JayM

Expert

- Joined

- Oct 29, 2018

- Messages

- 476

- Reaction score

- 266

- Points

- 488

- Location

- Pickering, ON

- Country

- Canada

- Snowmobile

- 2017 Sidewinder R-TX SE

Be careful,not to much deflection! if you run the belt to tight it will rub inside on the primary shaft before it "squilll"

Just slightly above secondary

For sure, I'm about 1/8th below the top of secondary now.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,612

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

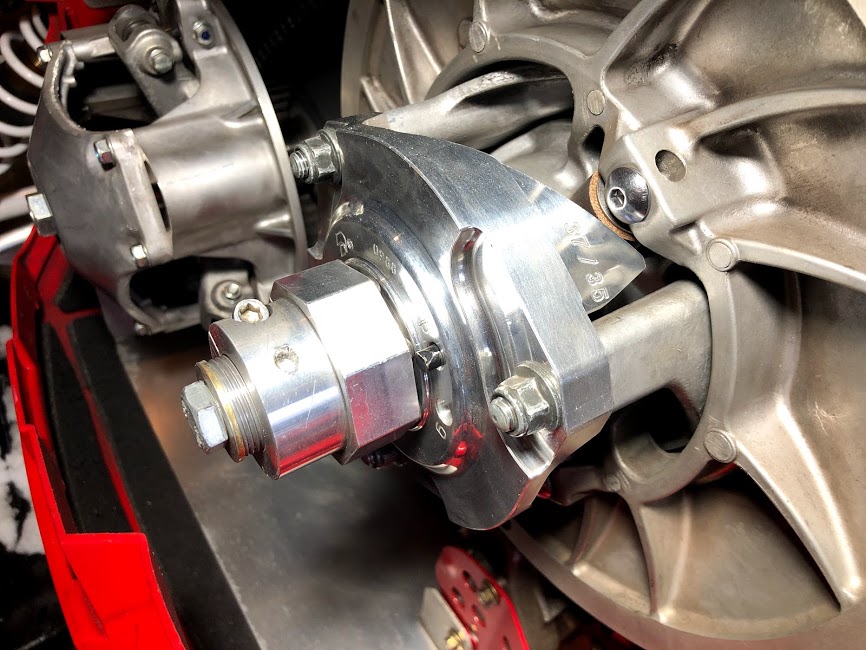

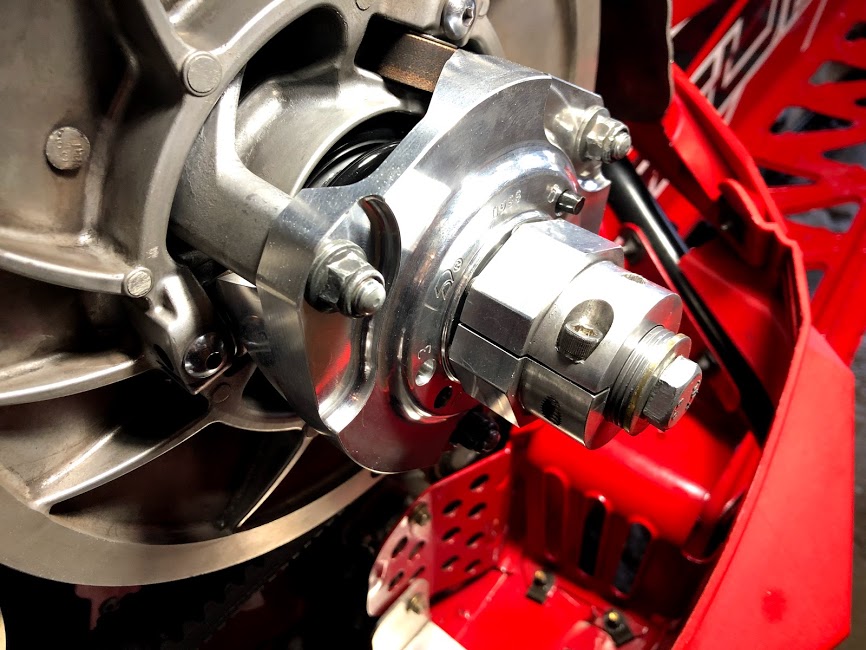

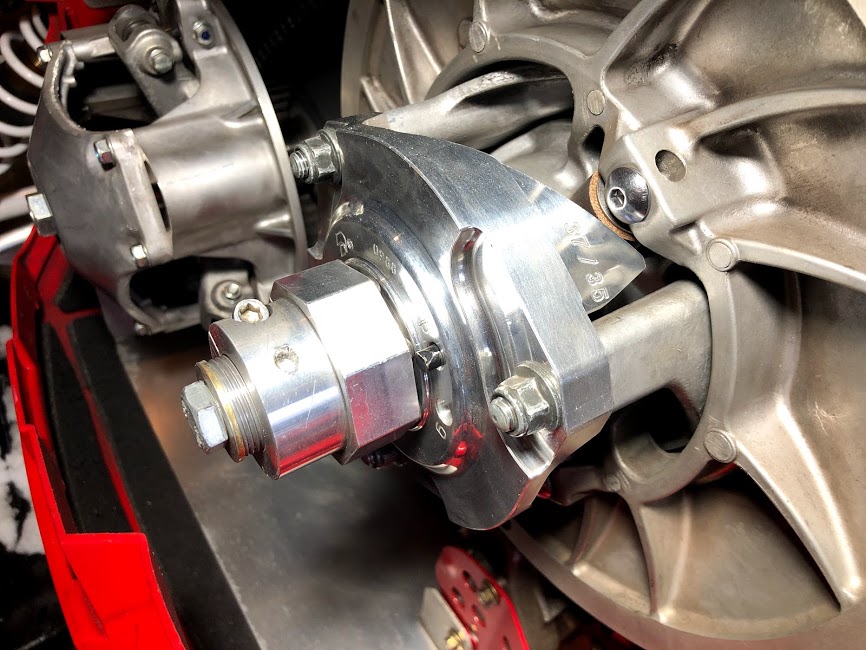

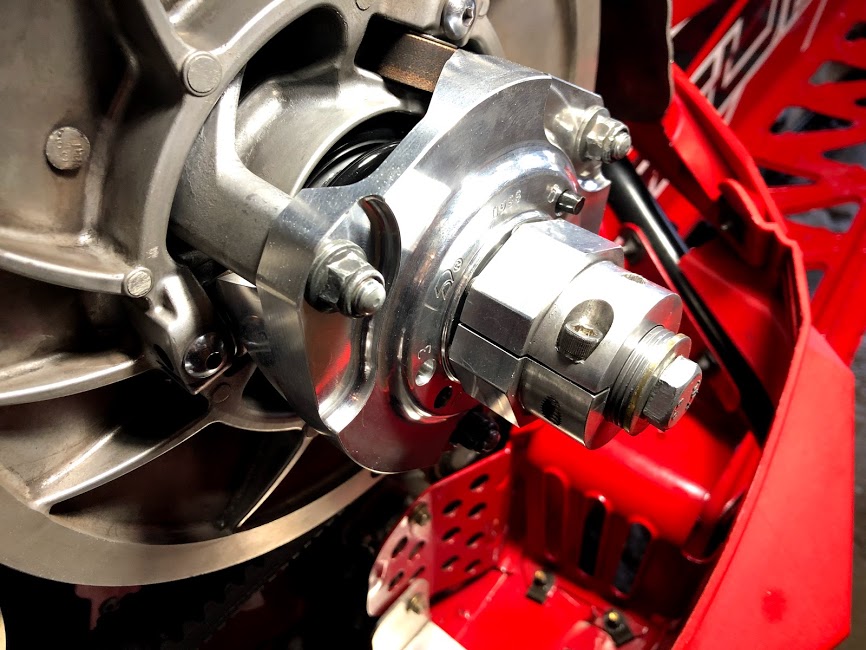

This is how mine is set up.

First I set my offset with the hurricane offset tool.

Second I cut the aluminum plug to be flush with the clutch hub. This is my clutch bolt......The washer next to the aluminum plug holds my clutch from floating. The two small washers are used to set my belt deflection. I don't need to take my clutch apart to adjust deflection.

Make sure the washer used to remove float will fit inside the helix bushing.

I'm running darn near same setup as OP but I like the BOP adjuster, so when I blow a belt I can use the adjuster as a belt change tool, and also it adjusts deflection perfectly. No need for shim washers, just the 4 washers Travis sent with the long bolt.

All my info here:

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/page-34#post-1449153

Large fender style washer to stop float is 35-36mm OD X m10 ID.(approx 2-3mm thickness)

I also use an Apex shim overtop of the float plug, to dial in the float and not side load the bearing.

Dan

Last edited:

Dan, why haven't you put a washer that matches the diameter of the BOP belt adjuster or one slightly smaller? That would bug the crap out of me. Can you actually get enough leverage with that adjuster to change a belt with a stout spring in there?

PowderFalcon

Pinnin' it!

- Joined

- Jan 29, 2007

- Messages

- 990

- Reaction score

- 511

- Points

- 1,358

- Location

- Drumbo, ON

- Country

- Canada

- Snowmobile

- 2021 Sidewinder SRX

i'm running darn near same setup as OP but I like the BOP adjuster, so when I blow a belt I can use the adjuster as a belt change tool, and also it adjusts deflection perfectly. No need for shim washers, just the 4 washers Travis sent with the long bolt.

Large fender style washer to stop float is 35-36mm OD X m10 ID.(approx 2-3mm thickness)

Dan

I’m running same setup Dano! Works mint being able to lock down the secondary and still have the adjustability with Travis’ tool. Love it!

500 miles with nothing but smiles so far running 290hp

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,612

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Not sure what you mean....but this setup is perfect.Dan, why haven't you put a washer that matches the diameter of the BOP belt adjuster or one slightly smaller? That would bug the crap out of me. Can you actually get enough leverage with that adjuster to change a belt with a stout spring in there?

Easily change belts with the allen key, do it all the time.

Dan

Crossfire12

TY 4 Stroke Guru

- Joined

- Feb 13, 2017

- Messages

- 884

- Reaction score

- 543

- Points

- 858

- Location

- New York Adirondacks

- Country

- USA

- Snowmobile

- 2010 Z1 Turbo ,2017 zr9000, F1100 turbo, 700 srx

- LOCATION

- Sacandaga reservoir

First you all want float now you all don’t want float, what’s going ON!!!!!

