jpilk99

Pro

- Joined

- Dec 11, 2021

- Messages

- 147

- Reaction score

- 38

- Points

- 223

- Location

- Bolton, MA

- Country

- USA

- Snowmobile

- 2006 Yamaha Apex GT

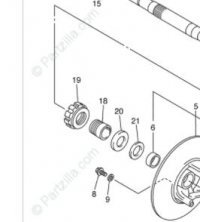

Oh, and one last question that I mentioned earlier about seeing a loose part, what I believe is called a "nut bearing" - #19 in the parts diagram. How tight does this need to be torqued too? I can probably snug it in pretty well with just pliers and the a little tap - tap - tap with a flat head screwdriver...

Attachments

72Gran

Lifetime Member

- Joined

- Jan 25, 2009

- Messages

- 149

- Reaction score

- 120

- Points

- 1,033

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 92 Vmax 4

21 Sidewinder LTX GT

98 Venture TF

If you look very close at this picture you can see the threads on the inside of the knurled part about half way between the outside knurl and the hole where the bolt goes in. It’s actually two pieces.Weird, I have an email that "stevewithOCD" posted a Reply, but, ...I don't see it here in the forum. It was in response to the focus on this black knurled knob that I have in my setup and the chrome/silver one in the video: Steve said:

stevewithOCD replied to a thread you are watching at TY4stroke: Snowmobile Forum | Yamaha - 4 Stroke.

Clutch servicing

It works the same.

When the bolt is tight, the locking screws unloosen to allow the collar to adjust in & out.

Yours is probably rusted or seized on there.

See the middle cylinder?

The collar pushes up against the Helix pushing the sheaves further apart.

When you loosen the collar on the threaded cylinder it allows the sheaves to get closer together.

This is what I've begun to think/understand that my Super Torquer is adjusted by those 3 allen bolts & locking nuts shown here. That's what I believe Steve was commenting on. (Weird that his post is not visible, or maybe I'm just missing something. Thanks Steve).

Happy New Year all!!!! Looking forward to putting secondary back on tomorrow and giving it a try to adjust and tighten up the belt deflection.

The three Allen bolts just hold the roller assembly to the clutch.

72Gran

Lifetime Member

- Joined

- Jan 25, 2009

- Messages

- 149

- Reaction score

- 120

- Points

- 1,033

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 92 Vmax 4

21 Sidewinder LTX GT

98 Venture TF

Yes you can tighten the nut with a punch or beater screwdriver. The nut locks the jack shaft bearing in place.Oh, and one last question that I mentioned earlier about seeing a loose part, what I believe is called a "nut bearing" - #19 in the parts diagram. How tight does this need to be torqued too? I can probably snug it in pretty well with just pliers and the a little tap - tap - tap with a flat head screwdriver...

72Gran

Lifetime Member

- Joined

- Jan 25, 2009

- Messages

- 149

- Reaction score

- 120

- Points

- 1,033

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 92 Vmax 4

21 Sidewinder LTX GT

98 Venture TF

You can see the threads in this picture.If you look very close at this picture you can see the threads on the inside of the knurled part about half way between the outside knurl and the hole where the bolt goes in. It’s actually two pieces.

The three Allen bolts just hold the roller assembly to the clutch.

Attachments

jpilk99

Pro

- Joined

- Dec 11, 2021

- Messages

- 147

- Reaction score

- 38

- Points

- 223

- Location

- Bolton, MA

- Country

- USA

- Snowmobile

- 2006 Yamaha Apex GT

I must be misunderstanding something but whether there are threads there: it’s not threaded Onto anything. That black knurled knob is effectively just a big ol washer. See the other pics of the knob and bolt in my hand? The knob is not threaded onto any …tube or column (for lack of a better term) that would be actuated by rotating the knob. You could turn that knob 100 revolutions and nothing would happen because it’s not threaded onto anything.You can see the threads in this picture.

jpilk99

Pro

- Joined

- Dec 11, 2021

- Messages

- 147

- Reaction score

- 38

- Points

- 223

- Location

- Bolton, MA

- Country

- USA

- Snowmobile

- 2006 Yamaha Apex GT

Sorry if I’m stone cold dumb on this…. In that video, the knurled chrome knob is threaded onto another piece that I’m calling a tube/column

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,060

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Weird, I have an email that "stevewithOCD" posted a Reply, but, ...I don't see it here in the forum. It was in response to the focus on this black knurled knob that I have in my setup and the chrome/silver one in the video: Steve said:

stevewithOCD replied to a thread you are watching at TY4stroke: Snowmobile Forum | Yamaha - 4 Stroke.

Clutch servicing

It works the same.

When the bolt is tight, the locking screws unloosen to allow the collar to adjust in & out.

Yours is probably rusted or seized on there.

See the middle cylinder?

The collar pushes up against the Helix pushing the sheaves further apart.

When you loosen the collar on the threaded cylinder it allows the sheaves to get closer together.

This is what I've begun to think/understand that my Super Torquer is adjusted by those 3 allen bolts & locking nuts shown here. That's what I believe Steve was commenting on. (Weird that his post is not visible, or maybe I'm just missing something. Thanks Steve).

Happy New Year all!!!! Looking forward to putting secondary back on tomorrow and giving it a try to adjust and tighten up the belt deflection.

My comment was made about the newer piece someone sent a pic of so i deleted it.

