Seavey82

Pro

It's not horrible I am just OCD, you can finish it yourself to take out any imperfections with a razor blade or a foam scraper. You can just tell their not concerned with perfection. Looks like it was just taken out of the mold and slapped in a box looks like they never took the time to clean it up. I can tell from your pics that wrp took their time with the foam, rounded and cleaned it up nicely before they sent it. I did touch mine in several places before I installed the cover, but no I really wasent overly impressed with the quality of the foam. The seat cover itself was really nice quality.Yes its the heat demon. Sorry to hear the seat concepts may not be as precise. Was considering getting one for one of our other nytros.

Last edited:

4strokes

Expert

- Joined

- Mar 13, 2018

- Messages

- 323

- Age

- 51

- Location

- charlemont ma

- Country

- USA

- Snowmobile

- 18 winder xtx 09 nytro xtx 06 apex gt

I agree with this, I just did one for my apex and they sent me the right cover with the wrong foam. In a huge box, twice the size, bouncing around and torn. then back and forth for a week before they finally sent the right one. no part numbers on foam, cover or box or paperwork of any kind. they made me send several pics like I had no idea what I was talking about. and yes, my nytro wrp cover from years ago had a much better looking logo. there are no other options out there, is what it is. I dont think it would kill them to mark the stuff with an id or fitment

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

Same... 2x oversize box with zero packing... The packing bag was dislodged and the water vapor barrier, cover and instruction sheet were dispersed in the box which was broken by careful UPS handling! I never throught to check it was a Nytro seat cover or Nytro foam... I bought mine through Barn of Parts so know they will take care of anything but too bad not a better presentation. I did read a foam scraper / file / cheese grater thing is common to shape raw foam out of the mold. I thought mine looked more like the WRP, will have to check tomorrow. Plan to put sled in garage Monday and work on it so all prepped by early December. Regardless, excited to have a higher seating position, foam appeared heavy and dense and cover quality appeared good too.I agree with this, I just did one for my apex and they sent me the right cover with the wrong foam. In a huge box, twice the size, bouncing around and torn. then back and forth for a week before they finally sent the right one. no part numbers on foam, cover or box or paperwork of any kind. they made me send several pics like I had no idea what I was talking about. and yes, my nytro wrp cover from years ago had a much better looking logo. there are no other options out there, is what it is. I dont think it would kill them to mark the stuff with an id or fitment

Seavey82

Pro

My brother just received his seat concepts seat in for his apex and guess what, they sent him the wrong foam. Not even remotely close so he will be sending it back and wont be getting a replacement. Hope he doesnt struggle returning it like you did. Guess seat customs havent learned much since your return. You can tell they aren't sled people and definently dont pay attention to detail. That will be the last order they see from either one of us. We don't care if they are the only game in town.I agree with this, I just did one for my apex and they sent me the right cover with the wrong foam. In a huge box, twice the size, bouncing around and torn. then back and forth for a week before they finally sent the right one. no part numbers on foam, cover or box or paperwork of any kind. they made me send several pics like I had no idea what I was talking about. and yes, my nytro wrp cover from years ago had a much better looking logo. there are no other options out there, is what it is. I dont think it would kill them to mark the stuff with an id or fitment

Last edited:

jimbur

Expert

- Joined

- Aug 16, 2013

- Messages

- 204

- Location

- Bernville Pa

- Country

- USA

- Snowmobile

- 09 NYTRO XTX

14 NYTRO XTX

08 NYTRO RTX

07 PHAZER

- LOCATION

- Pa.

My brother just received his seat concepts seat in for his apex and guess what, they sent him the wrong foam. Not even remotely close so he will be sending it back and wont be getting a replacement. Hope he doesnt struggle returning it like you did. Guess seat customs havent learned much since your return. You can tell they aren't sled people and definently dont pay attention to detail. That will be the last order they see from either one of us. We don't care if they are the only game in town.

Shame on them.

Guess I'll look more closely at mountain mod seats if buying anything in the future. I like that they have storage and great design although the price of them are obscene.