First you all want float now you all don’t want float, what’s going ON!!!!!

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,612

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

LOL..... All the kids are doin it! ..... Its all the Rave!First you all want float now you all don’t want float, what’s going ON!!!!!

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,527

- Reaction score

- 3,795

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

I am going to leave my float @3mm. Set it perfect with the Hurricane tool and let it float outward @2-3mm.First you all want float now you all don’t want float, what’s going ON!!!!!

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,061

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

The stock float is set up just like the Apex with about 1mm of float.

When i started using belt remover/adjuster tools, they came with a lot of float. Mine was 4 to 6mm or maybe more. I can't remember.

3 years ago, like Danno says, it was all the RAVE.

After blowing 7 belts i decided to look into a few things. I went back to my AAEN clutch book.

In theory the secondary should always push in, but sometimes it "floats" back as in braking. I just believe there are times when that float is in the wrong place at the wrong time, then 200 Horse Power says BAMMM!

Once Mr Knapp mentioned it, i removed my float to 1mm just like my 5000 mile per belt Apex.

Like sooo many clutch gurus here have said, a couple mm's shouldn't be blowing belts, but if i was off with my offset and i had 4mm of float then i could have been 6 to 8mm off at any time.

In the Porn world, an extra 8mm doesn't make you a star, but in the clutch world....................that's a lot!

When i started using belt remover/adjuster tools, they came with a lot of float. Mine was 4 to 6mm or maybe more. I can't remember.

3 years ago, like Danno says, it was all the RAVE.

After blowing 7 belts i decided to look into a few things. I went back to my AAEN clutch book.

In theory the secondary should always push in, but sometimes it "floats" back as in braking. I just believe there are times when that float is in the wrong place at the wrong time, then 200 Horse Power says BAMMM!

Once Mr Knapp mentioned it, i removed my float to 1mm just like my 5000 mile per belt Apex.

Like sooo many clutch gurus here have said, a couple mm's shouldn't be blowing belts, but if i was off with my offset and i had 4mm of float then i could have been 6 to 8mm off at any time.

In the Porn world, an extra 8mm doesn't make you a star, but in the clutch world....................that's a lot!

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,617

- Reaction score

- 4,238

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

I was always of the opinion that float solely existed so that when the bolt that holds the clutch on was tightened, the bearing wasn't pushed on the jackshaft. When Doo came out with the stepped jackshaft against the bearing, which meant no more bushings, spacers and little washers on the bolt, I thought that's brilliant(and about time).a lot less f'in around.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,612

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

I left about .2mm only, using an Apex shim overtop.

Full write-up here:

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/page-34#post-1449153

Ill paste it in here for those that dont click above.

--------------

Removing the float while using the BOP belt adjuster

I was able to set up my BOP adjuster very nicely. Travis should like this! So anyone with the BOP adjuster, this is an easy setup with a few easy mods and a 35mm OD washer.

So anyone with the BOP adjuster, this is an easy setup with a few easy mods and a 35mm OD washer.

This setup will allow for belt deflection adjusting, and also removal/installing belts as we all love, and will remove the float fully or just the amount you want.

Lowering the offset as per the Hurricane alignment bar, Secondary hub backside gets machined down, and so the secondary slides inward approx 3 to 4mm. To reduce the massive amount of float that is produced afterwards, material needs to be cut off the stock aluminum float plug. So first get your secondary exactly where the Hurricane bar wants it.

Once secondary is sitting perfect with Hurricane alignment bar, insert the stock alum float plug. The alum float plug will get cut down close to flush with outer hub..... When I cut mine, I left it a tad longer then flush, and used an old Apex shim OVERTOP of the Alum float plug to remove the float down to approx .2mm(Basically nothing). These shims are much larger and fit over the alum plug like the apex used to have(pics below).....I like to allow for this small spacing so there is no side loading when bolted tight.

NOTE: Initially the amt left hanging out of my HUB was 7mm!(check yours as not all will be exact same). That large amount of float, is increased if using the belt adjuster, as hub may float inside the adjuster even further outward once into the shift. This is where the 35mm washer comes into play.

