Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

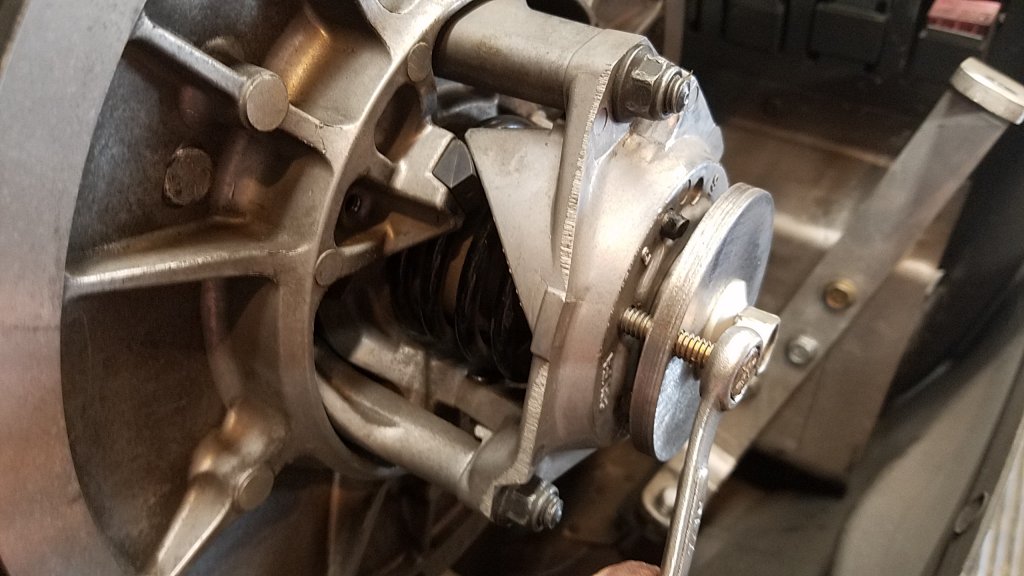

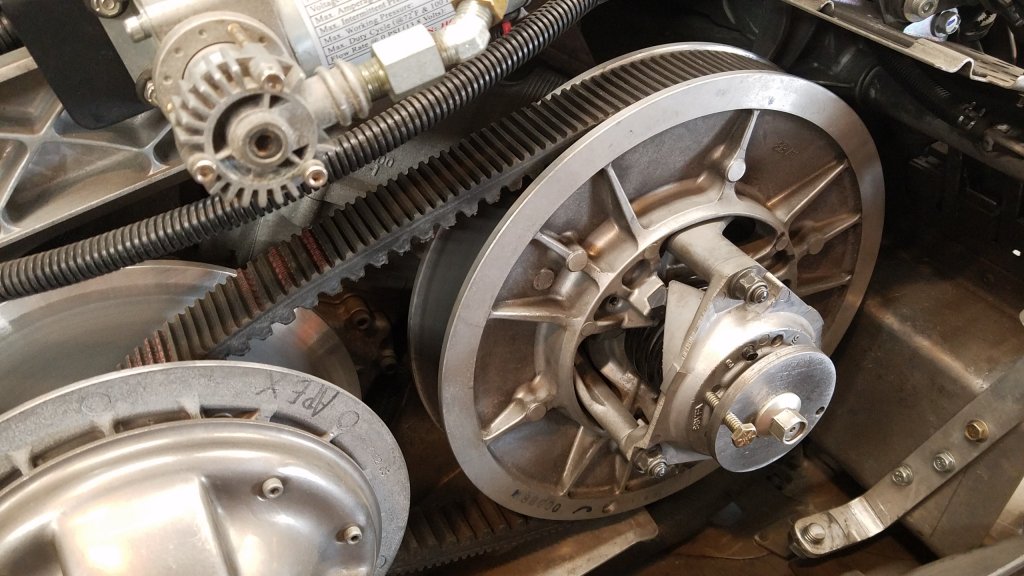

Here is a simple method to produce your own drive belt changing tool at home in the garage with basic tools:

1) Use a 3-1/4" holesaw to cut a circle out of 1/4" flat stock, then drill and tap M6 x 1 bolt holes on the outer edges. Make sure all three holes are in a straight plane.

2) Drill the center hole out to accommodate the diameter of the secondary retaining bolt.

3) Once installed, use a 10mm wrench to turn a fully threaded bolt (50mm length minimum) against the helix and open the sheaves. Only one bolt is needed to open the sheaves. I drilled and tapped a hole on each side in an attempt to maintain balance.

The M6 bolt needs to be removed and stowed in the trunk during operation!

1) Use a 3-1/4" holesaw to cut a circle out of 1/4" flat stock, then drill and tap M6 x 1 bolt holes on the outer edges. Make sure all three holes are in a straight plane.

2) Drill the center hole out to accommodate the diameter of the secondary retaining bolt.

3) Once installed, use a 10mm wrench to turn a fully threaded bolt (50mm length minimum) against the helix and open the sheaves. Only one bolt is needed to open the sheaves. I drilled and tapped a hole on each side in an attempt to maintain balance.

The M6 bolt needs to be removed and stowed in the trunk during operation!

