- Joined

- Apr 13, 2003

- Messages

- 21,663

- Reaction score

- 9,272

- Points

- 2,103

- Location

- Schofield, WI

- Website

- www.totallyamaha.com

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

Keep up the great work on the build!! Very nice detail.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Thank you, Tom! I love this kind of sled work!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I just sub-assembled the air system control solenoids and will soon begin making the mounting brackets . My 2012 Apex has 6 solenoids mounted every where from the headlight pod to the sides of the delta box, but these locations are rather inconvenient and required some goofy brackets to make it work. The Vector will have 7 solenoids, but they'll be more spread out under the hood with much simpler mounting.

Let the fun begin!

...stay tuned!

Let the fun begin!

...stay tuned!

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

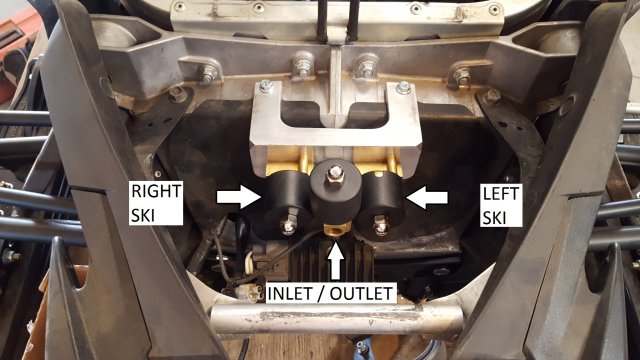

The mounting bracket for the ski solenoids is complete. When I started my Apex M20 build, I thought the solenoids needed to be close to a heat source to keep them from freezing. However, 3 consecutive winters of use has proved these little solenoids are bulletproof! I have not had one issue with any of them freezing or failing! They've always worked, regardless of the temperature. So...that being said, I am locating each solenoid assembly as close as possible to the shocks they're operating. There's a huge void in the nose of these pre-power steer sled's, so that seemed like a good location to start with for the ski's.

Cheers!

Cheers!

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

OK...Turtle from Muffin Works sent me a tracking number on the tunnel extension they shipped; it will be here tomorrow. I CAN'T WAIT to get this extension and cooler project advanced to the final stage! I may even have to tell my wife I'm skipping dinner and working late in the shop!

I already have the longer coolant hoses that Travis from Barn of Parts sent, so once the cooler is in, that part will be a breeze!

...stay tuned!

I already have the longer coolant hoses that Travis from Barn of Parts sent, so once the cooler is in, that part will be a breeze!

...stay tuned!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Thanks Turtle!

- Joined

- Apr 13, 2003

- Messages

- 21,663

- Reaction score

- 9,272

- Points

- 2,103

- Location

- Schofield, WI

- Website

- www.totallyamaha.com

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

Right on!! Turtle to the rescue!!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