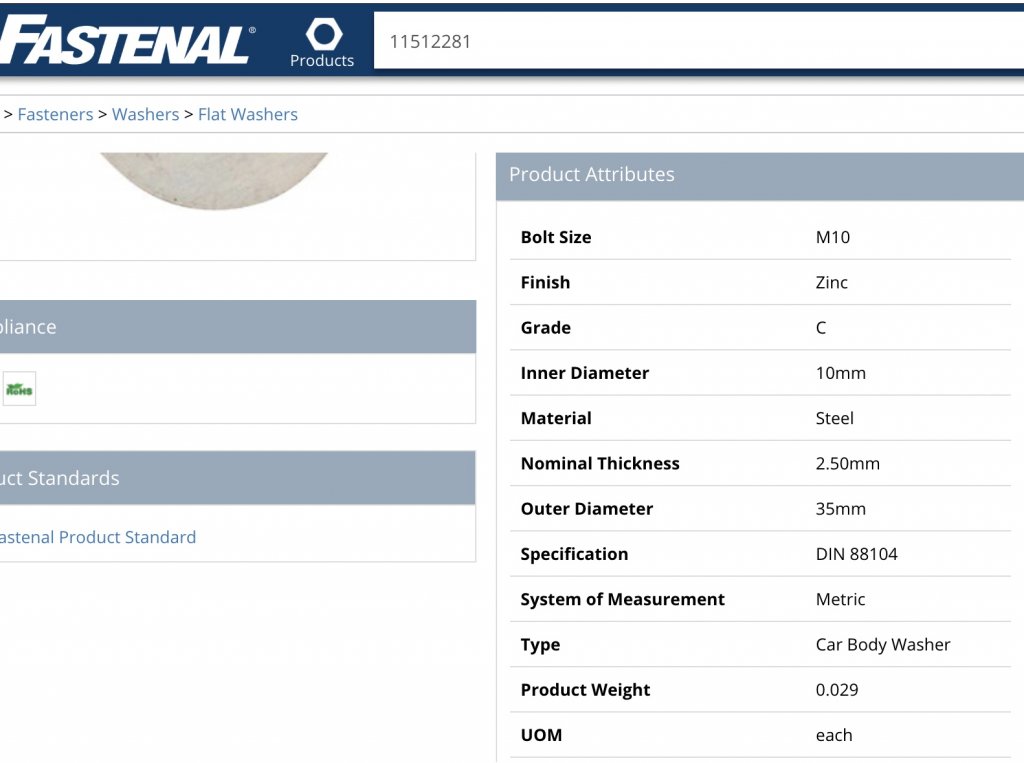

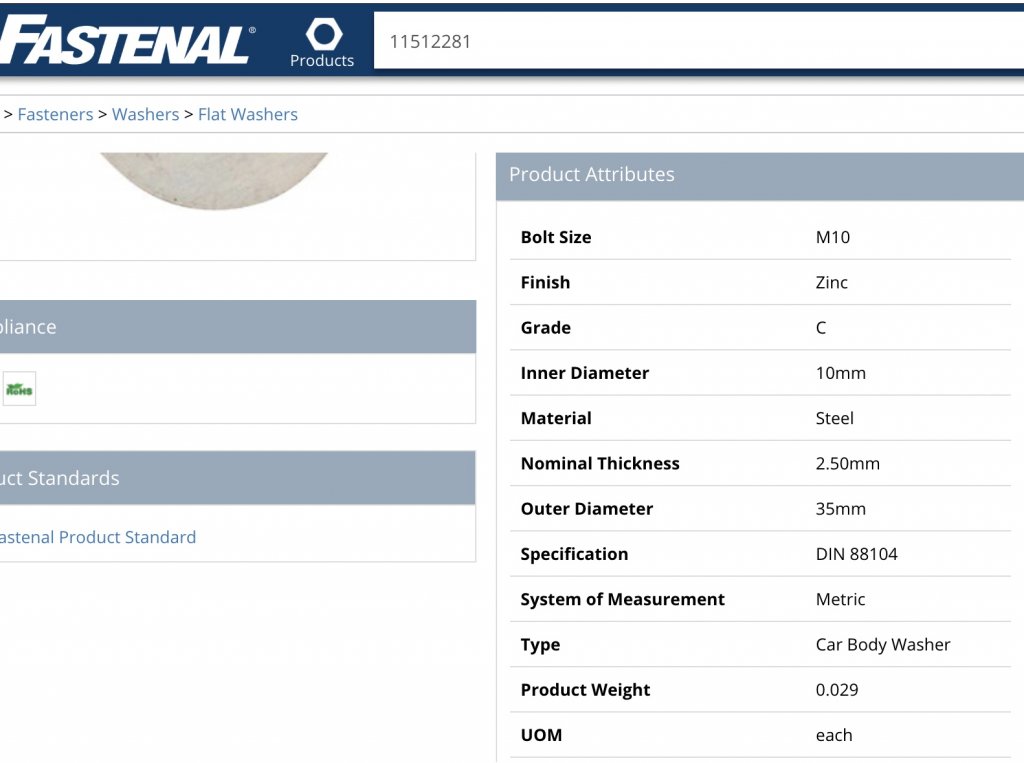

Next in line to the newly cut down float plug, you need a larger fender style washer, be sure its thick enough too. I found fastenal has 10mm X 35mm OD X 2.5mm thick.

Next we use the 4 small washers that Travis includes in his adjuster. This helps as the main bolt he gives you is very long, and also helps with adjuster to remove belts.

Next is the adjuster itself.

Next I use a large washer outside, i chose one that is a tad larger then BOP threaded adjuster diam, so if the adjuster ever came loose, it cannot spin off.

Now the adjuster works as a deflection tool and also a belt change tool too. Possibly Travis will include a 35mm large washer for guys who want no float

Remember, the '12 cats had this float setup with the helix, and they were belt killers, and now the new Cat 998s are locked down like the doos, and sure enough their belt life seems reasonable. Time will tell.

