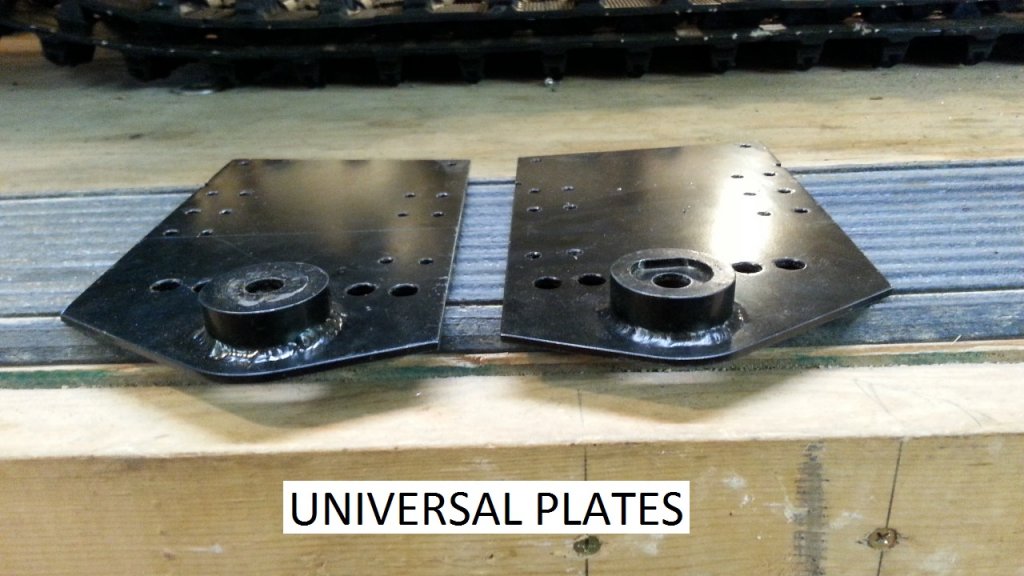

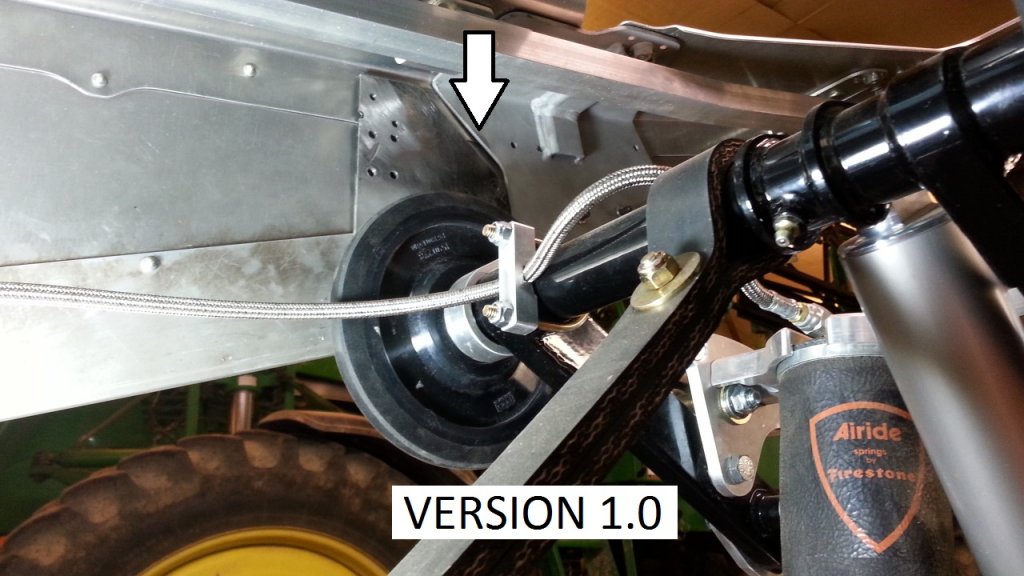

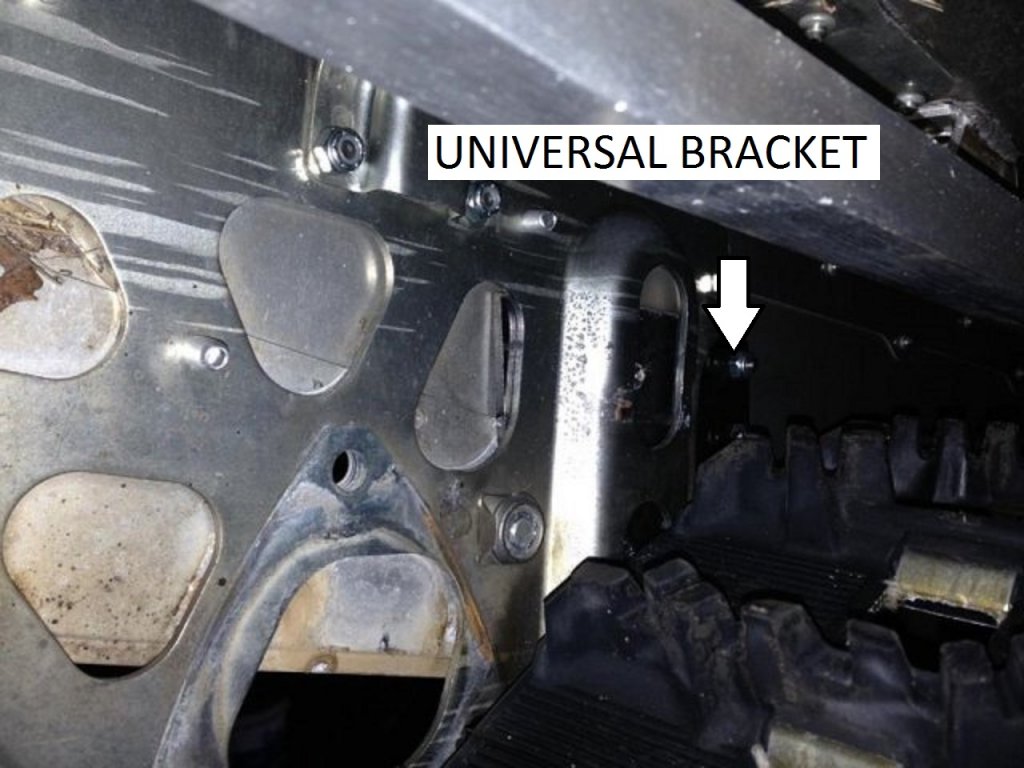

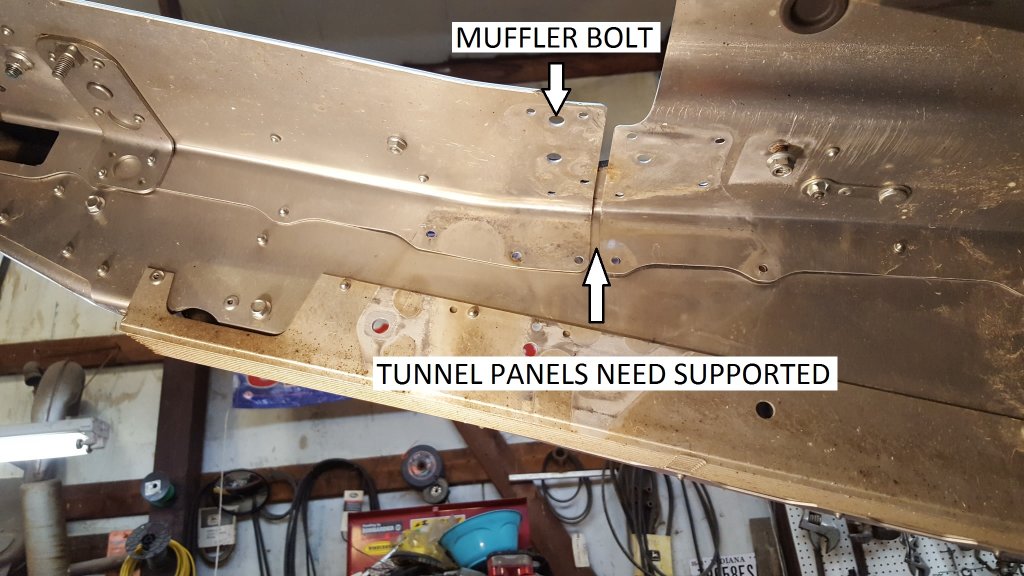

Mounting an M20 into a 2011+ Apex presents a challenge because, unlike older Apex models, the factory drop brackets are multi-purposed for mounting the stock suspension, muffler and joining a gap in the upper tunnel panels. They simply can’t be removed or re-positioned for mounting the skid. For this reason, TF supplies a universal bracket so the factory brackets can remain in place and continue doing their job. Unfortunately, the correct position of the universal bracket lands in the same location as factory.  Without the modifications I made for version 1.0, the universal brackets have to be sandwiched in between the tunnel and factory brackets (pictured below). Either way, the suspension can be tricky to install and remove for service, especially if you’re by yourself...but aren't all suspensions?

Without the modifications I made for version 1.0, the universal brackets have to be sandwiched in between the tunnel and factory brackets (pictured below). Either way, the suspension can be tricky to install and remove for service, especially if you’re by yourself...but aren't all suspensions?

