Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

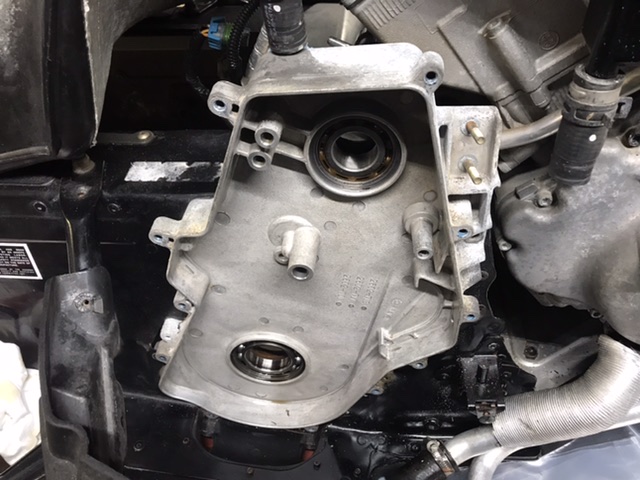

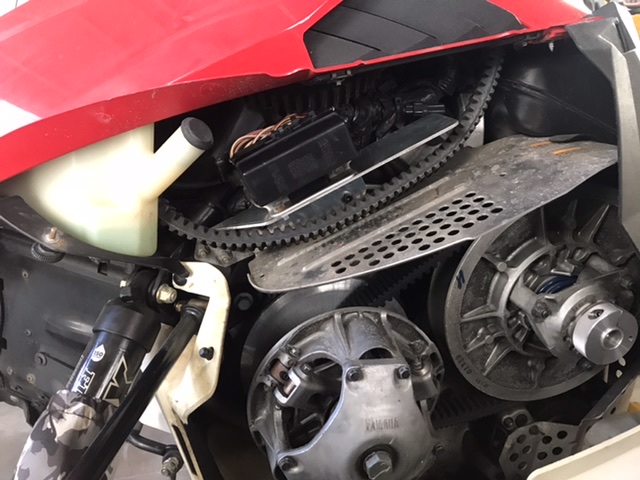

I ended up pulling the jackshaft back out because I couldn’t stand the oxidation on the covers. And since I got a new back country 1.75” track, the driveshaft had to come out so a few more bolts and the inside case came out.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

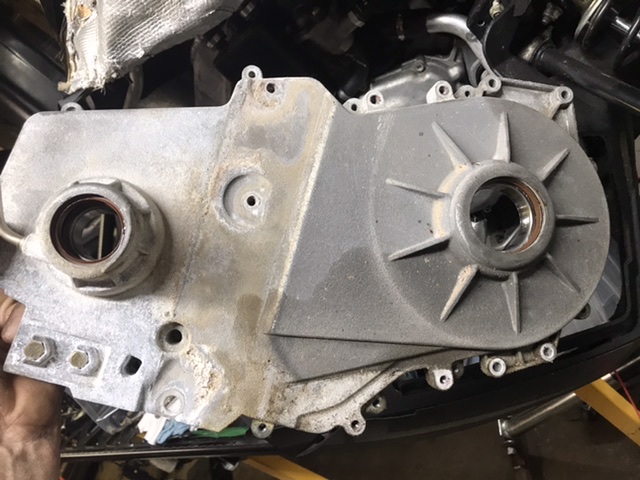

Next thing I had to do is get the covers cleaned up. My sandblasting cabinet was in need of replacement gloves and media so I used my blasting pod with baking soda. Not as good as my cabinet would have done but non the less, it worked.

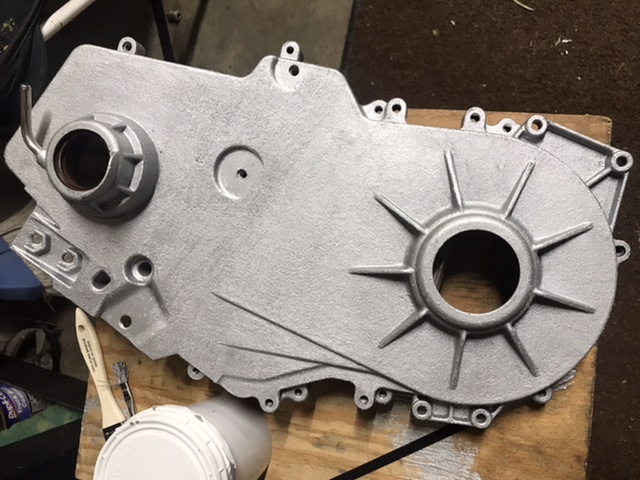

After I blasted the covers and hosed down my driveway from all the baking soda, I painted covers with some POR15 high temp aluminum paint.