4strokes

Expert

- Joined

- Mar 13, 2018

- Messages

- 323

- Age

- 51

- Location

- charlemont ma

- Country

- USA

- Snowmobile

- 18 winder xtx 09 nytro xtx 06 apex gt

losers, they probably sent my return tight out to the next guy. the future looks bright

Seavey82

Pro

Yeah I was looking at mountain mod I have read great things on their seats, and there are several options to choose just not sure if he is still making seats or not? I agree the price is high but at least it come on a pan. Hopefully seat customs gets their stuff together.

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

I went out and checked my foam after reading above and it appears to be the correct seat for a Nytro and smooth, a few mild mold marks but from what I have read in general not bad. I don't have an impression yet on the cover quality but seems pretty well made but time will tell. I was not aware of many Nytro options and the WRP form has good reviews so hoping this version lives up to their reputation.

Seavey82

Pro

Hooray, how did u make out with the seat? I heard they are grooming in northern Maine already. I'm sure I will be heading to Caribou soon.

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

Bring on the snow! 15" in York Maine tonight, tomorrow, 6" Tuesday... Too bad I leave for Ft. Benning GA tomorrow for three days. Can't wait to ride, doing my seat this weekend.

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

Planning to start on this season's updates Thursday, seems like December has flown by. We started out with 18" but next week in the 40s will likely kill the 3" of snow left on the ground in Southern Maine. Up north they have zip, unusual snow pattern with us getting two storms approx 20" total... Hoping for a few good storms so January has some riding. Will post pics of the updates: black hood, black tank cover, black WRP / Seat Concepts Seat, PowerMadd Sentinel LED light inserts & dash on/off switch (tbd type switch and where), repack main bearings (two on clutch side, one in chain-case), refill chain-case, blue LED ground effects (had for a few years and have not put them on), regular grease and lube points (synthetic waterproof), aluminum polish tunnel, replace Yamaheater dash switch (or re-solder connections underneath), install updated Rocz HID ballasts. Possibly install a GPS on bars so I can see while riding but not sure yet if that will happen this year or not, anyone tried the new Garmin with large screen? Need to do some research on the exact models out now... Bring on the SNOW! Happy Holidays to all!

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

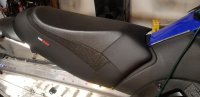

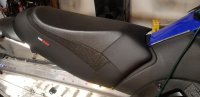

Finally had some time to get working on Nytro 2019 improvements (or are they 2020!). Considering we have no riding in Maine, we will call them 2020 improvements. So I started with my new Seat Concepts (previously WRP) taller seat upgrade. I know zip about seat upholstery so did some youtube lookups. I found a motorcycle seat video that was helpful as some have noted that their seat foam was "rough" from the mfg. This is true, mine was not ready for installation as received (and as I learned on the motorcycle video). They have a foam "rasp" which of course I did not have but I just bought some sanding disc "screens" for my orbital sander and they worked GREAT! Very little material comes off so I could not screw it up! As the pictures show (and I posted a lot as nobody seems to post the details, just before and after), there was a lot of "shaping" and final smoothing out to do. ANY imperfection that protrudes will be felt after the cover is installed. Dimples and other foam mold imperfections (I had three large lines on the rear) are not a big deal and you cant feel or see them after the cover is on. I am glad I did not just install the foam as is and took the time to smooth out all the foam seams where the two halves of the mold came together. When I removed the existing Yamaha seat I was surprised only the front lip was glued down, the rest was free floating. The Seat Concepts instructions were generic and not super helpful. I noticed the foam fit perfectly into the seat pan so no need for the "white EPS foam spacer" they mention in Step #4. They also make no mention of smoothing out the foam or provide any details on the glue step "how to"... Next post will show the glue step.