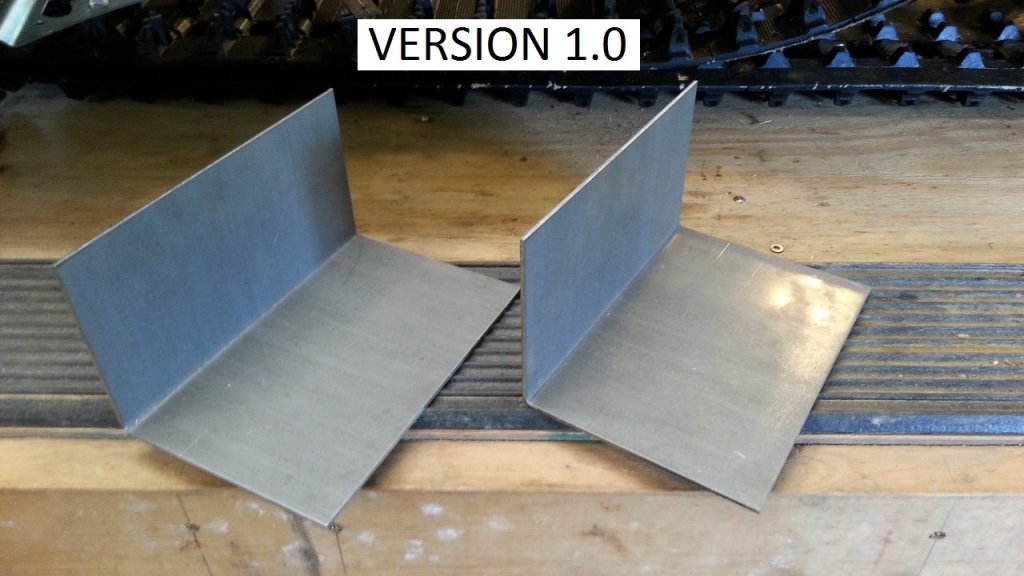

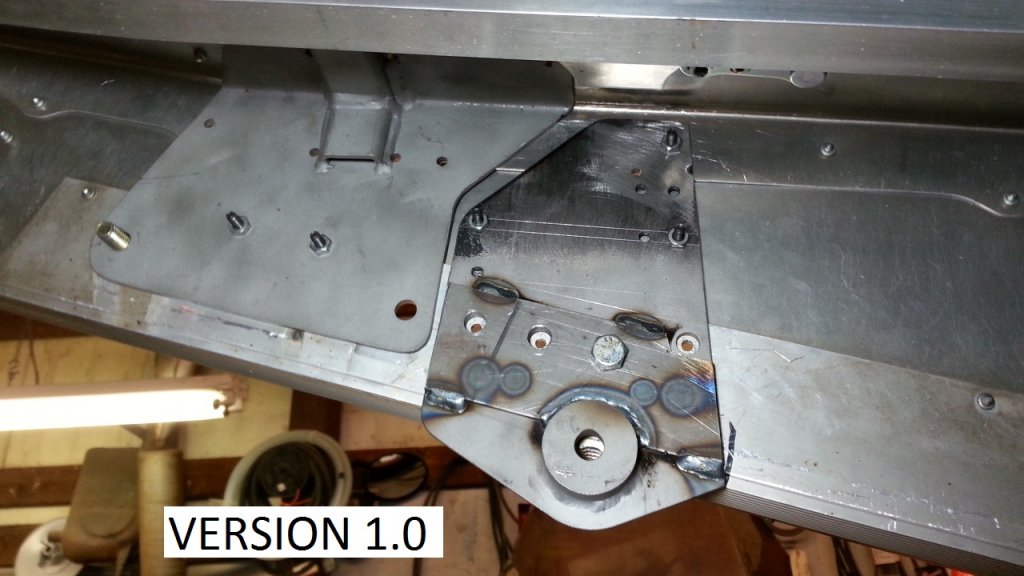

When I began version 1.0 in 2013, there were no instructions on how to deal with the interference. All I could think to do was make new brackets that support the muffler while leaving clearance for the universal bracket. There are a handful of other ways to make this work, but the pictures below re-cap what I came up with:

Since 2013, TF has amended their instructions to simply sandwich the universal brackets as described above. The pics below are from Soldiers Papa's 128" M20 Apex.

When I began version 1.0 in 2013, there were no instructions on how to deal with the interference. All I could think to do was make new brackets that support the muffler while leaving clearance for the universal bracket. There are a handful of other ways to make this work, but the pictures below re-cap what I came up with:

Since 2013, TF has amended their instructions to simply sandwich the universal brackets as described above. The pics below are from Soldiers Papa's 128" M20 Apex.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

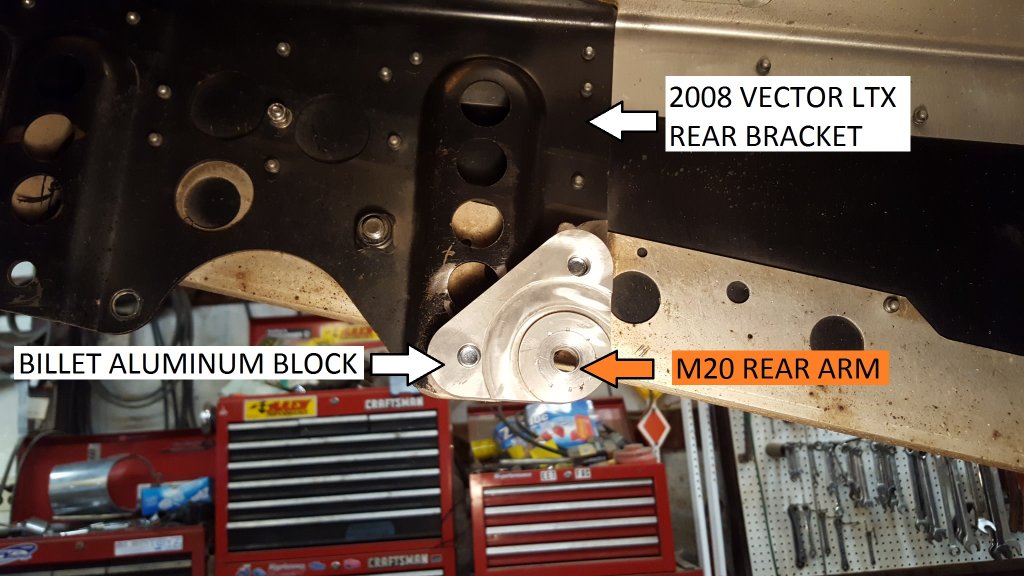

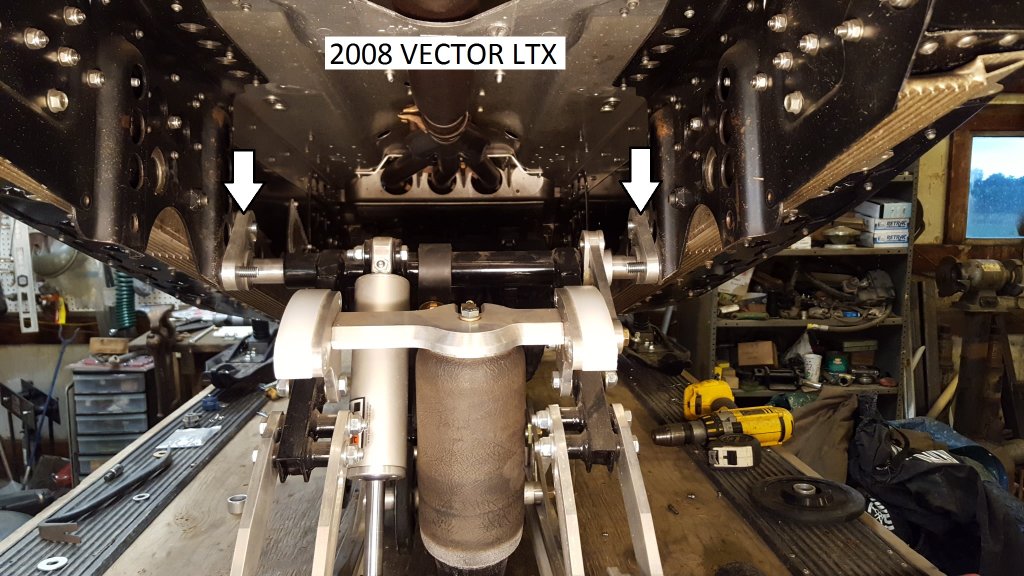

Let's rewind to the summer of 2016...