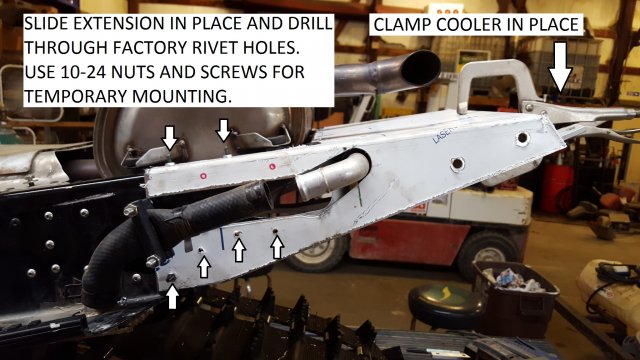

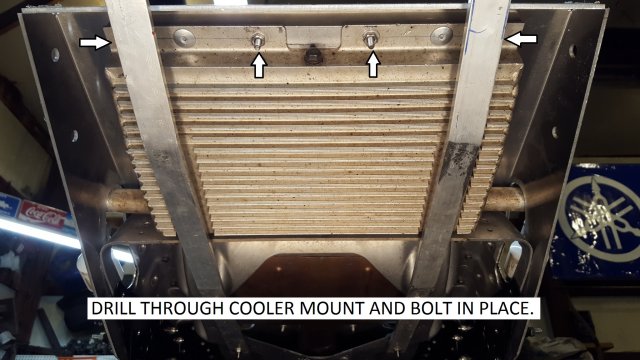

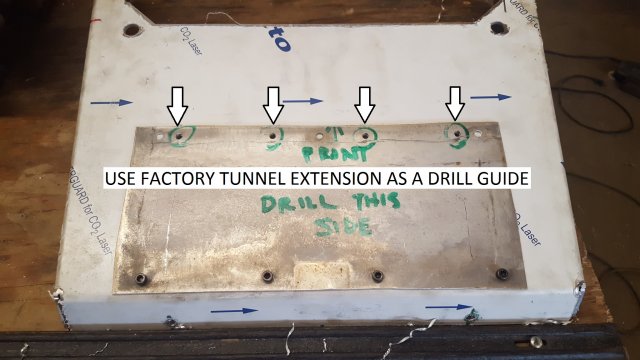

The tunnel extension and cooler are located and temporarily fastened in place. It's a tight fit, but it will work!

I first had to establish the new coolant elbow location using the angle iron pieces I fashioned for the mock up. A hole saw was used to cut a 1-1/4" hole, then material was cut away to join the new hole with the existing slot; the extension now slides in over the cooler in the new location.

Next, I centered the cooler, clamped it in place and drilled through the extension using the cooler mounting holes as a guide. I use stainless mounting screws and nuts as much as possible, but I'll have to use rivets for the front side of the cooler because there is no way to get a nut on the inside of the square tubes that space the cooler down. I'll save this step for final assembly.

I also want to note that I'm making mini cooler protectors using 1/4" x 1" aluminum flat stock. This may not be necessary, but it will help in case the skid finds an extra 1/2" of travel, if you know what I mean!

Now it's time to fit and cut the new coolant lines that Barn of Parts sent to me. Travis, thank you again for getting the new hoses out to me ASAP!

Cheers!

I'll powder coat the extension gloss black before final assembly.

I first had to establish the new coolant elbow location using the angle iron pieces I fashioned for the mock up. A hole saw was used to cut a 1-1/4" hole, then material was cut away to join the new hole with the existing slot; the extension now slides in over the cooler in the new location.

Next, I centered the cooler, clamped it in place and drilled through the extension using the cooler mounting holes as a guide. I use stainless mounting screws and nuts as much as possible, but I'll have to use rivets for the front side of the cooler because there is no way to get a nut on the inside of the square tubes that space the cooler down. I'll save this step for final assembly.

I also want to note that I'm making mini cooler protectors using 1/4" x 1" aluminum flat stock. This may not be necessary, but it will help in case the skid finds an extra 1/2" of travel, if you know what I mean!

Now it's time to fit and cut the new coolant lines that Barn of Parts sent to me. Travis, thank you again for getting the new hoses out to me ASAP!

Cheers!

I'll powder coat the extension gloss black before final assembly.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I always worry about integrity, so I made a few small plates to add strength back to the areas I weakened from cutting out the coolant elbow holes. Otherwise, the extension is plenty tough as is! I also made a small strap to joint the rear of the footboard with the tunnel. These parts will all be hidden by the plastic side covers when complete.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

The mini cooler protectors are complete and temporarily bolted in place. I wish I had a press brake to make perfect bends, but a hammer, vice and block of wood is all I have.

Now the cooler and tunnel extension can be removed for final prep before powder coat.