The oil tank I went with black. Same high temp POR15

After I blasted the covers and hosed down my driveway from all the baking soda, I painted covers with some POR15 high temp aluminum paint.

The oil tank I went with black. Same high temp POR15

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

New bearing and seal for driveshaft on the chaincase cover.

New bearing and seal for the caliper side. But then realized, I got the non sealed 6009 bearing. Had to order another one.

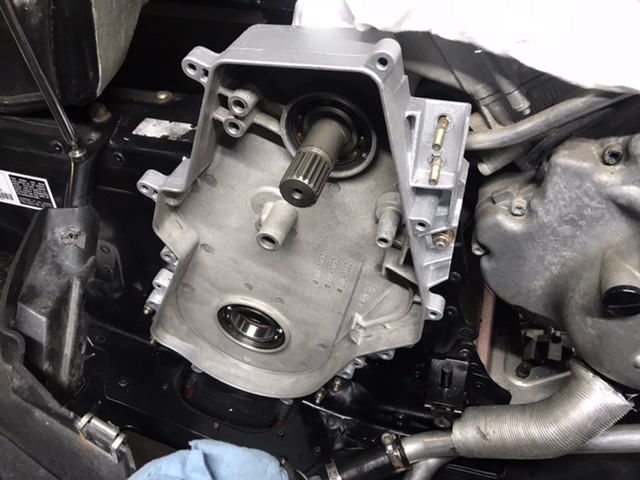

Got the inside cover mounted with seals and bearings installed.

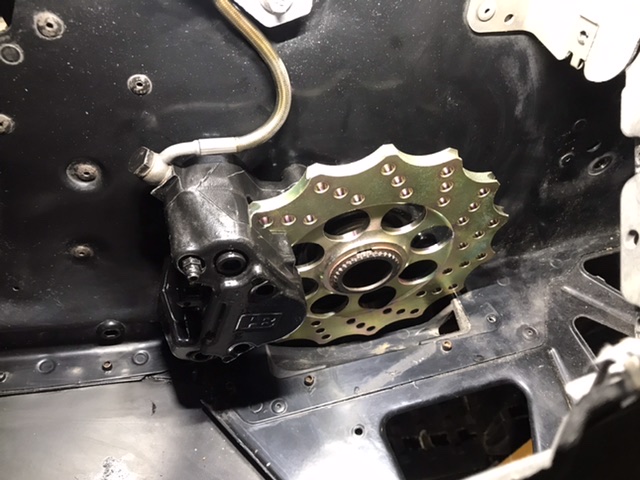

Since I was waiting on caliper bearing to show up, I went ahead and pulled the caliper and blasted and painted it. Again, high temp POR15. This time I was able to use my blast cabinet again.

New bearing and seal for the caliper side. But then realized, I got the non sealed 6009 bearing. Had to order another one.

Got the inside cover mounted with seals and bearings installed.

Since I was waiting on caliper bearing to show up, I went ahead and pulled the caliper and blasted and painted it. Again, high temp POR15. This time I was able to use my blast cabinet again.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

My rotor was rusty so I decided I was gonna replace it. Called up Black Diamond Xtreme and they set me up with this one.

But what the heck, I’ll run the old rotor thru the blast cabinet and clean it up. At least I’ll have a spare if I ever need it.

I painted the rotor minus the mating surface obviously, but I don’t have a pic of it on hand. Not important anyway, it’s just gonna sit on a shelf.

But what the heck, I’ll run the old rotor thru the blast cabinet and clean it up. At least I’ll have a spare if I ever need it.