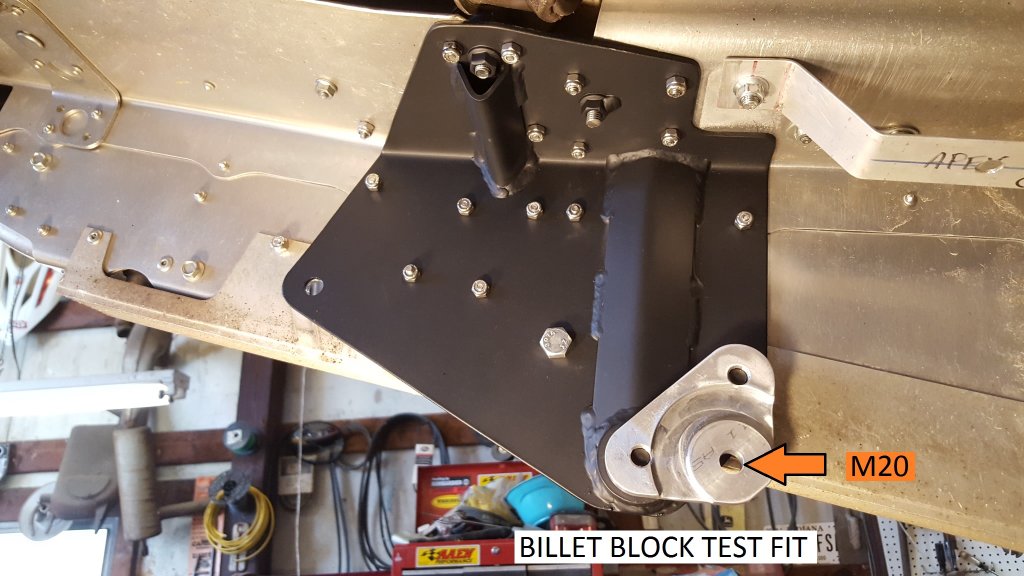

I ordered an M20 to install in my 2008 Vector LTX. This is when I learned that, for the older LTX models, TF supplies a machined, billet aluminum block that bolts directly to the factory brackets and self-locates the M20 rear arm in the tunnel! Wow...what a great feature! They really did a great job adapting this supension to the LTX sleds...like it's supposed to be there!

I ordered an M20 to install in my 2008 Vector LTX. This is when I learned that, for the older LTX models, TF supplies a machined, billet aluminum block that bolts directly to the factory brackets and self-locates the M20 rear arm in the tunnel! Wow...what a great feature! They really did a great job adapting this supension to the LTX sleds...like it's supposed to be there!

