Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I came home from lunch and noticed the brown truck had made a delivery! New Camoplast Intense 136 x 15 x 1.5 has arrived!

- Joined

- Apr 13, 2003

- Messages

- 21,654

- Reaction score

- 9,272

- Points

- 2,103

- Location

- Schofield, WI

- Website

- www.totallyamaha.com

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

I came home from lunch and noticed the brown truck had made a delivery! New Camoplast Intense 136 x 15 x 1.5 has arrived!

View attachment 118915 View attachment 118916 View attachment 118917 View attachment 118918

Awesome.. its like Xmas every time a package comes...LOL

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

*NOTE*

The descriptions below only apply to LTX / Attak sleds that use the Team Fast billet adapter for fastening the rear arm to the factory drop brackets. Click the link below for universal Delta Box installations, or contact Team Fast for your particular application:

https://ty4stroke.com/threads/team-fast-m20-apex-xtx-version-1-0.119161/

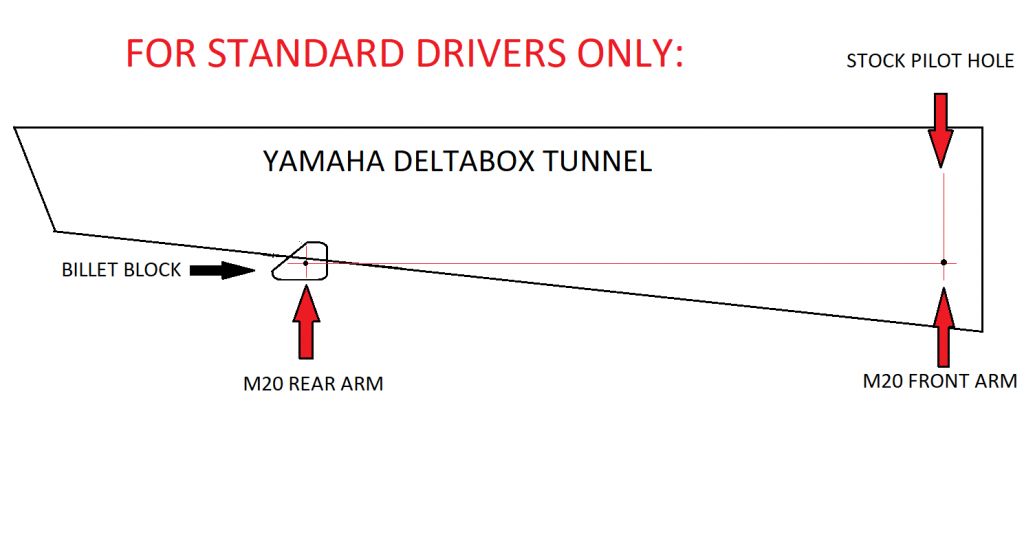

Team Fast really did a great job adapting the M20 for use in the LTX / Attak sleds! The front arm self-locates right in an existing pilot hole in each footwell, unless sled has extrovert drivers. The rear arm self-locates from the supplied aluminum blocks that bolt directly to the stock drop brackets...Beautiful design!

PLEASE READ CAREFULLY:

