Allan there is a pattern emerging. #1 on both of ours was tightest and #5 was loosest. Coincidence? Maybe but I think factory issue.

Allan

TY 4 Stroke Junkie

- Joined

- Oct 19, 2014

- Messages

- 719

- Reaction score

- 270

- Points

- 788

- Location

- Newfoundland

- Country

- Canada

- Snowmobile

- 2016 Sr Viper XTX

If you look at the #'s the shim with the biggest change is #1 and #6 with 24 and 28 I'm think this was my tight valves?The difference in your numbers is the lash. There goes Cobras theory.

Also the one with 28 lash is more clearance than the manual recommends? (.021 to .025 recommend clearance )

I also looked up the shim chart in service manual and don't see any shims below #230. maybe there not all listed.

Last edited:

Froggy

Lifetime Member

- Joined

- Apr 29, 2016

- Messages

- 149

- Reaction score

- 70

- Points

- 753

- Location

- Kipawa,Quebec

- Country

- Canada

- Snowmobile

- 2020 Winder LTX SE 17600 km and counting

2016 Viper LTX LE 23986 km sold

2015 Viper LTX DX Wife's 22500 km sold

2010 Vector LTX GT 25000 km sold

2024 SRX Leftover 3700 km

I'm in the same boat as Allan, My shims are from 186 - 194 which are way below the chart, is there a new chart to consult or just do the math as I measured them with feeler gauges that have mm and inches on them? My # 1 cylinder was the worst with less than .0015" or .04mm feeler gauge being able to pass through. Only have 2 bad intake valves 1 at the minimum clearance and the other at the maximum clearance which I want to adjust. I have 4 tight exhaust valves from .0015" (.04mm) to .006" (.15mm) and the other 2 exhaust valves are at the max of .0085" (.21mm). I'm presuming that this is the culprit to my hard starting and low compression on the #1 and #2 cylinders when checked last fall. Is the tight clearances due to the material that the head is made from? Any input from the TY crowd is greatly appreciated.

Allan

TY 4 Stroke Junkie

- Joined

- Oct 19, 2014

- Messages

- 719

- Reaction score

- 270

- Points

- 788

- Location

- Newfoundland

- Country

- Canada

- Snowmobile

- 2016 Sr Viper XTX

How many km/miles yours?I'm in the same boat as Allan, My shims are from 186 - 194 which are way below the chart, is there a new chart to consult or just do the math as I measured them with feeler gauges that have mm and inches on them? My # 1 cylinder was the worst with less than .0015" or .04mm feeler gauge being able to pass through. Only have 2 bad intake valves 1 at the minimum clearance and the other at the maximum clearance which I want to adjust. I have 4 tight exhaust valves from .0015" (.04mm) to .006" (.15mm) and the other 2 exhaust valves are at the max of .0085" (.21mm). I'm presuming that this is the culprit to my hard starting and low compression on the #1 and #2 cylinders when checked last fall. Is the tight clearances due to the material that the head is made from? Any input from the TY crowd is greatly appreciated.

Just do the math and measure the replacement shim. I set mine to the top of clearance and left the intakes alone. I believe the tight tolerances are from Yamaha setting them wrong and valve train design. I cannot believe the resistance when turning this motor over caused by the valvetrain. Crazy spring pressure and aggressive cam profile. I spoke to my dealer and they have had to adjust valves on sleds with 200mi on them. That tells me they were tight from day one.I'm in the same boat as Allan, My shims are from 186 - 194 which are way below the chart, is there a new chart to consult or just do the math as I measured them with feeler gauges that have mm and inches on them? My # 1 cylinder was the worst with less than .0015" or .04mm feeler gauge being able to pass through. Only have 2 bad intake valves 1 at the minimum clearance and the other at the maximum clearance which I want to adjust. I have 4 tight exhaust valves from .0015" (.04mm) to .006" (.15mm) and the other 2 exhaust valves are at the max of .0085" (.21mm). I'm presuming that this is the culprit to my hard starting and low compression on the #1 and #2 cylinders when checked last fall. Is the tight clearances due to the material that the head is made from? Any input from the TY crowd is greatly appreciated.

