Norse

Pro

- Joined

- Jan 1, 2019

- Messages

- 181

- Location

- Sápmi

- Country

- Norway

- Snowmobile

- 2013 Arctic Cat M1100 HCR 162"

Boondocker turbo 250HP(sold)

2016 Yamaha SR Viper MTX LE 162"

MCXpress 270HP, lots of mods (sold)

2021 Arctic Cat M8000 Hardcore Alpha 155"

N/A (sold)

2023 Yamaha SW MTX LE 153"

M&M Racing 270HP, Elevate, lots of mods

Ignore post #58 because the power will be inconsistent, so measuring the feeding connector won't help. I'm also not sure if it's broken either.

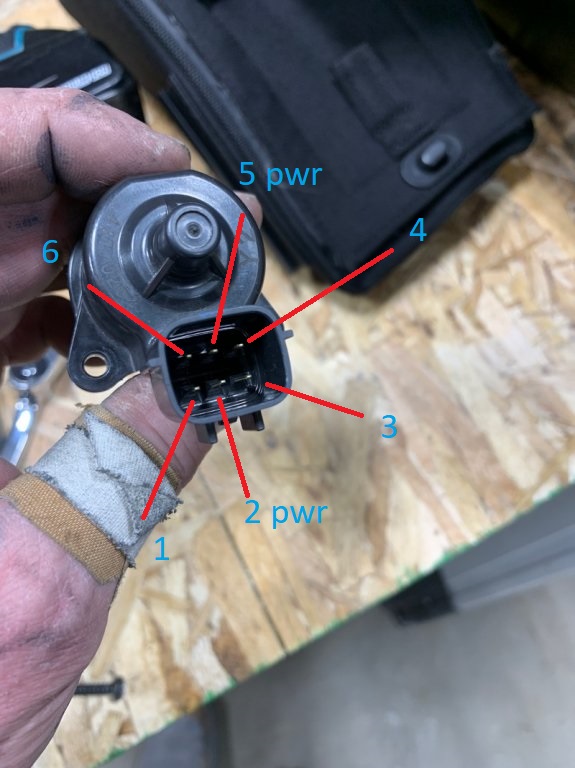

If you measure the ones that aren't pwr, there should only be 2 pairs (not pwr) that have x ohms. For instance if you measure 1-6 X omhs but also 1-3 X ohms, it has a short. I assume the ecu would do a background check on those coils and let you know if they were faulty, so you'd get a code in the dash. And that's assuming. However, from your measurements it sounds like your coils are good. The buzzing could mean something gets it stuck so it needs proper cleaning, it could mean a wire along the way is broken, or something mechanical inside it broke.

Best of luck.

If you measure the ones that aren't pwr, there should only be 2 pairs (not pwr) that have x ohms. For instance if you measure 1-6 X omhs but also 1-3 X ohms, it has a short. I assume the ecu would do a background check on those coils and let you know if they were faulty, so you'd get a code in the dash. And that's assuming. However, from your measurements it sounds like your coils are good. The buzzing could mean something gets it stuck so it needs proper cleaning, it could mean a wire along the way is broken, or something mechanical inside it broke.

Best of luck.

Snorunner

Expert

- Joined

- Jul 17, 2018

- Messages

- 392

- Age

- 65

- Location

- Deerwood

- Country

- USA

- Snowmobile

- 2016 Vector XTX

2017 Vector XTX

2001 Arctic Cat

I will date myself again back in the day an IAC valve used a stepper motor. So the coils would create a magnetic field to pull in the valve. And create a magnetic field in the opposite direction to pull out the valve. So has this changed. Is the Ecu sending opposing signals to make it move in both directions?

Norse

Pro

- Joined

- Jan 1, 2019

- Messages

- 181

- Location

- Sápmi

- Country

- Norway

- Snowmobile

- 2013 Arctic Cat M1100 HCR 162"

Boondocker turbo 250HP(sold)

2016 Yamaha SR Viper MTX LE 162"

MCXpress 270HP, lots of mods (sold)

2021 Arctic Cat M8000 Hardcore Alpha 155"

N/A (sold)

2023 Yamaha SW MTX LE 153"

M&M Racing 270HP, Elevate, lots of mods

It's a stepper motor, but not the good old 4 wire, 2 coils. This one probably has 4 coils for more precise adjustment. 2 coils connected together, but with 1 power wire between them. Then 2 signal wires on each side. In that case measuring would be done from the middle pins (2 or 5) to the pins on the sides. If they're all good then something is either jamming the valve or it ain't getting power.I will date myself again back in the day an IAC valve used a stepper motor. So the coils would create a magnetic field to pull in the valve. And create a magnetic field in the opposite direction to pull out the valve. So has this changed. Is the Ecu sending opposing signals to make it move in both directions?

Ignore post #61 lol wrong again.

Snorunner

Expert

- Joined

- Jul 17, 2018

- Messages

- 392

- Age

- 65

- Location

- Deerwood

- Country

- USA

- Snowmobile

- 2016 Vector XTX

2017 Vector XTX

2001 Arctic Cat

It's a stepper motor, but not the good old 4 wire, 2 coils. This one probably has 4 coils for more precise adjustment. 2 coils connected together, but with 1 power wire between them. Then 2 signal wires on each side. In that case measuring would be done from the middle pins (2 or 5) to the pins on the sides. If they're all good then something is either jamming the valve or it ain't getting power.