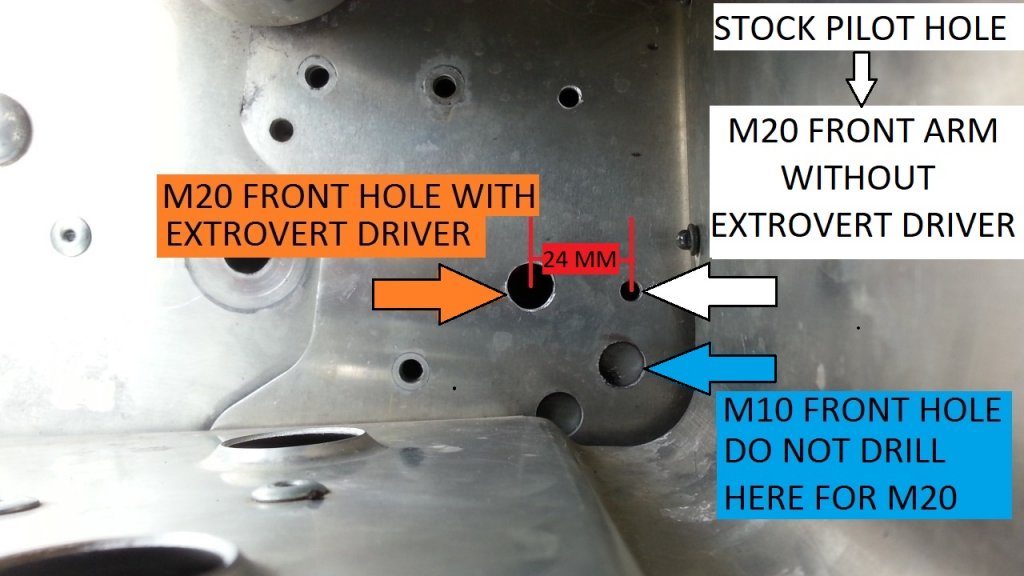

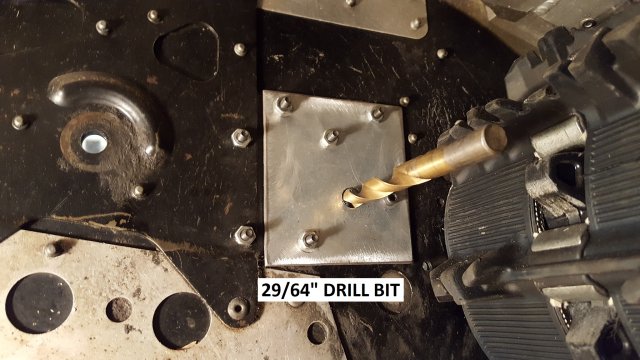

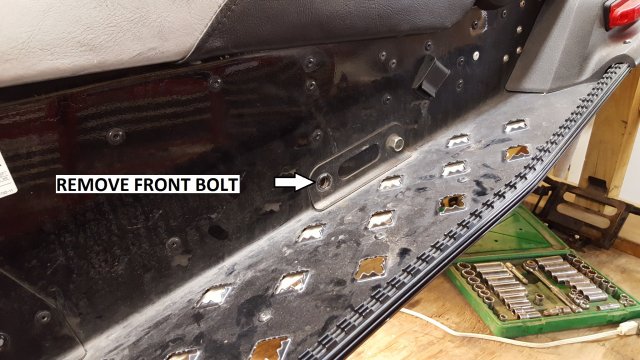

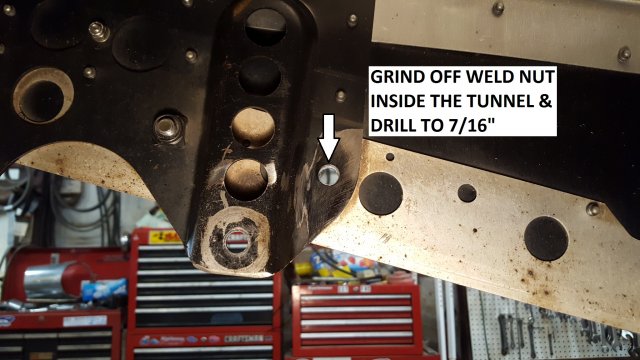

As per instructions, I used a 3/16" bit to drill through a factory pilot hole in each footwell. This is the area where the bulkhead overlaps the tunnel. The bulkhead has a 3/16 hole in it, but the tunnel does not. You have to drill through these holes from the outside of the tunnel (inside each footwell). An extended length 3/16 drill bit is very helpful for this job and can be purchased fairly cheap at most hardware retailers.

Sleds WITHOUT extrovert drivers:

The factory pilot holes (white arrow) would be finish-drilled to accommodate a 7/16" bolt for mounting the front swingarm.

Sleds WITH extrovert drivers:

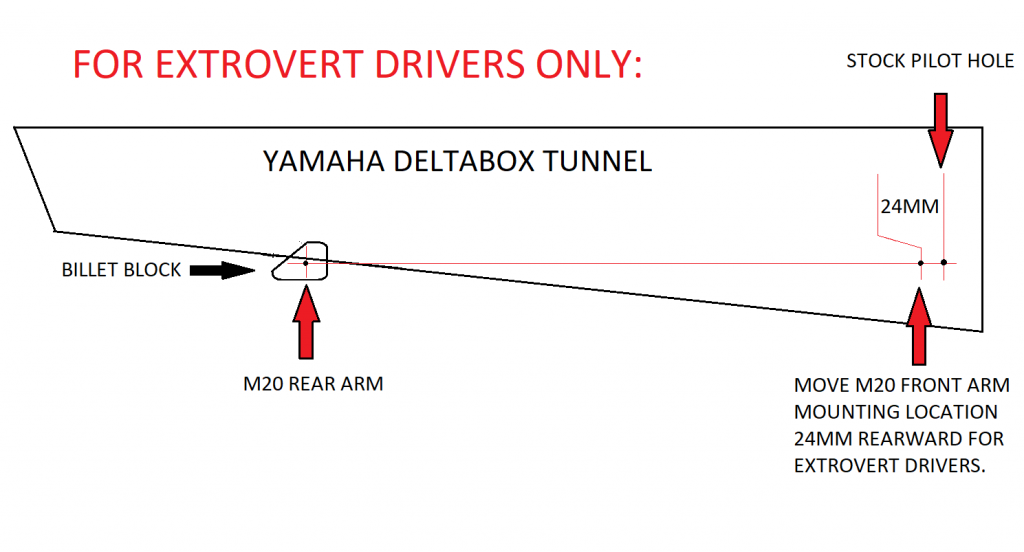

The front arm will mount 24mm farther back on the tunnel. (orange arrow)

The BLUE ARROW is for mounting of an M10 air front arm. DO NOT DRILL OUT THIS HOLE FOR M20 FRONT ARM INSTALLATION! M10's and M20's have different geometry and mount to different locations on the tunnel.

Moving the front arm mounting holes rearward on the tunnel to accommodate extrovert drivers, also requires the entire front swing arm and shock to be moved 24mm rearward on the suspension rails. Owners need to confirm their application with Team Fast so their suspension can be shipped accordingly.

The descriptions below only apply to LTX / Attak sleds that use the Team Fast billet adapter for fastening the rear arm to the factory drop brackets. Click the link below for universal Delta Box installations, or contact Team Fast for your particular application:

https://ty4stroke.com/threads/team-fast-m20-apex-xtx-version-1-0.119161/

Team Fast really did a great job adapting the M20 for use in the LTX / Attak sleds! The front arm self-locates right in an existing pilot hole in each footwell, unless sled has extrovert drivers. The rear arm self-locates from the supplied aluminum blocks that bolt directly to the stock drop brackets...Beautiful design!

PLEASE READ CAREFULLY:

As per instructions, I used a 3/16" bit to drill through a factory pilot hole in each footwell. This is the area where the bulkhead overlaps the tunnel. The bulkhead has a 3/16 hole in it, but the tunnel does not. You have to drill through these holes from the outside of the tunnel (inside each footwell). An extended length 3/16 drill bit is very helpful for this job and can be purchased fairly cheap at most hardware retailers.

Sleds WITHOUT extrovert drivers:

The factory pilot holes (white arrow) would be finish-drilled to accommodate a 7/16" bolt for mounting the front swingarm.

Sleds WITH extrovert drivers:

The front arm will mount 24mm farther back on the tunnel. (orange arrow)

The BLUE ARROW is for mounting of an M10 air front arm. DO NOT DRILL OUT THIS HOLE FOR M20 FRONT ARM INSTALLATION! M10's and M20's have different geometry and mount to different locations on the tunnel.

Moving the front arm mounting holes rearward on the tunnel to accommodate extrovert drivers, also requires the entire front swing arm and shock to be moved 24mm rearward on the suspension rails. Owners need to confirm their application with Team Fast so their suspension can be shipped accordingly.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

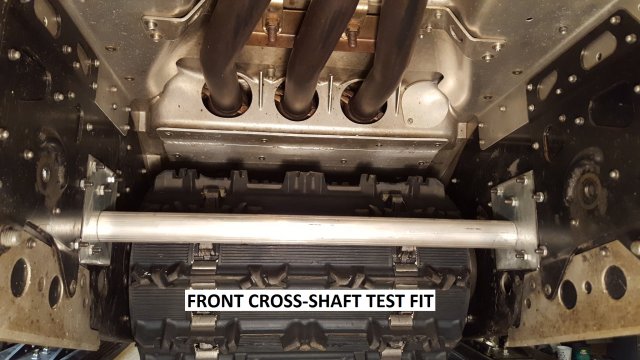

Front arm support plates are complete. I chose to make my own for 3 reasons:

1.) Old 151" holes needed to be covered and reinforced.

2.) I prefer to use as many existing holes in the tunnel as possible, verses drilling more.

3.) Thicker material (12 ga) for more strength and a snug fit when the cross-shaft is in place.

All parts will be powder coated before final assembly. Now it's time to locate the rear arm! Stay tuned!

1.) Old 151" holes needed to be covered and reinforced.

2.) I prefer to use as many existing holes in the tunnel as possible, verses drilling more.

3.) Thicker material (12 ga) for more strength and a snug fit when the cross-shaft is in place.

