grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,116

- Reaction score

- 971

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

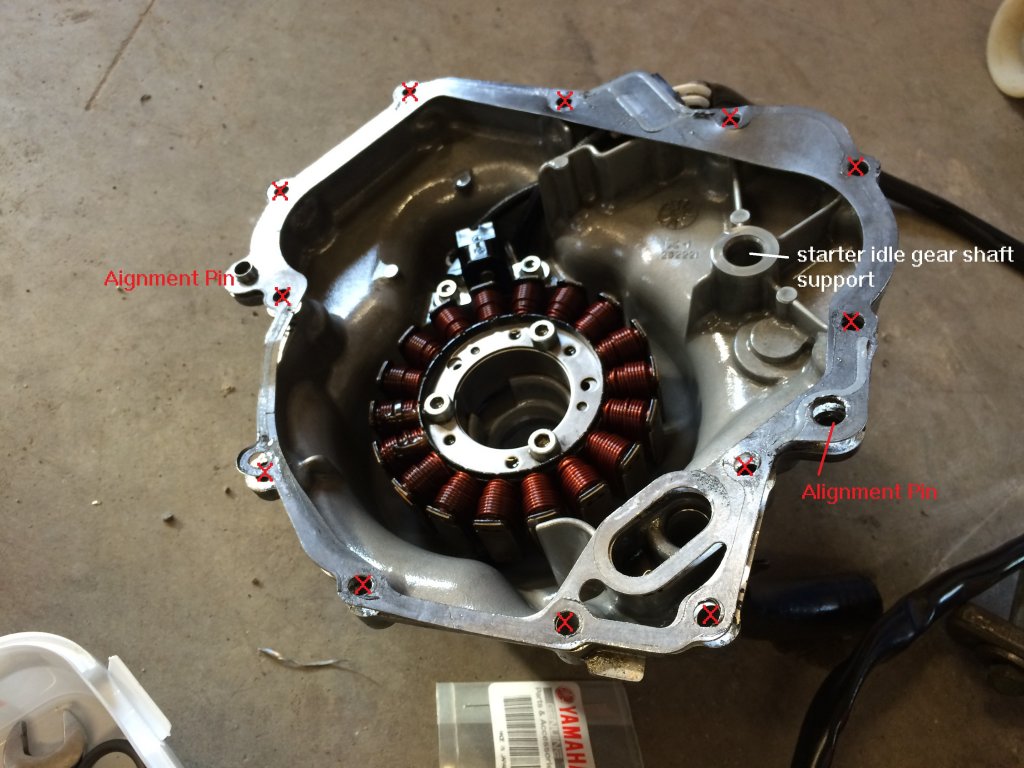

There are 12 cap screws around the perimeter that need removed. If you can get an equal gap around the cover all the bolts should be removed and most likely the flywheel magnet his holding it. It's a strong magnet.

green53

Newbie

- Joined

- Feb 6, 2019

- Messages

- 18

- Reaction score

- 8

- Points

- 63

- Location

- canada

- Country

- Canada

- Snowmobile

- 2009 vector ltx

Thanks Grizz!

green53

Newbie

- Joined

- Feb 6, 2019

- Messages

- 18

- Reaction score

- 8

- Points

- 63

- Location

- canada

- Country

- Canada

- Snowmobile

- 2009 vector ltx

Hey Grizz, is it worthwhile replacing gears with the updated idler gear 8ES-15512-01-00 and the one way clutch with part 8GL-15590-00? if the clutch chattered the hub, is the crank pooched? Do I also need to replace the flywheel gear so they are all new?

Thanks.

Thanks.

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,116

- Reaction score

- 971

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

I don't always update the gears unless there is damage but I usually recommend it. The locking hub that the one way clutch engages is part of the flywheel gear. So if the hub is bad you replace the gear. The gear also has a bushing that rides on the crank but I've never seen an issue there. If the flywheel gear/hub are good I wouldn't bother replacing it because there is no update for that gear. The two parts that tend to fail are the idler gear and the one way clutch.

green53

Newbie

- Joined

- Feb 6, 2019

- Messages

- 18

- Reaction score

- 8

- Points

- 63

- Location

- canada

- Country

- Canada

- Snowmobile

- 2009 vector ltx

Thanks again Grizz!

green53

Newbie

- Joined

- Feb 6, 2019

- Messages

- 18

- Reaction score

- 8

- Points

- 63

- Location

- canada

- Country

- Canada

- Snowmobile

- 2009 vector ltx

So glad that forum members like Grizz take the time to lend a hand, offer advise. Because of these guys I was able to finally get the stator cover off and found 2 teeth missing on the idler gear. Off to the Crappo Tire ( Canadian Tire Store!) to get a third metric bolt for my puller and inspect the clutch and flywheel gear. Any ideas where the teeth pieces could be and how to remove them? The engine is still in the chassis. Thanks again.

