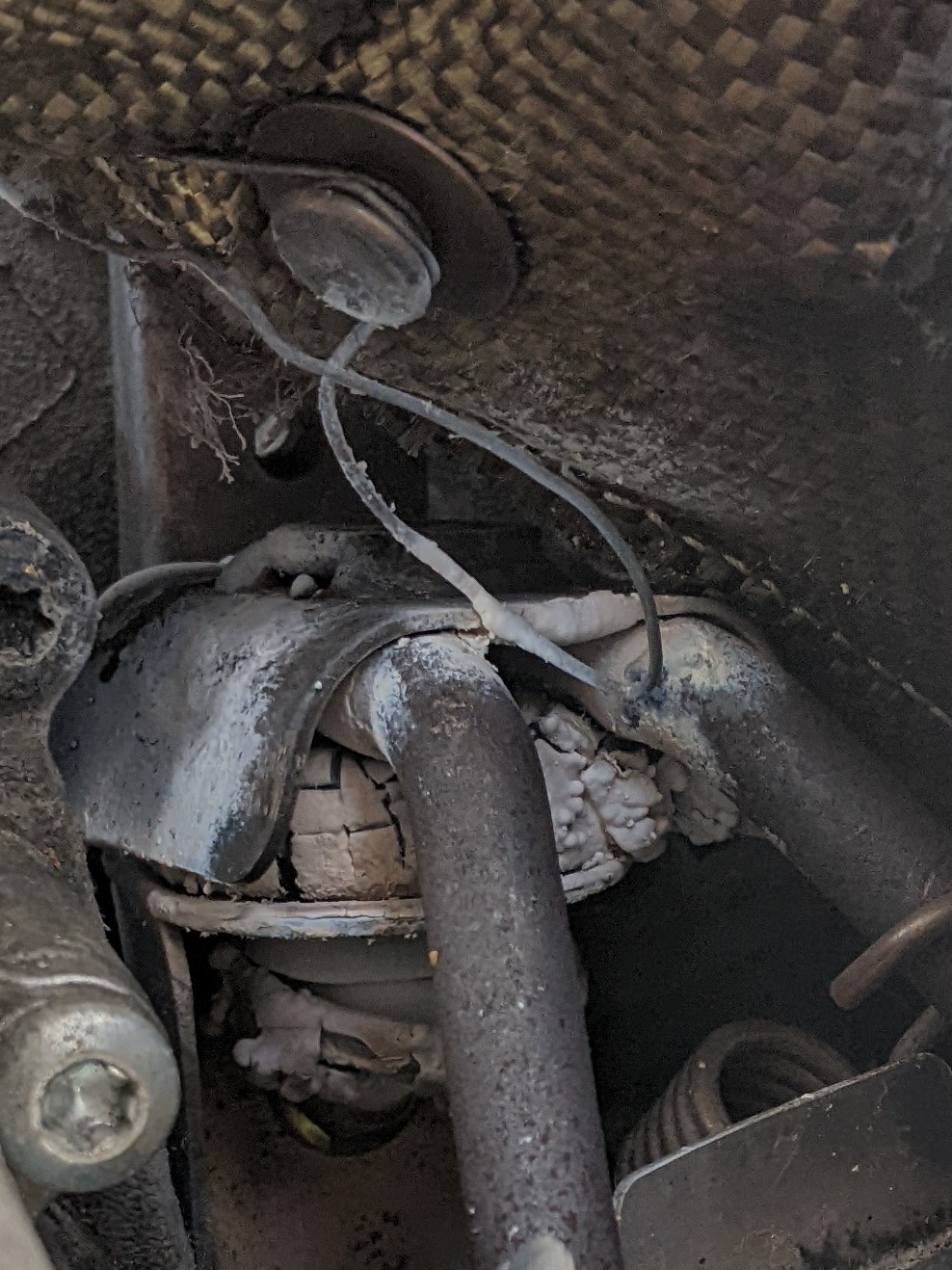

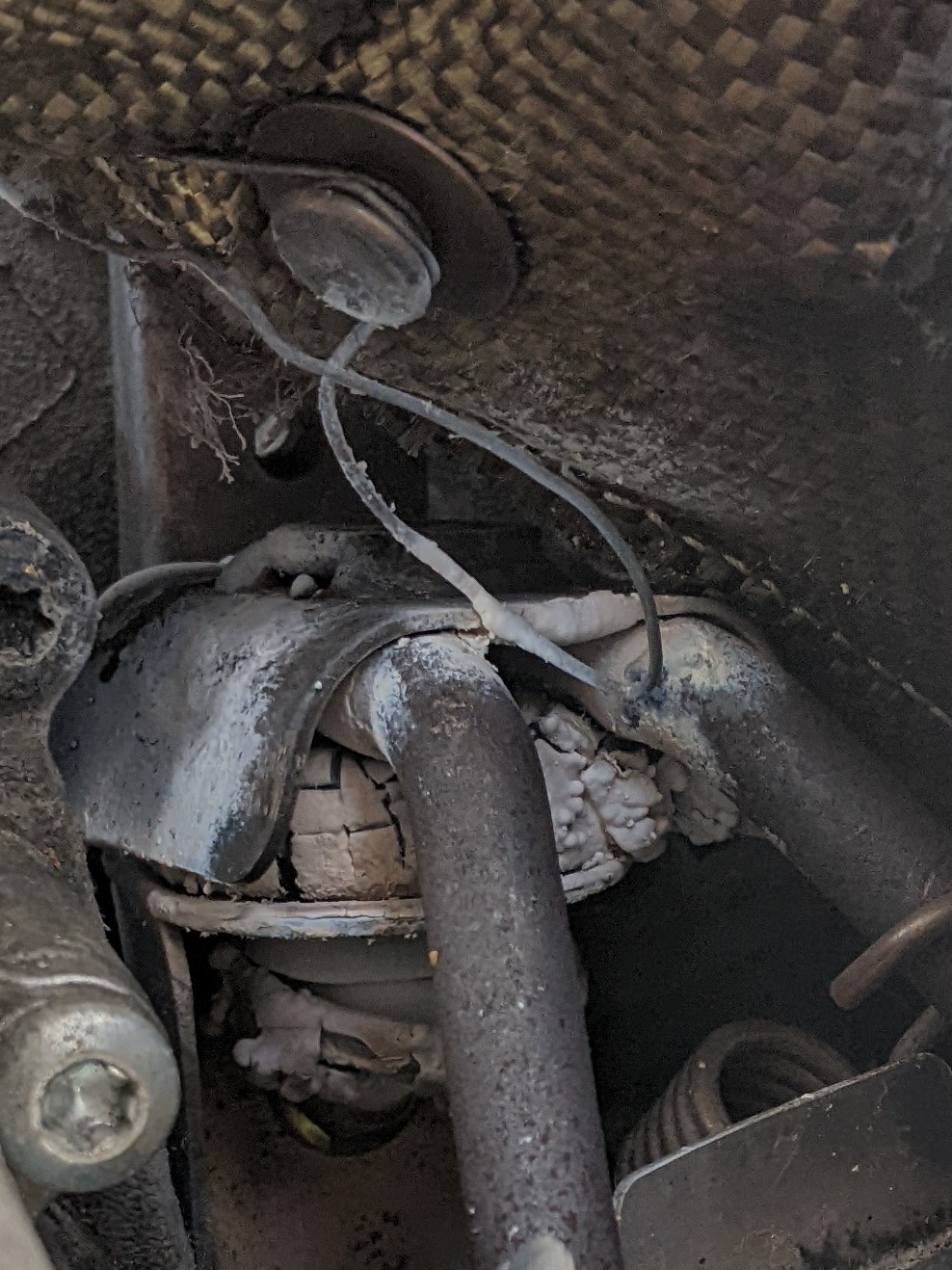

This happened on the railbed running back south after a weekend up in the Munising area (worst trails I have ever ridden on in my life this weekend). We were cruising at 90-95 from Crystal Falls to Watersmeet and when we stopped just outside Watersmeet to wait for the viper in our group, I noticed there was smoke coming out of the vents on the machine. After pulling the side panel there was visible flame below the exhaust. Copious amounts of snow and 1 cracked header later this was the result.

