Nikolai

TY 4 Stroke God

Busy all summer keeping the RZR going every weekend. Leaving in a few days for a hunt then back to the sled. Cleaned the shop and got the frame out to finish the rear motor mounts.

Nikolai

TY 4 Stroke God

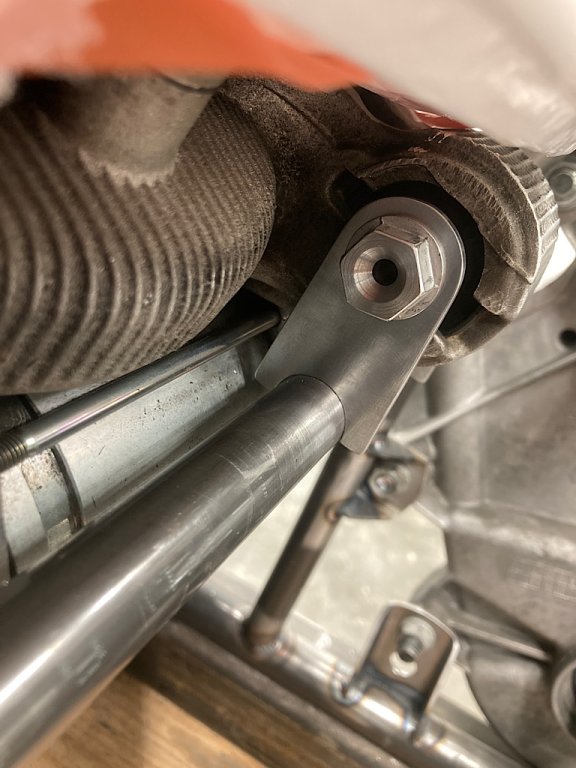

Rear motor mounts tacked in place. Used .090 plate, 0.2 lbs for all 4 tabs.

Some of them are tight but clearing is clearing. Pulled the motor so I can pull the frame from the jig and get them welded up. Also going to weld nuts on the back of the chaincase tabs while the frame is out.

Some of them are tight but clearing is clearing. Pulled the motor so I can pull the frame from the jig and get them welded up. Also going to weld nuts on the back of the chaincase tabs while the frame is out.

Nikolai

TY 4 Stroke God

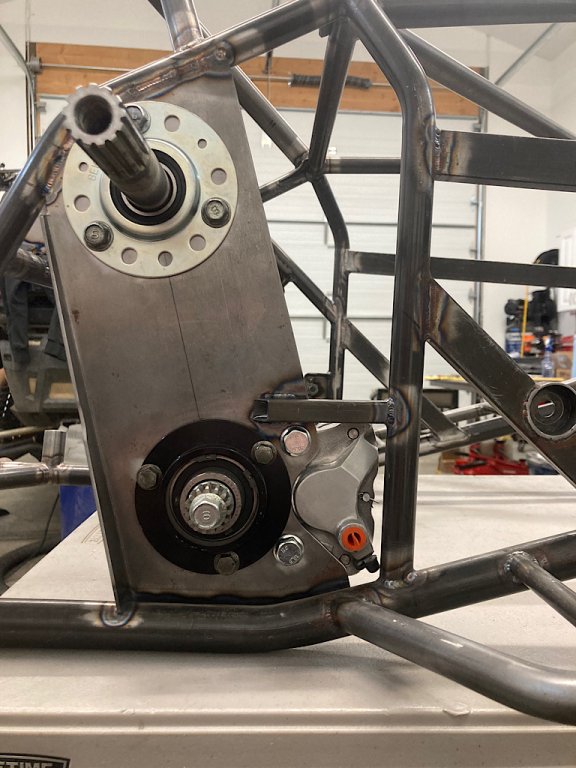

Tack welded nuts to the backside of the chaincase tabs. With the narrow tunnel and design of the chassis getting a wrench on the nuts would have been difficult. This will make chaincase installation a breeze. It’s also positioned exactly where I want and there’s pretty much no slop so it takes the guesswork out of getting the alignment correct each time.

Rear motor mount tabs welded. Only welded one side. From my experience with the front mounts the tabs get hot and then makes welding the other side difficult due to contamination. I don’t think I will have any issues and if I do after time then it’s easy enough to fix.

Next is to make a mount for the speedo gear sensor, add the brace/gusset behind the driven clutch and then finally wrap up the steering post.

Rear motor mount tabs welded. Only welded one side. From my experience with the front mounts the tabs get hot and then makes welding the other side difficult due to contamination. I don’t think I will have any issues and if I do after time then it’s easy enough to fix.

Next is to make a mount for the speedo gear sensor, add the brace/gusset behind the driven clutch and then finally wrap up the steering post.

Nikolai

TY 4 Stroke God

Could not decide to what to do on clutch side to stiffen plate so I just welded a short piece of 1/2 x .035 square tube on. Took the little bit of flex out of the brake caliper. If it’s not enough down the road I can weld a vertical piece of 1/2 in if it becomes necessary.

Nikolai

TY 4 Stroke God

Need some opinions on steering bushing material. This is for the steering arm.

