The wobble bearing? Easy. I used a extension and 15/16 socket. Came right out after clip removal. Will get some pics.Is it difficult to remove the old bearing in the chaincase? Special tools?

Janne339

TY 4 Stroke Junkie

The wobble bearing? Easy. I used a extension and 15/16 socket. Came right out after clip removal. Will get some pics.

Yes, the wobble bearing. I am not so good in english

Removing Jackshaft and Wobblebearing

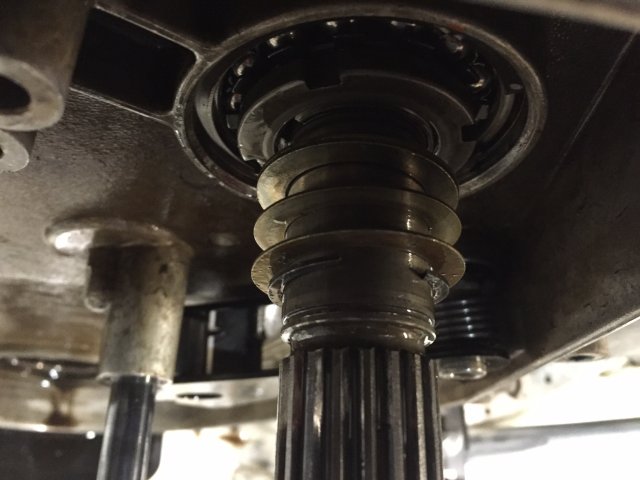

Once gears and everything else is removed you remove this little clip and the washers and shim. This little clip was a bugger. Wanted to go back in groove all the time. I ended up using that tool and a small screwdriver. Here is pic of it.

Next you push the tab of locking washer out of slot in Nut.

Then using punch or a socket with tangs on it tap the nut loose. Helps to have someone hold the secondary but not needed.

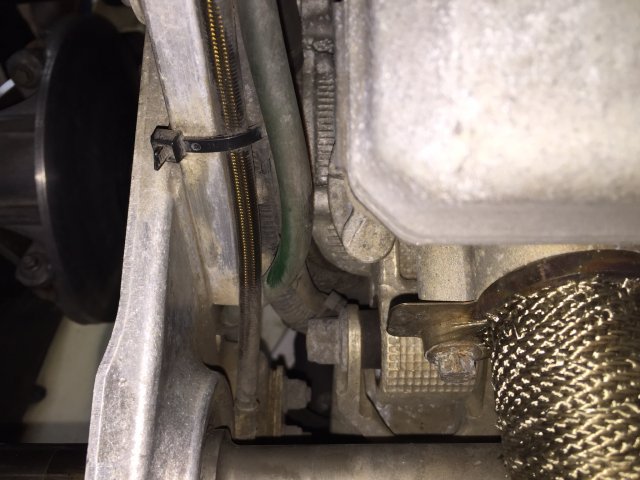

Once nut is loose move to left side of sled and remove the big assortment of bolts,nuts from the Jackshaft support. Cut all zip ties attached to it. The belt guard does not need to be removed just the bolts holding it on.

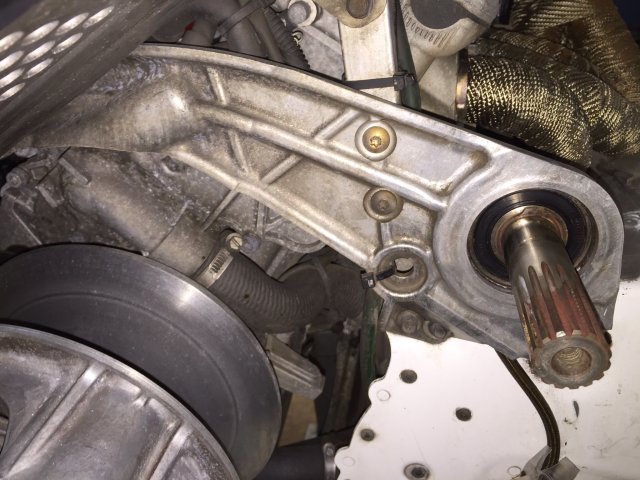

Wiggle it to make sure you got them all. Then go back to chaincase. Loosen the nut a good turn or two. Then using a punch tap on the nut first on top then bottom then sides. You will feel the locking taper sleeve loosen. Once loose slide the shaft out the left side.