I painted the rotor minus the mating surface obviously, but I don’t have a pic of it on hand. Not important anyway, it’s just gonna sit on a shelf.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

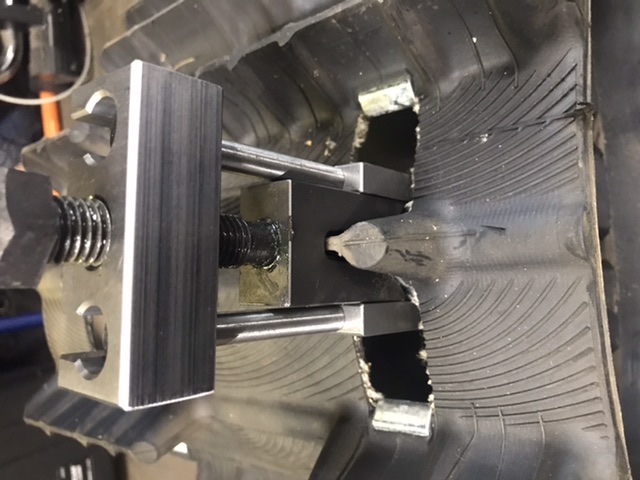

The new track is clipped every other hole so I decided to fully clip it. Ordered 5 packs of 10 clips.

My clip tool is in northern Wisconsin so I went ahead and ordered one that I can use “on sled” because my other one isn’t. This is for up to a 2” paddle, many other options available.

My clip tool is in northern Wisconsin so I went ahead and ordered one that I can use “on sled” because my other one isn’t. This is for up to a 2” paddle, many other options available.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Not sure why it’s turning my pics but you can still see em at least.

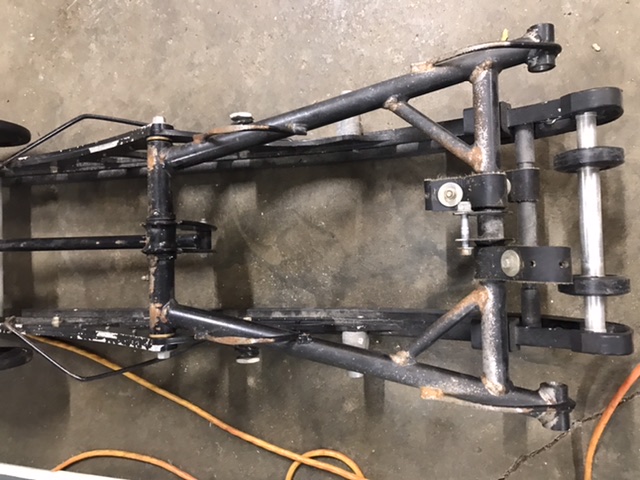

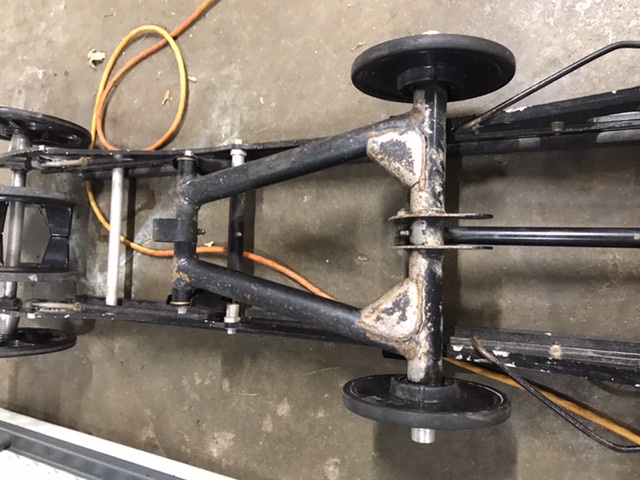

Turning my attention to the skid, I wanted to check/replace any worn bushings and bearings.

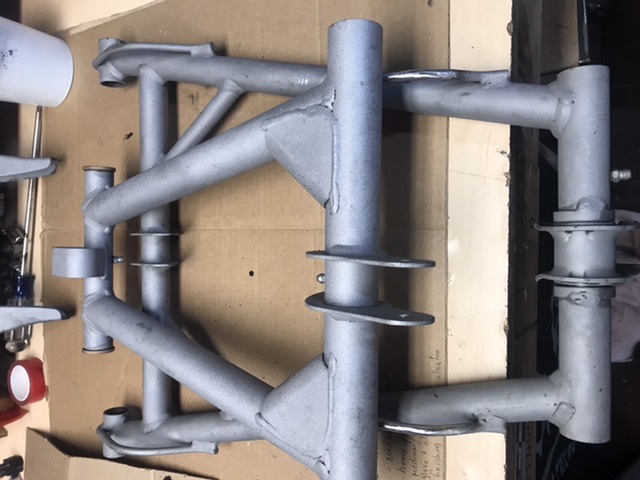

Looks like it took a beating from some of the roads we had to travel at the end of last season. My plan was to have all this powder coated but the shop was saying 5-7 week turnaround. My POR15 chassis coat will work just fine. And at least this way, I can touch up any rock chips or scratches that occur.

