Allan

TY 4 Stroke Junkie

- Joined

- Oct 19, 2014

- Messages

- 719

- Reaction score

- 270

- Points

- 788

- Location

- Newfoundland

- Country

- Canada

- Snowmobile

- 2016 Sr Viper XTX

Maybe someone could explain this to me. when they were seeing if I have tight valves they did a leak down test as per my bill , 12% on #1 , 12% on #2 and 18% on #3 .

why was this done and what do it show? tks

why was this done and what do it show? tks

cobrajet ltx dx

Lifetime Member

- Joined

- Oct 5, 2014

- Messages

- 345

- Reaction score

- 242

- Points

- 928

- Location

- pa

- Country

- USA

- Snowmobile

- 2015 yamaha ltx dx

I’ll try to keep it simple....

What they were determining was cylinder condition before year down.

Piston set at compression stroke, intake, exhaust valves completely closed. The pump the cylinder with shop air and determine what percentage of air is lost. Either through valve seating which will show a lose through the top end (valves , head)or a lose through the bottom end ( piston, rings).Yamaha has a spec for that.

I do this test all the time with Subaru engines at my dealership.

Anything over 8% on our DI motors is suspect.

If there result was out of Yamaha’s spec, and checking your complaint, they we’re seeing if your head was ok before doing valve adjustments.because they aren’t physically pulling valves out for a visual inspection.

Carbon cleaning does help bring those #’s down if mechanically your motor is ok

What they were determining was cylinder condition before year down.

Piston set at compression stroke, intake, exhaust valves completely closed. The pump the cylinder with shop air and determine what percentage of air is lost. Either through valve seating which will show a lose through the top end (valves , head)or a lose through the bottom end ( piston, rings).Yamaha has a spec for that.

I do this test all the time with Subaru engines at my dealership.

Anything over 8% on our DI motors is suspect.

If there result was out of Yamaha’s spec, and checking your complaint, they we’re seeing if your head was ok before doing valve adjustments.because they aren’t physically pulling valves out for a visual inspection.

Carbon cleaning does help bring those #’s down if mechanically your motor is ok

Last edited:

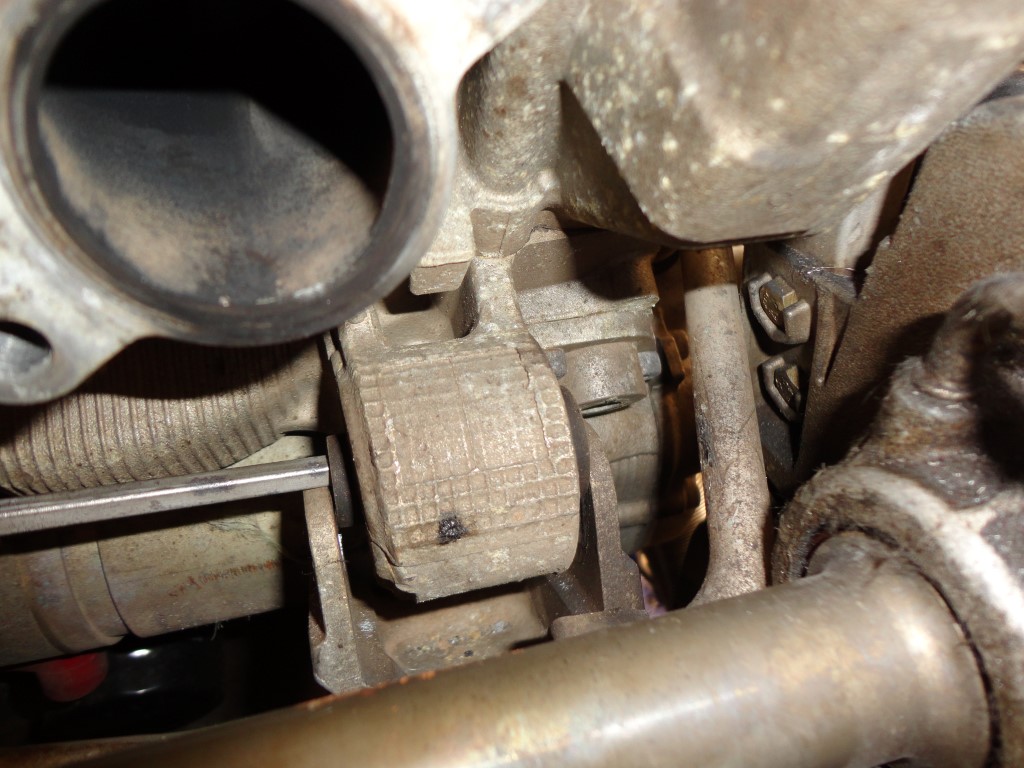

#3 I bet was the tight one. One observance I have made and I believe I will be able to show you guys is over summer when engine is not being run the intake valves rust alot. I bet first tank of gas this has a effect on sealing and could be a reason behind your higher % on other 2 cylinders Allan. My motor has not been run since April. Never had a issue with this rust I have seen but its definitely there. So bad gas and possibly valves not sealing 100% cause of rust and you get all kinds of folks wondering why they run like crap begining of season. Few weeks later and never hear anything . Old gas is out of system and valves are sealing as good as they ever will. Also remember with our valve system as the motor gets warmer the clearances tighten up. So the warmer sled is the crummier it should idle and start.

They probably wouldnt have even checked valves if not for seeing that 18%. That documentation probably helped your case for partial reimbursement.Maybe someone could explain this to me. when they were seeing if I have tight valves they did a leak down test as per my bill , 12% on #1 , 12% on #2 and 18% on #3 .