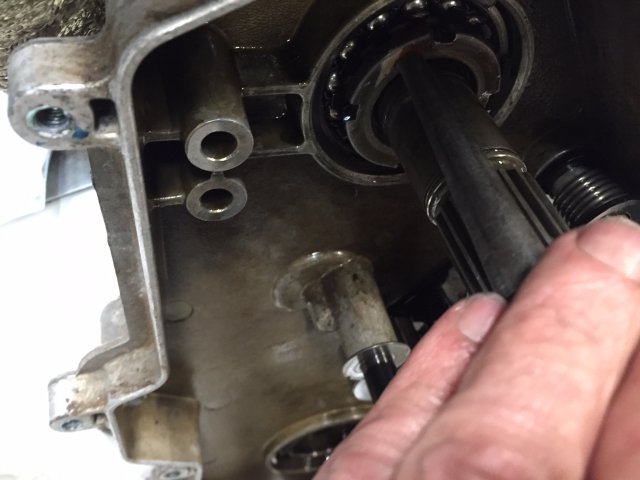

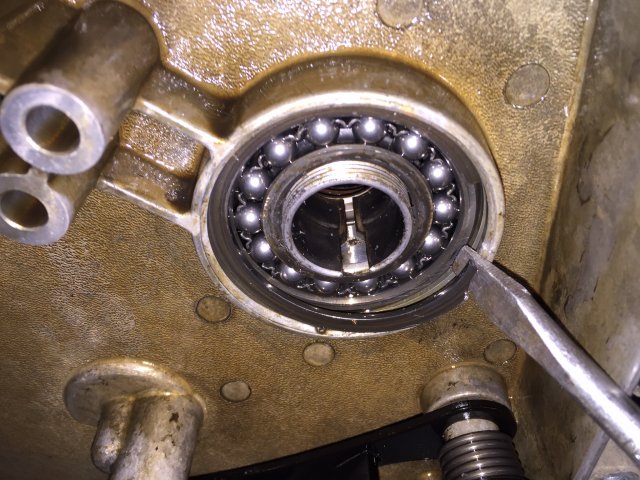

Shaft is out. Now bearing. Remove Clip as so.

Once clip is removed you can use a long extension and 15/16 socket to drive bearing out. It comes out pretty easy. This is all the original parts. Nothing wore or broke.

While doing this take new bearing and put in Ziplock bag and then put in freezer. If replacing seal do it now. Springed lip of seal to inside of case. Have a big socket or bearing driver of slightly small size than OD of bearing within reach. Using a propane torch or heat gun warm the bearing pocket. Be careful of seal.

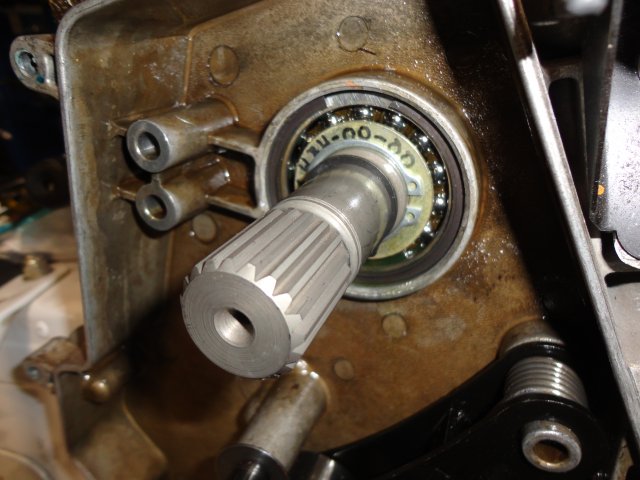

If old style shaft and bearing are being used the bigger side of the tapered inner race goes in first along with the collar and taper sleeve.

16 and newer it does not matter since bearing ID is not tapered.

Slide it in by hand then once in as far as you can get it by hand send it home with driver. Do all this quickly as possible to keep case warm and bearing cold. It is home when you both hear and feel it bottom. Clip groove will be plainly visible and a little more. Then install clip starting with the cut away end in groove. Just push it in. Starting at cutaway and working it in all the way around.

Lube the bearing with chaincase lube. I use some grease on the seal.

Once gears and everything else is removed you remove this little clip and the washers and shim. This little clip was a bugger. Wanted to go back in groove all the time. I ended up using that tool and a small screwdriver. Here is pic of it.

Next you push the tab of locking washer out of slot in Nut.

Then using punch or a socket with tangs on it tap the nut loose. Helps to have someone hold the secondary but not needed.

Once nut is loose move to left side of sled and remove the big assortment of bolts,nuts from the Jackshaft support. Cut all zip ties attached to it. The belt guard does not need to be removed just the bolts holding it on.

Wiggle it to make sure you got them all. Then go back to chaincase. Loosen the nut a good turn or two. Then using a punch tap on the nut first on top then bottom then sides. You will feel the locking taper sleeve loosen. Once loose slide the shaft out the left side.

Shaft is out. Now bearing. Remove Clip as so.

Once clip is removed you can use a long extension and 15/16 socket to drive bearing out. It comes out pretty easy. This is all the original parts. Nothing wore or broke.

While doing this take new bearing and put in Ziplock bag and then put in freezer. If replacing seal do it now. Springed lip of seal to inside of case. Have a big socket or bearing driver of slightly small size than OD of bearing within reach. Using a propane torch or heat gun warm the bearing pocket. Be careful of seal.

If old style shaft and bearing are being used the bigger side of the tapered inner race goes in first along with the collar and taper sleeve.

16 and newer it does not matter since bearing ID is not tapered.

Slide it in by hand then once in as far as you can get it by hand send it home with driver. Do all this quickly as possible to keep case warm and bearing cold. It is home when you both hear and feel it bottom. Clip groove will be plainly visible and a little more. Then install clip starting with the cut away end in groove. Just push it in. Starting at cutaway and working it in all the way around.