The sled was able to limp the rest of the way home but the header was obviously failed (very loud and no boost). I am guessing the bellows cut loose (again) and shot hot exhaust at the rubber grommet then when I put snow on it to put the fire out it cracked the top side of the header. At least I thoroughly clean the inside of the sled out every year and leave no oil residue anywhere in the machine after service otherwise this would have been much much worse.

I will also note this is the second time the header has failed this year for me. I love the pull the header tunes provide but am seriously considering going away from a header just due to the safety issues of continuous exhaust leaks when it fails.

The sled was able to limp the rest of the way home but the header was obviously failed (very loud and no boost). I am guessing the bellows cut loose (again) and shot hot exhaust at the rubber grommet then when I put snow on it to put the fire out it cracked the top side of the header. At least I thoroughly clean the inside of the sled out every year and leave no oil residue anywhere in the machine after service otherwise this would have been much much worse.

I will also note this is the second time the header has failed this year for me. I love the pull the header tunes provide but am seriously considering going away from a header just due to the safety issues of continuous exhaust leaks when it fails.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,226

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

That sucks.

With the fuel tank so close it could end badly very quickly.

With the fuel tank so close it could end badly very quickly.

Exactly, Hence why I was willing to just dump snow on the hot exhaust and turbo area. A new header and turbo is cheaper than a full sled!That sucks.

With the fuel tank so close it could end badly very quickly.

JLR

VIP Member

- Joined

- Dec 6, 2006

- Messages

- 69

- Location

- Winnipeg, Mb

- Country

- Canada

- Snowmobile

- 2011 apex mcx 290, 2018 sidewinder xtx se 137 precision stage 4, 2020 Sidewinder Srx

whose header you running?

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,672

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

So I see you have a Lava header cover on this sled. What I have found is using header wrap actually works against the heat problems on the 998. I have a buddy of a sled out east with a header with header wrap melt thru the tank, while sleds WITHOUT header wrap using the exact same header have zero issues at all with underhood heat or tank issues. Maybe he'll chime in here or maybe he won't, I know he's been real busy.

Also have a sled here local I was working with that always smelled like plastic with header wrap on a new header this season, we took the header wrap off and no more plastic smell... I'd caution anyone with header wrap to remove it. Header wrap also promotes header cracking and breakage!

I had a 998 in here that was owned by a huge turbo race car guy that I installed a header on, we spoke about header and turbo wraps ect. and he said they absolutely do not use wraps or blankets on exhaust systems any longer because of the issues associated with them just like you experienced here. They guy knows his stuff races runs cars with over 4500 HP and has been doing this for years and has done and tried it all. I believe and trust him, especially seeing the consequences now this year on sleds with header wraps. The sled we took of the header wrap on a while ago also delivers a bit more boost now and runs better too. A half pound more boost easily even though the air temps are about 15 degrees warmer out! And no more plastic burning smell to boot.

The header wrap actually takes more time and energy to heat up being it is more mass to the tubes thickness, it also retains heat longer and creates problems. Get rid of the wrap and go back to the stock shielding!

It doesn't matter what brand of header you have, header wrap is not good for it, it will break prematurely.

Also have a sled here local I was working with that always smelled like plastic with header wrap on a new header this season, we took the header wrap off and no more plastic smell... I'd caution anyone with header wrap to remove it. Header wrap also promotes header cracking and breakage!

I had a 998 in here that was owned by a huge turbo race car guy that I installed a header on, we spoke about header and turbo wraps ect. and he said they absolutely do not use wraps or blankets on exhaust systems any longer because of the issues associated with them just like you experienced here. They guy knows his stuff races runs cars with over 4500 HP and has been doing this for years and has done and tried it all. I believe and trust him, especially seeing the consequences now this year on sleds with header wraps. The sled we took of the header wrap on a while ago also delivers a bit more boost now and runs better too. A half pound more boost easily even though the air temps are about 15 degrees warmer out! And no more plastic burning smell to boot.

