Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Reaction score

- 111

- Points

- 218

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

Thanks Sevey, I tried to clear up the ambiguous parts of all the other starter installation threads so a person familiar with a wrench but not a mechanic could follow it step by step. Thanks to those in the past that set the stage for this VERY SIMPLIFIED approach, great work!

You are exactly right, as you ease the motor mount bolts gently inward, there will be a moment when it passes out of the threaded collar and into the rubber mount, at this point the engine will drop down as you see a 1/4" or so. Easy way to know it is clear. Push mount bolts in slowly so they DO NOT drop out of the rubber portion of the mount. If they do, you just added removal of your a-arms and lower front plastics to your project as you can't access the bolts easily to re-insert them. This is where my 18" 1/4" extension worked perfect (wondered when I bought the 12" one when I would use it - added a 6" to it to get 18"). You can slip a 17mm socket on the 18" extension from the opposite side and capture the bolt head and gently put pressure on the bolt as you jack it into alignment and it simply slips back into the threaded collars, amazing again how simple that was.

Back to removal, once the bolts are clear, then you simply jack up the engine, first the suspension will decompress and very little engine up motion, then as the skis come off the concrete blocks (so now your 2x4x8" block on the jack in the only thing holding the sled in the front) the next few jack pulls only moves the engine up rotating easily on the rear engine mount bolt (very long bolt, side to side it appears). You don't need to touch the rear engine mount bolt, it allows rotation as is. Things were surprisingly stable with the three point support and i was comfortable being under it.