why was this done and what do it show? tks

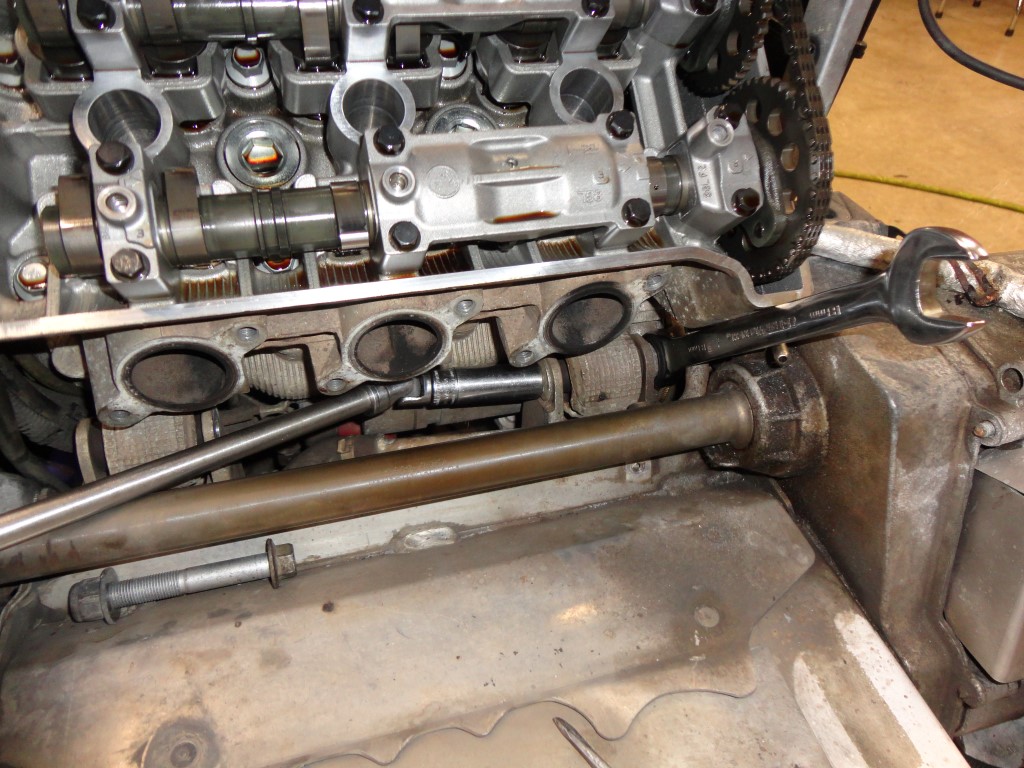

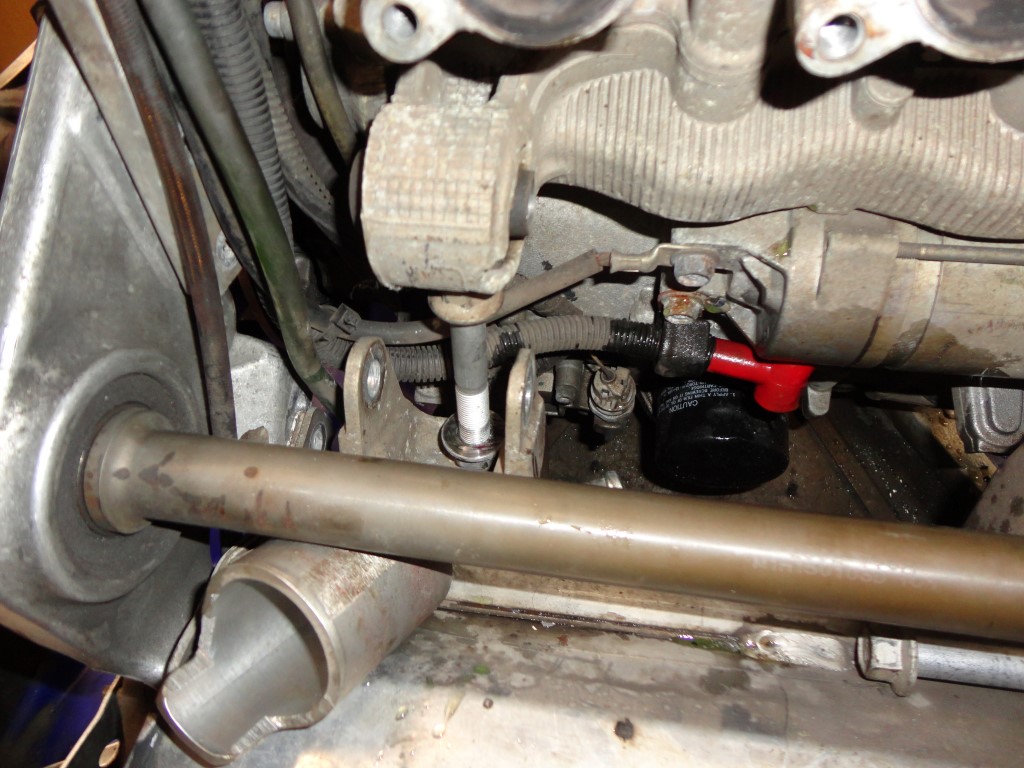

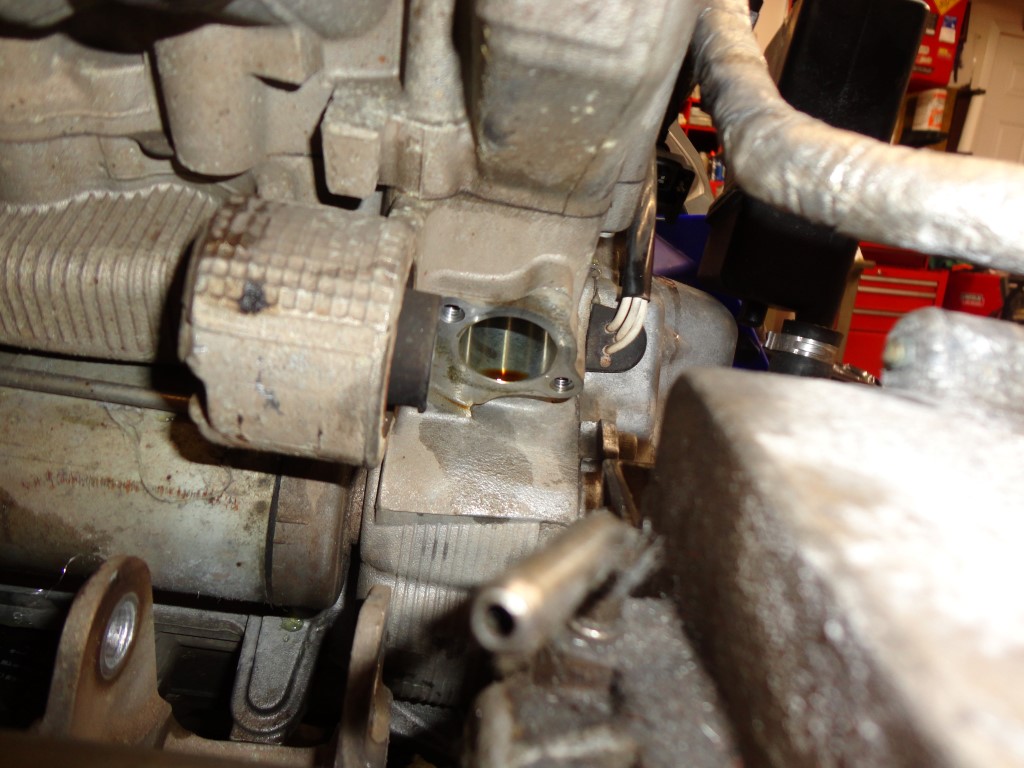

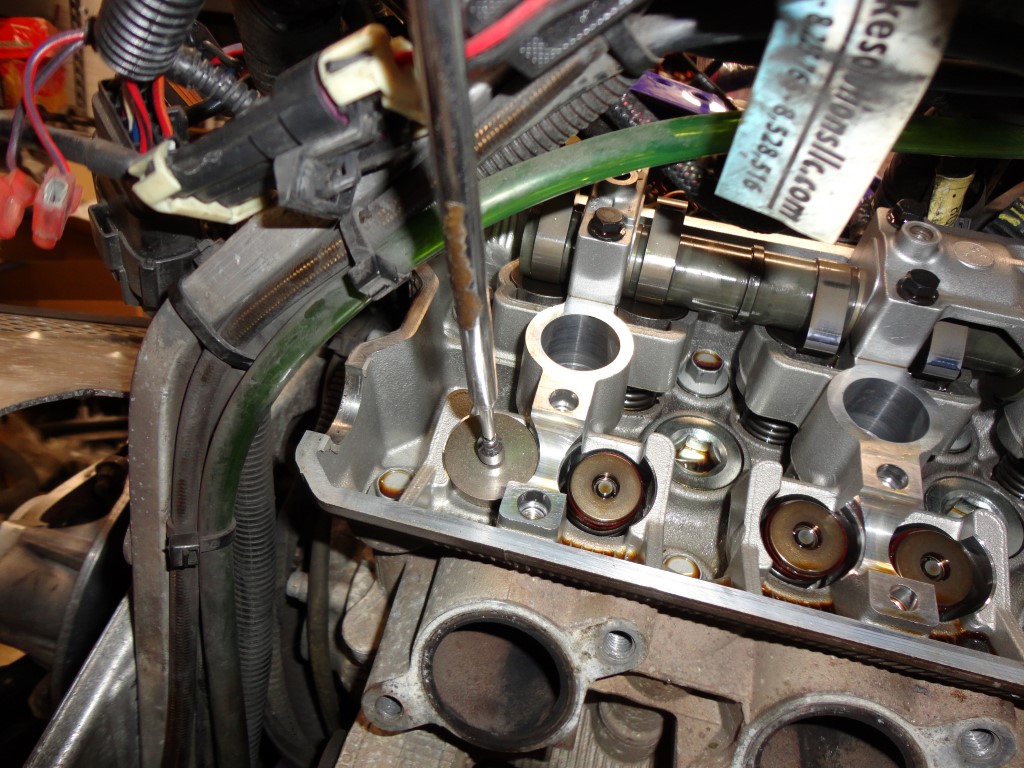

Well this is going to be the furthest mine has ever been taken down! Not fun. Have to now remove the Jackshaft brace and lift some more and see what stops me but that cam chain tensioner is still not accessible. Calling it a day. First time is always a bitch!

Last edited:

cobrajet ltx dx

Lifetime Member

- Joined

- Oct 5, 2014

- Messages

- 345

- Reaction score

- 242

- Points

- 928

- Location

- pa

- Country

- USA

- Snowmobile

- 2015 yamaha ltx dx

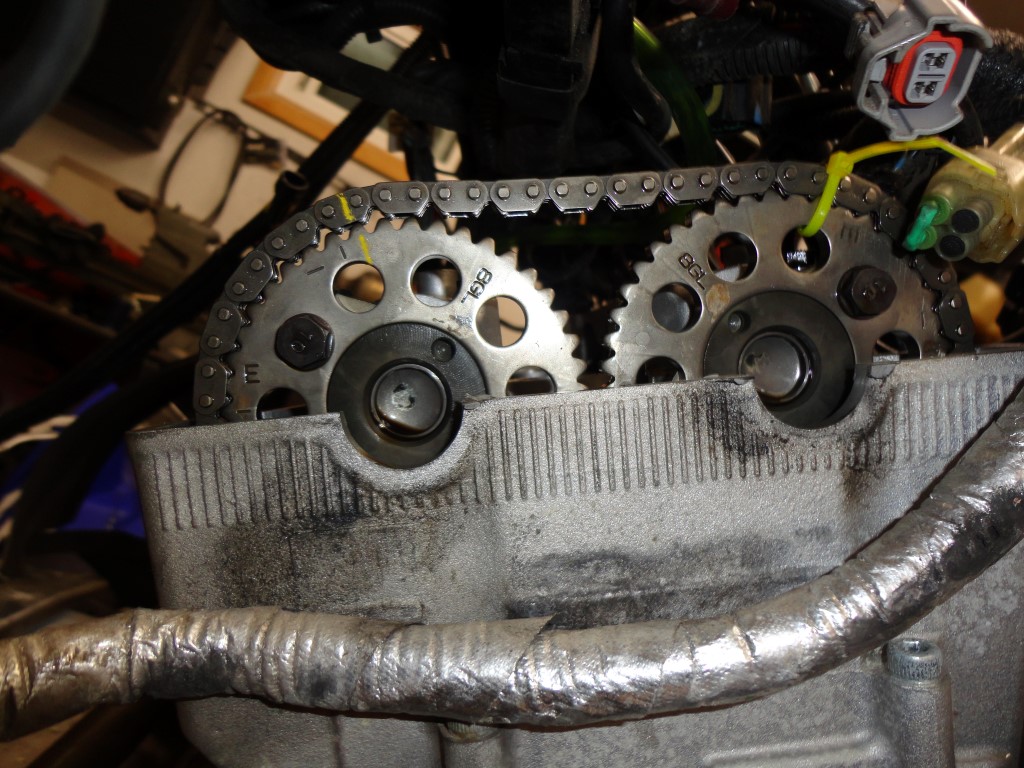

Does the chain tensioner have a ratcheting plunger on the end were it rides on the back of the guide or is it a fixed position type.

I believe it's ratcheting type with spring and oil assist. Wish they would have made it so you could release ratchet and push it back from chain galley. But there is just a little catch that you release once cams are timed. We will see. Should have it out tomorrow.

Does the chain tensioner have a ratcheting plunger on the end were it rides on the back of the guide or is it a fixed position type.

Allan

TY 4 Stroke Junkie

- Joined

- Oct 19, 2014

- Messages

- 719

- Reaction score

- 270

- Points

- 788

- Location

- Newfoundland

- Country

- Canada

- Snowmobile

- 2016 Sr Viper XTX

I seen mine all stripped down. jackshaft brace was removed and the steering & braces. Also interested in seeing what your leak down # are. Good luck with it , your doing a great job providing to us all on the procedure of this.

Dang didnt even take a 1/4 or a whole beer for me.

Timing

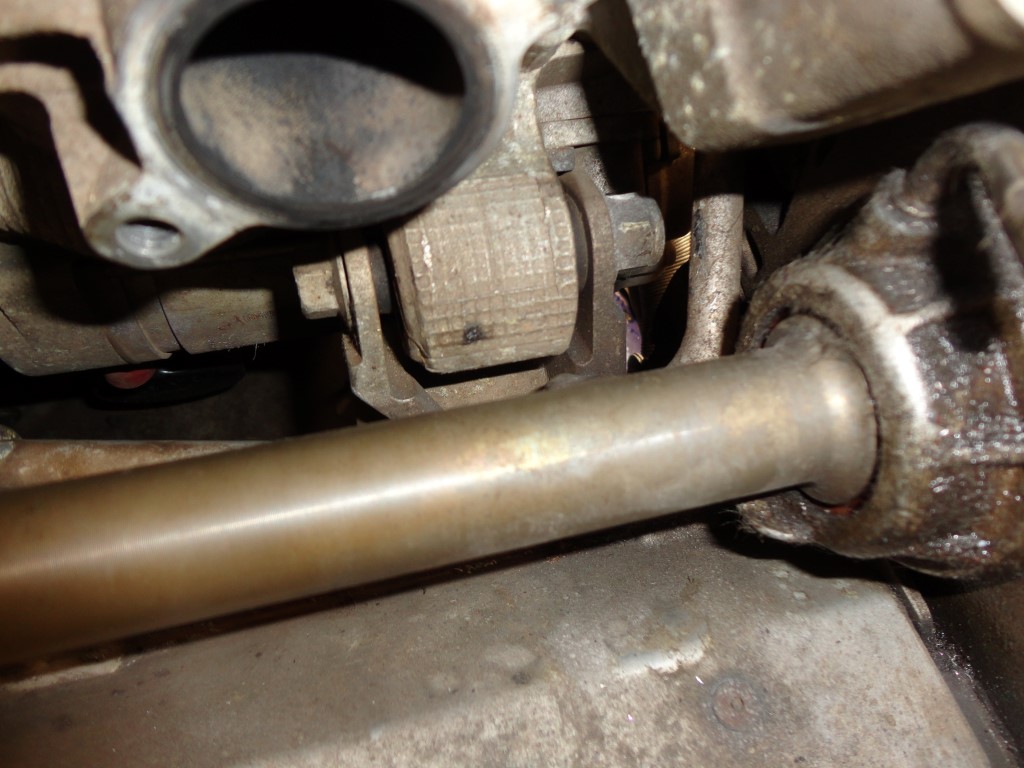

The state of it to get there.