Ignore post #61 lol wrong again.

Thanks for the reply. Interested because I am pondering switching to the Procross chassis. Ergonomics and modifications to make it more ergonomic. And want to know what I might be up against in the future! I have been sold on the 4 Stroke Yamaha ever since I switched!

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

It's a stepper motor, but not the good old 4 wire, 2 coils. This one probably has 4 coils for more precise adjustment. 2 coils connected together, but with 1 power wire between them. Then 2 signal wires on each side. In that case measuring would be done from the middle pins (2 or 5) to the pins on the sides. If they're all good then something is either jamming the valve or it ain't getting power.

Ignore post #61 lol wrong again.

That’s absolutely correct, it’s two coils each with a center tap. It’s identical to a Mitsubishi IAC valve. It’s common for them to stick and read ohms perfectly fine.

Try the new nytro IAC

picasso

Expert

- Joined

- Nov 11, 2014

- Messages

- 255

- Age

- 52

- Location

- Holland, Michigan

- Country

- USA

- Snowmobile

- SR Viper R-TX DX

One pin must be for making cave open, the other to close it? Wonder why there would be 6 pins?

picasso

Expert

- Joined

- Nov 11, 2014

- Messages

- 255

- Age

- 52

- Location

- Holland, Michigan

- Country

- USA

- Snowmobile

- SR Viper R-TX DX

Ignore my previous, just seen above comments. My motor/valve is definitely broken. The shaft came out. Won’t stay in either. It falls out

picasso

Expert

- Joined

- Nov 11, 2014

- Messages

- 255

- Age

- 52

- Location

- Holland, Michigan

- Country

- USA

- Snowmobile

- SR Viper R-TX DX

So just out curious. What stops the travel on this ? If I pull it out of the housing, and let’s say I cycle the key, will it run the threaded shaft right out of the motor?. Does the housing limit the travel ? Does the motor have something internal to tell it to stop?

Norse

Pro

- Joined

- Jan 1, 2019

- Messages

- 181

- Location

- Sápmi

- Country

- Norway

- Snowmobile

- 2013 Arctic Cat M1100 HCR 162"

Boondocker turbo 250HP(sold)

2016 Yamaha SR Viper MTX LE 162"

MCXpress 270HP, lots of mods (sold)

2021 Arctic Cat M8000 Hardcore Alpha 155"

N/A (sold)

2023 Yamaha SW MTX LE 153"

M&M Racing 270HP, Elevate, lots of mods

Well something has to make it stop, and I bet it's not electrical. Guess it's the throttle body?

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

So just out curious. What stops the travel on this ? If I pull it out of the housing, and let’s say I cycle the key, will it run the threaded shaft right out of the motor?. Does the housing limit the travel ? Does the motor have something internal to tell it to stop?

All of the IAC’s I have seen have the stop built in. Plunger should not come out.

picasso

Expert

- Joined

- Nov 11, 2014

- Messages

- 255

- Age

- 52

- Location

- Holland, Michigan

- Country

- USA

- Snowmobile

- SR Viper R-TX DX

Hoping so. Mine, just slipped right out. Thought maybe some one has first hand experience. Because these are so hard to come by, don’t want to experiment around too much. Lol

fxnytrortxkid

TY 4 Stroke God

- Joined

- Apr 19, 2007

- Messages

- 1,582

- Age

- 43

- Location

- Rensselaer, ny

- Country

- USA

- Snowmobile

- 09 nytro rtx

Nope it goes out stops and returns. Make a stoke about 1/4” long (in and out)

picasso

Expert

- Joined

- Nov 11, 2014

- Messages

- 255

- Age

- 52

- Location

- Holland, Michigan

- Country

- USA

- Snowmobile

- SR Viper R-TX DX

Alright, finally got an IAC valve. I ended up buying a brand new throttle body to get this. I tried finding a used one, no luck. Tried getting a Nytro one, no luck. So... ordered the new one. Good news- it solved my issue. Sled starts with just a turn of the key. Bad news- I have a brand new throttle body that I don’t need.

I still don’t know if a 2008 Nytro IAC valve will work in a 2015 viper. I’d like to know.

I still don’t know if a 2008 Nytro IAC valve will work in a 2015 viper. I’d like to know.

Stormbringer

Extreme

- Joined

- Jun 5, 2018

- Messages

- 109

- Location

- Valparaiso Indiana

- Country

- USA

- Snowmobile

- 18 sidewinder rtx 15 viper rtx

Sorry about your expense. One way you can look at it, if you had let them fix it it would have cost you a lot more (parts and labor). And who knows what else would they have sold you.

picasso

Expert

- Joined

- Nov 11, 2014

- Messages

- 255

- Age

- 52

- Location

- Holland, Michigan

- Country

- USA

- Snowmobile

- SR Viper R-TX DX

Good point! Lol!Sorry about your expense. One way you can look at it, if you had let them fix it it would have cost you a lot more (parts and labor). And who knows what else would they have sold you.

I think I’m still going to order an IAC valve for the Nytro. It’s on back order with a March date. I really want to know if it will work in the Viper. I still have the other sled that occasionally starts hard at a cold start. It’s not as bad as my sled. Since I’m pissing money away!

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 29

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.