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

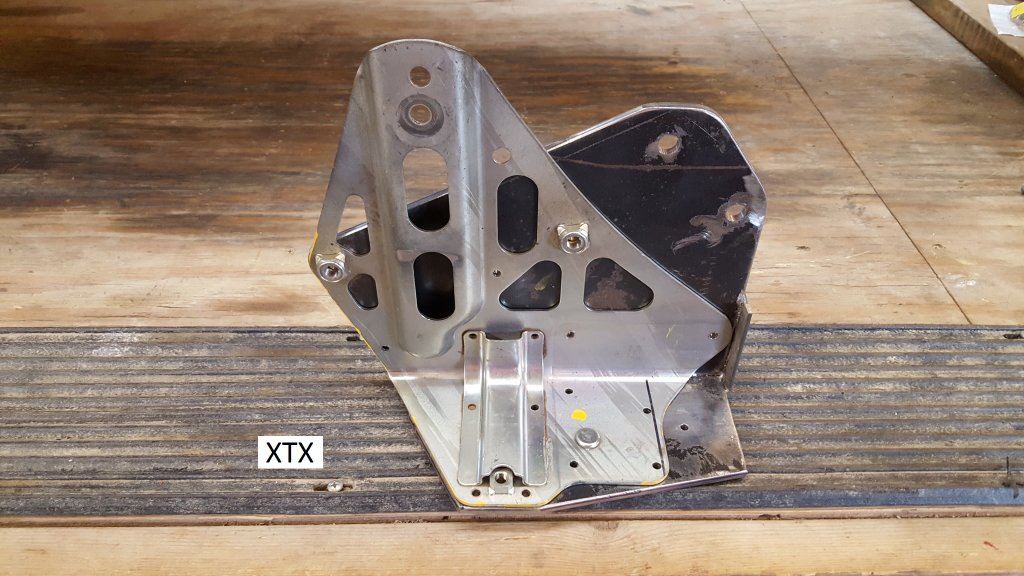

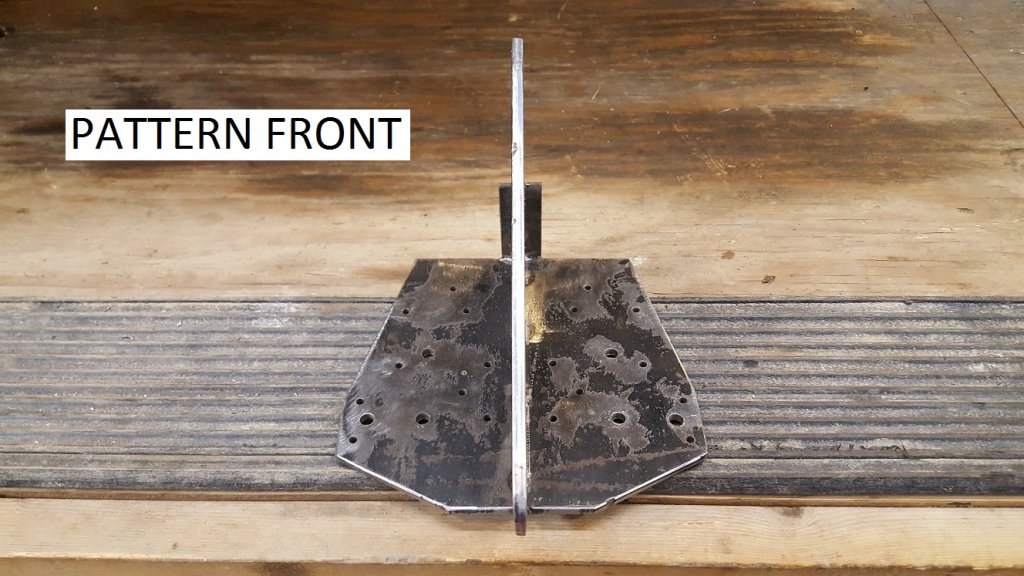

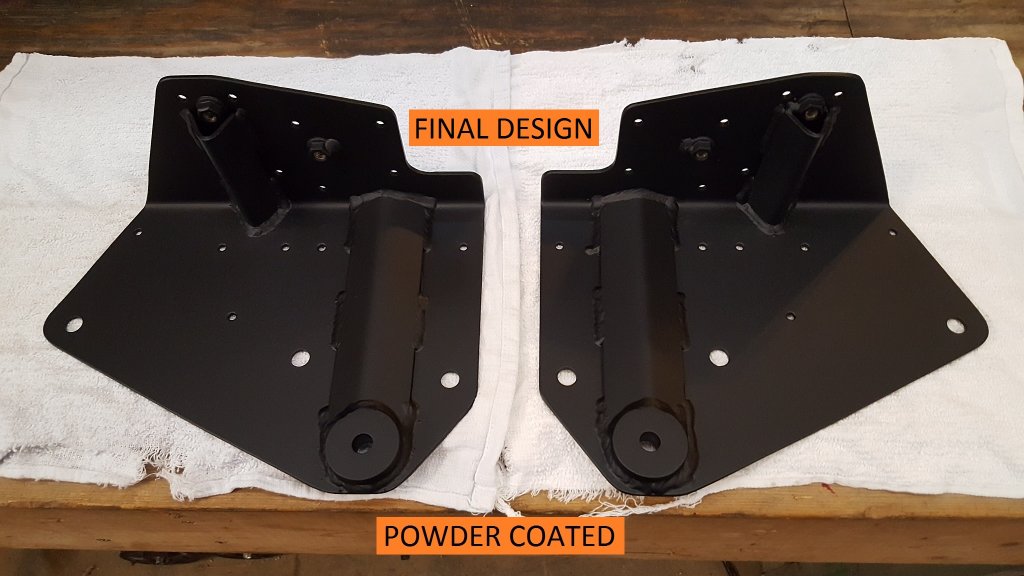

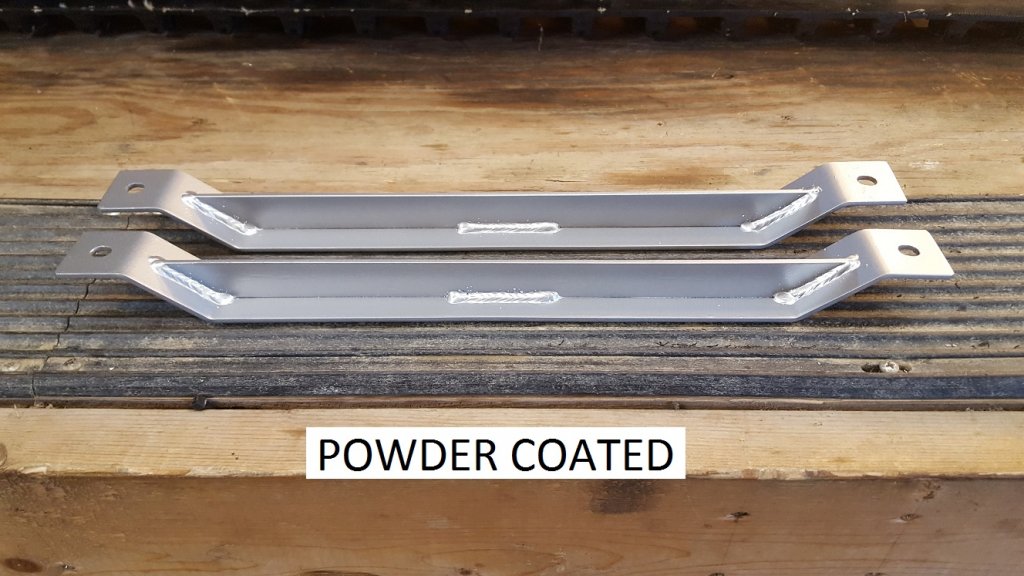

When my buddy decided to M20 his sled, I started dreaming of ways to build my own rear brackets that would not only support the muffler, but also accept the billet aluminum blocks used on the LTX models. I put in a call to Barn of Parts, and Travis sent me some brackets from an LTX model to use as a pattern. I immediately went to work and established a jig to make hybrid brackets that are a blend of both an LTX and XTX. The jig will allow me to accurately reproduce additional brackets if needed in the future.

This takes a lot of time, as I cut all my parts by hand.

View attachment 128709

View attachment 128709

Note* When ordering the skid, I simply specified that it was for a 2008 Apex LTX so there would be no confusion as to what mounting kit I needed!

This takes a lot of time, as I cut all my parts by hand.

Note* When ordering the skid, I simply specified that it was for a 2008 Apex LTX so there would be no confusion as to what mounting kit I needed!

Last edited:

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Reaction score

- 92

- Points

- 753

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

Exceptional work my friend.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Here is an explanation of why I chose to make new, hybrid brackets altogether...

