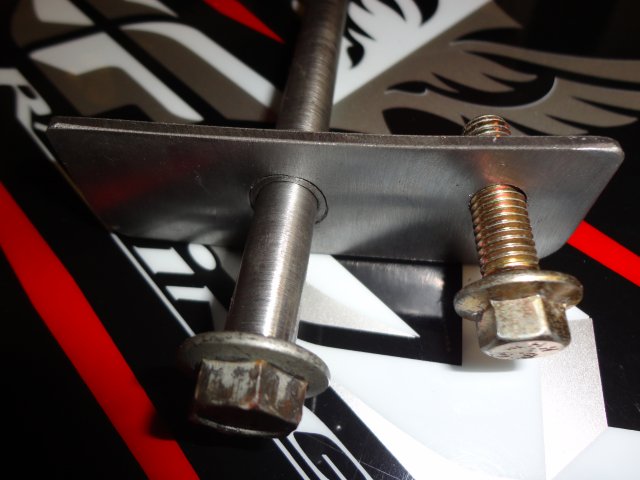

Made two of these plates one for each rail and then a flat plate for inside of rail same thing but without the insert in it. They are .105 thick so two are only .040 thinner than rail itself. This means I have to cut the length of shaft the thickness of the two plates on inside. Tomorrow night. Insert is 5/8 in dia stepped down and pressed into the outside plate. Same length as rails are thick - a few thousandths. Holes are a real nice fit with bolts. Drilled the one good rail hole out to 5/8in to accept the insert. Other side I need to weld up first. Will add another smaller shoulder bolt forward once its all bolted in. Wheel mount will be milled off thickness of plate so it can fit under mount. Should work and if not its new rails. Nothing to lose but time. Hey Swampcat had a good one. "Egged hole for Easter"

Alsim

Expert

- Joined

- Oct 6, 2014

- Messages

- 389

- Age

- 63

- Country

- Canada

- Snowmobile

- LTX SE 2018

Good job! It's will never happend again

Janne339

TY 4 Stroke Junkie

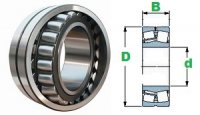

The ones I see fail it's the cage that fails so that tells me side forces are culprit either from chassis flex or tightening the locking sleeve in wrong position. With the clips on new shaft the shaft can float a little. Should help. Either new or old style assembly is key. Bearing can't be under any side load. Don't see roller style helping since cage is still there. Plain Ball bearing non float style might. Side force ratings would be good info. Need to find out if that's what's in Sidewinder.Would it work better with a spherical roller bearing (jack shaft) in the chain case? Stronger than a ball bearing?

Janne339

TY 4 Stroke Junkie

side forces are culprit either from chassis flex or tightening the locking sleeve in wrong position. With the clips on new shaft the shaft can float a little. Should help.

Maybe the locking sleeve is the problem? The shaft is to tight to the bearing?

Do you no what bearing in the -16 ?

-14 use a PEER

Peer also but no taper on id of inner race since no locking sleeve.Maybe the locking sleeve is the problem? The shaft is to tight to the bearing?

Do you no what bearing in the -16 ?

-14 use a PEER

Janne339

TY 4 Stroke Junkie

Peer also but no taper on id of inner race since no locking sleeve.

Radial internal clearance in the -16 bearing? C3?

Attachments

Its in already and old one I cant see rating on there. I believe it did have C3 rating. Sorry just not sure.Radial internal clearance in the -16 bearing? C3?

Janne339

TY 4 Stroke Junkie

Upgrade to -16 jackshaft

Janne339

TY 4 Stroke Junkie

Start with Parts list for 16 Jackshaft Update. Number 16 and 17 are reverse order in this diagram. Washer Goes Against Gear! Snapring goes on first.

View attachment 117824

View attachment 117805 View attachment 117806

Do you need some extra shims or washers? Or just the washers in the diagram?

I have the new jackshaft, bearings and washers at home. Order the parts in the diagram.

/Janne

Just the parts in diagram. A couple shims were same size as old ones but figured why chance it.

Cannondale, before you upgraded the jackshaft with OEM parts, did you investigate the upgrade offered by OSP? Just wondering. They have posted a removal tutorial on YT. I'm not advertising for them, just finding the best option for me when I do my upgrade this summer.

No. Never looked into that. Is a couple companies making shafts.Cannondale, before you upgraded the jackshaft with OEM parts, did you investigate the upgrade offered by OSP? Just wondering. They have posted a removal tutorial on YT. I'm not advertising for them, just finding the best option for me when I do my upgrade this summer.

Janne339

TY 4 Stroke Junkie

More shims needed?

No. The shims line up the gears. Some play there is good since it puts less strain on the wobble bearing than the old locking collar system. Is definitely more there than mine has though.

Similar threads

- Replies

- 8

- Views

- 3K

- Replies

- 5

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.