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

Ok, now the fun experiment with the spray adhesive. Totally by luck I bought a can of 3M Super-77 spray adhesive to glue some photos onto foam board for a show I was attending... perfect, I had the right stuff. So the glue goes on super thin and goes from thin liquid to tacky to dry fast so no screwing around. I decided to hit the entire pan and foam even though the Yamaha only glued the lip. I think it was the right call but this stuff sticks, do some dry runs as you don't have a 2nd chance for the first adhesion. I lined up the large blocks on the bottom of the seat as they press forward and line up the front edge (critical) so the foam seems like it stick up over the front of the pan which I learned is what you want. As you can see in the first two pictures the initial glue did not capture the edges, impossible to get to them all before the glue dried up. I debated if it was really critical to glue the edges to the pan and decided to err on the side of caution and glue everything up tight (I don't plan to ever install another seat on this sled). The system that ended up working the best was to hold the foam back on a small 6" section of the seat (I started with the front) and spray in glue to wet both the foam and seat pan, then pull the foam (pull hard) out and into position as flush with the edge of the plastic pan as possible. The Yamaha foam actually overlapped the pan but the new foam did not have the same thin foam edge to overlap so I improvised. I am glad I did this as I suspect relying on the cover to hold the edge down over time stretches the cover (others with a WRP might have real experience with this). Anyways, I used a pair of clamps on the front edge and taped next to it. As you can see in the picture what I thought was a huge overlap on the front edge aligned perfectly when I glued the edges down. I went around the entire seat this way, foam was solid and tight to the pan when done. Ready for next step, the cover...

Last edited:

Hooray!

TY 4 Stroke Junkie

- Joined

- Aug 12, 2017

- Messages

- 707

- Location

- Maine USA

- Country

- USA

- Snowmobile

- 2009 Yamaha FX Nytro XTX

1998 Yamaha VMAX 700 XTC

So with zero experience but plenty of time, I started with the water shield, nothing more than a super thin sheet of plastic (think cheap paint tarp). I was not sure about even using this as the Yamaha did not have one but decided to go with it, went on easy enough and I taped it to the bottom pan and it never really got in the way and you can cant feel any of the areas it was doubled up on the corners through the cover. I tacked the front and then stretched the rear with the help of my Brother-in-law to check position and realized that the front has to go another 1.5" forward as the seat is designed so that the part you sit on overlaps the foam top edges all the way around (a picture of the end product would have been super helpful in the instructions). Anyways, after tacking, stretching, carefully pulling out the staples with a thin screwdriver so as to no rip the cover, I had things in position where I thought after stretching out the rear it would be where I wanted it... this was a total guess as the cover has a lot of stretch... the system used was a 2x4x8 sitting on two milk crates and my helper on top stretching the cover evenly with one hand on each side of the cover and me underneath stapling (and trying not to shoot a staple at my helper!). The pneumatic stapler was a huge help and used same depth staples as Yamaha did albeit slight smaller. The instructions say don't overtighten the cover but I wanted to duplicate what the stock seat tension was like which was pretty tight so I did not hold back too much on tension, results look fantastic so I would say go tight and you will get what you want. After going all the way around using the 2x4 method, I then went around again and actually removed most of the first staples and did a 4" section at a time with the pan side up as I could control the stapler and make sure every staple was tight. This cleaned up the crazy line of staples that I did while on my back with 8" of working space! End result as you can see in the picture looks really good to me. The cover it tight but not overly tight (I hope). There is some space between the seat cover and the little flip up on the rear of the seat and no amount of tensioning could eliminate it, just the way it was designed I guess but I think the Yamaha seat has the same thing. Last step is to do final trim and then install on sled after I put on the black tank cover panel. I dry fit it on the sled and think it looks fantastic. Appears to be very high quality cover materials (just like the old WRPs I think) and after sanding the foam, the foam too seems solid. I like the overall look and as noted guessed right on the final tacking of the front of the cover as the rear of the seat perfectly lines up with about a 3/4" reveal all the way around the "bump" with the top most flexible cover material where you sit down. Zero wrinkles and I am hopeful it will last many seasons, thanks Seat Concepts for supporting our Nytro habit! Happy New Year to all.

Last edited:

mp5

Expert

- Joined

- Feb 14, 2011

- Messages

- 363

- Age

- 55

- Location

- New Brunswick, Canada

- Country

- Canada

- Snowmobile

- 09 Nytro XTX

Looks great man...good job

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.