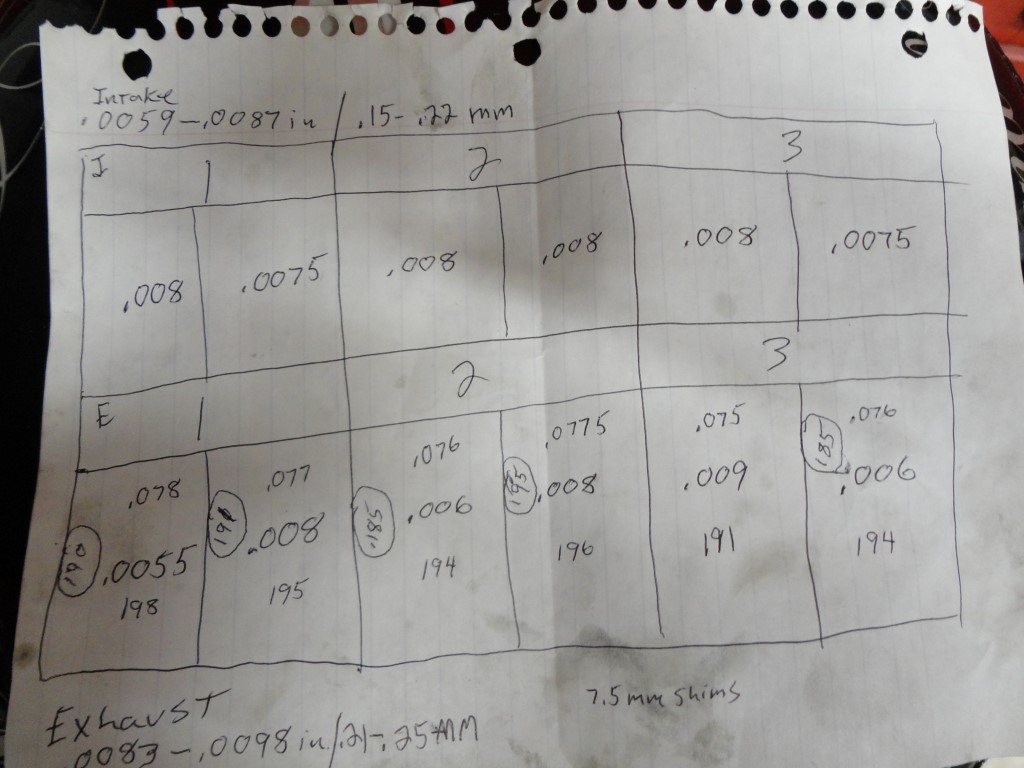

These were my final numbers. I believe I tweaked #2E a bit from whats written down. Circled are final shims. Been busy with work and shocks so as far as I got. The Mag side mount bolt was a bugger to get back in. Clutch side slid in with one finger so thats not good either! Will be checking clutch alignment.

Guys this kit is the way to go if doing this. I was able to find some shims I had and some at dealer but this is only $65 and allows you to dial it right in.

Condensed all my posts in first post. Put in FAQ. Suggest all other here do same and then once we all have seen our results in real world testing I will lock this thread. Is easier to read when all is right on first few pages.

Froggy

Lifetime Member

- Joined

- Apr 29, 2016

- Messages

- 149

- Reaction score

- 70

- Points

- 753

- Location

- Kipawa,Quebec

- Country

- Canada

- Snowmobile

- 2020 Winder LTX SE 17600 km and counting

2016 Viper LTX LE 23986 km sold

2015 Viper LTX DX Wife's 22500 km sold

2010 Vector LTX GT 25000 km sold

2024 SRX Leftover 3700 km

Allan, I'm working on the 2016 Viper which is just under 18000 km. Hopefully my wife's 2015 which has 16000 km is good for a while with the factory tune. Hers starts and runs perfect while the 2016 has always been a slow turning slug to start.How many km/miles yours?

DVW

Extreme

- Joined

- Nov 14, 2017

- Messages

- 74

- Reaction score

- 52

- Points

- 83

- Location

- Prior Lake Mn

- Country

- USA

- Snowmobile

- Arctic Cat 7000

My dealer developed a way to adjust valves with minimal disturbance of parts. They did not lift the engine. My valves got tight at 15k miles and then after 9k miles they got tight again. The second time around they developed the process because the first valve adjustment was labor intensive. They will likely use this minimally invasive process on other similar machines.

Last edited by a moderator:

I took off the minimum needed to get at Cam Chain Tensioner. Rest is pretty easy. Always welcome shortcuts but if you or they dont help its just advertising and frankly I dont believe it.My dealer developed a way to adjust valves with minimal disturbance of parts. They did not lift the engine. My valves got tight at 15k miles and then after 9k miles they got tight again. The second time around they developed the process because the first valve adjustment was labor intensive. They will likely use this minimally invasive process on other similar machines.

Last edited:

DVW

Extreme

- Joined

- Nov 14, 2017

- Messages

- 74

- Reaction score

- 52

- Points

- 83

- Location

- Prior Lake Mn

- Country

- USA

- Snowmobile

- Arctic Cat 7000

I see your point. The process took some thought on the part of the folks at Xxxxxxxx xxxxxx. I did not want to disrespecting their intellectual property. I think I did help. By telling everyone that a process does exist will cause it to enter public domain in short order. It’s not rocket science. When the lightbulb goes on in your head you will be a believer.I took off the minimum needed to get at Cam Chain Tensioner. Rest is pretty easy. Always welcome shortcuts but if you or they dont help its just advertising and frankly I dont believe it.

Last edited by a moderator:

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,518

- Reaction score

- 3,788

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

The only possible way would be to compress the tensioner while still in the vehicle OR make sure the tensioner did not move when removing the cams.

I don’t keep secrets like that and neither should you. Either spill the beans or shut up. It’s not even funny the work involved in this. Now I am a dimwit for not figuring this out! Bull. Yes I am pissed. Hate people like you.I see your point. The process took some thought on the part of the folks at Xxxxxxxxxxx. I did not want to disrespecting their intellectual property. I think I did help. By telling everyone that a process does exist will cause it to enter public domain in short order. It’s not rocket science. When the lightbulb goes on in your head you will be a believer.

DVW

Extreme

- Joined

- Nov 14, 2017

- Messages

- 74

- Reaction score

- 52

- Points

- 83

- Location

- Prior Lake Mn

- Country

- USA

- Snowmobile

- Arctic Cat 7000

Canandale27, I am sorry I angered you and can see that I was insensitive. I have much respect for you. Just like that it has been brought into public domain. As with other things that you have brought to light this process will be shared with others. I will shut up.The only possible way would be to compress the tensioner while still in the vehicle OR make sure the tensioner did not move when removing the cams.

Similar threads

- Replies

- 38

- Views

- 13K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.