Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Is it just me or does everyone feel they keep throwing endless money at their toys?

I’m making progress though.

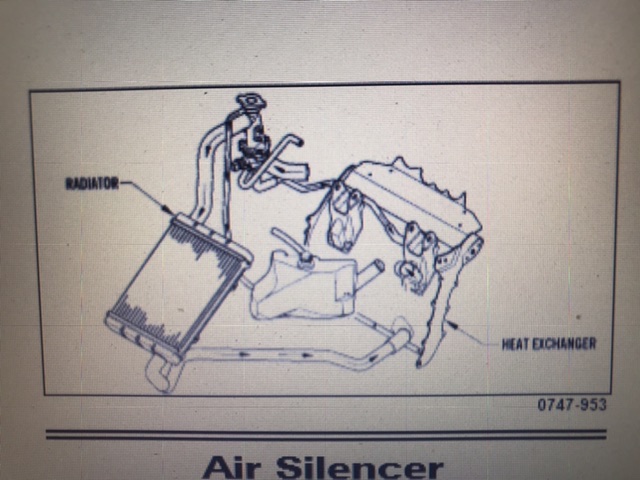

I drained the coolant last night, gonna pull the radiator to clean out the belly pan and also clean and comb the radiator fins before spray bombing it.

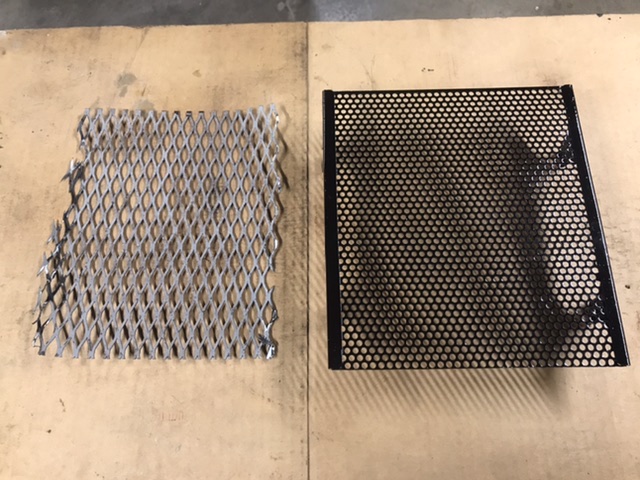

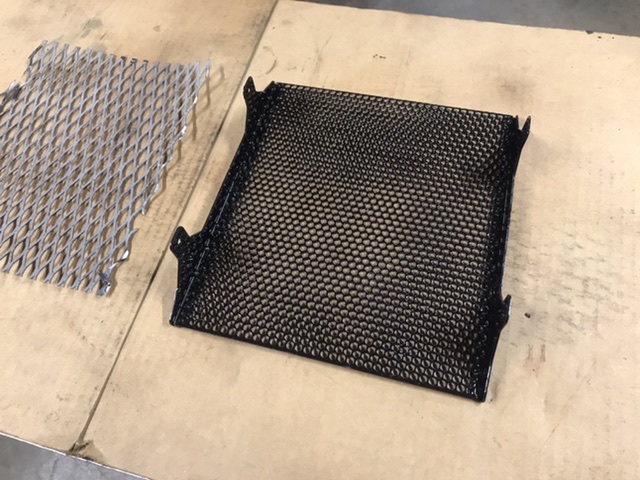

I got the radiator protector screen changed out, welded, blasted and painted. I’ll get pics today when I get home. Gonna be a lot better than the factory one.

I’m still waiting for my bushings and DuPont slides to come in for my skid before I can reassemble that. List is still a mile long but I’m steady scratching things off. Getting the wrap done is gonna be my most time consuming part. I’m also waiting for a sheet of 6061 1/8” aluminum to stiffen up the tunnel, skid plate, and a custom front bumper.

I’m making progress though.

I drained the coolant last night, gonna pull the radiator to clean out the belly pan and also clean and comb the radiator fins before spray bombing it.

I got the radiator protector screen changed out, welded, blasted and painted. I’ll get pics today when I get home. Gonna be a lot better than the factory one.