Now the cooler and tunnel extension can be removed for final prep before powder coat.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

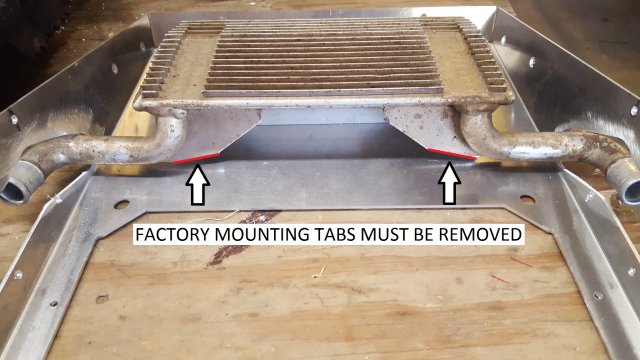

As I mentioned earlier, it would be better if the cooler laid flat against the tunnel extension, but it's necessary to space it down, unless you modify the elbows.

Here's a few more pictures:

Here's a few more pictures:

Last edited:

Agman 57

Lifetime Member

- Joined

- Dec 28, 2006

- Messages

- 926

- Reaction score

- 291

- Points

- 1,228

- Location

- Fostoria, Ohio

- Country

- USA

- Snowmobile

- 2018 Apex XTX LE, 50th Ann.

2018 Sidewinder LTX LE, 50th Ann.

2017 Sidewinder BTX LE

1992 V-Max 4 (Modded)

2002 ZR 120 G-daughter's

Great build Joe, You do Top Notch work, Great detail on the documentation of your work and a well thought out project!

Looks like this will even be a better finished project than your apex was, as unbelievable as that sounds because it was an outstanding project

Looks like this will even be a better finished project than your apex was, as unbelievable as that sounds because it was an outstanding project

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Thanks, Dan! I wish I could be more consistent on a timely completion, but life, work and a new employee are keeping me busy. These are good things though.Great build Joe, You do Top Notch work, Great detail on the documentation of your work and a well thought out project!

Looks like this will even be a better finished project than your apex was, as unbelievable as that sounds because it was an outstanding project

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

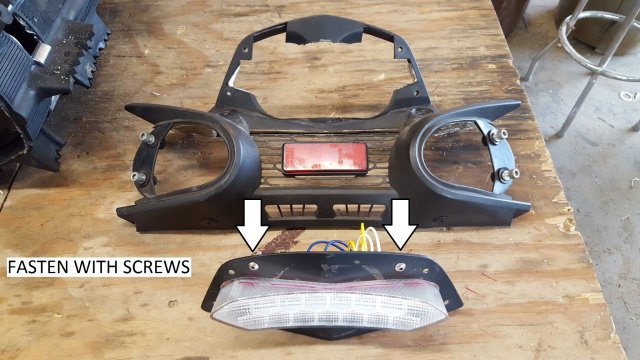

Today's project was re-working the tail light assembly. When I made this sled into a 151" track, I removed and blocked off the factory tail light and placed an FX Nytro light on the tunnel extension. Now that I'm changing the sled back to a 136" track, I determined a tunnel mounted light would be too close to the exhaust flares and probably melt. I thought about using an aftermarket light, but then I found a way to squeeze the Nytro light up into the original factory position. Now a re-powder coated blockoff plate is in order.

Here are some pics:

Here are some pics:

- Joined

- Apr 13, 2003

- Messages

- 21,663

- Reaction score

- 9,272

- Points

- 2,103

- Location

- Schofield, WI

- Website

- www.totallyamaha.com

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

Today's project was re-working the tail light assembly. When I made this sled into a 151" track, I removed and blocked off the factory tail light and placed an FX Nytro light on the tunnel extension. Now that I'm changing the sled back to a 136" track, I determined a tunnel mounted light would be too close to the exhaust flares and probably melt. I thought about using an aftermarket light, but then I found a way to squeeze the Nytro light up into the original factory position. Now a re-powder coated blockoff plate is in order.

Here are some pics:

View attachment 120374 View attachment 120375 View attachment 120376 View attachment 120377 View attachment 120378 View attachment 120379

Way cool Joe!! BTW, its a good thing you took off that White Yamaha MUSIC tuning fork

Similar threads

- Replies

- 124

- Views

- 20K

- Replies

- 385

- Views

- 75K

- Replies

- 16

- Views

- 7K

- Replies

- 28

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.