Dan

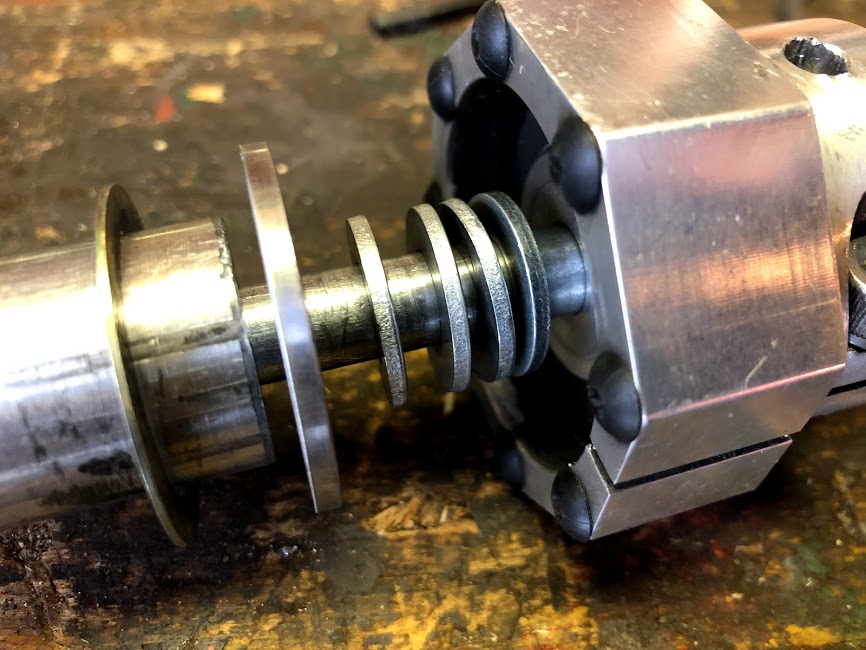

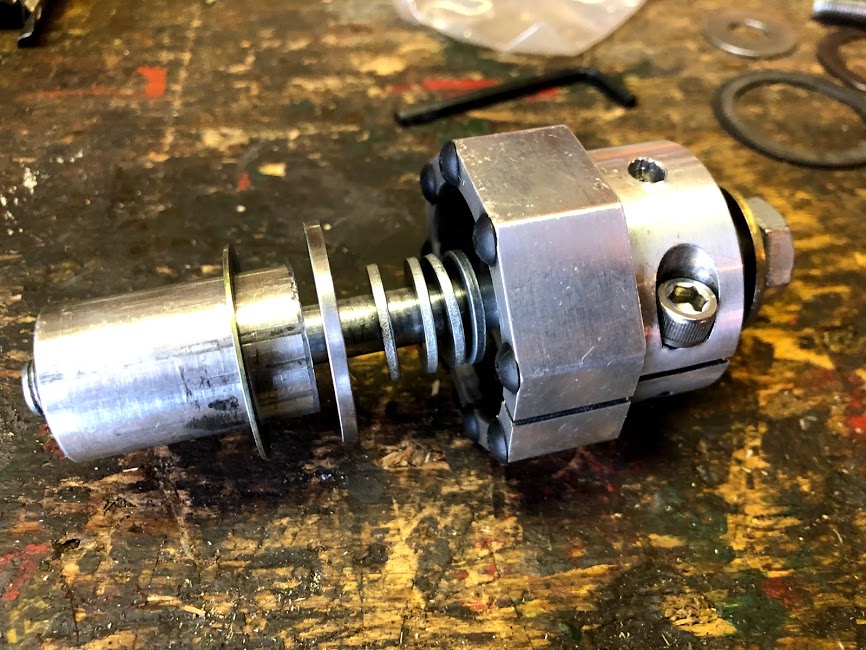

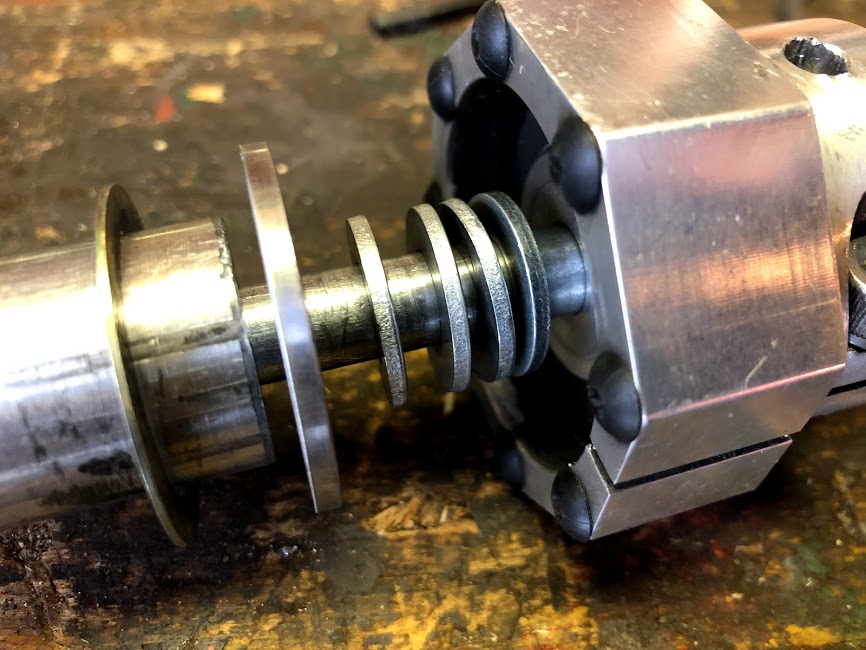

Notice the thin Apex shim on left, overtop of Alum float plug.