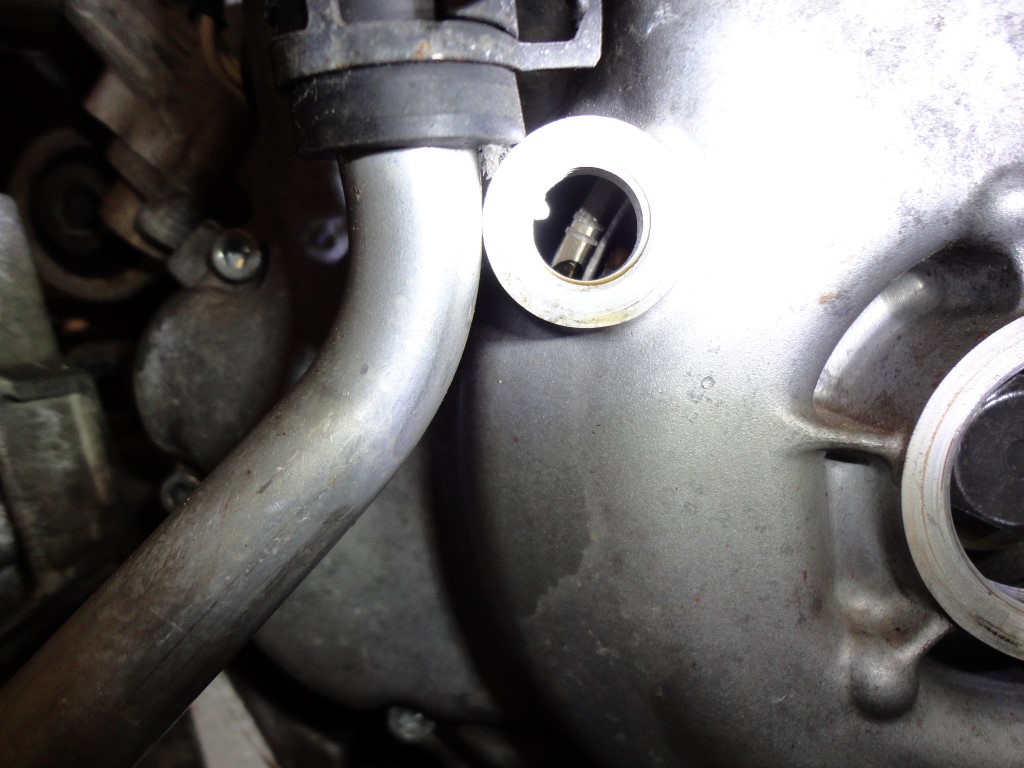

Length of engine mount bolt is how high up it needs to go for easy Cam Chain Tensioner removal.

Timing

The state of it to get there.

Length of engine mount bolt is how high up it needs to go for easy Cam Chain Tensioner removal.