I’m still waiting for my bushings and DuPont slides to come in for my skid before I can reassemble that. List is still a mile long but I’m steady scratching things off. Getting the wrap done is gonna be my most time consuming part. I’m also waiting for a sheet of 6061 1/8” aluminum to stiffen up the tunnel, skid plate, and a custom front bumper.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Here’s the new screen I made.

Radiator getting cleaned.

Radiator getting cleaned.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

My new slides should be here this week. After looking at the ones on there now, I’m gonna run them this year and keep my eye on them. I thought they were a lot more worn they are.

The thinnest area is right behind the front bogey wheel and I can’t get a 17mm on it. These are DuPont slides also so they should be good for another year as long as I can stay off the roads, we get some good snow and I keep my scratchers down.

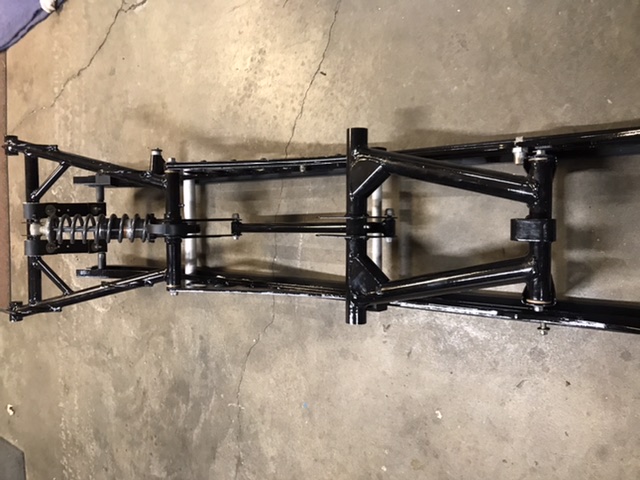

I wanted to get the rails powder coated but it would have taken too long so I decided to just paint them myself. It was a PITA to remove the slides. Block of wood and a hammer trying not to damage them and they wouldn’t barely move. I ended up having to use an air hammer but put a piece of angle iron in front of slide to protect the bottom of the rail and also the slide. It finally went. Then I sanded everything down and taped off the bottom rail before applying some POR15. I put ear plugs in the bolt holes to avoid paint getting in there. Very time consuming but it looks a lot better than it did. I’ll take pics of finished product when I get home later today.

The thinnest area is right behind the front bogey wheel and I can’t get a 17mm on it. These are DuPont slides also so they should be good for another year as long as I can stay off the roads, we get some good snow and I keep my scratchers down.

I wanted to get the rails powder coated but it would have taken too long so I decided to just paint them myself. It was a PITA to remove the slides. Block of wood and a hammer trying not to damage them and they wouldn’t barely move. I ended up having to use an air hammer but put a piece of angle iron in front of slide to protect the bottom of the rail and also the slide. It finally went. Then I sanded everything down and taped off the bottom rail before applying some POR15. I put ear plugs in the bolt holes to avoid paint getting in there. Very time consuming but it looks a lot better than it did. I’ll take pics of finished product when I get home later today.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

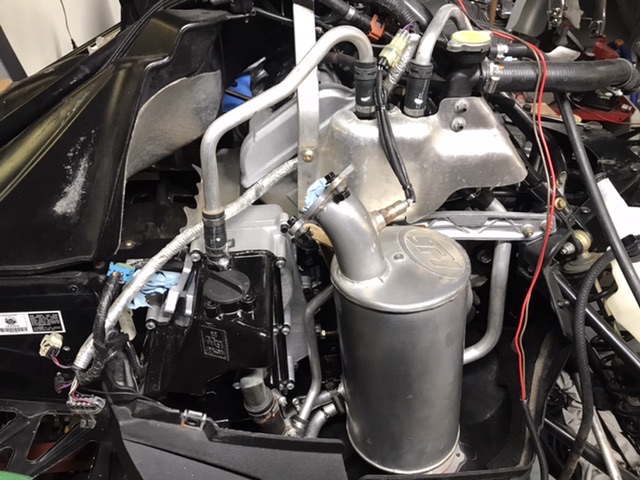

Radiator is ready to go back in.