The header wrap actually takes more time and energy to heat up being it is more mass to the tubes thickness, it also retains heat longer and creates problems. Get rid of the wrap and go back to the stock shielding!

It doesn't matter what brand of header you have, header wrap is not good for it, it will break prematurely.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,226

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Great info!So I see you have a Lava header cover on this sled. What I have found is using header wrap actually works against the heat problems on the 998. I have a buddy of a sled out east with a header with header wrap melt thru the tank, while sleds WITHOUT header wrap using the exact same header have zero issues at all with underhood heat or tank issues. Maybe he'll chime in here or maybe he won't, I know he's been real busy.

Also have a sled here local I was working with that always smelled like plastic with header wrap on a new header this season, we took the header wrap off and no more plastic smell... I'd caution anyone with header wrap to remove it. Header wrap also promotes header cracking and breakage!

I had a 998 in here that was owned by a huge turbo race car guy that I installed a header on, we spoke about header and turbo wraps ect. and he said they absolutely do not use wraps or blankets on exhaust systems any longer because of the issues associated with them just like you experienced here. They guy knows his stuff races runs cars with over 4500 HP and has been doing this for years and has done and tried it all. I believe and trust him, especially seeing the consequences now this year on sleds with header wraps. The sled we took of the header wrap on a while ago also delivers a bit more boost now and runs better too. A half pound more boost easily even though the air temps are about 15 degrees warmer out! And no more plastic burning smell to boot.

The header wrap actually takes more time and energy to heat up being it is more mass to the tubes thickness, it also retains heat longer and creates problems. Get rid of the wrap and go back to the stock shielding!

It doesn't matter what brand of header you have, header wrap is not good for it, it will break prematurely.

So I see you have a Lava header cover on this sled. What I have found is using header wrap actually works against the heat problems on the 998. I have a buddy of a sled out east with a header with header wrap melt thru the tank, while sleds WITHOUT header wrap using the exact same header have zero issues at all with underhood heat or tank issues. Maybe he'll chime in here or maybe he won't, I know he's been real busy.

Also have a sled here local I was working with that always smelled like plastic with header wrap on a new header this season, we took the header wrap off and no more plastic smell... I'd caution anyone with header wrap to remove it. Header wrap also promotes header cracking and breakage!

I had a 998 in here that was owned by a huge turbo race car guy that I installed a header on, we spoke about header and turbo wraps ect. and he said they absolutely do not use wraps or blankets on exhaust systems any longer because of the issues associated with them just like you experienced here. They guy knows his stuff races runs cars with over 4500 HP and has been doing this for years and has done and tried it all. I believe and trust him, especially seeing the consequences now this year on sleds with header wraps. The sled we took of the header wrap on a while ago also delivers a bit more boost now and runs better too. A half pound more boost easily even though the air temps are about 15 degrees warmer out! And no more plastic burning smell to boot.

The header wrap actually takes more time and energy to heat up being it is more mass to the tubes thickness, it also retains heat longer and creates problems. Get rid of the wrap and go back to the stock shielding!

It doesn't matter what brand of header you have, header wrap is not good for it, it will break prematurely.

That is great info, I had gone to the lava wrap because the stock heatshield broke on me. It seemed like the additional shielding would help but if it is just going to hurt the thing more I will be going back to a stock shield.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,672

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

That is great info, I had gone to the lava wrap because the stock heatshield broke on me. It seemed like the additional shielding would help but if it is just going to hurt the thing more I will be going back to a stock shield.

I understand totally, but after experiencing this heat issue and having a hand in how it shook out, along with talking with my turbo race car buddy, I am absolutely no longer ever going to wrap or insulate the exhaust systems with nothing but the factory type shielding. The wraps and blankets are problematic and the tank is just too close to chance it. Still hard for me to believe, but the wraps and blankets hold the heat and make things hotter that are in close proximity like the fuel tank! Air gaps, airflow and shielding are the ticket in this case.