All parts will be powder coated before final assembly. Now it's time to locate the rear arm! Stay tuned!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

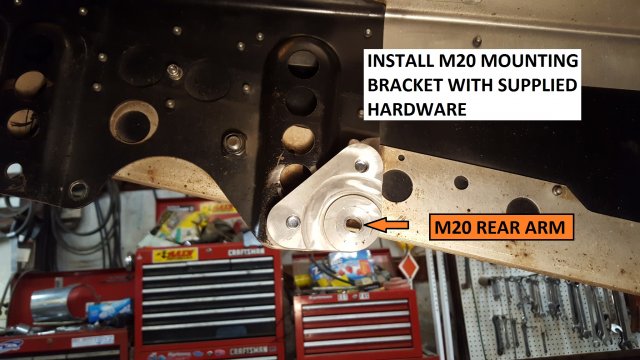

Rear arm mounting locations are complete. Dusty Dan is right...this is the most simple step of the entire process, by far! The machined billet aluminum brackets, supplied by Fast, self-locate the M20 from the stock drop brackets! This is a huge plus! Kudos to Fast for doing their homework and providing such an awesome way to install an M20 into an LTX sled!

This is literally a 30 minute job! Time to test fit the entire skid!

This is literally a 30 minute job! Time to test fit the entire skid!

Last edited:

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Reaction score

- 92

- Points

- 753

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

From the looks of the tool boxes, I don't imagine you run short on the right tool for the job?Rear arm mounting locations are complete. Dusty Dan is right...this is the most simple step of the entire process, by far! The machined billet aluminum brackets, supplied by Fast, self-locate the M20 from the stock drop brackets! This is a huge plus! Kudos to Fast for doing their homework and providing such an awesome feature! Now they just need to make these brackets for the 128" and 144" Apex owners!

View attachment 118944 View attachment 118945 View attachment 118946 View attachment 118947

This is literally a 30 minute job! Time to test fit the entire skid!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I began test fitting the skid early this morning and ran into my first hiccup; the front arm went right in, but the rear arm cross-shaft appears to be 1/2" too wide. No big deal. A call to Fast is in order to get the correct part.

...stay tuned!

View attachment 118949

View attachment 118949

...stay tuned!

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

A call to Fast is in order to get the correct part.

After an over-the-phone verification with Team Fast, it was determined that I did receive the correct cross-shaft. The tunnel has to be physically spread apart, approximately 1/2 inch (1/4" each side), to accept the rear arm! Yikes!

To achieve the spread job, I've decided to unveil the newest tool in my arsenal...

The skid fits! Now it's time to move on and change out the track.

Not shown in the pictures above: I used the spreader to obtain the needed tunnel opening, then wedged a piece of pipe in place to hold that width, just above the rear arm.

Last edited:

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Reaction score

- 92

- Points

- 753

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

Well done Joe!!!After an over-the-phone verification with Team Fast, it was determined that I did receive the correct cross-shaft. The tunnel has to be physically spread apart, approximately 1/2 inch, to accept the rear arm! Yikes!That makes me cringe, but it is what it is.

To achieve the spread job, I've decided to unveil the newest tool in my arsenal...

"The Spreader-outer!"

View attachment 120016 View attachment 120017 View attachment 120018 View attachment 120019 View attachment 120020 View attachment 120021

The skid fits! Now it's time to move on and change out the track.

Not shown in the pictures above: I used the spreader to obtain the needed tunnel opening, then wedged a piece of cut-to-fit pipe in place to hold that width. I then removed the spreader and pushed the rear arm up in to position, then removed the pipe.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

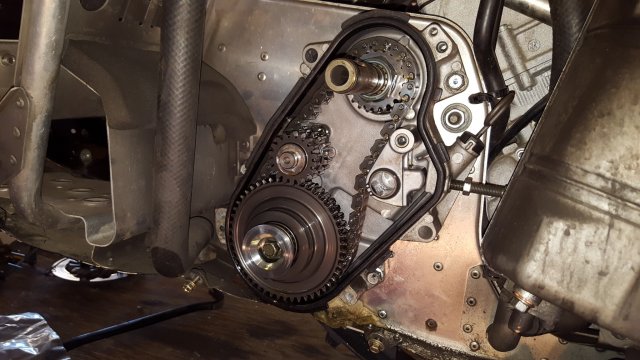

Chaincase is removed and the axle is out.

Last edited:

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Reaction score

- 1,501

- Points

- 1,753

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

Joe you are the best. Great work.