One rail all done. Gonna wait a few days to install slides and start putting back together. Let this paint fully cure, I keep garage at 58-62*.

I also made up some plates for the front skid bolt. Need some finishing touches and paint. Made these out of 1/8” stainless steel.

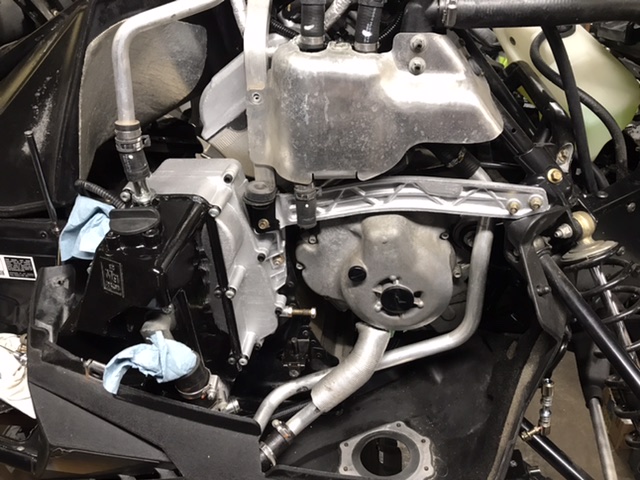

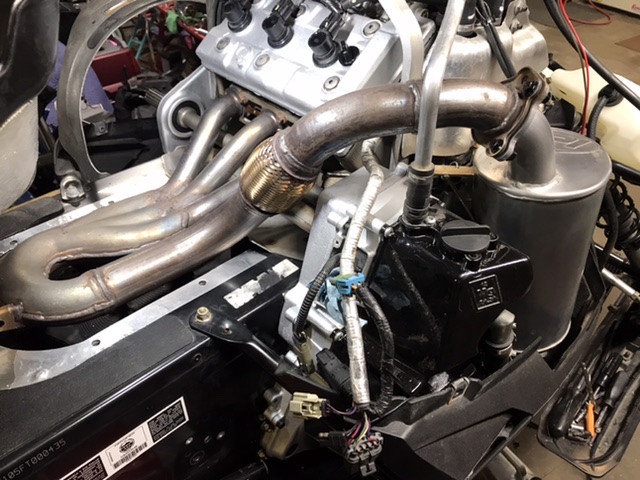

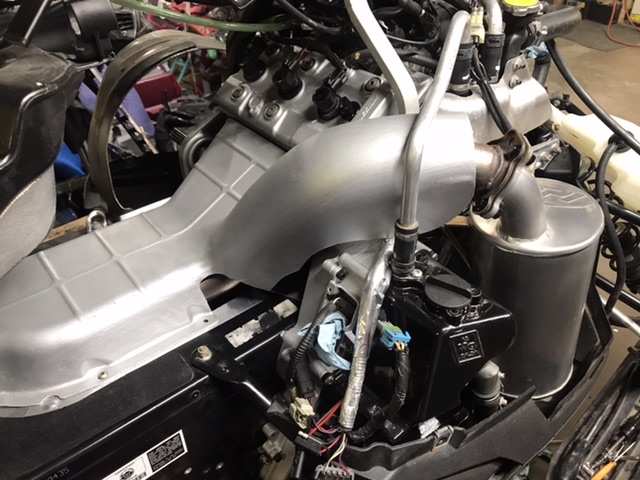

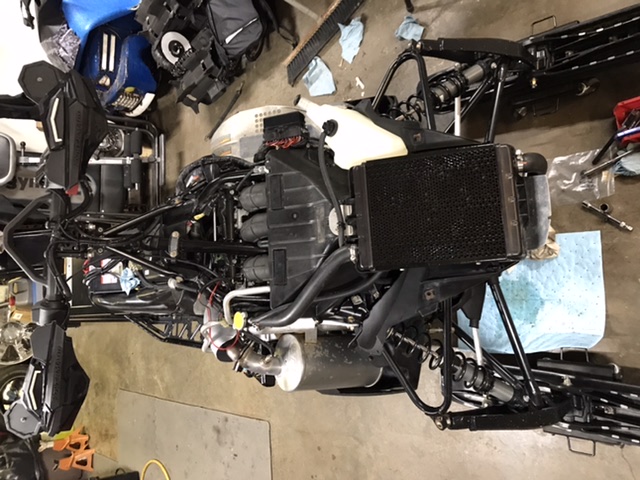

Things are starting to get put back together. Exhaust header going on as soon as I get my copper gasket. I have a few wires to tuck away and protect from heat too.