I always knew the wrap would promote breakage of the exhaust system, but figured the wraps would insulate the underwood temps better, but in this case of the 998's, I absolutely see quite the opposite of what I thought to be true on the idea on all fronts. The wraps are actually dangerous on the 998 application.

I have another client that wanted the header wrapped, so I did it, I tested the sled and could smell plastic, but I figured it was the new muffler we just put on it, I could see the plastic belly pan melting at the outlet, so figured that was the plastic smell, I texted him this morning after seeing this and asked if he still smelled plastic, he said he did always, so I told him to get the sled over here so I can remove the header wrap on it, I'm 100% certain that after I cut the header wrap off, that it will get rid of the plastic burning smell he's still having and he will no longer have the heat issues.

We replaced the stock shields on the first sled I did because the header wrap absolutely had them discolored, baked and broken up beyond repair. There expensive to replace, but they work!

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

On my second season running the header without wrapping it. No issues. I do have additional fire wall heat material added where the two heat shields come together.

Last edited:

Put a new heat shield on mine and it cracked and broke within 450 miles this year and the original lasted over 3000 miles wasn’t impressed.

Bought a new header blanket it doesn’t cover the entire header it’s the same size as the stock shield.

I don’t see it holding a lot more heat then the factory shield unless you wrap the three pipes with header wrap and the whole pipe and flex joint and use the blanket all together.

Aftermarket headers will crack after 3000 plus miles of hard rough trail driving with the stock shield

Bought a new header blanket it doesn’t cover the entire header it’s the same size as the stock shield.

I don’t see it holding a lot more heat then the factory shield unless you wrap the three pipes with header wrap and the whole pipe and flex joint and use the blanket all together.

Aftermarket headers will crack after 3000 plus miles of hard rough trail driving with the stock shield

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

How much do the louvers in the top of the tunnel help with keeping the exhaust cooler using the stock shields?

Does the track create a vaccum to pull the heat out of that area?

I feel that the upper heat shield acts like a scoop to direct air thru that area and down out thru the tunnel louvers.

Does the track create a vaccum to pull the heat out of that area?

I feel that the upper heat shield acts like a scoop to direct air thru that area and down out thru the tunnel louvers.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

The plastic area between the factory frog skin vents i opened up and installed frog skin material to allow more air flow thru the secondary intercooler. Brings in huge amounts of cooler air under the hood.

I didnt take a picture with the screen installed.

I didnt take a picture with the screen installed.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,672

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

How much do the louvers in the top of the tunnel help with keeping the exhaust cooler using the stock shields?

Does the track create a vaccum to pull the heat out of that area?

I feel that the upper heat shield acts like a scoop to direct air thru that area and down out thru the tunnel louvers.

Exactly my thoughts too. I believe all this to be true and an effective means of cooling the pipe and under the tank area.

I know wrapping the header with wrap was not the right thing to do with certainty. I feel it reduced and eliminated the air blowing past the pipe and made it run much hotter, holding in the heat around this whole area and literally baked the heat shielding and burned the hole in another members tank from out east. The sleds with no wrapping have no such issues with the exact same header.

I will say this, I did not have the header wrapped directly, only had the blanket on it. Still saw this failure. Probably going to be a couple weeks before I can get up north with a trailer and bring the sled back to the shop to even start tearing into it to find out how bad exactly this failure was.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

I will say this, I did not have the header wrapped directly, only had the blanket on it. Still saw this failure. Probably going to be a couple weeks before I can get up north with a trailer and bring the sled back to the shop to even start tearing into it to find out how bad exactly this failure was.

Were you at the Jack Pine lodge on Saturday?

Similar threads

- Replies

- 33

- Views

- 3K

- Replies

- 19

- Views

- 6K

- Replies

- 21

- Views

- 2K

- Replies

- 13

- Views

- 1K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.