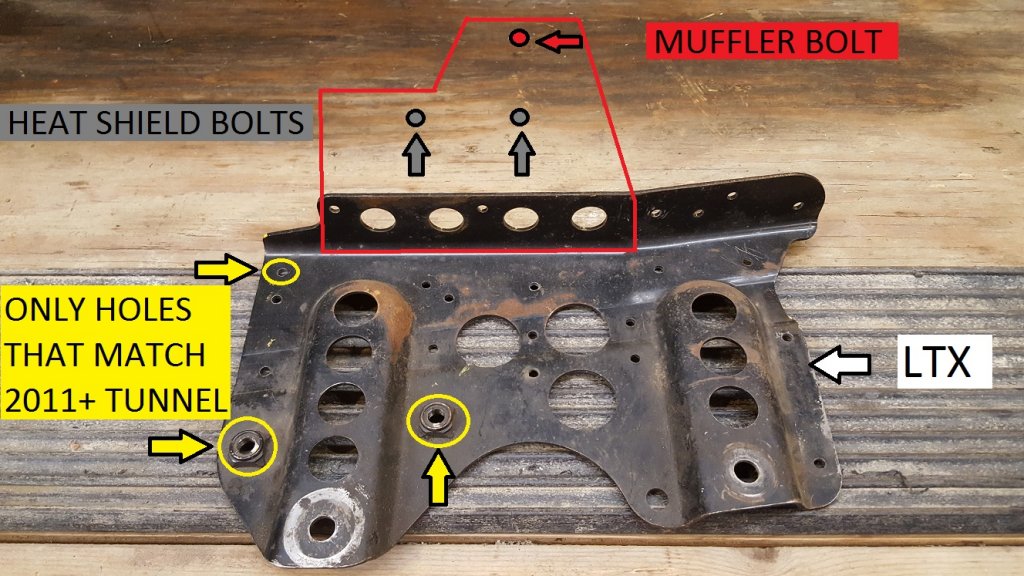

The LTX bracket will fit the 2011+ tunnel and would probably work fine for installing an M20. You would have to fabricate and weld on a custom made flange to support the muffler and upper tunnel panels. The downside to this; there are only three holes in the LTX bracket that line up with the newer tunnel. You would either have to drill new holes in the bracket to match the tunnel, or drill all new holes in the tunnel to match the bracket... It makes me cringe at the thought of drilling any more holes in the tunnel than necessary, so in my mind, there was no other choice than to make completely new brackets.

It makes me cringe at the thought of drilling any more holes in the tunnel than necessary, so in my mind, there was no other choice than to make completely new brackets.

There are probably other ways to make this come together, but my goal is easy serviceability, and the billet blocks are best way to install and remove these skids IMHO.

The LTX bracket will fit the 2011+ tunnel and would probably work fine for installing an M20. You would have to fabricate and weld on a custom made flange to support the muffler and upper tunnel panels. The downside to this; there are only three holes in the LTX bracket that line up with the newer tunnel. You would either have to drill new holes in the bracket to match the tunnel, or drill all new holes in the tunnel to match the bracket...

There are probably other ways to make this come together, but my goal is easy serviceability, and the billet blocks are best way to install and remove these skids IMHO.

Last edited:

Al Bundy

Lifetime Member

- Joined

- Mar 4, 2016

- Messages

- 316

- Reaction score

- 92

- Points

- 328

- Location

- Maine

- Country

- USA

- Snowmobile

- 2004 Rx Warrior

"There are probably other ways to make this come together, but my goal is easy serviceability, and the billet blocks are best way to install and remove these skids IMHO.  "

"

That sure beats having to take the entire mounting bracket off to remove the skid!

"

"That sure beats having to take the entire mounting bracket off to remove the skid!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

You are correct, my friend!That sure beats having to take the entire mounting bracket off to remove the skid!

Your Warrior could be retrofitted with LTX brackets to accept the aluminum blocks. You would have to have a different mount kit which would include different spacers and the blocks.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