One rail all done. Gonna wait a few days to install slides and start putting back together. Let this paint fully cure, I keep garage at 58-62*.

I also made up some plates for the front skid bolt. Need some finishing touches and paint. Made these out of 1/8” stainless steel.

Things are starting to get put back together. Exhaust header going on as soon as I get my copper gasket. I have a few wires to tuck away and protect from heat too.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

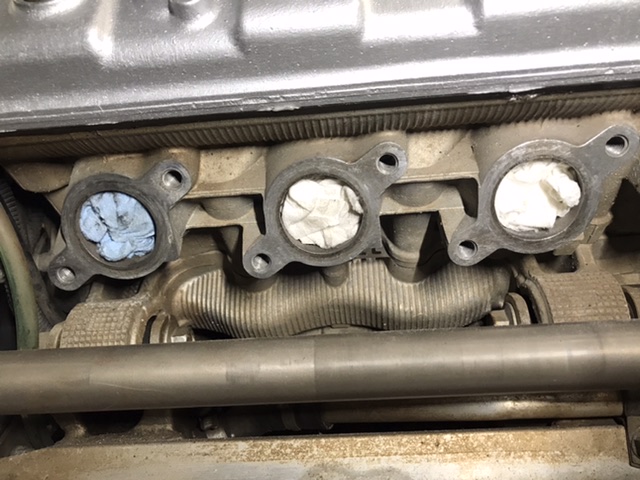

Cleaned off the head with a small brass brush to remove a small amount of carbon from mating surface.

While in there I found a loose rivet so I replaced it.

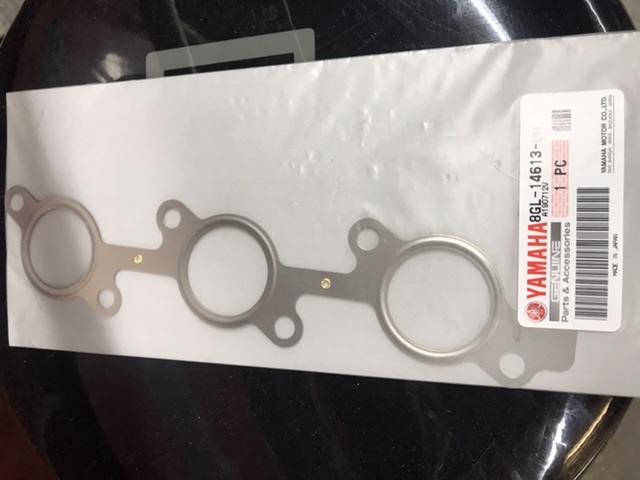

New gasket

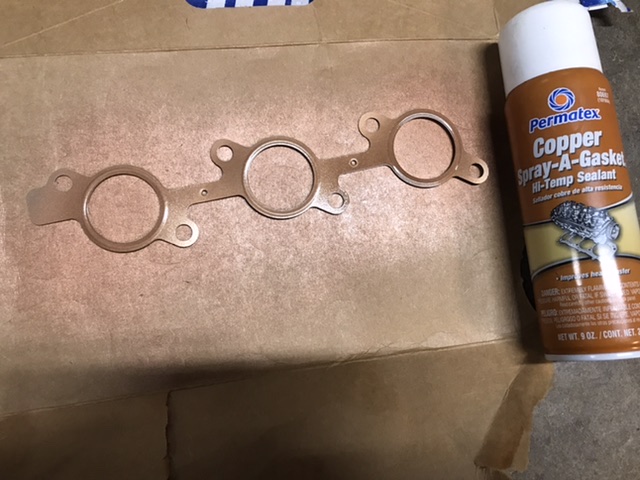

Before installing header I sprayed gasket with copper seal. I always use this stuff when using metal gaskets on aluminum. I’ve always had good luck with this stuff, especially on turbo flanges. Always seals.

