Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I feel the washer/tool I made is far from complex, so pitch your philosophy to someone else who cares.Innovation is good............... to an extent. I work as an electrical engineer doing research at a University and one important principle that I teach students is to keep things simple or the KISS principle.

KISS, a backronym for "keep it simple, stupid", is a design principle noted by the U.S. Navy in 1960. The KISS principle states that most systems work best if they are kept simple rather than made complicated; therefore simplicity should be a key goal in design, and that unnecessary complexity should be avoided.

View attachment 144097

Merry Christmas by the way.

Last edited:

grizztracks

TY Advertiser

- Joined

- Feb 24, 2005

- Messages

- 3,117

- Reaction score

- 972

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Adding even one additional component to a system makes it more complex. Nothing against you for trying to be innovative but this idea is not new and I'm not a fan of any of the other versions either. Keep at it. You never know when a useful idea will pop up.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

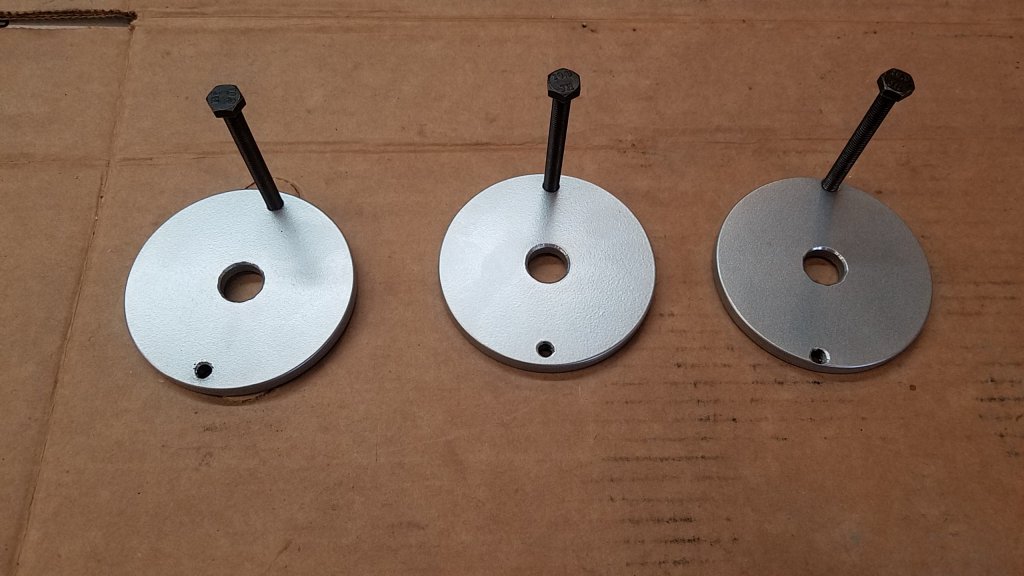

I removed the stock, thick washer from the 14mm retaining bolt, and replaced it with my 3-1/4" cut-out. That's about as non-complex as it can get. I lost about 1/8" of bolt thread engagement into the jackshaft; easily corrected with a longer bolt if necessary.Adding even one additional component to a system makes it more complex.

There are a handful of add-on belt tools available that I think are well made and useful to many. I'm simply trying, however, to show how you can produce a simple, home made tool in the garage; hence the DIY in the title. I love taking the time to display this kind of work and nowhere did I claim credit as the originator of this idea.

At least one OEM manufacturer thought a belt changing tool was a good idea, as there is a belt changing & deflection setting feature built into the pulley of this mid-90's snowmobile pictured below. I'm not sure they were even creators of this idea, but I do know of at least one other company that's been using a similar, built-in feature for years.

You've made it clear that you have an issue with this style of belt adjuster/changing tool, so please take your arrogant philosophy and move on!

Last edited:

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,061

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

A bigger washer is about as simple as it gets.

Although i've never needed a belt removal tool for my Apex, my Sidewinder is almost impossible without a tool.

And i've changed A LOT of belts on it. The belt guard is tight to the clutch & isn't removable in the field.

I torque my helix on, so if i use a 12mm wrench on one bolt, it could get out of torque. It's also hard to push the helix while turning a wrench.

