Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

smoothride said:Just FYI you willn't have ice build up in the tunnel because this suspension uses up all the room in the tunnel.

Hey Smoothride, does your track rub excessively against the tunnel protectors? I finally got around to aligning my track, but I can hear it rubbing a little when I spin 'er over on the stand. How tight do you have your track with the M20? I have a 1.5" - 2" sag in track. I run that much sag on my Vector, but it doesn't rub. Maybe I should tighten a little?

I'm thinking of rermoving the tunnel protectors, but I worry the track might contact the EXup and damage it. I could remove the tunnel protectors and smash the brackets a little to give more clearance. I need to re-remove the seat and tank to adjust my handlebars, so it really would not be that much more work to drop the protectors while I'm in there. I just don't want to have the cleats eaten on a brand new track.

What about you Yamahatd?

It sounds like the rear brackets are set to high in the tunnel. I would not remove the tunnel protectors, they are there for a reason. I will check the clearance won my 1.25 ripsaw. Brian at fast may be able to help. He bailed me out a couple of times and I bought mine used. He ROCKS!

Yes my track rubs the tunnel protectors when the thing bottoms out. My sled is not studed.

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Reaction score

- 1,501

- Points

- 1,753

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

Absolutely great work and write up. Thanks!!!!!!

My 1.25 track has about am inch of clearance down the length of the tunnel protectors. As Smoothride stated mine will also rub if bottomed. How is the clearance at the front heat exchanger

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Last edited:

I think tightening the track will solve your problem. I run about 1/2 " free sag

Don't tighten the track to tight because they use the track as a shock. As the suspension travels the track will tighten. If you have to tight you are going to pull harder on your drive shaft. When the suspension is at full travel the track is very tight with a 1 1/2 of sag in the track.

Smoothride I was unaware of that detail. I thoughtThe install instructions called for it to be tighter

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

smoothride said:Don't tighten the track to tight because they use the track as a shock. As the suspension travels the track will tighten. If you have to tight you are going to pull harder on your drive shaft. When the suspension is at full travel the track is very tight with a 1 1/2 of sag in the track.

Does my track lug / tunnel protector clearance look ok in the pic?

I just confirmed the instructions call for 1/2" or more of free sag without any weight. 1 1/2" of sag I think would cause ratcheting. I plan to loosen my track and see if I get any and who knows I may get a better ride. ...

Yes it looks good just don't stud it because I find that they start to hit the exhaust.northernsledder.jk said:smoothride said:Don't tighten the track to tight because they use the track as a shock. As the suspension travels the track will tighten. If you have to tight you are going to pull harder on your drive shaft. When the suspension is at full travel the track is very tight with a 1 1/2 of sag in the track.

Does my track lug / tunnel protector clearance look ok in the pic?

I find that mine would ratchet in deep snow with that amount sag.yamahatd said:I just confirmed the instructions call for 1/2" or more of free sag without any weight. 1 1/2" of sag I think would cause ratcheting. I plan to loosen my track and see if I get any and who knows I may get a better ride. ...

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,664

- Reaction score

- 1,156

- Points

- 1,308

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

A few days ago, I walked past the Apex and the rear end was flat on the ground. All the air had bled out of the shock. I aired it back up and looked for any damage from something I may have left laying in the track. I sprayed soap water on everything, but no bubbles. Yesterday morning, it was flat again. It didn't make sense because it held air all summer.