I seen the paint on tunnel where heat shield mounts was a little ugly so I cleaned it up and touched it up with spray paint and then put down some aluminum tape.

Finally got the header installed

Heat shield in place but still cleaning up the mounting plates.

While in there I found a loose rivet so I replaced it.

New gasket

Before installing header I sprayed gasket with copper seal. I always use this stuff when using metal gaskets on aluminum. I’ve always had good luck with this stuff, especially on turbo flanges. Always seals.

I seen the paint on tunnel where heat shield mounts was a little ugly so I cleaned it up and touched it up with spray paint and then put down some aluminum tape.

Finally got the header installed

Heat shield in place but still cleaning up the mounting plates.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

I replaced a few bushings on the arms. I bought them all but ended up only having to replace 4 of them.

DuPont slides came in. Suckers are expensive. I went with the MTX slides obviously but realized that’s not what was on here. The ones on here have the inserts in the slides only 41” from the front. So the last ~11” don’t have the inserts. The MTX slides have the inserts 52” from the front which will make the entire slide have inserts when I put them on after cutting to size. The difference in price is double. $140 for a single MTX slide vs $160 for a pair of 144” slides for a Nitro. I’m gonna run what was on there for now, they don’t have much wear and I’ll have these MTX slides for when the time comes.

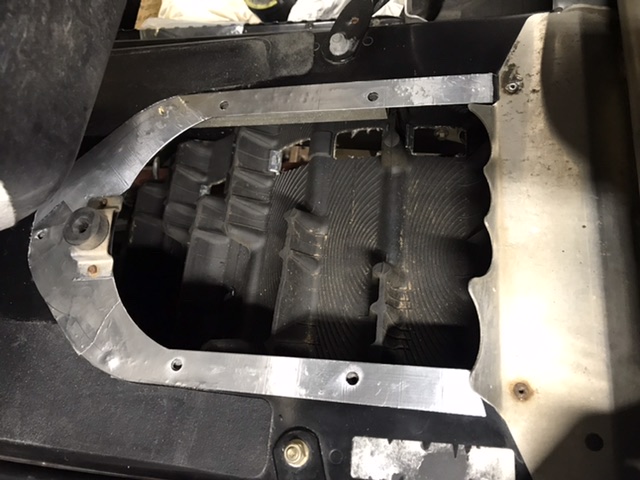

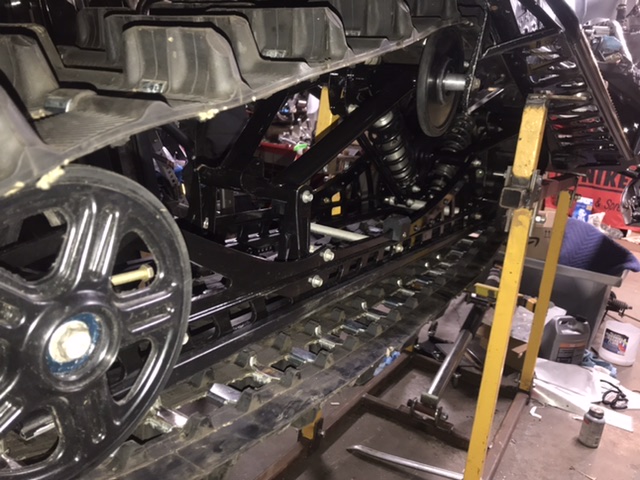

My skid going back together after paint.

After fully clipping the backcountry track I got the skid back in.

Looking at the aluminum panels under the belly pan, I decided to make new ones out of 1/8” stainless. The one under the engine took a hit and showed slight damage.

Before installing, I secured my oil drain hose with a wire clamp and shoved it under the top part of the clip so the bolt holds it in place.

Then put covers on.