I think Mr Red Beard has used the KISS method and "engineered" a great tool for HIM.

Although i've never needed a belt removal tool for my Apex, my Sidewinder is almost impossible without a tool.

And i've changed A LOT of belts on it. The belt guard is tight to the clutch & isn't removable in the field.

I torque my helix on, so if i use a 12mm wrench on one bolt, it could get out of torque. It's also hard to push the helix while turning a wrench.

I think Mr Red Beard has used the KISS method and "engineered" a great tool for HIM.

titanrcr

TY 4 Stroke Junkie

- Joined

- Jan 3, 2011

- Messages

- 587

- Reaction score

- 135

- Points

- 808

- Location

- Old Forge, New York

- Country

- USA

- Snowmobile

- 2019 Sidewinder LTX LE

2015 Viper LTX SE

2011 Apex

A bigger washer is about as simple as it gets.

Although i've never needed a belt removal tool for my Apex, my Sidewinder is almost impossible without a tool.

And i've changed A LOT of belts on it. The belt guard is tight to the clutch & isn't removable in the field.

I torque my helix on, so if i use a 12mm wrench on one bolt, it could get out of torque. It's also hard to push the helix while turning a wrench.

I think Mr Red Beard has used the KISS method and "engineered" a great tool for HIM.

X2, Well Said!

CaptCaper

VIP Member

- Joined

- Jan 1, 2007

- Messages

- 2,274

- Reaction score

- 197

- Points

- 1,283

- Location

- Northern N.H.

- Country

- USA

- Snowmobile

- 2016 RS Vector XTX 1.25 Lug wifes..2013 RS Vector LTX.. 2003 600 VMax Past Machines 3-2007 Attaks 1-2010 Vector LTX.. sorry no Stinkdoos or poo's cats.

Kudo's to the kid who home made the tool... Beat's paying $90 for a couple of them like I needed. I tried the wrench way once and the nut started to over torque.. tricky and still a bit hard. I've always pushed in hand etc and done them but this Vector XTX the other day I couldn't get the darn belt off.. I struggled thru getting the wifes vector ltx off . I used the "wrench" method to get the XTX belt done but ordered Rich's tool right off as I didn't want to deal with it again especially on the trail if I ever needed it done. I'd like to get a Rich's for the LTX as well as I'm always taking the belt off in the season to check for bent studs,etc. Too old to fight it.. If I made it It would be out of wack.

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Reaction score

- 1,501

- Points

- 1,753

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

cracks me up as wellSteve, you crack me up bud! lol

Steve you have a way with inside jokes about the posts only us diehards who read them all would get...thanks makes me chuckle but then again makes me feel good that I am not the only one to read all these posts.....LOL I am NOT THE ONLY WEIRD ONE

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,061

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

cracks me up as well

Steve you have a way with inside jokes about the posts only us diehards who read them all would get...thanks makes me chuckle but then again makes me feel good that I am not the only one to read all these posts.....LOL I am NOT THE ONLY WEIRD ONE

You are not weird!

You are blessed with OCD!

Welcome. We hold session 24 hours a day here on TY.

We will have to give you name. YamadoOCD

livewire_101proof

Extreme

I had a similar piece, same cutout piece but welded a piece of pipe to the one side of it. That way u dont need the 1/4" bolt diging up the helix when u use it. The side with the pipe on it (only like an inch long) will push on the helix instead.

I kinda agree with grizz on the simplicity and never found it needed on other sleds but did this just for my dads viper since it has hardly any room around the secondary for me to get ahold of it, was kind of a pain stock and almost impossible with his clutch kit that had a real stiff secondary spring. In his case that little tool was pretty handy

I kinda agree with grizz on the simplicity and never found it needed on other sleds but did this just for my dads viper since it has hardly any room around the secondary for me to get ahold of it, was kind of a pain stock and almost impossible with his clutch kit that had a real stiff secondary spring. In his case that little tool was pretty handy

radianguy

TY 4 Stroke God

- Joined

- Jan 1, 2007

- Messages

- 1,949

- Reaction score

- 104

- Points

- 1,058

- Location

- Corner Brook Newfoundland, Canada

- Country

- Canada

- Snowmobile

- 2009 Yamaha FX NYTRO XTX 1.75

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I made a handful of these DIY tools to give the guys I ride with!

