edge_232

Expert

- Joined

- Jan 15, 2014

- Messages

- 254

- Reaction score

- 25

- Points

- 388

- Location

- Madison WI

- Country

- USA

- Snowmobile

- 2011 Nytro MTX slowly being modded

2005 IQR Trail Converted

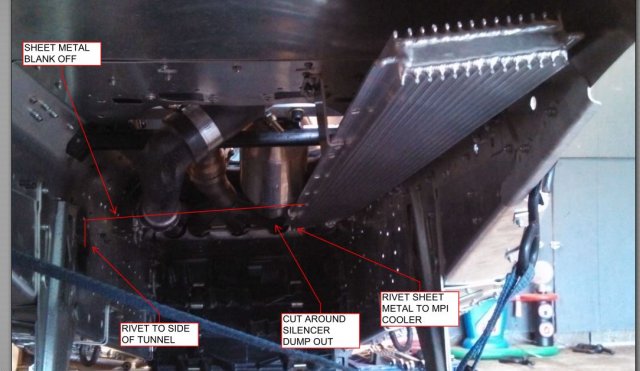

I ended up making a tunnel block off plate this weekend to see if it will help with all the icing. The plate is a little rough right now but if it works I'll make a better one this summer. To help simplify the process I bought a 16" x 8"x 48" 90 degree bent piece of ductwork from Home Depot for $15. Basically it's 2 sides of a square piece of duct.

I cut the the 8" short side down to 3/4" and used it as a mounting tab to rivet to the left side of the tunnel. This way I didn't need to try and make the 90 degree bend. I had to notch the 90 degree bend in spots to avoid some existing rivets.

I then cut the width down so I could rivet the right side to the plate heat exchanger & being sure to leave a small gap so the plate can rub on the exchanger (It shouldn't matter with the plate riveted to the exchanger but just to be safe).

Once the plate got to the rear of the sled just before the drop bracket and the rear exchanger vertical mount I trimmed both sides of the plate in (left side 1/2" to miss the drop bracket & the right side by 3/4" so it can fold up & be riveted to the top of the tunnel).

With the push turbos exhaust being dumped under the tunnel I also had to cut a opening in the plate to allow the silencer to stub out of the plate and into the tunnel.

I talked to Matt at MPI and asked him if he thought I would have any cooling issues now that the top of the heat exchanger is blocked off and no snow will get to it. He didn't thing there would be an issue since their cooler is so large. Before I but the plate on I was running 154 degree with the scratchers down and as soon as I jumped into some powder the temps dropped to 140's. Now with the back of the cooler still open I should get some snow thrown to the top side of it.

You can't tell in the picture but I stopped the plate just in front of the Y-pipe in the header so some of the heat can still escape from this void and typically I haven't had an icing issue in this area.

I'm also you to spray the plate and tunnel side walls with the cheaper yearly application of "Sure Foot" . So with the plate and that I should have the icing fixed I hope.

My only other 2 concerns are:

1) with the plate going all the way across will this cause excess heat ?

2) also with the plate all the way across it puts my turbo charge tube in this tighter space with the exhaust. Will this effect the temp of the incoming air and make iot too hot or effect performance?

Now to get out and test it.

I cut the the 8" short side down to 3/4" and used it as a mounting tab to rivet to the left side of the tunnel. This way I didn't need to try and make the 90 degree bend. I had to notch the 90 degree bend in spots to avoid some existing rivets.

I then cut the width down so I could rivet the right side to the plate heat exchanger & being sure to leave a small gap so the plate can rub on the exchanger (It shouldn't matter with the plate riveted to the exchanger but just to be safe).

Once the plate got to the rear of the sled just before the drop bracket and the rear exchanger vertical mount I trimmed both sides of the plate in (left side 1/2" to miss the drop bracket & the right side by 3/4" so it can fold up & be riveted to the top of the tunnel).

With the push turbos exhaust being dumped under the tunnel I also had to cut a opening in the plate to allow the silencer to stub out of the plate and into the tunnel.

I talked to Matt at MPI and asked him if he thought I would have any cooling issues now that the top of the heat exchanger is blocked off and no snow will get to it. He didn't thing there would be an issue since their cooler is so large. Before I but the plate on I was running 154 degree with the scratchers down and as soon as I jumped into some powder the temps dropped to 140's. Now with the back of the cooler still open I should get some snow thrown to the top side of it.