1. Oilite bushing over aluminum sleeve

2. Oilite bushing over 4130 steel sleeve

3. UHMW bushing over aluminum sleeve

4. UHMW bushing over 4130 steel sleeve

Lightest is UHMW, but not sure what would be “best”. Both bushing and sleeve will be replaceable.

1. Oilite bushing over aluminum sleeve

2. Oilite bushing over 4130 steel sleeve

3. UHMW bushing over aluminum sleeve

4. UHMW bushing over 4130 steel sleeve

Lightest is UHMW, but not sure what would be “best”. Both bushing and sleeve will be replaceable.

Brotherdan

Expert

- Joined

- Sep 8, 2017

- Messages

- 366

- Age

- 52

- Location

- Belmont,maine

- Country

- USA

- Snowmobile

- 2011 apex xtx blue, starr suspension,gytr front shocks,camso 1.5 track cut down, snowtrackers work in process,2003 rx1er originally 121 converted to 136"monoshock 2 ck136 rear suspension with clicker vector ltx shock,muffin works tunnel extension, seat concepts(wrp) seat,apex hooked handlebars converted to all underhood wiring,8"lake effect billet aluminum riser,gytr frontshocks,yamaheater hand warmer kit,rocks ridelite,rocks power supply, rocks heated bag,, tunnel braces,blue skid plate,garmin gps, aggressive snowtrackers on apex single keel skis,rollerski ski wheel kit,108 warthog studs&blue studboy backers,pioneer wheel lowering kit, dupont slides, 4th wheel kit,yamaha saddle, tank& windshield bags, powermadd led handguards, bar mount mirror kit, apex radiator& electric fan added, apex rear cooler,autometer temp guage, apex new style large diameter drive shaft with extroverts machined for chaincase,thunder products clutching,1987 enticer 340ltr 2100miles,1984 enticer 340,1996 wolverine 350,big wheel kit,winch,racks,k&n,full skidplates

My vote is oillite& steel sleeve based on success of bothNeed some opinions on steering bushing material. This is for the steering arm.

1. Oilite bushing over aluminum sleeve

2. Oilite bushing over 4130 steel sleeve

3. UHMW bushing over aluminum sleeve

4. UHMW bushing over 4130 steel sleeve

Lightest is UHMW, but not sure what would be “best”. Both bushing and sleeve will be replaceable.

Nikolai

TY 4 Stroke God

Made some progress on the steering.

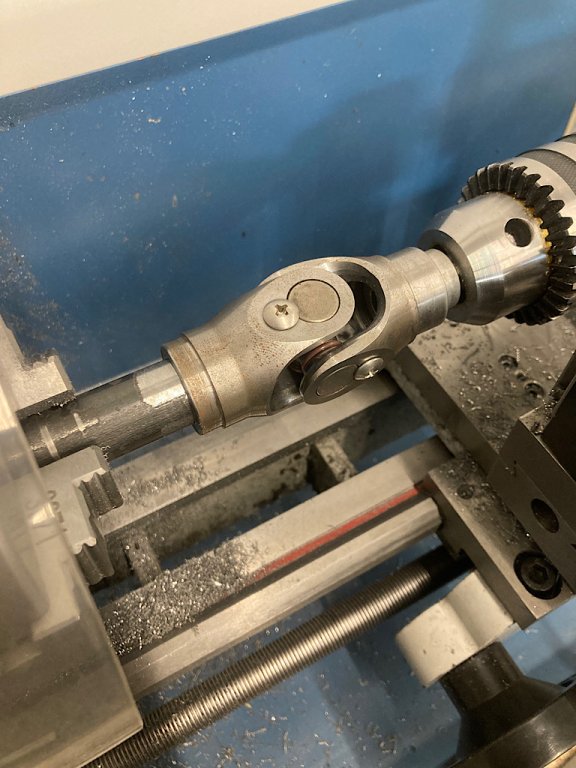

Got the oilite bushing turned down and then cut to length. Shortened it enough to be able to get a puller in between it and the u-joint once it’s welded so the bushing can easily be replaced.

I originally drilled the frame for a 12mm bolt since that’s what Cat and Yamaha use but it seems heavy and overkill to me. Decided to use a 10mm grade 10.9 bolt that I cut down. 10mm bolt & K-nut is only 28g.

The pivot tube is 7/8x.058 chromoly. I made an end cap to fuse on that reduces the frame hole from 12mm to 10mm.

Checking bolt length prior to fusing.

Fused, cut to same length as the oilite bushing and a UHMW cap to keep snow out. Thrust washer so the bushing isn’t directly on the frame.

Checking steering post tube clearance to frame one last time before welding the u-joint into the steering arm.

Bushing setup was pretty light by the time it was all said and done. The oilite bushing, steel pivot tube, bolt & nut are only 112g which is 0.25 lbs.

Got the oilite bushing turned down and then cut to length. Shortened it enough to be able to get a puller in between it and the u-joint once it’s welded so the bushing can easily be replaced.

I originally drilled the frame for a 12mm bolt since that’s what Cat and Yamaha use but it seems heavy and overkill to me. Decided to use a 10mm grade 10.9 bolt that I cut down. 10mm bolt & K-nut is only 28g.