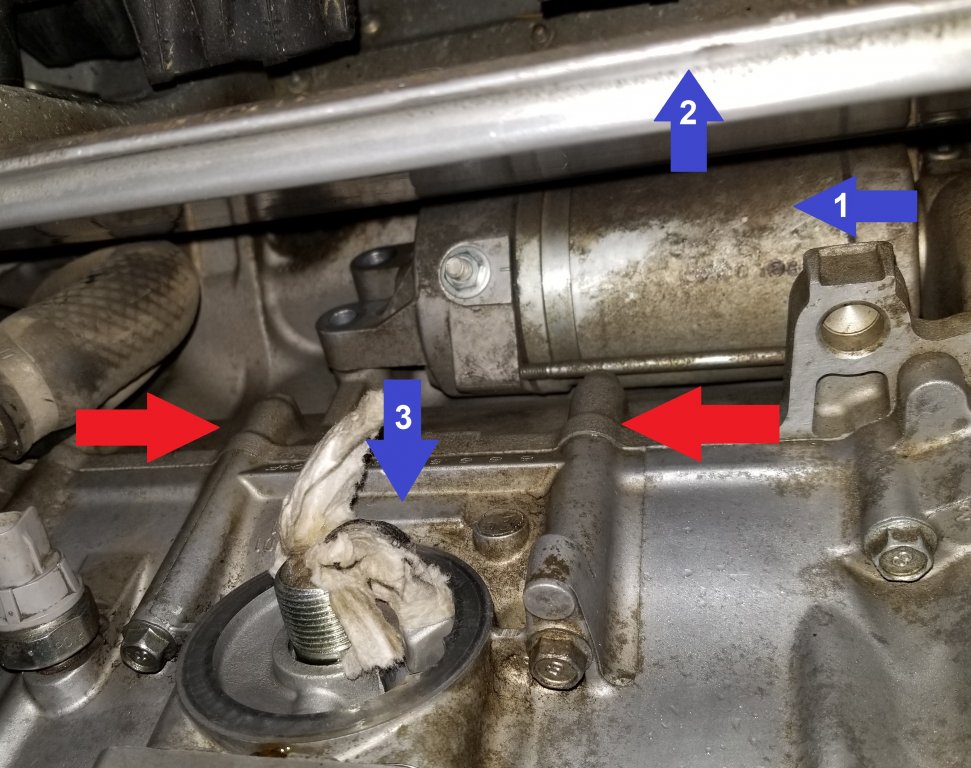

KEY is not to try to remove the starter while it is horizontal, if you do you have to push the engine up even more to clear the two casting bumps (red arrows below) for the bolts. The "drop out" of the starter people have mentioned means you have to go 50% more with the engine up, maybe even remove the steering shaft as the airbox starts to hit is, also stretches all the hoses connected I suspect (oil, coolant) and brings the radiator interference into play. All NOT required, instead of "drop out" the blue arrows show what I did, [1] pull starter out of engine by gently prying flat head screwdriver against engine and starter end, mine slid out easily as well lubricated inside [2] rotate starter vertical with the gear up as plenty of room above, then [3] while vertical slide down between bumps (red arrows). Not having to go that extra 1/2" to clear the bumps is huge, means the airbox does even come close to the steering shaft, the front engine mounts don't even move beyond the alignment threaded collars (which I suspect is why some have to mess with unscrewing these collars). Very simple, very limited engine motion required. I had my starter right there next to me, greases gear and o-ring and as I pulled the old starter out, aligned new one with it exactly and reversed the motion to get back up and in position. Wiggled the starter by rotating it every so slightly and the gear meshed into the engine gear like greased lightning, starter mounts aligned perfectly (lower bolt first, then upper). I was actually shocked how simple as I realized I just saved $1000 and it was not any harder than removing my skid! My old starter spins smoothly so likely only needs a brush kit ($36) and now I have a back up. I may look into the starter saver LED that tells you if the starter remains hot after starting as this can destroy it silently as it will be rotating at engine RPM (yikes!). Good luck, nuts anyone would disconnect anything other then front engine mount bolts to do this project let alone remove engine!

You are exactly right, as you ease the motor mount bolts gently inward, there will be a moment when it passes out of the threaded collar and into the rubber mount, at this point the engine will drop down as you see a 1/4" or so. Easy way to know it is clear. Push mount bolts in slowly so they DO NOT drop out of the rubber portion of the mount. If they do, you just added removal of your a-arms and lower front plastics to your project as you can't access the bolts easily to re-insert them. This is where my 18" 1/4" extension worked perfect (wondered when I bought the 12" one when I would use it - added a 6" to it to get 18"). You can slip a 17mm socket on the 18" extension from the opposite side and capture the bolt head and gently put pressure on the bolt as you jack it into alignment and it simply slips back into the threaded collars, amazing again how simple that was.

Back to removal, once the bolts are clear, then you simply jack up the engine, first the suspension will decompress and very little engine up motion, then as the skis come off the concrete blocks (so now your 2x4x8" block on the jack in the only thing holding the sled in the front) the next few jack pulls only moves the engine up rotating easily on the rear engine mount bolt (very long bolt, side to side it appears). You don't need to touch the rear engine mount bolt, it allows rotation as is. Things were surprisingly stable with the three point support and i was comfortable being under it.

KEY is not to try to remove the starter while it is horizontal, if you do you have to push the engine up even more to clear the two casting bumps (red arrows below) for the bolts. The "drop out" of the starter people have mentioned means you have to go 50% more with the engine up, maybe even remove the steering shaft as the airbox starts to hit is, also stretches all the hoses connected I suspect (oil, coolant) and brings the radiator interference into play. All NOT required, instead of "drop out" the blue arrows show what I did, [1] pull starter out of engine by gently prying flat head screwdriver against engine and starter end, mine slid out easily as well lubricated inside [2] rotate starter vertical with the gear up as plenty of room above, then [3] while vertical slide down between bumps (red arrows). Not having to go that extra 1/2" to clear the bumps is huge, means the airbox does even come close to the steering shaft, the front engine mounts don't even move beyond the alignment threaded collars (which I suspect is why some have to mess with unscrewing these collars). Very simple, very limited engine motion required. I had my starter right there next to me, greases gear and o-ring and as I pulled the old starter out, aligned new one with it exactly and reversed the motion to get back up and in position. Wiggled the starter by rotating it every so slightly and the gear meshed into the engine gear like greased lightning, starter mounts aligned perfectly (lower bolt first, then upper). I was actually shocked how simple as I realized I just saved $1000 and it was not any harder than removing my skid! My old starter spins smoothly so likely only needs a brush kit ($36) and now I have a back up. I may look into the starter saver LED that tells you if the starter remains hot after starting as this can destroy it silently as it will be rotating at engine RPM (yikes!). Good luck, nuts anyone would disconnect anything other then front engine mount bolts to do this project let alone remove engine!