You can't tell in the picture but I stopped the plate just in front of the Y-pipe in the header so some of the heat can still escape from this void and typically I haven't had an icing issue in this area.

I'm also you to spray the plate and tunnel side walls with the cheaper yearly application of "Sure Foot" . So with the plate and that I should have the icing fixed I hope.

My only other 2 concerns are:

1) with the plate going all the way across will this cause excess heat ?

2) also with the plate all the way across it puts my turbo charge tube in this tighter space with the exhaust. Will this effect the temp of the incoming air and make iot too hot or effect performance?

Now to get out and test it.

edge_232

Expert

- Joined

- Jan 15, 2014

- Messages

- 254

- Reaction score

- 25

- Points

- 388

- Location

- Madison WI

- Country

- USA

- Snowmobile

- 2011 Nytro MTX slowly being modded

2005 IQR Trail Converted

Well my blank off plate never made it to testing. After I thought about it more it was a bad idea to have the charge tube in the same "chamber" as the header & hot air. Plus the turbo is designed to have snow thrown on it to help cool it. Now try not to laugh too much about my proto type (I'm still trying not to) I'll be testing it this weekend & if it works all make a nice one out of aluminium. Here are pictures before install and after.

Now this should be better for the sled but not as good for icing but better than nothing I hope.

Now this should be better for the sled but not as good for icing but better than nothing I hope.

harrysmith500

Newbie

Awesome write up! Going to get a brake assembly from Ebay and get to work!

edge_232

Expert

- Joined

- Jan 15, 2014

- Messages

- 254

- Reaction score

- 25

- Points

- 388

- Location

- Madison WI

- Country

- USA

- Snowmobile

- 2011 Nytro MTX slowly being modded

2005 IQR Trail Converted

Just be sure to get the correct one.

Year Model

03-06 Firecat 500/600

03 Z 440

03 ZL 600/800

03 ZR 900/800

04-06 Firecat 600/700

04-06 Sabercat 500/600/700

Year Model

03-06 Firecat 500/600

03 Z 440

03 ZL 600/800

03 ZR 900/800

04-06 Firecat 600/700

04-06 Sabercat 500/600/700

edge_232

Expert

- Joined

- Jan 15, 2014

- Messages

- 254

- Reaction score

- 25

- Points

- 388

- Location

- Madison WI

- Country

- USA

- Snowmobile

- 2011 Nytro MTX slowly being modded

2005 IQR Trail Converted

Well I ended up having to pull my MPI heat exchange and relocate it farther forward about 3-1/4" to be exact. When the rear suspension was fully compressed the track would just barely rub on the inside 3 ribs of the heat exchange. I put 200 miles on and just a little of ware was notice.

I'll have to post pictures later. Now I have the Power Claw 2.6" track on (.6" longer than what I had) and nothing hits at all and the at track is amazing! It worked great in the backwoods of the UP. Needless to saw I had to work the sled pretty good in the tight sections but got the hang of it by the third day. Now she is a heavy girl and will never be like a Pro but fun all the same. I 'll do a more descriptive write up later when I have more time and there are a few things I want to change or adjust.

I'll have to post pictures later. Now I have the Power Claw 2.6" track on (.6" longer than what I had) and nothing hits at all and the at track is amazing! It worked great in the backwoods of the UP. Needless to saw I had to work the sled pretty good in the tight sections but got the hang of it by the third day. Now she is a heavy girl and will never be like a Pro but fun all the same. I 'll do a more descriptive write up later when I have more time and there are a few things I want to change or adjust.

Off Trail Mike

Gone Riding!

- Joined

- Dec 26, 2009

- Messages

- 703

- Reaction score

- 39

- Points

- 838

- Location

- Bathurst, NB, Canada

- Country

- Canada

- Snowmobile

- MTX

Hey Edge:

PC 2.6?? Using 7 tooth drivers? Didn't thing there was room but good to know I can upgrade some day

OTM.

PC 2.6?? Using 7 tooth drivers? Didn't thing there was room but good to know I can upgrade some day

OTM.

edge_232

Expert

- Joined

- Jan 15, 2014

- Messages

- 254

- Reaction score

- 25

- Points

- 388

- Location

- Madison WI

- Country

- USA

- Snowmobile

- 2011 Nytro MTX slowly being modded

2005 IQR Trail Converted

Plenty of room, well enough & that track makes me look like I somewhat know what I'm doing.