Couple more hours sitting at the blast cabinet taking off the original powder coat.

I believe my weak front spring is to blame for the front hoops getting worn down. They were pretty flat from the track clips hitting them. So I just did like I used to do to my old carbides and built them back up with the welder.

Didn’t take pics of them ground down and smoothed out. But they look like new again.

I was contemplating welding up the gussets and filling these weep holes to keep debris out. I don’t want them to rust on the inside.

But instead of welding on them and taking a risk of heat fracturing and weakening them, I’m gonna coat the inside with this internal frame coating.

First coat of chassis paint is on. Gonna finish it up with some top coat from POR15 as well.

Turning my attention to the skid, I wanted to check/replace any worn bushings and bearings.

Looks like it took a beating from some of the roads we had to travel at the end of last season. My plan was to have all this powder coated but the shop was saying 5-7 week turnaround. My POR15 chassis coat will work just fine. And at least this way, I can touch up any rock chips or scratches that occur.

Couple more hours sitting at the blast cabinet taking off the original powder coat.

I believe my weak front spring is to blame for the front hoops getting worn down. They were pretty flat from the track clips hitting them. So I just did like I used to do to my old carbides and built them back up with the welder.

Didn’t take pics of them ground down and smoothed out. But they look like new again.

I was contemplating welding up the gussets and filling these weep holes to keep debris out. I don’t want them to rust on the inside.

But instead of welding on them and taking a risk of heat fracturing and weakening them, I’m gonna coat the inside with this internal frame coating.

First coat of chassis paint is on. Gonna finish it up with some top coat from POR15 as well.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

I pretty much have this caught up to where I’m at. I skipped a lot of little things.

Front skid spring from Stringray Mods

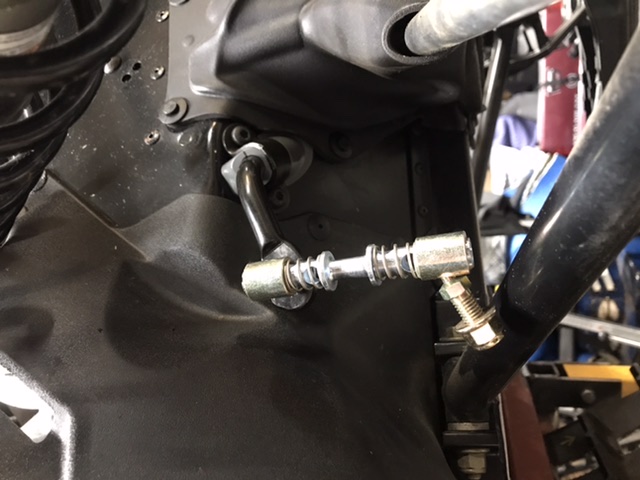

I made an oil drain hose from some AN fittings and braided line. Has a plug at the end for draining.

Made one for my brothers XTX too. This is installed.

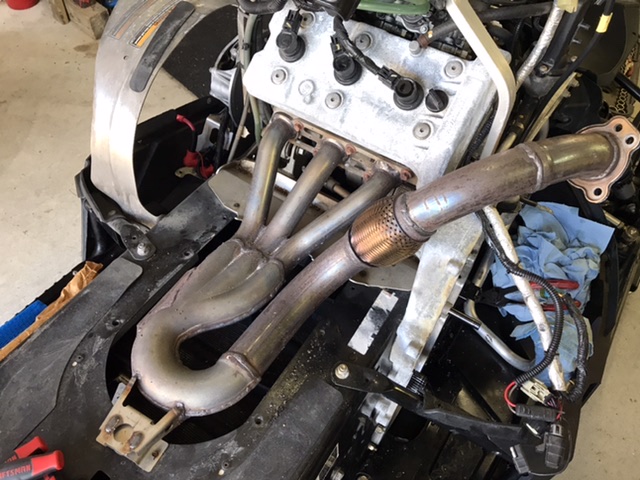

Pulled my header and trying to decide if I should paint it with some high heat paint, wrap it or have it ceramic coated. I need to make up my mind soon.