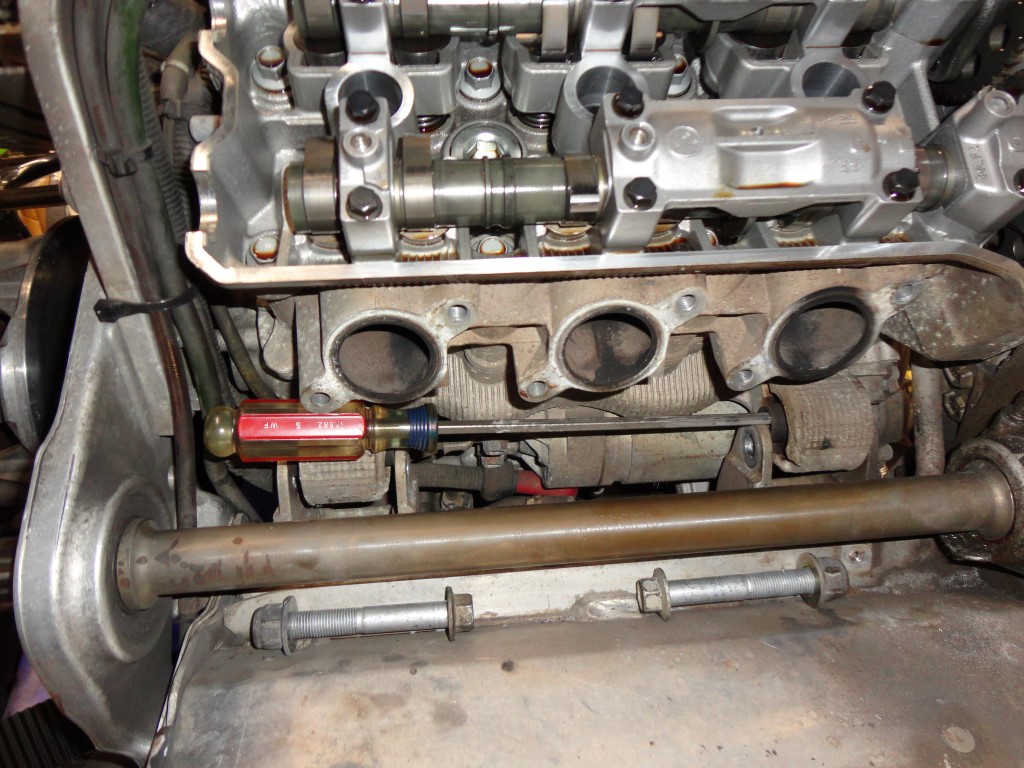

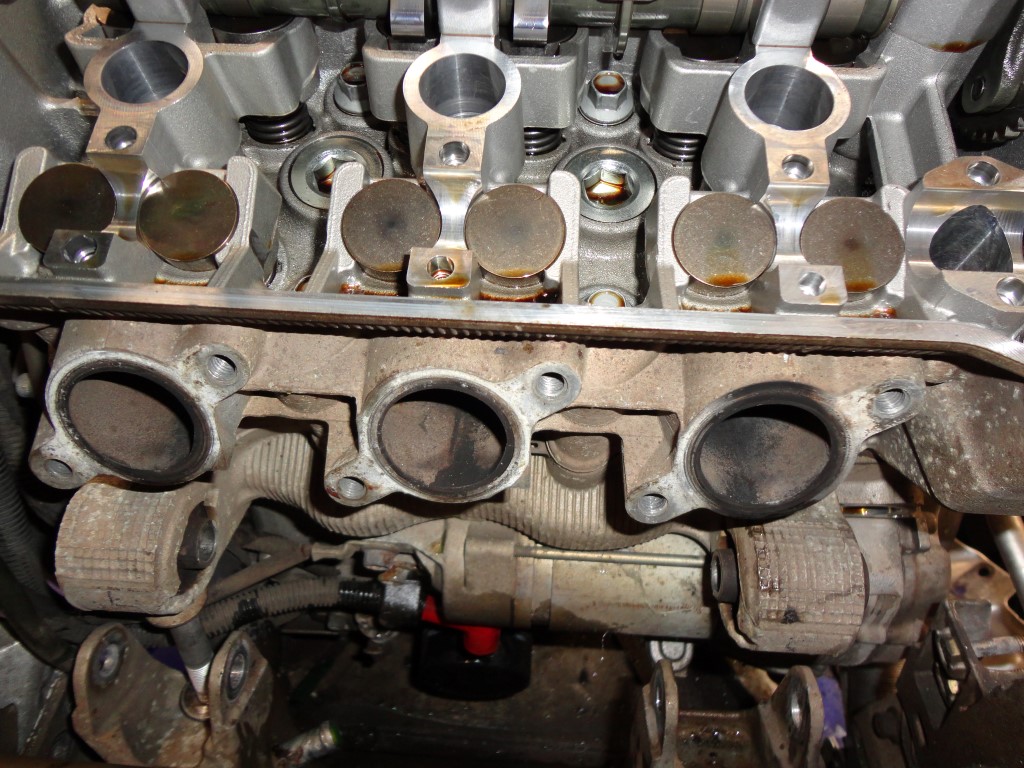

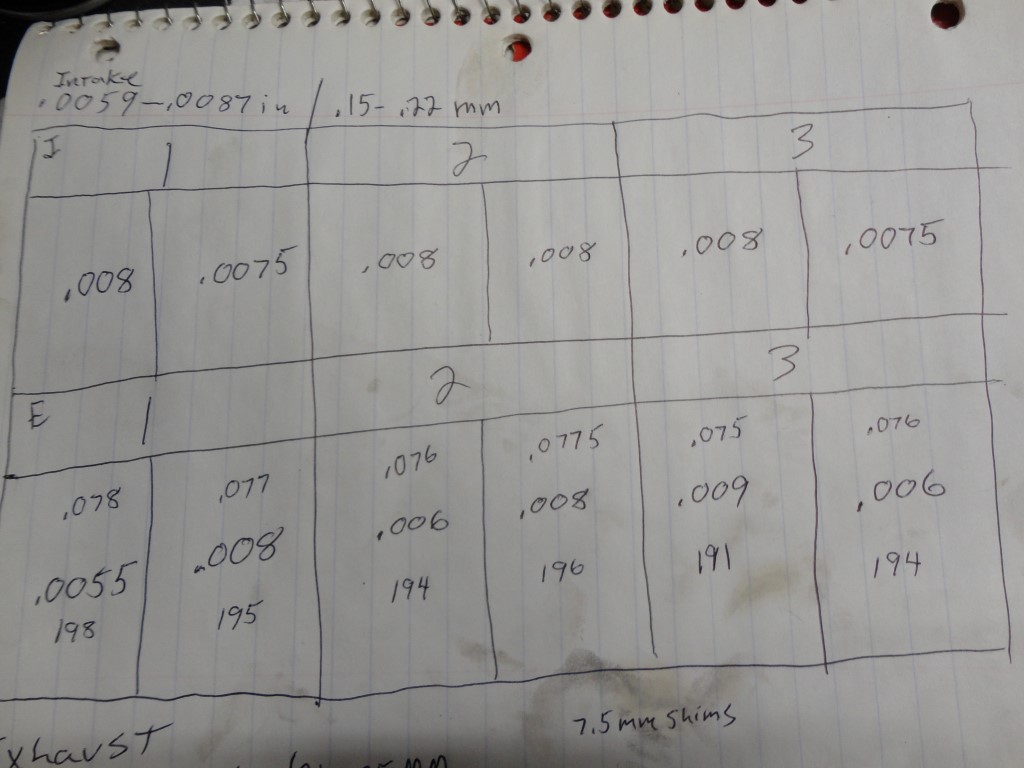

Results for new shim sizing. Guys these results tell me they were never adjusted right at factory. I use a magnet to pull both the bucket and shim out at same time. That way you dont have to go fishing. The 100 numbers are the sizes printed on the shims. I dont own a MM feeler guage and cant seem to find one that has all the sizes I need so have to do the math and measure. No biggie. Have always done it this way but would like a true MM feeler guage for simplicity if anyone knows where to get a good one.

cobrajet ltx dx

Lifetime Member

- Joined

- Oct 5, 2014

- Messages

- 345

- Reaction score

- 242

- Points

- 928

- Location

- pa

- Country

- USA

- Snowmobile

- 2015 yamaha ltx dx

There all in the 190 range, that’s all normal Japanese engineering and setup. No different from what I see with all Subaru bucket shim setups.

They were somewhere within there specs when assembled but you’ll NEVER have the same number shims installed because unfortunately there parts aren’t 100% exact.

To get the exact spec you want will require different shim #’s.

I usually see 180’s-190’s for intake and

200’s-230’s for exhaust as far as shim #’s go.

They were somewhere within there specs when assembled but you’ll NEVER have the same number shims installed because unfortunately there parts aren’t 100% exact.

To get the exact spec you want will require different shim #’s.

I usually see 180’s-190’s for intake and

200’s-230’s for exhaust as far as shim #’s go.

I know that but don't you find it odd that the only valve in tolerance is also the one with the smallest shim? Rest I would bet were set to bottom of tolerance which in my opinion is too tight to begin with. The #1 is the only real oddball.There all in the 190 range, that’s all normal Japanese engineering and setup. No different from what I see with all Subaru bucket shim setups.