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Reaction score

- 111

- Points

- 218

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

Fresh clean starter installed! You can see between above pic above and this one how much things open up with very little motion upward of engine...

grizztracks

TY Advertiser

- Joined

- Feb 24, 2005

- Messages

- 3,118

- Reaction score

- 975

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Good information....... I hope you removed that old oil filter gasket before installing the new filter.

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Reaction score

- 111

- Points

- 218

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

Good reminder Grizz, if comment was on my post, I changed my oil and filter in December not expecting to do a starter in January. As the pic shows, oil seal surface was clean, filter gasket was new and I relubricated it. Note, I left the oil tank cap on and was careful to keep oil filter from spilling as much as possible. Only about 1/4 cup of oil drained so I put filter back on and plan to start and check level tomorrow.

HardCard

Newbie

- Joined

- Jan 28, 2018

- Messages

- 2

- Reaction score

- 0

- Points

- 21

- Location

- New jersey

- Country

- USA

- Snowmobile

- 2009 Yamaha Nytro

Bought my Nytro three years ago, at the end of last year starter stopped working, I went to the local starter shop, he ordered me up a new aftermarket starter with a one your warranty. I used the sled for the first time this year since the install, rode maybe 130 miles.. At home I was going over the sled went to start it and nothing, just a click. Bottom line the starter was not working, out it comes, I installed a new OEM starter, I took the starter back to the shop, and when he took it apart, it was all corroded, and the brushes were shot. My question how could this happen in 130 miles? Aren't these starters sealed? Do I have another issue that is killing my starters? I notice there was no belly pan so not sure if this was a issue before I got it...any help would be appreciated...

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Reaction score

- 111

- Points

- 218

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

HardCard, if you search "starter" in all these threads you will come up with 20+ threads going way back to 2009 about Nytro starters. Many address what I had to overcome above with the front motor mount technique but some also talk about "starter saver" LEDs. These are LEDs installed on the starter energizer circuit and mounted on the dash so you can see the status of the power to the starter. If you did not replace the starter solenoid / relay at the same time you did the starter, you may have a faulty solenoid / relay which keeps power on your starter even after the key turns back to run and the engine is running. My understanding is that the starter remains engaged in the sense that it spins at the RPM of the engine with no other symptoms or faults except what you describe, tear down a new starter and brushes are spent, magnets are broken, etc due to the fact it just ran for 130 miles! Standard protocol is always replace solenoid / relay along with starter. I am considering installing the LED as well as that would not be good to learn this with a "click" after a few hundred miles. Regarding the skid plate, MountainTech, Barn of Parts and a few others make a solid aluminum ones worth considering if yours is gone, I plan to purchase the MT version eventually. If you have nothing, easy to take out the oil filter, the cooler, the lower engine castings, etc and that would be an expensive repair. The stock setup is marginal, made marginally better with the stock plastic skid plate (which I have) but the aluminum ones are reported to be super solid.

HardCard

Newbie

- Joined

- Jan 28, 2018

- Messages

- 2

- Reaction score

- 0

- Points

- 21

- Location

- New jersey

- Country

- USA

- Snowmobile

- 2009 Yamaha Nytro

Yep, been all through those posts, I DID replace the starter relay the first time I replaced the starter, and I have also added the warning light the second time the starter crapped out, but I cannot believe the starter is designed to stay engaged with the flywheel? There has to be another "Bendix type gear" that only engages the starter when the starter gets power, there is no way any starter would last spinning at those RPM's Thanks for the info!