Lube the bearing with chaincase lube. I use some grease on the seal.

2014,15 parts on left. 2016 on right

And all in! Fits perfect.

And all in! Fits perfect.

Parts List on first page was edited. Order of parts is wrong on that diagram.

Janne339

TY 4 Stroke Junkie

Thanks!

Just finishing up going through suspension for install. Got that sweet new Axis center shock from Hygear. Ran into a snag. Can see the shaft wore into aluminum allowing bolt to be loose. (and I didnt catch it) egged the lower center shock mount shaft bolt hole in rail. Dangit! Not looking good for the weekend ride. Hope snow stays for another week.

Vilas

Expert

- Joined

- Sep 6, 2014

- Messages

- 288

- Location

- Urbana, Illinois

- Country

- USA

- Snowmobile

- 2014 Viper xtx, Thunder products clutch kit

This is a fantastic write up. Thanks for all of the great pictures and the clear instructions!

Alsim

Expert

- Joined

- Oct 6, 2014

- Messages

- 389

- Age

- 63

- Country

- Canada

- Snowmobile

- LTX SE 2018

Nice Write up! Thank You2014,15 parts on left. 2016 on right

View attachment 117822

And all in! Fits perfect.

View attachment 117823

Alsim

Expert

- Joined

- Oct 6, 2014

- Messages

- 389

- Age

- 63

- Country

- Canada

- Snowmobile

- LTX SE 2018

Just finishing up going through suspension for install. Got that sweet new Axis center shock from Hygear. Ran into a snag. Can see the shaft wore into aluminum allowing bolt to be loose. (and I didnt catch it) egged the lower center shock mount shaft bolt hole in rail. Dangit! Not looking good for the weekend ride. Hope snow stays for another week.

View attachment 117833

View attachment 117834

Hi Cannondale !

Will you use the wheel hole and bolt the shaft on it ? May be you could inverse the shaft and the wheel. You have a groove in the wheel's fixation to fit to rail. You surlery have less stress to the rail and could use this hole for the wheel

kurzy

Pro

- Joined

- Mar 25, 2011

- Messages

- 148

- Location

- Peterborough On, Can.

- Country

- Canada

- Snowmobile

- '08 40th. Anniversary Nytro RTX

Cannondale, I've been reading the thread and it's very informative. I was trying to figure out why you are changing the jackshaft assembly? Is it an update, or a weight issue? Don't want to sound ignorant, but I read it all again and just wanted to ask why. Thanks for the great info.

- Joined

- Apr 14, 2003

- Messages

- 6,539

- Location

- Hessel, Michigan

- Country

- USA

- Snowmobile

- Sidewinder, SR Viper XTX, SR Viper XTX, 2016 Apex XTX and Pro-Line Pro Stock 1000

Cannondale, I've been reading the thread and it's very informative. I was trying to figure out why you are changing the jackshaft assembly? Is it an update, or a weight issue? Don't want to sound ignorant, but I read it all again and just wanted to ask why. Thanks for the great info.

I would guess it is because of the issues some are having with the wobble bearing. Plus this is upgraded to the 2016 jackshaft and bearing.

TestMaster

Lifetime Member

- Joined

- Sep 28, 2013

- Messages

- 693

- Age

- 73

- Location

- Alba, Michigan

- Website

- www.gdls.com

- Country

- USA

- Snowmobile

- 2014 SR Viper LTX SE

2014 SR Viper LTX DX

2001 Venture 600

Given to a friend - 1998 SRX 700s

Just finishing up going through suspension for install. Got that sweet new Axis center shock from Hygear. Ran into a snag. Can see the shaft wore into aluminum allowing bolt to be loose. (and I didnt catch it) egged the lower center shock mount shaft bolt hole in rail. Dangit! Not looking good for the weekend ride. Hope snow stays for another week.

View attachment 117833

View attachment 117834

I'll have to check my center shock, thanks for the heads up! This is my second year with the Hygear rear Axis Pro shocks and third with the Front Axis Pro.

Last edited:

Yes and thought since was having it all apart time to replace. That bearing makes me nervous. Shaft is supposedly stronger. At 8000 mi really everything other than motor is suspect with the way I ride. Bit embarassed over the egged out hole but fully admit just greasing and casual glance at everything last few rides. Will pay more attention. Maybe a Mid season skid pull and go over.I would guess it is because of the issues some are having with the wobble bearing. Plus this is upgraded to the 2016 jackshaft and bearing.

This egged hole is the one the lower shock mount shaft is bolted to. So has to be where it is. But do plan on tieing the wheel mount hole to the shaft hole and drilling a new third hole in steel plates. This wont happen again. Will have to weld the rail hole shut and redrill also.Hi Cannondale !

Will you use the wheel hole and bolt the shaft on it ? May be you could inverse the shaft and the wheel. You have a groove in the wheel's fixation to fit to rail. You surlery have less stress to the rail and could use this hole for the wheel

Similar threads

- Replies

- 8

- Views

- 3K

- Replies

- 5

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.