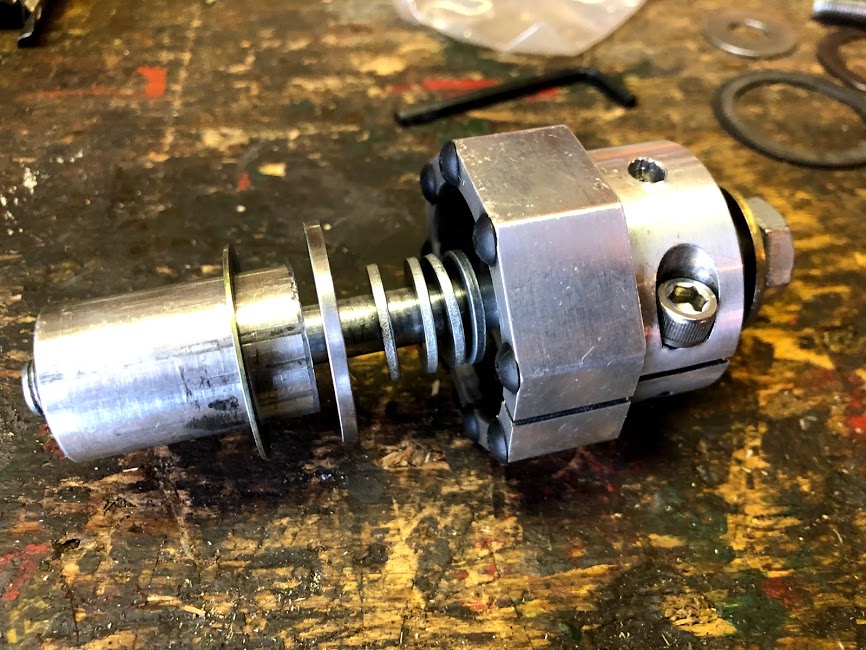

Float plug,Apex shim, 35mm fender washer, 4 washers came with BOP adjuster, BOP adjuster, large washer.

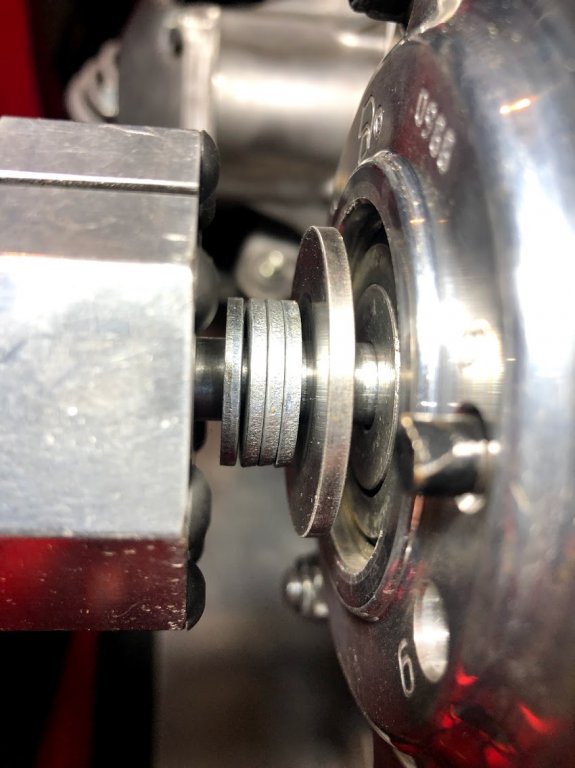

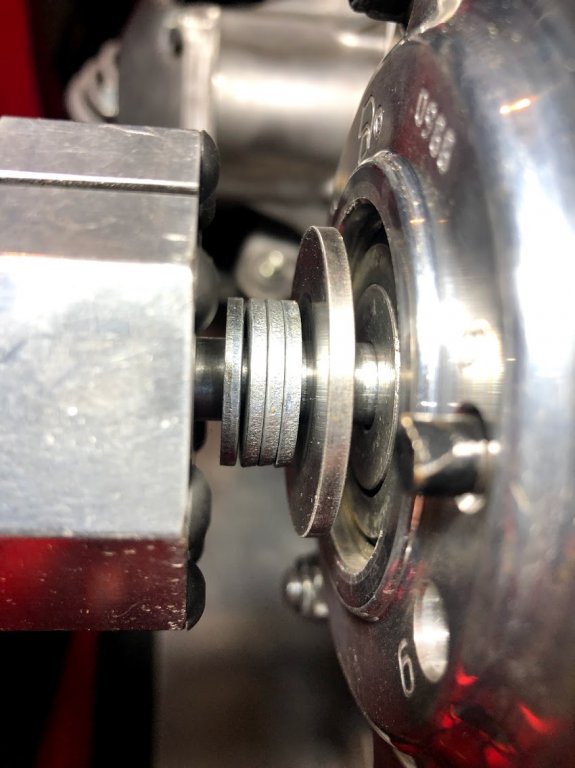

Apex shim sitting overtop of stock float plug,dials in perfect amt of float(.2mm now,so basically nothing)