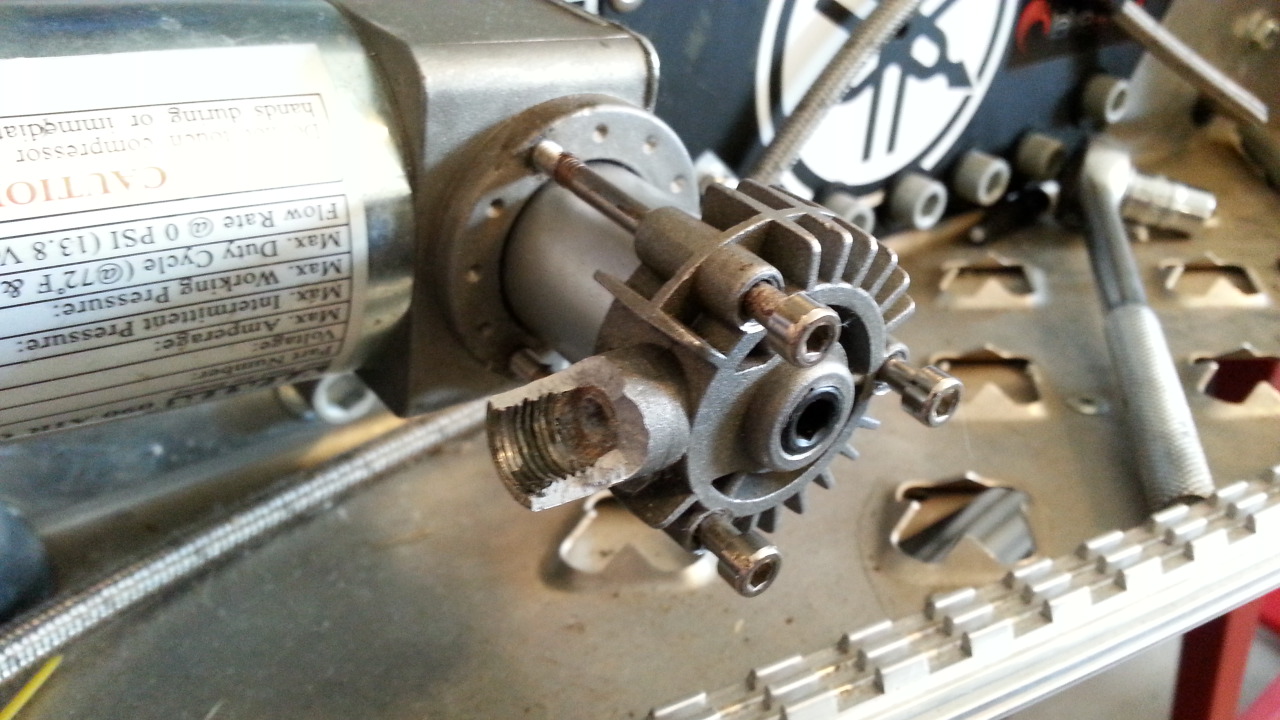

I removed the airline from the compressor, attached a Schrader valve and inflated the shock independent of the pump. This morning, the airbag was still fully inflated. I then removed all the fittings from the pump, cleaned and applied new thread sealant to everything. As I threaded an elbow into the compressor cylinder head, the female threads split apart. Maybe the thing was already fractured, but I'll take the blame. However, I do feel this is where my leak was coming from.

Maybe the thing was already fractured, but I'll take the blame. However, I do feel this is where my leak was coming from.

I called Fast, but they do not offer individual parts for this compressor. I searched online and found a company down in Florida that sells the same pump. They said for me to buy just the head was $50, or the complete unit was $65! Long story...short, I have a new pump coming.

The new compressor is getting moved under the hood. I just don't trust it being mounted to the tunnel. I didn't give it much thought at first, but now I feel there are too many things that can go wrong. A stick or chunk of ice might take it out, not to mention getting bumped in the trailer, etc. There will also be all new plumbing. Since the threads broke so easily, I'm concerned about the weight of all those parts hanging from a single 1/8" diecast aluminum thread port. (see last pic)

I'll post pics of the change when complete.

I removed the airline from the compressor, attached a Schrader valve and inflated the shock independent of the pump. This morning, the airbag was still fully inflated. I then removed all the fittings from the pump, cleaned and applied new thread sealant to everything. As I threaded an elbow into the compressor cylinder head, the female threads split apart.

Maybe the thing was already fractured, but I'll take the blame. However, I do feel this is where my leak was coming from.

Maybe the thing was already fractured, but I'll take the blame. However, I do feel this is where my leak was coming from. I called Fast, but they do not offer individual parts for this compressor. I searched online and found a company down in Florida that sells the same pump. They said for me to buy just the head was $50, or the complete unit was $65! Long story...short, I have a new pump coming.

The new compressor is getting moved under the hood. I just don't trust it being mounted to the tunnel. I didn't give it much thought at first, but now I feel there are too many things that can go wrong. A stick or chunk of ice might take it out, not to mention getting bumped in the trailer, etc. There will also be all new plumbing. Since the threads broke so easily, I'm concerned about the weight of all those parts hanging from a single 1/8" diecast aluminum thread port. (see last pic)

I'll post pics of the change when complete.

Last edited:

- Joined

- Apr 13, 2003

- Messages

- 21,656

- Reaction score

- 9,272

- Points

- 2,103

- Location

- Schofield, WI

- Website

- www.totallyamaha.com

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

I have another under hood compressor like on my super charger I could sell.

Similar threads

- Replies

- 124

- Views

- 20K

- Replies

- 141

- Views

- 24K

- Replies

- 28

- Views

- 4K

- Replies

- 18

- Views

- 10K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.