I also did the air box mod.

Probably going to make my own version of this bumper. Not gonna be a priority right now though.

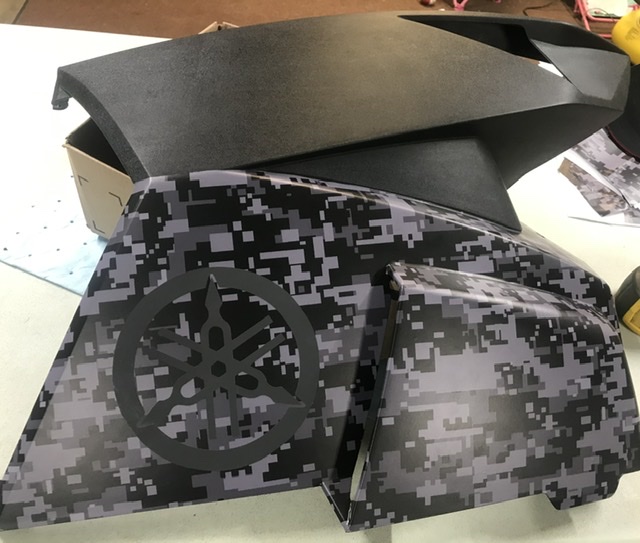

Then I started vinyl wrapping the side panels. My decals were starting to peel so I figured I’d give it a shot. Very time consuming to say the least. I didn’t want a pre cut graphic because it’s nit a full wrap and I didn’t want to see the lines. Also, to me seems like all those exposed seams would be easier to lift and peel. I’ll see how this turns out.

Had my wife cut me this Yamaha tuning fork emblem on her Cricut vinyl cutter.

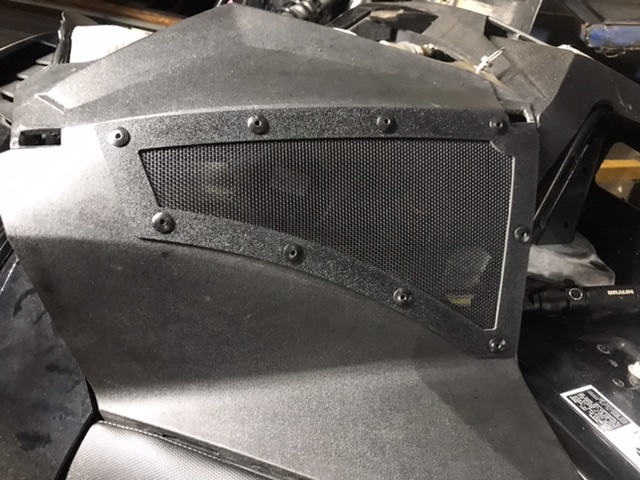

I also added some knee vents. I have a full vent kit but I’m not putting them on just yet. I’ll only do more if it seems like I need to.