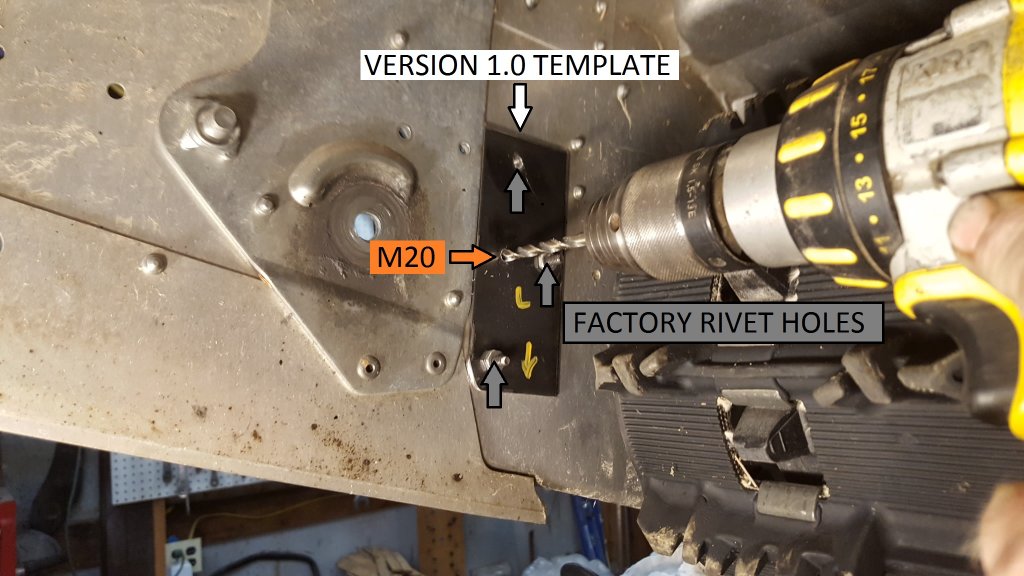

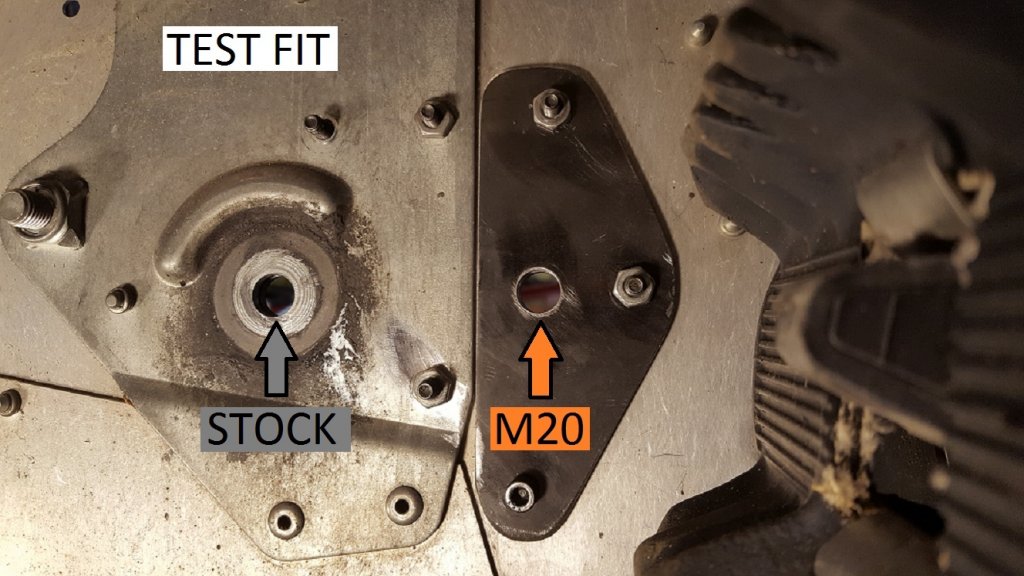

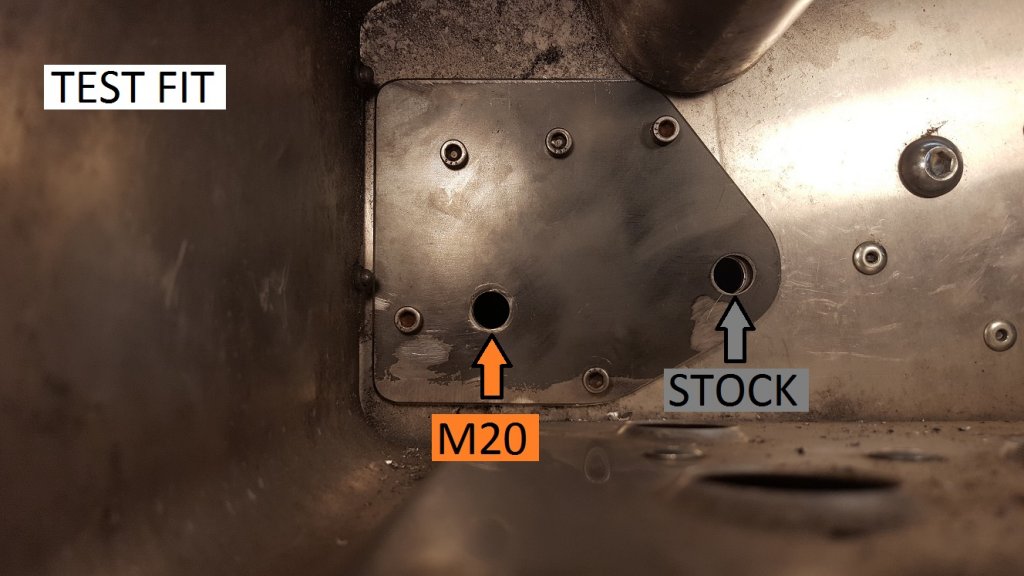

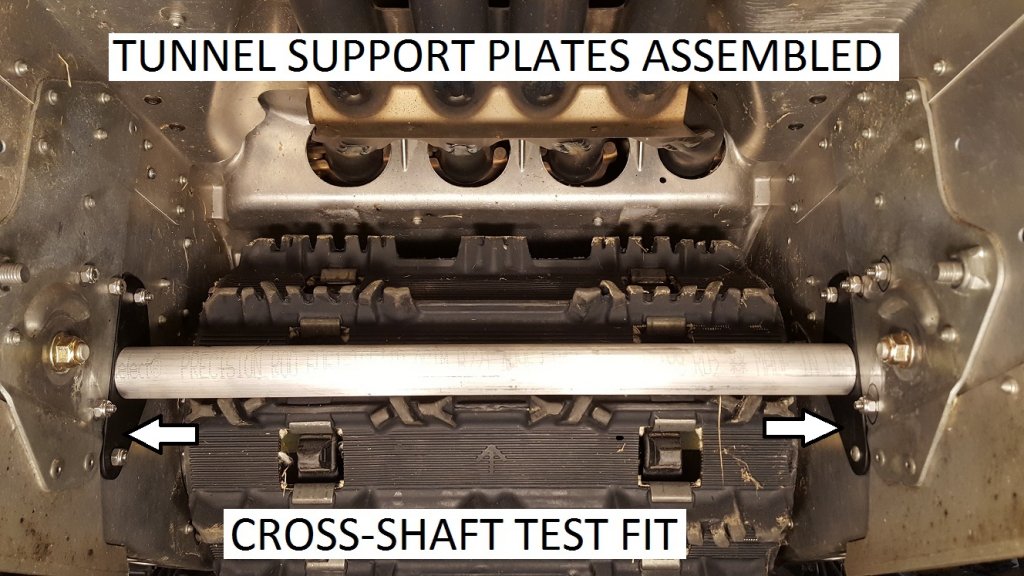

Tunnel support plates and locating the front arm:

TF supplies tunnel support plates that rivet inside the tunnel for the front arm, but I choose to make my own out of 11ga steel for two reasons:

1) A thicker plate takes up all the slack on each end of the cross shaft and keeps the tunnel from "sucking in" when tightening the bolts.

2) My plates utilize existing rivet holes in the tunnel.

In addition to the support plate inside the tunnel, I also make outside plates that fasten to the factory brackets for extra beef and rigidity.