Last edited:

VX1R

Lifetime Member

- Joined

- Sep 19, 2004

- Messages

- 2,287

- Location

- Inver Grove Heights, MN

- Country

- USA

- Snowmobile

- Ordered: 2025 SW LTX-LE Final Edition

Current Riders:

2018 SW LTX-LE

2002 SRX Custom

Rough Trail: 2023 Lynx Xterrian 900TurboR

Vintage Riders:

1980 Enticer 300 Twin

1986 Inviter

1998 Phazer Mt. Lite

1996 Phazer Mt. Lite Mod

The creative abilities of TY members and their willingness to share with other members is what makes TY such a great resource of information.

Really nice job on your DIY belt changing tool Joe.

Looks like I'll be getting my set of hole saws out of hibernation.

Hillbilly engineering at it's finest

Really nice job on your DIY belt changing tool Joe.

Looks like I'll be getting my set of hole saws out of hibernation.

Hillbilly engineering at it's finest

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Thank you, Don!The creative abilities of TY members and their willing to share with other members is what makes TY such a great resource of information.

Really nice job on your DIY belt changing tool Joe.

Looks like I'll be getting my set of hole saws out of hibernation.

Hillbilly engineering at it's finest

The bolt will leave a small scar on the helix, but not bad. Using an old feeler gauge between the bolt and helix would work well and wouldn't take up much space in the trunk either.

Here are a few more pics of my high tech manufacturing process, utilizing a piece of flooring from a grain bin to mark the holes in a straight plane:

Last edited:

Carla 123

TY 4 Stroke Junkie

- Joined

- Feb 27, 2017

- Messages

- 523

- Location

- Lester beach

- Country

- Canada

- Snowmobile

- 2015 viper xtx boosted

17 zr9000 precision stage 3

Nice job

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,360

- Age

- 56

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

The bad news is, you'll never get to use your ingenuitive tool since you drive an Apex.

The good news is, you'll never get to use your ingenuitive tool since you drive an Apex.

The good news is, you'll never get to use your ingenuitive tool since you drive an Apex.

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

Joe good work again

Mooseman

I'm not all knowing. Post your question in forum.

- Joined

- Nov 3, 2009

- Messages

- 3,944

- Location

- Greely, Ontario

- Country

- Canada

- Snowmobile

- '07 Venture MP (gone)

'07 Phazer FX (gone)

'09 Phazer GT (gone)

'10 RS Venture GT (My current ride)

'10 Nytro FX (son's)

- LOCATION

- Greely, ON Canada

Cool tool! Unfortunately wouldn't be able to use it on my sleds neither.

Rockmeister

TY Advertiser

- Joined

- Feb 7, 2007

- Messages

- 2,187

- Location

- NE Indiana

- Website

- www.yamaheater.com

- Country

- USA

- Snowmobile

- 2007 Attak - LOVE my sled!!!

Nice Joe!

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,360

- Age

- 56

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Needs an official name. A catchy name.

1. The Phalangee Saver

2. Red Beards Cold Hands Belt Remover

3. The Circle of Life

4. The Red Rotary Pinky saver

5. The Grain Bin Belt HiJacker

6. TorqueMcPusher

Any more?

1. The Phalangee Saver

2. Red Beards Cold Hands Belt Remover

3. The Circle of Life

4. The Red Rotary Pinky saver

5. The Grain Bin Belt HiJacker

6. TorqueMcPusher

Any more?

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Steve, you crack me up bud! lolNeeds an official name. A catchy name.

1. The Phalangee Saver

2. Red Beards Cold Hands Belt Remover

3. The Circle of Life

4. The Red Rotary Pinky saver

5. The Grain Bin Belt HiJacker

6. TorqueMcPusher

Any more?

CaptCaper

VIP Member

- Joined

- Jan 1, 2007

- Messages

- 2,181

- Location

- Northern N.H.

- Country

- USA

- Snowmobile

- 2016 RS Vector XTX 1.25 Lug wifes..2013 RS Vector LTX.. 2003 600 VMax Past Machines 3-2007 Attaks 1-2010 Vector LTX.. sorry no Stinkdoos or poo's cats.

I just bought the Richmotorsports tool. I think he allows for the washer spacing? I had to remove the large on and install a thinner one .. It works well but it's $45 ..and I need at least 2..ugh..

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,110

- Age

- 60

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

All you need is a 12mm wrench on a helix bolt. The longer the wrench the easier it is and it's about as simple as it gets.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I had never seen the tool you mentioned above. It does look nice and is priced right.I just bought the Richmotorsports tool. I think he allows for the washer spacing? I had to remove the large on and install a thinner one .. It works well but it's $45 ..and I need at least 2..ugh..

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

But I wouldn't have been able to use my grain floor piece as a drill guide??All you need is a 12mm wrench on a helix bolt. The longer the wrench the easier it is and it's about as simple as it gets.

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,110

- Age

- 60

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Innovation is good............... to an extent. I work as an electrical engineer doing research at a University and one important principle that I teach students is to keep things simple.

Last edited:

Similar threads

- Replies

- 7

- Views

- 3K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.