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,116

- Reaction score

- 971

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

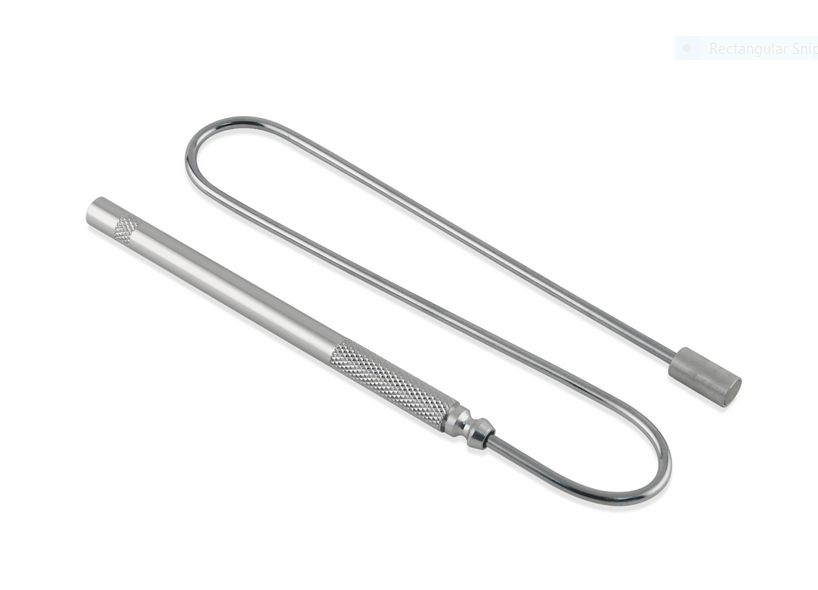

You can try fishing the pieces out with a bendable magnet. With the flywheel and flywheel starter gear off you can reach into the sump area with the magnet and usually find the pieces.

green53

Newbie

- Joined

- Feb 6, 2019

- Messages

- 18

- Reaction score

- 8

- Points

- 63

- Location

- canada

- Country

- Canada

- Snowmobile

- 2009 vector ltx

ok, got the magnet as per the picture, but can't seem to get down in the sump from the bottom drain. can I remove the lower chain cover and poke down from there?

Before I get pulling more stuff off, is it worthwhile flushing the sump with ATF?

Thanks.

Before I get pulling more stuff off, is it worthwhile flushing the sump with ATF?

Thanks.

green53

Newbie

- Joined

- Feb 6, 2019

- Messages

- 18

- Reaction score

- 8

- Points

- 63

- Location

- canada

- Country

- Canada

- Snowmobile

- 2009 vector ltx

I pulled the engine and removed the sump to find the last gear tooth about an inch from the drain hole, in 3 pieces. Ready to put back together and get into the 4 plus feet of snow here! Thanks to forum members again!

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,516

- Reaction score

- 4,182

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Wrong thread guys.

Last edited:

coldrunning

Newbie

- Joined

- Jan 4, 2020

- Messages

- 12

- Reaction score

- 5

- Points

- 303

- Location

- Fairbanks, AK

- Country

- USA

- Snowmobile

- 2006 Yamaha VK Pro

Seems I'm in sort of similar straights with my 2006 VK10L/VK Professional. Had the same whirring sounds in the end, but never any grinding to begin with. I replaced starter first, no fix, and teeth okay, so I pulled the side cover off. The stock idler gear is perfect. However, 3 Allen head bolts that lock the one way clutch to the flywheel were sheared off completely and kicking around under the cover. Am assuming when I get in there that the clutch hub on the starter flywheel gear will be toast.

Problem is, I haven't gotten the crankshaft bolt out yet because I don't want to turn the engine backwards. Is the crankshaft bolt threaded normally (CW = tighten) or is it reverse threaded? How do I get the crankshaft bolt out without turning the engine backwards?? ? I used a long breaker bar but couldn't apply much force on it while trying to hold back the flywheel with a medium size screwdriver shoved through the flywheel into a small pocket behind it. I assume that after I get that bolt out I can use the harmonic balance puller to removed the flywheel.

Big thanks to everyone who contributed to this thread through the years, especially @grizztracks and @cannondale27 !

Problem is, I haven't gotten the crankshaft bolt out yet because I don't want to turn the engine backwards. Is the crankshaft bolt threaded normally (CW = tighten) or is it reverse threaded? How do I get the crankshaft bolt out without turning the engine backwards?? ? I used a long breaker bar but couldn't apply much force on it while trying to hold back the flywheel with a medium size screwdriver shoved through the flywheel into a small pocket behind it. I assume that after I get that bolt out I can use the harmonic balance puller to removed the flywheel.

Big thanks to everyone who contributed to this thread through the years, especially @grizztracks and @cannondale27 !

Attachments

Wow that sucks! Use a impact to remove bolt. It’s right hand thread.

Litre1000

Lifetime Member

- Joined

- Oct 11, 2006

- Messages

- 52

- Reaction score

- 19

- Points

- 958

- Location

- N. IL.

- Country

- USA

- Snowmobile

- 93 Storm, Redline Revolt, Nytro, IQR

- LOCATION

- N. IL

I’ll be digging into my 2013 Nytro next week. The stator has apparently gone south. I only measured 40 volts AC @3000 rpm. Gonna change the starter and sprag because I heard it squeaking twice before while trying to start. Should be fun....

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,116

- Reaction score

- 971

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

I also use an impact to remove the flywheel bolt but if you don't have an impact you could use a pry bar to hold the primary clutch instead.

coldrunning

Newbie

- Joined

- Jan 4, 2020

- Messages

- 12

- Reaction score

- 5

- Points

- 303

- Location

- Fairbanks, AK

- Country

- USA

- Snowmobile

- 2006 Yamaha VK Pro

Wow that sucks! Use a impact to remove bolt. It’s right hand thread.

Impact was the ticket. Thanks for that! Didn't even need air, my 18v cordless was plenty. Had my crow bar ready just in case. New parts on order.

Allen head bolts that broke off seemed to have backed out of the flywheel part way. Is it ok to use threadlocker in this oily space when I put it back together?

Hub on the flywheel starter gear showed the same marks @grizztracks found before. And the spring from the one-way clutch again shows the same stretch-kink issue. I wonder if the clutch solution is as simple as a larger diameter, beefier spring or one made with stiffer steel. Probably wiser to just design a more elegant system less likely to fail though, and since this rig is a 2006, Yamaha has probably already done so?

High heat colors on the back side of the flywheel starter gear.

Similar threads

- Replies

- 1

- Views

- 1K

- Replies

- 8

- Views

- 2K

- Replies

- 1

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.