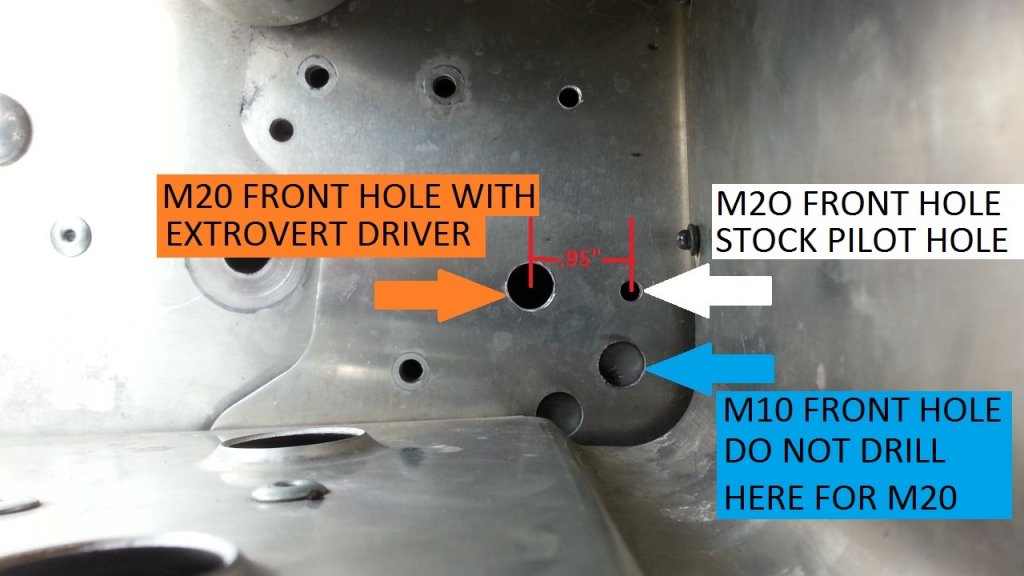

As per M20 instructions, I used a 3/16" bit to drill out an existing pilot hole in each footwell (WHITE ARROW). On sleds without extrovert drivers, the two pilot holes (WHITE ARROW) would be drilled out to 7/16" for mounting the front swingarm. Sleds with extrovert drivers need to have the front swing arm location moved back .95" (24mm) (ORANGE ARROW). Make sure you discuss this with TF so they can ship your skid accordingly, as it affects the position of the front shock on the slide rails.

The BLUE ARROW is for mounting of an M10 air front arm. DO NOT DRILL OUT THIS HOLE FOR M20 FRONT ARM INSTALLATION! M10's and M20's have different geometry and mount to different locations on the tunnel.

TF supplies tunnel support plates that rivet inside the tunnel for the front arm, but I choose to make my own out of 11ga steel for two reasons:

1) A thicker plate takes up all the slack on each end of the cross shaft and keeps the tunnel from "sucking in" when tightening the bolts.

2) My plates utilize existing rivet holes in the tunnel.

In addition to the support plate inside the tunnel, I also make outside plates that fasten to the factory brackets for extra beef and rigidity.

As per M20 instructions, I used a 3/16" bit to drill out an existing pilot hole in each footwell (WHITE ARROW). On sleds without extrovert drivers, the two pilot holes (WHITE ARROW) would be drilled out to 7/16" for mounting the front swingarm. Sleds with extrovert drivers need to have the front swing arm location moved back .95" (24mm) (ORANGE ARROW). Make sure you discuss this with TF so they can ship your skid accordingly, as it affects the position of the front shock on the slide rails.

The BLUE ARROW is for mounting of an M10 air front arm. DO NOT DRILL OUT THIS HOLE FOR M20 FRONT ARM INSTALLATION! M10's and M20's have different geometry and mount to different locations on the tunnel.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

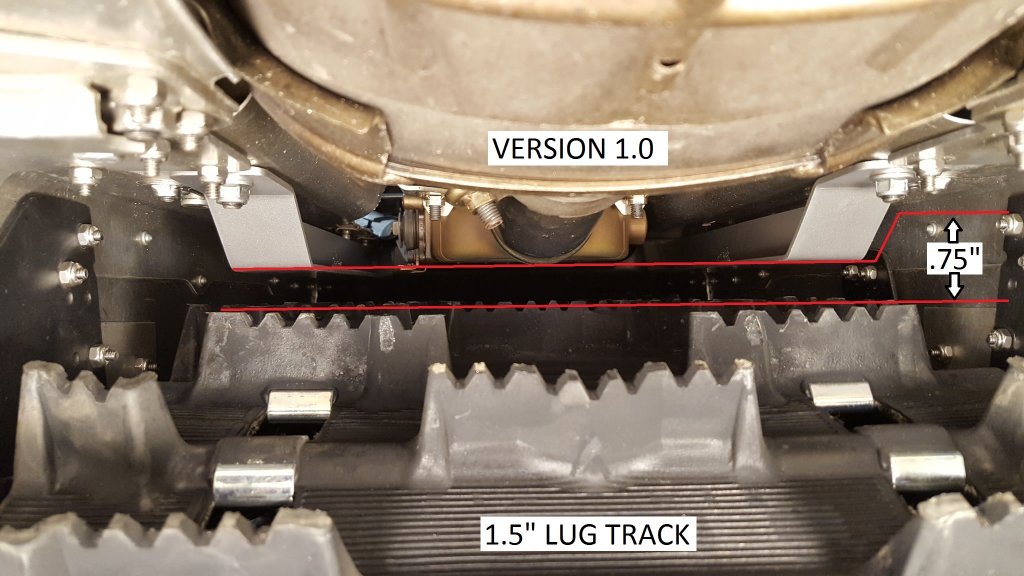

There is only 3/4" clearance between the track and exhaust, so I made tunnel runners that keep the track from getting too slap happy and possibly damaging the exhaust. I just started bending metal until I got the correct bends. It took a few tries with some scrap, but once I got it, I transferred the angles over to the final parts shown in the picture.

Note* Since 2013 TF has lowered the mounting position of the rear arm so that track lug / tunnel protector clearance can be maintained on sled's that require the universal bracket.

Note* Since 2013 TF has lowered the mounting position of the rear arm so that track lug / tunnel protector clearance can be maintained on sled's that require the universal bracket.

Last edited:

Similar threads

- Replies

- 385

- Views

- 74K

- Replies

- 141

- Views

- 24K

- Replies

- 28

- Views

- 3K

- Replies

- 18

- Views

- 10K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.