dirkdiggler

Suspended

Hmm That sucks. Sorry about that

vice108

TY 4 Stroke Junkie

Ouch!

The studs are probably seated just fine. There were several posts last year of guys having the same issue with their 05 RX1s. The mono skid is great - but you cant stud the very middle like you could with a pro-action. I spent a lot of time this preseason drawing up my own 144 pattern to avoid studding the center.

The studs are probably seated just fine. There were several posts last year of guys having the same issue with their 05 RX1s. The mono skid is great - but you cant stud the very middle like you could with a pro-action. I spent a lot of time this preseason drawing up my own 144 pattern to avoid studding the center.

I too studded mine so that there were no studs right over the shock but that still does not excuse the way the track rubs on this very expensive shock. This has been a big concern of mine since I brought my sled home, there was a rub mark all the way around my track just from loading it at the dealer. Judging by the way they are handling the hand warmer issue, I am sure they will jump all over replacing a 1200.00 shock, especially if you have studded your track.

suprfst

Lifetime Member

- Joined

- Dec 4, 2004

- Messages

- 727

- Reaction score

- 8

- Points

- 973

- Location

- Tawas Michigan

- Website

- www.smcfabrication.com

As ulmer had said earlier the track is only supported at the edges.I think track tension plays a big part in how far it will wear into the shock.Ive been running my 05 on the loose side(just tight enough so it doesnt ratchet) since I got it.I have studs in the very center and I do have some wear on the shock but very little.The tighter the track is the closer its going to pull the track to the shock.

ripsawsam

Newbie

- Joined

- Nov 26, 2005

- Messages

- 18

- Reaction score

- 0

- Points

- 451

Sounds like your studs are not below flush with the track

did use mis match manufacturers between studs and backers ??

the only way for the stud to rub is if the head is sticking out from the track

all mine are below flush. ??

did use mis match manufacturers between studs and backers ??

the only way for the stud to rub is if the head is sticking out from the track

all mine are below flush. ??

yammiman

Expert

What about the pads? - are they or were they there? - if not, that has to play a major role in the problem - are they wearing out too soon like some of the boogie wheels we are reading about? - just my 2 cents

welterracer

TY 4 Stroke God

Ive got 650 miles on mine with studs right up the middle and NO wear on the shock..

I guess im just lucky!

I guess im just lucky!

SRXracer

Expert

I tend to agree that it looks like those studs are not tight enough. On a couple of them it looks like you can see the whole side edge of the base of the stud. How tight are you putting them on? They should be warping the bottom of the track some, at least that is how we have always done ours. We always put ours in with a airwrench, and tighten pretty much till they stop turning. Although i don't think we would turn the wrench down a notch from full power. I am using the angled backers on the GT, i will check it next time i am over at the shop and see what mine looks like.

chrishall

Pro

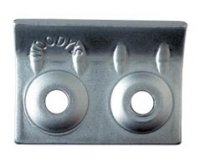

Sorry guys, I was bashing a different type of backer. These are backers with a 45 dregree bend in them. These are the ones that don't work at all. They bend up to the point where they no longer come in contact with the back lug and I had to change out all the double backers because 3/4 of them had broke in 2. These are just added weight that you shouldn't use.

Cheers,

Chris

Cheers,

Chris

Attachments

Bossman said:I agree with QCRider and I also have been studding tracks for 20 years and have always had picks in the middle with no problems. Almost every pattern I have every seen uses studs down the middle. The template we use has it set so you can use the double backer right in the center.

Hey, we've all been studding tracks for over 20 years. I always thought it was common knowledge to stay off the center two inches of the track.

YammiMoose said:BA APEX said:Rotax! said:Is it me or... I can see the whole head of the stud. They don't look like they are seated very well....

.

I noticed that too.

QCRider

TY 4 Stroke Master

- Joined

- Feb 27, 2004

- Messages

- 1,032

- Reaction score

- 2

- Points

- 0

- Location

- Seacoast Region, New Hampshire

- Website

- www.myspace.com

steve 05 RX-1 said:As ulmer had said earlier the track is only supported at the edges.I think track tension plays a big part in how far it will wear into the shock.Ive been running my 05 on the loose side(just tight enough so it doesnt ratchet) since I got it.I have studs in the very center and I do have some wear on the shock but very little.The tighter the track is the closer its going to pull the track to the shock.

I think you are onto something here. I also run my track loose, it is studded with 168 studs and I have no damage.

ReX

TY 4 Stroke God

Under throttle the track will always be pulled very tight along the top, causing it to pull closer to the shock. I don't think running it loose is the answer (but too tight will make it a little worse).

I'm running the woodys pre-punched ripsaw which has stud holes very close to the middle and I did install all 144 studs. My skid seems worse for this than a buddies Apex. My track just touches the shock just sitting there. His Apex has about 1/8" of clearance.

Although the track is rubbing the shock/rear arm bracket, the shock doesn't seem to be wearing any quicker than last year. I made sure the studs were tightened on the tight side of things - tight enough that the track slightly bulges outwards between the two and keeps the studs from really hitting.

In reality my studs must be lightly touching every now and then as there is a bit of a clicking every once in a while and it was worse before I retorqued the studs to 15 ft-lbs (did it 3 times each after a few 100 kms).

I'm running the woodys pre-punched ripsaw which has stud holes very close to the middle and I did install all 144 studs. My skid seems worse for this than a buddies Apex. My track just touches the shock just sitting there. His Apex has about 1/8" of clearance.

Although the track is rubbing the shock/rear arm bracket, the shock doesn't seem to be wearing any quicker than last year. I made sure the studs were tightened on the tight side of things - tight enough that the track slightly bulges outwards between the two and keeps the studs from really hitting.

In reality my studs must be lightly touching every now and then as there is a bit of a clicking every once in a while and it was worse before I retorqued the studs to 15 ft-lbs (did it 3 times each after a few 100 kms).

Bossman

Expert

Wolfie if it common knowledge to stay off the center then why is it that the templates woodies gives you show studs in the center. Unfortinately studs in tracks are not always installed properly and some product might not just work with new designs of suspensions. Watching your track tension with stud is very important. From the looks of these pictures the degree of his damage is probably caused be the fact that the studs cant be sucked flush into the track because of the angled backers. Im not going to tell anyone how to stud there own track but there is no reason you shouldnt be able to run picks in the center of the track unless there is a design flaw in the suspension. Could the support pads from the Attak be used on the Apex?

QCRider

TY 4 Stroke Master

- Joined

- Feb 27, 2004

- Messages

- 1,032

- Reaction score

- 2

- Points

- 0

- Location

- Seacoast Region, New Hampshire

- Website

- www.myspace.com

Bossman said:Could the support pads from the Attak be used on the Apex?

GREAT Question!! I asked yesterday on the RX Forum and have yet to see an answer...

Similar threads

- Replies

- 1

- Views

- 936

- Replies

- 10

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.