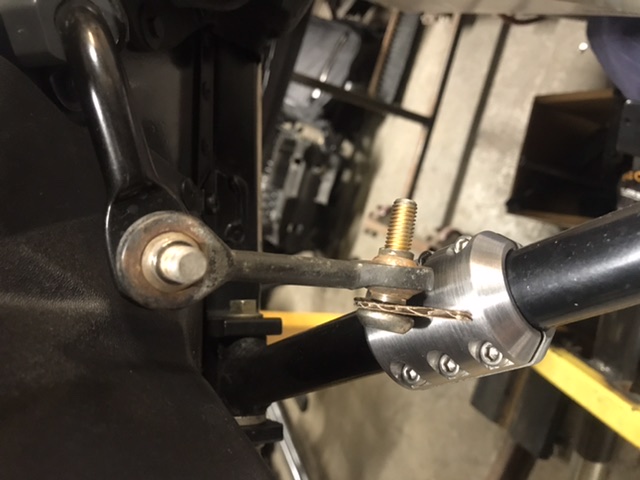

Front end going back together after I tightened up 17mm nut at the bottom of steering post, again. This time I removed nut and cleaned threads before applying some blue loctite.

Still waiting for copper exhaust gasket so I turned my attention to the sway bar lower link brackets. I was hesitant on welding tabs directly to the arms just so I didn’t fatigue them. I decided to go to a bolt on method. This is what I came up with. 1” I.D. X 1.75” O.D. X 2” long. I’m gonna weld a tab on these.

I also seen this on someone else’s skid and asked about it. Seems they put a wheel on the center of the arm and it helps to keep the track off the loops that were worn on mine. I found it on an ‘18 Sidewinder so I ordered it. Wheel is 2 pieces which were like $5/each and two screws. It was less than $10 from Partszilla so I said what the hell.

DuPont slides came in. Suckers are expensive. I went with the MTX slides obviously but realized that’s not what was on here. The ones on here have the inserts in the slides only 41” from the front. So the last ~11” don’t have the inserts. The MTX slides have the inserts 52” from the front which will make the entire slide have inserts when I put them on after cutting to size. The difference in price is double. $140 for a single MTX slide vs $160 for a pair of 144” slides for a Nitro. I’m gonna run what was on there for now, they don’t have much wear and I’ll have these MTX slides for when the time comes.

My skid going back together after paint.

After fully clipping the backcountry track I got the skid back in.

Looking at the aluminum panels under the belly pan, I decided to make new ones out of 1/8” stainless. The one under the engine took a hit and showed slight damage.

Before installing, I secured my oil drain hose with a wire clamp and shoved it under the top part of the clip so the bolt holds it in place.

Then put covers on.

Front end going back together after I tightened up 17mm nut at the bottom of steering post, again. This time I removed nut and cleaned threads before applying some blue loctite.

Still waiting for copper exhaust gasket so I turned my attention to the sway bar lower link brackets. I was hesitant on welding tabs directly to the arms just so I didn’t fatigue them. I decided to go to a bolt on method. This is what I came up with. 1” I.D. X 1.75” O.D. X 2” long. I’m gonna weld a tab on these.

I also seen this on someone else’s skid and asked about it. Seems they put a wheel on the center of the arm and it helps to keep the track off the loops that were worn on mine. I found it on an ‘18 Sidewinder so I ordered it. Wheel is 2 pieces which were like $5/each and two screws. It was less than $10 from Partszilla so I said what the hell.

Last edited:

Clyder6R

Extreme

- Joined

- Dec 24, 2015

- Messages

- 99

- Reaction score

- 61

- Points

- 283

- Location

- Atlantic Canada

- Country

- Canada

- Snowmobile

- 2015 Yamaha Viper MTX 153 McXpress 190 kit

Glad to see you like the wheel! Cheers Caleb from sr viper on FB lol

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Glad to see you like the wheel! Cheers Caleb from sr viper on FB lol

At least I give credit when it’s due and not pawn it off as my own idea. Hahaha. Glad you found me. I’m sure there’s plenty of people on both. Just sucks that FB gets more traffic than forums anymore. I can’t stand the FB platform. Here, seems like I’m yelling down an empty hallway. Bout to give up. I’ll just keep the pics for myself so I can always go back and see what I did and when I did it.