OTM

I know you were using your Evols just for the extra volume for the main chamber. I can't remember what pressure did you end up using?

I ran mine 120 in the evol & 50 in the main I think & seemed fine. Just want to try it your way too.

OTM

I know you were using your Evols just for the extra volume for the main chamber. I can't remember what pressure did you end up using?

I ran mine 120 in the evol & 50 in the main I think & seemed fine. Just want to try it your way too.

edge_232

Expert

- Joined

- Jan 15, 2014

- Messages

- 254

- Reaction score

- 25

- Points

- 388

- Location

- Madison WI

- Country

- USA

- Snowmobile

- 2011 Nytro MTX slowly being modded

2005 IQR Trail Converted

So the initial location I had my the MPI heat exchanger mounted was not forward enough in the tunnel and after 200 miles I notice some rubbing on the end of the cooler.

To the best of my knowledge the cooler was mounted in the relatively correct location and at this time my paddles were only 2". Once I install my new 2.6" PC the rubbing will only get worse so I had to relocate the cooler. Now remember I have a Cat M-Series so it is possible that the stock Nytro MTX track might not rub so this is no fault or complaints about MPI's cooler. The height of the cooler was fine since it couldn't go any higher anyways.

I left the tunnel drop brackets and side mounts for the cooler in their current locations connected to the tunnel and just drilled the rivets out to the cooler.

Once I found the forward most location I could mount the cooler, I marker the new mounting locations on the cooler and drilled them out. I was able to shift the cooler roughly 3-1/4" farther forward. In this picture you can see the old mounting location vs the new one.

Since the cooler is rigidly mounted I was able locate the cooler with in 1/2" of the header.

For future reference to anyone mounting one of the MPI coolers, you can mount it roughly 4" from the tunnel / heat shield.

Now I have run this new set up in the UP with my new 2.6" PC track for about 100 trail miles and 100 miles off trail and it works great with no rubbing or issues.

To the best of my knowledge the cooler was mounted in the relatively correct location and at this time my paddles were only 2". Once I install my new 2.6" PC the rubbing will only get worse so I had to relocate the cooler. Now remember I have a Cat M-Series so it is possible that the stock Nytro MTX track might not rub so this is no fault or complaints about MPI's cooler. The height of the cooler was fine since it couldn't go any higher anyways.

I left the tunnel drop brackets and side mounts for the cooler in their current locations connected to the tunnel and just drilled the rivets out to the cooler.

Once I found the forward most location I could mount the cooler, I marker the new mounting locations on the cooler and drilled them out. I was able to shift the cooler roughly 3-1/4" farther forward. In this picture you can see the old mounting location vs the new one.

Since the cooler is rigidly mounted I was able locate the cooler with in 1/2" of the header.

For future reference to anyone mounting one of the MPI coolers, you can mount it roughly 4" from the tunnel / heat shield.

Now I have run this new set up in the UP with my new 2.6" PC track for about 100 trail miles and 100 miles off trail and it works great with no rubbing or issues.

edge_232

Expert

- Joined

- Jan 15, 2014

- Messages

- 254

- Reaction score

- 25

- Points

- 388

- Location

- Madison WI

- Country

- USA

- Snowmobile

- 2011 Nytro MTX slowly being modded

2005 IQR Trail Converted

As for the tunnel icing with the rear mounted Push Turbo I think I might just be screwed. The small heat shield seems to work some but I will need to get complete closure from the tunnel to the turbo but my main concern then is keeping the turbo and not trapping the heat around the turbo.

Existing heat shield, now I did put a divider wall between the charge tube and the header. Basicly this did nothing for me LOL.

This was my old design I never tested because I was afraid of trapping the heat around the turbo. I think it would of worked better for the icing but didn't try it.

One day I coated the tunnel with some DuPont Snow and Ice repellent and it seemed to help some.

But as of so far this has been the very best tool for excessive tunnel icing.

LMAO this is the truth!

LMAO this is the truth!

Now has anyone used one of the skinz light weight seats that removes the rear tunnel shrouding around the exhaust and in my case the turbo? And how is the heat from this.