They were somewhere within there specs when assembled but you’ll NEVER have the same number shims installed because unfortunately there parts aren’t 100% exact.

To get the exact spec you want will require different shim #’s.

I usually see 180’s-190’s for intake and

200’s-230’s for exhaust as far as shim #’s go.

cobrajet ltx dx

Lifetime Member

- Joined

- Oct 5, 2014

- Messages

- 345

- Reaction score

- 242

- Points

- 928

- Location

- pa

- Country

- USA

- Snowmobile

- 2015 yamaha ltx dx

I’m with ya, there is how it should be

OUR NORMAL THOUGHT PROCESS

AND THERE IS JAPANESE THOUGHT PROCESS.

After 11yrs dealing with them, I’m still going WTF when it comes to There manufacturing wisdom.

Just get her back within a acceptable range and enjoy the upcoming season.

OUR NORMAL THOUGHT PROCESS

AND THERE IS JAPANESE THOUGHT PROCESS.

After 11yrs dealing with them, I’m still going WTF when it comes to There manufacturing wisdom.

Just get her back within a acceptable range and enjoy the upcoming season.

Allan

TY 4 Stroke Junkie

- Joined

- Oct 19, 2014

- Messages

- 719

- Reaction score

- 270

- Points

- 788

- Location

- Newfoundland

- Country

- Canada

- Snowmobile

- 2016 Sr Viper XTX

This is marked on my bill about the shims but there is no lash readings marked there.

My shim from stock starting on mag side. 184 , 184, 188, 189, 190, 188.

they were replaced with --------------------160, 175, 175, 170 180, 160,

My shim from stock starting on mag side. 184 , 184, 188, 189, 190, 188.

they were replaced with --------------------160, 175, 175, 170 180, 160,

The difference in your numbers is the lash. There goes Cobras theory.This is marked on my bill about the shims but there is no lash readings marked there.

My shim from stock starting on mag side. 184 , 184, 188, 189, 190, 188.

they were replaced with --------------------160, 175, 175, 170 180, 160,

Similar threads

- Replies

- 38

- Views

- 12K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.