I was waiting for a different pic to see the threads on yours.

I think yours is just rusted or corroded together.

I'm so damn curious about your new sled, i was thinking of driving an hour to go see you......

If i could find my Spider Wrench, i'd be there with coffee by now. I am stevewithOCD ya know

P.S:

Spider Wrench= big 3' bar & clutch holder combo designed to remove Spider on Primary Clutch

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,060

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

If there's a problem with your device, see if you can go back to stock bolt.

That device is for precision Tuning & ease of belt removal.

The Apex belt is RIDICULOUSLY easy to change & rarely do you need to change the belt height.

That device is for precision Tuning & ease of belt removal.

The Apex belt is RIDICULOUSLY easy to change & rarely do you need to change the belt height.

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,060

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

If you have no luck, i may grab a box of Apex parts & head up there.

Why Not?

There's no snow & i'm almost out of Steel Duck Shot

Why Not?

There's no snow & i'm almost out of Steel Duck Shot

jpilk99

Pro

- Joined

- Dec 11, 2021

- Messages

- 147

- Reaction score

- 38

- Points

- 223

- Location

- Bolton, MA

- Country

- USA

- Snowmobile

- 2006 Yamaha Apex GT

Hah!! Now I get it. Thanks Steve - and thanks so much for your offer. While I’d love to see you in my driveway with parts - I feel like I’m missing something ultra obvious. I have to drop off a snowblower but I’ll get my butt back in the driveway and keep forging ahead. I think if I take a video or two and upload them, of the secondary, that will be helpful. I’m thinking the previous owner took off the “threaded tube/column” and forgot to put it back. But At the same time, I’m 99.9% sure there are no threads on this black knurled knob. That’s what I’ll take a video of!!! Thank youIf you have no luck, i may grab a box of Apex parts & head up there.

Why Not?

There's no snow & i'm almost out of Steel Duck Shot

jpilk99

Pro

- Joined

- Dec 11, 2021

- Messages

- 147

- Reaction score

- 38

- Points

- 223

- Location

- Bolton, MA

- Country

- USA

- Snowmobile

- 2006 Yamaha Apex GT

Thanks 72Gran. I'm about to upload a video that (Im pretty sure) shows that there aren't threads on the knurl disc. Hopefully this vid will help show what the heck I got goin on here ;-)If you look very close at this picture you can see the threads on the inside of the knurled part about half way between the outside knurl and the hole where the bolt goes in. It’s actually two pieces.

The three Allen bolts just hold the roller assembly to the clutch.

jpilk99

Pro

- Joined

- Dec 11, 2021

- Messages

- 147

- Reaction score

- 38

- Points

- 223

- Location

- Bolton, MA

- Country

- USA

- Snowmobile

- 2006 Yamaha Apex GT

You rock, Steve. Thanks so much for the offer. Again, please sit tight til I get this video uploaded. Hopefully this will be illuminating.If you have no luck, i may grab a box of Apex parts & head up there.

Why Not?

There's no snow & i'm almost out of Steel Duck Shot

jpilk99

Pro

- Joined

- Dec 11, 2021

- Messages

- 147

- Reaction score

- 38

- Points

- 223

- Location

- Bolton, MA

- Country

- USA

- Snowmobile

- 2006 Yamaha Apex GT

Here's the video I just shot of the Super Torquer secondary and that knurled washer/disc:

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,498

- Reaction score

- 4,166

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Everything appears to be there. The threads are under the outer portion that has the allen head bolt.(pinch bolt)Here's the video I just shot of the Super Torquer secondary and that knurled washer/disc:

Put the clutch bolt in with everything in place, and tighten it up. Then loosen the allen head bolt and turn the outer portion. It is designed to be able to turn with your fingers, but if it won't then gently try some channel locks.

72Gran

Lifetime Member

- Joined

- Jan 25, 2009

- Messages

- 149

- Reaction score

- 120

- Points

- 1,033

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 92 Vmax 4

21 Sidewinder LTX GT

98 Venture TF

Dude there is nothing missing. The knurled piece is actually two pieces. Check the picture I sent you. I can clearly see the threads where my arrow is. Use a magnifying glass if needed.

Install it on the sled and tighten

Loosen the Allen bolt which is a lock for the threads

Turn the knurled knob to adjust

The centre bolt will hold the threaded part and when you turn the knurled part it will either compress or decompress the clutch spring which will change the distance between the clutch sheaves.

The tube or column your referring to is just a spacer the same as the small one you remove in your video.

You cant go back to the stock adjustment bolts in the back because with those bolts removed you sheaves should be as close together as possible and they are obviously not. Unless there are some shim washers between the sheaves we don’t see.

Install it on the sled and tighten

Loosen the Allen bolt which is a lock for the threads

Turn the knurled knob to adjust

The centre bolt will hold the threaded part and when you turn the knurled part it will either compress or decompress the clutch spring which will change the distance between the clutch sheaves.

The tube or column your referring to is just a spacer the same as the small one you remove in your video.

You cant go back to the stock adjustment bolts in the back because with those bolts removed you sheaves should be as close together as possible and they are obviously not. Unless there are some shim washers between the sheaves we don’t see.

Similar threads

- Replies

- 6

- Views

- 3K

- Replies

- 2

- Views

- 877

- Replies

- 34

- Views

- 17K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.