The threaded holes were changed from 1/4-20 to the more common M6 x 1 found on most Yamaha snowmobiles. In addition, the required 10mm wrench already exists in most Yamaha tool kits.

Powder coated and ready to go!

The threaded holes were changed from 1/4-20 to the more common M6 x 1 found on most Yamaha snowmobiles. In addition, the required 10mm wrench already exists in most Yamaha tool kits.

Powder coated and ready to go!

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

We've been riding the UP for a solid week and given the DIY washer some real-world testing! The secondary bolt has remained tight, although we did loctite the threads. I'm satisfied!

Last edited:

Agman 57

Lifetime Member

- Joined

- Dec 28, 2006

- Messages

- 926

- Reaction score

- 291

- Points

- 1,228

- Location

- Fostoria, Ohio

- Country

- USA

- Snowmobile

- 2018 Apex XTX LE, 50th Ann.

2018 Sidewinder LTX LE, 50th Ann.

2017 Sidewinder BTX LE

1992 V-Max 4 (Modded)

2002 ZR 120 G-daughter's

I want to Thank Redbeard for the DYI belt changing tool.

Just installed mine and tested it out and it works Great.

If I would ever shread a belt, it will be Great to hold the clutch open if it has strands of string from the belt wound up in it!

Hope I never need it, ( it’s on my “18” Apex) but great to have Incase it happens, have a OSP one on my Sidewinder, now maybe I need one on the rest of my sled?

Just installed mine and tested it out and it works Great.

If I would ever shread a belt, it will be Great to hold the clutch open if it has strands of string from the belt wound up in it!

Hope I never need it, ( it’s on my “18” Apex) but great to have Incase it happens, have a OSP one on my Sidewinder, now maybe I need one on the rest of my sled?

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

You're welcome, Dan! Not everyone is capable of twisting a secondary spring on their own. Any form of assistance tool on the secondary is cheap labor, especially when you're 1,000 miles deep into a week of bagger riding, or at night on the side of the trail. Been there!I want to Thank Redbeard for the DYI belt changing tool.

Just installed mine and tested it out and it works Great.

If I would ever shread a belt, it will be Great to hold the clutch open if it has strands of string from the belt wound up in it!

Hope I never need it, ( it’s on my “18” Apex) but great to have Incase it happens, have a OSP one on my Sidewinder, now maybe I need one on the rest of my sled?

VX1R

Lifetime Member

- Joined

- Sep 19, 2004

- Messages

- 2,286

- Reaction score

- 4,724

- Points

- 1,603

- Location

- Inver Grove Heights, MN

- Country

- USA

- Snowmobile

- Ordered: 2025 SW LTX-LE Final Edition

Current Riders:

2018 SW LTX-LE

2002 SRX Custom

Rough Trail: 2023 Lynx Xterrian 900TurboR

Vintage Riders:

1980 Enticer 300 Twin

1986 Inviter

1998 Phazer Mt. Lite

1996 Phazer Mt. Lite Mod

My wife and I got back home yesterday after spending Valentine's Day and the weekend riding in our favorite area; the Keweenaw area of the UP of MI. Nothing says romance like going snowmobiling, right?

When I brought in the mail that collected while we were gone I was happy to see that I was included in Redbeard's circle of friend's as Joe sent me one of his DIY belt changing tools.

He even put a awesome powder coated finish on the washer for a cool custom look. Like I mentioned earlier in this thread, there are some outstanding TY members like Joe who share their great ideas and make this site a valuable asset to us all.

I'm lacking a lot of hand strength when trying to open up the secondary to overcome the spring tension and this tool is perfect and super easy to use. Well done Joe!

When I brought in the mail that collected while we were gone I was happy to see that I was included in Redbeard's circle of friend's as Joe sent me one of his DIY belt changing tools.

He even put a awesome powder coated finish on the washer for a cool custom look. Like I mentioned earlier in this thread, there are some outstanding TY members like Joe who share their great ideas and make this site a valuable asset to us all.

I'm lacking a lot of hand strength when trying to open up the secondary to overcome the spring tension and this tool is perfect and super easy to use. Well done Joe!

Last edited:

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.