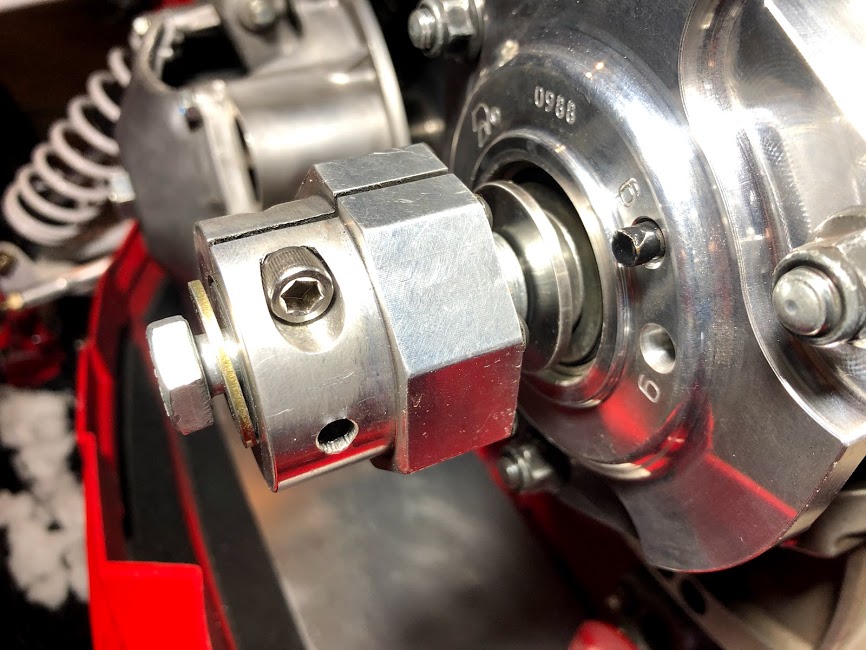

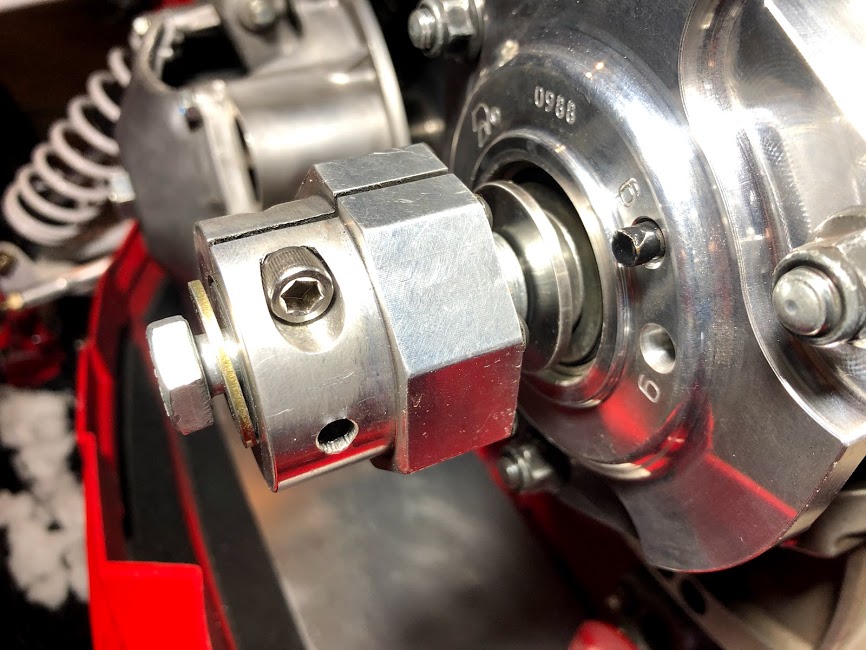

All tightened up and deflection set where I want with Adjuster, also used for removing belts easily.

Fastenal washer Part#: 11512281

Full write-up here:

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/page-34#post-1449153

Ill paste it in here for those that dont click above.

--------------

Removing the float while using the BOP belt adjuster

I was able to set up my BOP adjuster very nicely. Travis should like this!

This setup will allow for belt deflection adjusting, and also removal/installing belts as we all love, and will remove the float fully or just the amount you want.

Lowering the offset as per the Hurricane alignment bar, Secondary hub backside gets machined down, and so the secondary slides inward approx 3 to 4mm. To reduce the massive amount of float that is produced afterwards, material needs to be cut off the stock aluminum float plug. So first get your secondary exactly where the Hurricane bar wants it.

Once secondary is sitting perfect with Hurricane alignment bar, insert the stock alum float plug. The alum float plug will get cut down close to flush with outer hub..... When I cut mine, I left it a tad longer then flush, and used an old Apex shim OVERTOP of the Alum float plug to remove the float down to approx .2mm(Basically nothing). These shims are much larger and fit over the alum plug like the apex used to have(pics below).....I like to allow for this small spacing so there is no side loading when bolted tight.