Now if I went back to my old tunnel blank off design and one or these seat set ups it should keep the turbo cooler in my eyes. Any ideas or pointers would be appreciated.

Existing heat shield, now I did put a divider wall between the charge tube and the header. Basicly this did nothing for me LOL.

This was my old design I never tested because I was afraid of trapping the heat around the turbo. I think it would of worked better for the icing but didn't try it.

One day I coated the tunnel with some DuPont Snow and Ice repellent and it seemed to help some.

But as of so far this has been the very best tool for excessive tunnel icing.

LMAO this is the truth!

LMAO this is the truth!Now has anyone used one of the skinz light weight seats that removes the rear tunnel shrouding around the exhaust and in my case the turbo? And how is the heat from this.

Now if I went back to my old tunnel blank off design and one or these seat set ups it should keep the turbo cooler in my eyes. Any ideas or pointers would be appreciated.

Off Trail Mike

Gone Riding!

- Joined

- Dec 26, 2009

- Messages

- 703

- Reaction score

- 39

- Points

- 838

- Location

- Bathurst, NB, Canada

- Country

- Canada

- Snowmobile

- MTX

Plenty of room, well enough & that track makes me look like I somewhat know what I'm doing.

OTM

I know you were using your Evols just for the extra volume for the main chamber. I can't remember what pressure did you end up using?

I ran mine 120 in the evol & 50 in the main I think & seemed fine. Just want to try it your way too.

Rick:

75 in the evol chamber and 40-50 psi in the main chamber.

This setup gives you a lower effective spring rate so adjustments in the main will change the spring rate across the whole range of shock travel, not just the last 1/4 of the stroke, which is typical for a standard evol setup running 150+ psi . Translation: its easier to put on its side and you have a bit more adjustment to get it where you want it. I typically run my front end pretty soft, as I am more concerned with banking and side hilling than trail riding.

I suppose you could run almost zero PSI in the evol chamber to lower the rate even further, but never tried it.

Mike

harrysmith500

Newbie

Most of us in the west have given up on the season. You guys are still going hard out!

Off Trail Mike

Gone Riding!

- Joined

- Dec 26, 2009

- Messages

- 703

- Reaction score

- 39

- Points

- 838

- Location

- Bathurst, NB, Canada

- Country

- Canada

- Snowmobile

- MTX

edge_232

Expert

- Joined

- Jan 15, 2014

- Messages

- 254

- Reaction score

- 25

- Points

- 388

- Location

- Madison WI

- Country

- USA

- Snowmobile

- 2011 Nytro MTX slowly being modded

2005 IQR Trail Converted

Dam that looks awesome & I'm so jealous. Right we just got about 4" of wet stuff & it's already melting. It's been a poor winter for WI but I did get the testing in I need & in all most of my mods worked.

edge_232

Expert

- Joined

- Jan 15, 2014

- Messages

- 254

- Reaction score

- 25

- Points

- 388

- Location

- Madison WI

- Country

- USA

- Snowmobile

- 2011 Nytro MTX slowly being modded

2005 IQR Trail Converted

Off Trail Mike

Gone Riding!

- Joined

- Dec 26, 2009

- Messages

- 703

- Reaction score

- 39

- Points

- 838

- Location

- Bathurst, NB, Canada

- Country

- Canada

- Snowmobile

- MTX

Rick:

What is that??? Stocker with foam out??? I recognize the wrp in back which is comfy as h*ll but way to big for mountain riding. Skinz seat ( I have ) is narrow but too high as well. What you got goin' on there???

Going out this Thursday....spring coming, but still time. Going to be 35 deg. F this week for highs and down to 10 deg F. nights so winter still taking its sweet time to retreat.

Riding now is far better than freezing your butt off in Jan/Feb.

OTM

What is that??? Stocker with foam out??? I recognize the wrp in back which is comfy as h*ll but way to big for mountain riding. Skinz seat ( I have ) is narrow but too high as well. What you got goin' on there???

Going out this Thursday....spring coming, but still time. Going to be 35 deg. F this week for highs and down to 10 deg F. nights so winter still taking its sweet time to retreat.

Riding now is far better than freezing your butt off in Jan/Feb.

OTM

Similar threads

- Replies

- 25

- Views

- 6K

- Replies

- 58

- Views

- 7K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.