- Joined

- Jun 1, 2004

- Messages

- 7,881

- Reaction score

- 2,059

- Points

- 2,103

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

Looking good and thanks for sharing.

Clyder6R

Extreme

- Joined

- Dec 24, 2015

- Messages

- 99

- Reaction score

- 61

- Points

- 283

- Location

- Atlantic Canada

- Country

- Canada

- Snowmobile

- 2015 Yamaha Viper MTX 153 McXpress 190 kit

I prefer the forums over the FB, just easier to post photos quickly there is all. Looks like we are doing all the same things to identical sleds lolAt least I give credit when it’s due and not pawn it off as my own idea. Hahaha. Glad you found me. I’m sure there’s plenty of people on both. Just sucks that FB gets more traffic than forums anymore. I can’t stand the FB platform. Here, seems like I’m yelling down an empty hallway. Bout to give up. I’ll just keep the pics for myself so I can always go back and see what I did and when I did it.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

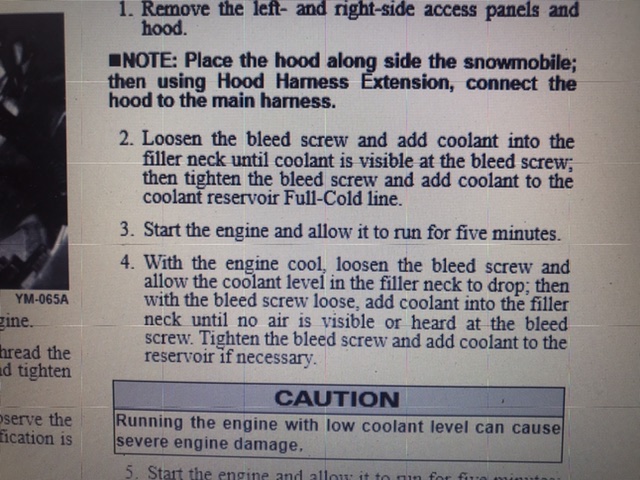

What is the best way to bleed the cooling system? I drained roughly 3 quarts and only got 2.5 back in. I’ve been running it, rocking it, squeezing hoses and topping up. What am I missing?

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Drilled mounting holes in new windshield and test fit. This will help keep the wind off me so much better.

Now for the sway bar. This clamp is gonna work out nice. Was about $50 to have them machined but I didn’t want to weld tab directly to the lower arm.

Test fit to arm. Very nice and will tighten down and not move.

Template of the tab I have to cut out of some 1/8” or 14 gauge steel. Probably go with the 1/8”.

I’ll have it cut, welded and painted tomorrow.

Now for the sway bar. This clamp is gonna work out nice. Was about $50 to have them machined but I didn’t want to weld tab directly to the lower arm.

Test fit to arm. Very nice and will tighten down and not move.

Template of the tab I have to cut out of some 1/8” or 14 gauge steel. Probably go with the 1/8”.

I’ll have it cut, welded and painted tomorrow.

Last edited:

Clyder6R

Extreme

- Joined

- Dec 24, 2015

- Messages

- 99

- Reaction score

- 61

- Points

- 283

- Location

- Atlantic Canada

- Country

- Canada

- Snowmobile

- 2015 Yamaha Viper MTX 153 McXpress 190 kit

Awesome! I may do a built thread on mine as well now.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Awesome! I may do a built thread on mine as well now.

I hope you do. I like seeing what others have done especially on the same sled.

I still need to order my clutch kit and 911 cover from Thunder Products and get my Mohawks. I have the hoops, mounts and carbides. Just seems like endless money being dropped here lately.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

SPI trail can. My brother wants to get the stock suitcase muffler modded on his and asked if I wanted to do mine as well. He runs an OSP mountain can and it drones like crazy cruising down the trail. I was a little worried about getting stopped and ticketed in northern Wisconsin but I don’t think this is too bad.

Similar threads

- Replies

- 5

- Views

- 3K

- Replies

- 20

- Views

- 9K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.