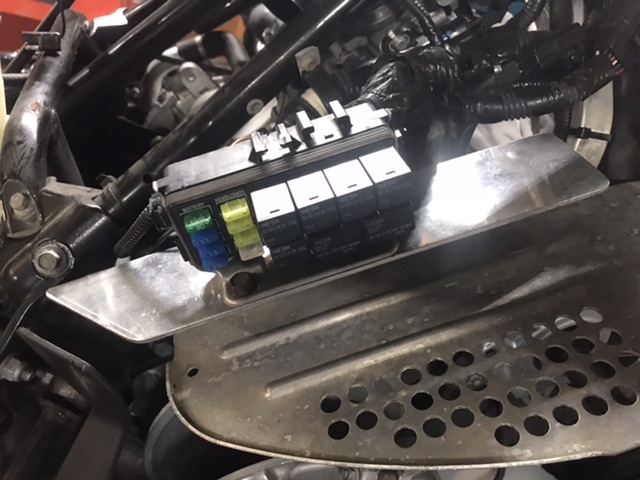

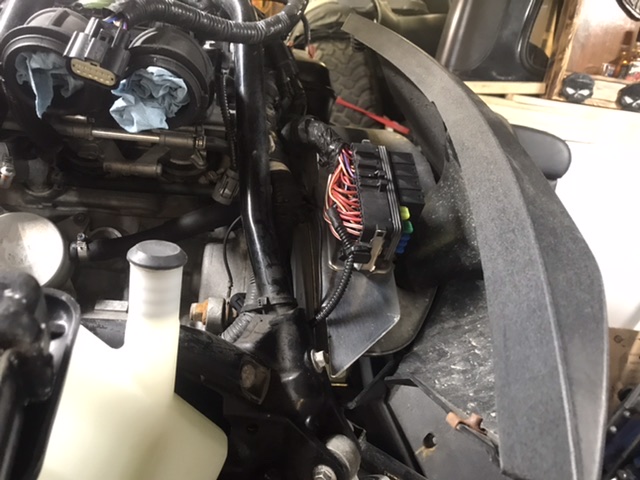

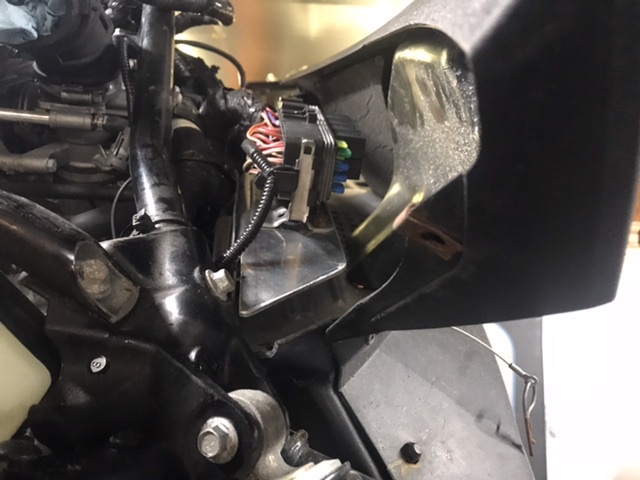

I also cut out a fuse box relocation bracket from some 1/8” aluminum. I have to bend it and drill for the holes so I’ll share when that’s complete.

Front skid spring from Stringray Mods

I made an oil drain hose from some AN fittings and braided line. Has a plug at the end for draining.

Made one for my brothers XTX too. This is installed.

Pulled my header and trying to decide if I should paint it with some high heat paint, wrap it or have it ceramic coated. I need to make up my mind soon.

I also did the air box mod.

Probably going to make my own version of this bumper. Not gonna be a priority right now though.

Then I started vinyl wrapping the side panels. My decals were starting to peel so I figured I’d give it a shot. Very time consuming to say the least. I didn’t want a pre cut graphic because it’s nit a full wrap and I didn’t want to see the lines. Also, to me seems like all those exposed seams would be easier to lift and peel. I’ll see how this turns out.

Had my wife cut me this Yamaha tuning fork emblem on her Cricut vinyl cutter.

I also added some knee vents. I have a full vent kit but I’m not putting them on just yet. I’ll only do more if it seems like I need to.

I also cut out a fuse box relocation bracket from some 1/8” aluminum. I have to bend it and drill for the holes so I’ll share when that’s complete.

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Reaction score

- 1,501

- Points

- 1,753

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

Wow great work

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

I have a few tweaks to make, but it fits.

I’m gonna round the front to match the radius of the belt guard. Don’t mind my homemade brake, I built it in a pinch for some floor pans I had to make. It works though.

mounted and test fit with side panel. I need to put hood on and make sure it’s low enough. I made 2 of these, second for my brothers sled.

I’m gonna round the front to match the radius of the belt guard. Don’t mind my homemade brake, I built it in a pinch for some floor pans I had to make. It works though.

mounted and test fit with side panel. I need to put hood on and make sure it’s low enough. I made 2 of these, second for my brothers sled.

Last edited:

- Joined

- Nov 11, 2016

- Messages

- 548

- Reaction score

- 961

- Points

- 1,018

- Location

- Cedarville, MI

- Country

- USA

- Snowmobile

- Yamaha, Polaris, AC and Ski-Doo

- LOCATION

- Cedarville, MI

- WEBSITE

- www.thunderproductsclutching.com

Looks great !

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Thanks guys.

I was able to get a little more done tonight. I got the 6009 sealed bearing for the caliper today. I removed the seals and packed the bearing with Amsoil low temp grease.

I put the bearing in the freezer and heated the caliper with a heat gun and it went in fairly easy.