The pivot tube is 7/8x.058 chromoly. I made an end cap to fuse on that reduces the frame hole from 12mm to 10mm.

Checking bolt length prior to fusing.

Fused, cut to same length as the oilite bushing and a UHMW cap to keep snow out. Thrust washer so the bushing isn’t directly on the frame.

Checking steering post tube clearance to frame one last time before welding the u-joint into the steering arm.

Bushing setup was pretty light by the time it was all said and done. The oilite bushing, steel pivot tube, bolt & nut are only 112g which is 0.25 lbs.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,173

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Put a grease fitting on that steering.

It will help with keeping it from freezing up from snow and make it last forever. Talking about that oilite bushing.

It will help with keeping it from freezing up from snow and make it last forever. Talking about that oilite bushing.

Nikolai

TY 4 Stroke God

Put a grease fitting on that steering.

It will help with keeping it from freezing up from snow and make it last forever. Talking about that oilite bushing.

Will do. Is it necessary after drilling the hole to file a small groove lengthwise so grease gets distributed evenly or is just the hole good enough?

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,173

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

I have them in my sidewinder with a added grease fitting and no grooves. Works fine. A inner radius groove with 4 grooves going up and down would help distribute the grease more but I dont think it would be necessary.

Nikolai

TY 4 Stroke God

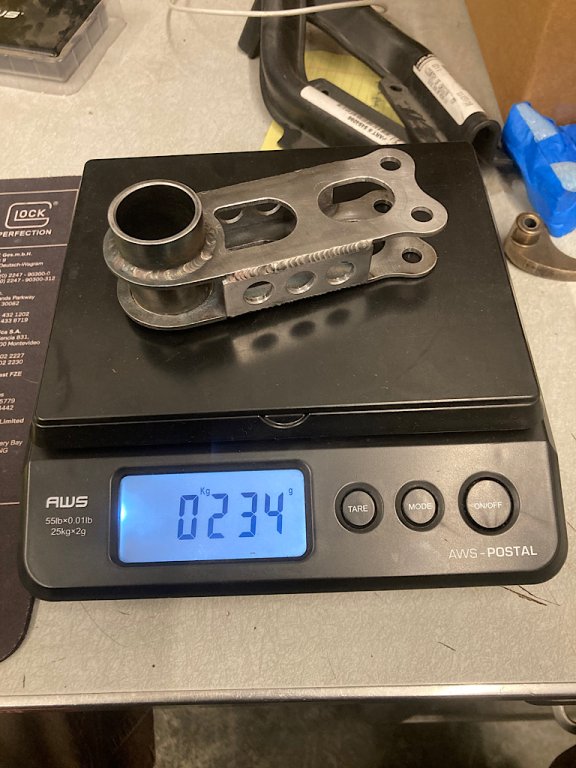

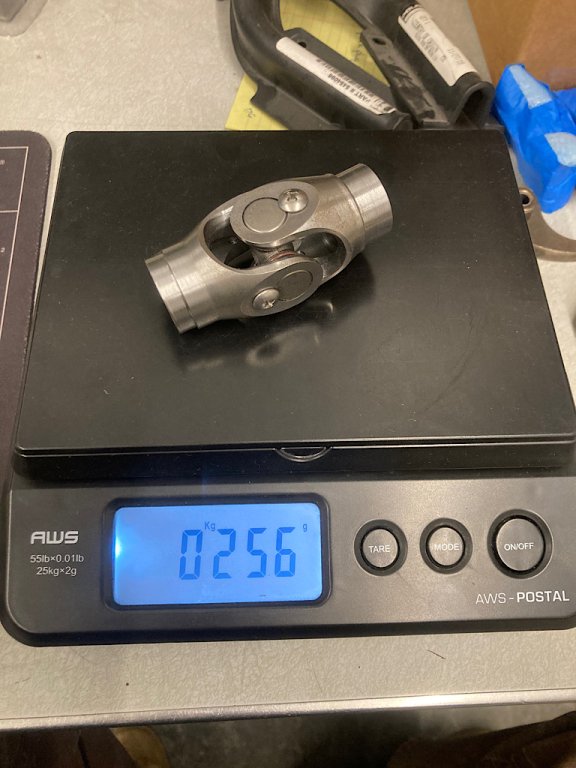

Shaved 13% off the steering arm, from 270g to 234g, enough to offset the weight of the bolt & nut that secure the pivot tube.

Also got the u-joint trimmed down as much as possible on each end.

Finally ready to weld it up.

Also got the u-joint trimmed down as much as possible on each end.

Finally ready to weld it up.

Nikolai

TY 4 Stroke God

U-joint welded to steering arm and added a grease zerk.

Have you considered 3d printing for lightweight parts?

Nikolai

TY 4 Stroke God

No I haven’t. What would/could be 3D printed?

HighSpeedLowDrag

Pro

What is your planned steering ratio? My next plan is to get my apex to 1-1 so the angle of the bars exactly match the angle the skis are pointed.

Similar threads

- Replies

- 4

- Views

- 4K

- Replies

- 32

- Views

- 5K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.