If I lived nearby I would be calling saying, "Hey Joe working on the sled tonight? Need any help, Can I Help, watch and learn? You'd get so sick of me and the ?s you'd send me home like a little kid.

LOL at myself .

Had a guy tell me today, " 17 weeks until snow" today, out of the blue, it is stinking hot here so he was surprised when I said,.......... I hope before that but I will take it when it comes, the sooner the better..

If I lived nearby I would be calling saying, "Hey Joe working on the sled tonight? Need any help, Can I Help, watch and learn? You'd get so sick of me and the ?s you'd send me home like a little kid.

LOL at myself .

Had a guy tell me today, " 17 weeks until snow" today, out of the blue, it is stinking hot here so he was surprised when I said,.......... I hope before that but I will take it when it comes, the sooner the better..

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Mark, Thank you! I'm just a plain JOE that loves sleds...lol. I wish I had more time to ride like you guys that live in the north. There is NO OTHER recreation that compares to snowmobiling IMO. I blame that on my neighbors that came and picked me up on a brand new Kawasaki Invader 440 in the winter of '79. I was a small kid then, but I caught the disease and continue to nurture it to this day...and I have a great wife that tolerates it...WIN - WIN! LOL!If I lived nearby I would be calling saying, "Hey Joe working on the sled tonight? Need any help, Can I Help, watch and learn? You'd get so sick of me and the ?s you'd send me home like a little kid.

It's good hearing from you, Mark!

Last edited:

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Reaction score

- 92

- Points

- 753

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

I owned a 1979 Kawasaki Invader 440, a great sled for the time. My friend recently commented on how fast it was at the time.Mark, Thank you! I'm just a plain JOE that loves sleds...lol. I wish I had more time to ride like you guys that live in the north. There is NO OTHER recreation that compares to snowmobiling IMO. I blame that on my neighbors that came and picked me up on a brand new Kawasaki Invader 440 in the winter of '79. I was a small kid then, but I caught the disease and continue to nurture it to this day...and I have a great wife that tolerates it...WIN - WIN! LOL!

It's good hearing from you, Mark!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

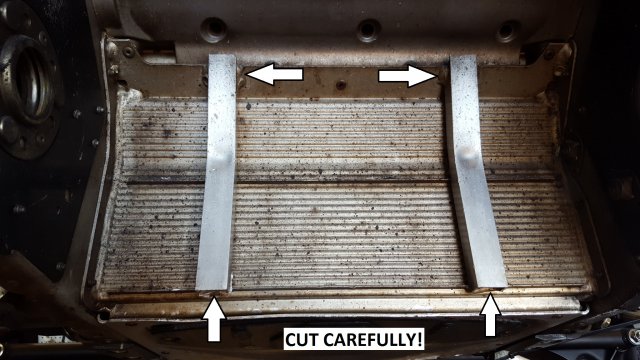

New track, drive axle bearings and chaincase are re-installed. I had to remove the front cooler protectors to make room for the taller track lugs.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

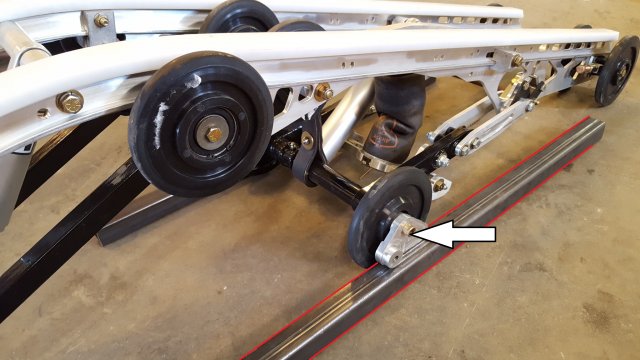

As per Team Fast instructions, the skid needs turned upside-down on a flat surface before tightening the bolts that attach the aluminum mounting brackets to the rear arm. This assures they'll align with the factory drop brackets when the skid is installed in the tunnel. As Dusty Dan mentioned in his his M20 build, the tunnel idler wheels won't allow the brackets to make contact with the floor, so blocks of wood or square tuning must be used to raise up the wheels.

I went to install the skid and realized I had not yet powder coated the front arm support plates. Oh well, I'll fire up the oven and coat the parts early tomorrow morning.

I went to install the skid and realized I had not yet powder coated the front arm support plates. Oh well, I'll fire up the oven and coat the parts early tomorrow morning.

Similar threads

- Replies

- 124

- Views

- 19K

- Replies

- 385

- Views

- 74K

- Replies

- 16

- Views

- 7K

- Replies

- 28

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.