NOTE: Initially the amt left hanging out of my HUB was 7mm!(check yours as not all will be exact same). That large amount of float, is increased if using the belt adjuster, as hub may float inside the adjuster even further outward once into the shift. This is where the 35mm washer comes into play.

Next in line to the newly cut down float plug, you need a larger fender style washer, be sure its thick enough too. I found fastenal has 10mm X 35mm OD X 2.5mm thick.

Next we use the 4 small washers that Travis includes in his adjuster. This helps as the main bolt he gives you is very long, and also helps with adjuster to remove belts.

Next is the adjuster itself.

Next I use a large washer outside, i chose one that is a tad larger then BOP threaded adjuster diam, so if the adjuster ever came loose, it cannot spin off.

Now the adjuster works as a deflection tool and also a belt change tool too. Possibly Travis will include a 35mm large washer for guys who want no float

Remember, the '12 cats had this float setup with the helix, and they were belt killers, and now the new Cat 998s are locked down like the doos, and sure enough their belt life seems reasonable. Time will tell.

Dan

Notice the thin Apex shim on left, overtop of Alum float plug.

Float plug,Apex shim, 35mm fender washer, 4 washers came with BOP adjuster, BOP adjuster, large washer.

Apex shim sitting overtop of stock float plug,dials in perfect amt of float(.2mm now,so basically nothing)

All tightened up and deflection set where I want with Adjuster, also used for removing belts easily.

Fastenal washer Part#: 11512281

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,323

- Reaction score

- 2,728

- Points

- 1,733

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

I left about .2mm only, using an Apex shim overtop.

Full write-up here:

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/page-34#post-1449153

Ill paste it in here for those that dont click above.

--------------

Removing the float while using the BOP belt adjuster

I was able to set up my BOP adjuster very nicely. Travis should like this!So anyone with the BOP adjuster, this is an easy setup with a few easy mods and a 35mm OD washer.

This setup will allow for belt deflection adjusting, and also removal/installing belts as we all love, and will remove the float fully or just the amount you want.

Lowering the offset as per the Hurricane alignment bar, Secondary hub backside gets machined down, and so the secondary slides inward approx 3 to 4mm. To reduce the massive amount of float that is produced afterwards, material needs to be cut off the stock aluminum float plug. So first get your secondary exactly where the Hurricane bar wants it.

Once secondary is sitting perfect with Hurricane alignment bar, insert the stock alum float plug. The alum float plug will get cut down close to flush with outer hub..... When I cut mine, I left it a tad longer then flush, and used an old Apex shim OVERTOP of the Alum float plug to remove the float down to approx .2mm(Basically nothing). These shims are much larger and fit over the alum plug like the apex used to have(pics below).....I like to allow for this small spacing so there is no side loading when bolted tight.

NOTE: Initially the amt left hanging out of my HUB was 7mm!(check yours as not all will be exact same). That large amount of float, is increased if using the belt adjuster, as hub may float inside the adjuster even further outward once into the shift. This is where the 35mm washer comes into play.

Next in line to the newly cut down float plug, you need a larger fender style washer, be sure its thick enough too. I found fastenal has 10mm X 35mm OD X 2.5mm thick.

Next we use the 4 small washers that Travis includes in his adjuster. This helps as the main bolt he gives you is very long, and also helps with adjuster to remove belts.

Next is the adjuster itself.

Next I use a large washer outside, i chose one that is a tad larger then BOP threaded adjuster diam, so if the adjuster ever came loose, it cannot spin off.

Now the adjuster works as a deflection tool and also a belt change tool too. Possibly Travis will include a 35mm large washer for guys who want no float

Remember, the '12 cats had this float setup with the helix, and they were belt killers, and now the new Cat 998s are locked down like the doos, and sure enough their belt life seems reasonable. Time will tell.

Dan

Notice the thin Apex shim on left, overtop of Alum float plug.

Float plug,Apex shim, 35mm fender washer, 4 washers came with BOP adjuster, BOP adjuster, large washer.

Apex shim sitting overtop of stock float plug,dials in perfect amt of float(.2mm now,so basically nothing)

All tightened up and deflection set where I want with Adjuster, also used for removing belts easily.

Fastenal washer Part#: 11512281

Nice write up Dan!

I felt this is so important in belt life that I made this thread instead of having it buried in other topics.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,612

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Nice write up Dan!

I felt this is so important in belt life that I made this thread instead of having it buried in other topics.

AGREE! Great work brother.

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,061

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Jesus Dan!

Can you do a thread on how to include all this info on these threads?

I mean i'm not as bad as SNOWBEAST, but i feel sooo inadequate!

Can you do a thread on how to include all this info on these threads?

I mean i'm not as bad as SNOWBEAST, but i feel sooo inadequate!

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,612

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

LOL.....Its hard to keep up with this sled i swear. We all need to be engineers here at TY just to get a days ride in and make it home..haha.Jesus Dan!

Can you do a thread on how to include all this info on these threads?

I mean i'm not as bad as SNOWBEAST, but i feel sooo inadequate!

Similar threads

- Replies

- 33

- Views

- 8K

- Replies

- 27

- Views

- 5K

- Replies

- 29

- Views

- 13K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.