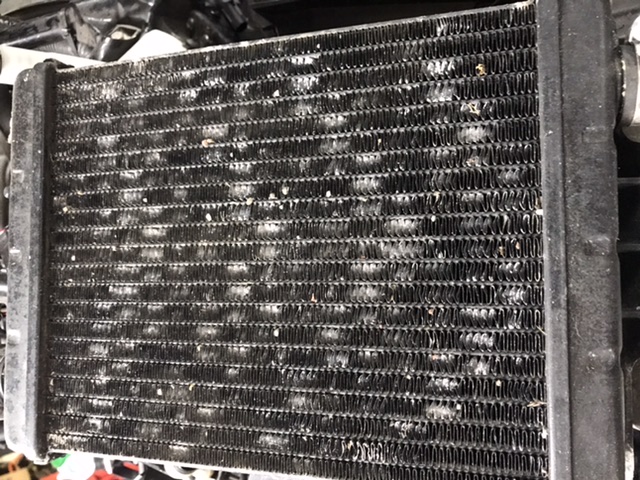

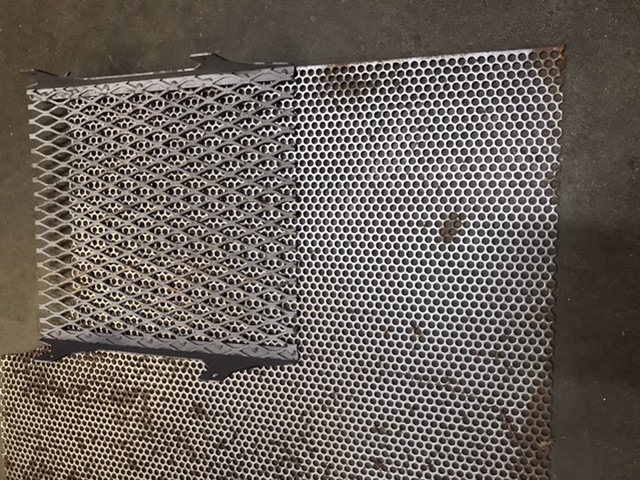

While the bearing was in the freezer I started to clean up the radiator. It takes a beating because the protective screen has too big of holes in it.

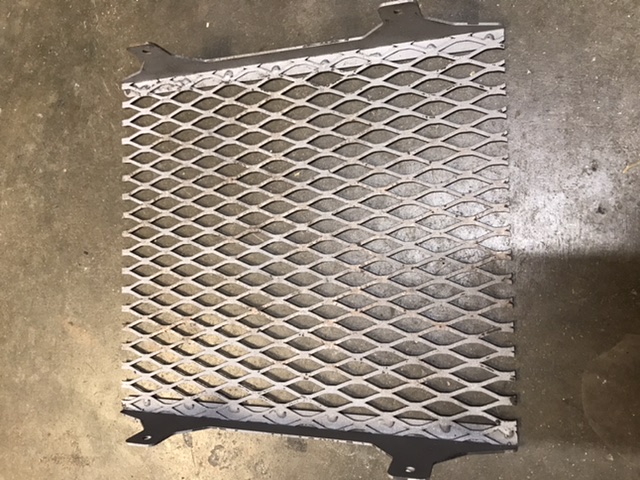

I will remove the radiator to clean it and comb the fins before I paint it. In the meantime I have to do something about the protective screen. I had a piece that will do a better job of protecting the radiator.

After I put the bearing in the caliper, I chased the threads with a tap and also ran a die over the bolts to clean out any thread lock.

I got the 153x15x1.75 Camoplast Backcountry track and driveshaft installed and bolted in the caliper with rotor. Blue Locktite applied to caliper bolts and torqued to 25ftlbs.

I really think I should get the bearing wedge from Barn of Parts because the inner race was not a press fit and I don’t want the bearing inner race to spin on the driveshaft.

Next step, get the skid back together and installed.

I was able to get a little more done tonight. I got the 6009 sealed bearing for the caliper today. I removed the seals and packed the bearing with Amsoil low temp grease.

I put the bearing in the freezer and heated the caliper with a heat gun and it went in fairly easy.

While the bearing was in the freezer I started to clean up the radiator. It takes a beating because the protective screen has too big of holes in it.

I will remove the radiator to clean it and comb the fins before I paint it. In the meantime I have to do something about the protective screen. I had a piece that will do a better job of protecting the radiator.