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Reaction score

- 111

- Points

- 218

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

Strange then... I went OEM starter after reading aftermarket starters dont last, found one from a friend of a friend for $300. I thought the same thing on the Bendix but people report the starter spinning at engine RPMs when there is a faulty relay... I don't quite understand those observations as I have not read anything technical on how it is actually happening. Maybe the guys that make the StarterSavers have the technical answers... bottom line, sucks. Good luck.

grizztracks

TY Advertiser

- Joined

- Feb 24, 2005

- Messages

- 3,118

- Reaction score

- 975

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

The Yamaha engines have a one way clutch that idles when the starter is not energized. The clutch locks the ring gear to a hub on the flywheel only when the starter is energized and rotates. If the starter relay does not return to it's normally open position after a start cycle it can cause the starter to lock to the engine RPMs because the one way clutch never releases. I've seen issues with the one way clutch that would indicate that the clutch itself could fail causing a lockup that would also cause damage to the starter. I always pull the stator cover when doing a starter change to inspect the starter related components.

HardCard, the starter issue you describe would make me believe the aftermarket replacement starter was used and not new. I've had a lot of these starter apart and never see corrosion and normally only see minimal brush wear.

HardCard, the starter issue you describe would make me believe the aftermarket replacement starter was used and not new. I've had a lot of these starter apart and never see corrosion and normally only see minimal brush wear.

grizztracks

TY Advertiser

- Joined

- Feb 24, 2005

- Messages

- 3,118

- Reaction score

- 975

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Failed one way clutch:

left: old one way clutch, right: new one way clutch on the flywheel

ring gear hub damage from a bad one way clutch

Failed one way clutch disassembled: notice the spring (lower right) that holds the locking rollers in the idle position is stretched so it most likely wasn't unlocking from the hub correctly.

left: old one way clutch, right: new one way clutch on the flywheel

ring gear hub damage from a bad one way clutch

Failed one way clutch disassembled: notice the spring (lower right) that holds the locking rollers in the idle position is stretched so it most likely wasn't unlocking from the hub correctly.

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Reaction score

- 111

- Points

- 218

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

Wow! Grizz, have you disassembled every Nytro part!?

grizztracks

TY Advertiser

- Joined

- Feb 24, 2005

- Messages

- 3,118

- Reaction score

- 975

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Wow! Grizz, have you disassembled every Nytro part!?

There's not much I haven't been into on these Yamaha machines.

grizztracks

TY Advertiser

- Joined

- Feb 24, 2005

- Messages

- 3,118

- Reaction score

- 975

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

here is a diagram of how the starter gears work:

The flywheel and one way clutch have been removed. The flywheel starter gear spins freely on the crankshaft and locks to the crank during a start cycle when the one way clutch on the back of the flywheel locks to it.

The flywheel and one way clutch have been removed. The flywheel starter gear spins freely on the crankshaft and locks to the crank during a start cycle when the one way clutch on the back of the flywheel locks to it.

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Reaction score

- 111

- Points

- 218

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

You are amazing! I want to know who thinks this sh!$ up though... wow, can you say complicated but I guess it works for a while... glad I like oil and being under the hood, pretty amazing it all works under the stress we put these sleds under.

- Joined

- Apr 13, 2003

- Messages

- 21,827

- Reaction score

- 9,421

- Points

- 2,103

- Location

- Schofield, WI

- Website

- www.totallyamaha.com

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

Failed one way clutch:

left: old one way clutch, right: new one way clutch on the flywheel

View attachment 137068

ring gear hub damage from a bad one way clutch

View attachment 137069

Failed one way clutch disassembled: notice the spring (lower right) that holds the locking rollers in the idle position is stretched so it most likely wasn't unlocking from the hub correctly.

View attachment 137070

How do you know when the one way clutch is out? Does it normally free wheel one direction? We are having an issue with a 2nd burned out starter.

Similar threads

- Replies

- 15

- Views

- 3K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.