After I put the bearing in the caliper, I chased the threads with a tap and also ran a die over the bolts to clean out any thread lock.

I got the 153x15x1.75 Camoplast Backcountry track and driveshaft installed and bolted in the caliper with rotor. Blue Locktite applied to caliper bolts and torqued to 25ftlbs.

I really think I should get the bearing wedge from Barn of Parts because the inner race was not a press fit and I don’t want the bearing inner race to spin on the driveshaft.

Next step, get the skid back together and installed.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Tested the fuse box relocation on my brothers XTX today. Fits great and no extension harness needed for fan.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Few more things checked off my list.

Fuse box is mounted for the last time. I made a pigtail for the fan to reverse it but I don’t think I’m gonna run it. I’m not completely sold on any benefits from doing it and the harness reaches without the extension.

I installed the sway bar but still need to fab up a bracket for the lower arm to attach the end link. I have a quick disconnect so I can detach it for off trail riding.

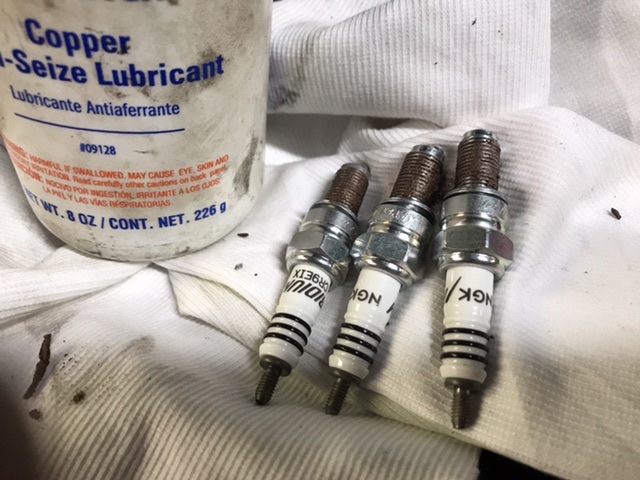

I pulled the plugs and pleasantly surprised the condition and color, not that I was expecting anything bad. I was told this sled was tuned for low altitude. Left to right is mag, center and PTO.

New plugs are iridium and I always put a little copper anti-seize on the threads.

I always add a small dab of electrical insulating compound where the plug makes contact with the coil and I used 111 lubricant where the coil seals in the hole. I’ve always had good luck with this stuff keeping things from sticking and also repelling moisture.

Still plugging away at my list to get this thing done.

Fuse box is mounted for the last time. I made a pigtail for the fan to reverse it but I don’t think I’m gonna run it. I’m not completely sold on any benefits from doing it and the harness reaches without the extension.

I installed the sway bar but still need to fab up a bracket for the lower arm to attach the end link. I have a quick disconnect so I can detach it for off trail riding.

I pulled the plugs and pleasantly surprised the condition and color, not that I was expecting anything bad. I was told this sled was tuned for low altitude. Left to right is mag, center and PTO.

New plugs are iridium and I always put a little copper anti-seize on the threads.

I always add a small dab of electrical insulating compound where the plug makes contact with the coil and I used 111 lubricant where the coil seals in the hole. I’ve always had good luck with this stuff keeping things from sticking and also repelling moisture.

Still plugging away at my list to get this thing done.

rallikuski

Newbie

- Joined

- Jan 8, 2018

- Messages

- 14

- Reaction score

- 2

- Points

- 433

- Location

- Finland

- Country

- Other

- Snowmobile

- sr viper mtx 153 mxc270

How hard was that sway bar installation? Any pics from installation?

I have 153 MTX too and last winter i was thinking installing sway bar too, just wondering what modifications it needs...

I have 153 MTX too and last winter i was thinking installing sway bar too, just wondering what modifications it needs...

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 185

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

How hard was that sway bar installation? Any pics from installation?

I have 153 MTX too and last winter i was thinking installing sway bar too, just wondering what modifications it needs...

removed block off plates from the sides and it slid right thru. Got the sway bar, mounting hardware and bolts from Babbittsonline. I need to fabricate and weld a plate to lower arm to attach end links. But the sway bar went in and bolted up no problem.

Similar threads

- Replies

- 5

- Views

- 3K

- Replies

- 20

- Views

- 9K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.