FrozenTows4

Lifetime Member

- Joined

- Nov 6, 2014

- Messages

- 489

- Age

- 66

- Location

- Brainerd Minnesota

- Country

- USA

- Snowmobile

- 2014 XF7000 Sold

2017 ZR6000RS

2018 ZR6000 El Tigre

- YOUTUBE

- FrozenTows1

What is your Experience with the Barn of Parts Driveshaft Saver?

https://www.barnofparts.com/driveshaft-saver-new

Here's mine...

Both machines received a Driveshaft Saver at seasons start.

Wedge installed flush at 40ftlbs.

I Did Not check to see if the bearing was actually locked onto the shaft.

Just torque and go.

Machine #1

At 4500 miles wedge was installed.

2900 miles since install.

Still spinning.

Machine #2

At 2400 miles wedge was installed.

150 miles since install. Wife did not get to ride due to a non-sled related injury.

We can see that the wedge was "trying" to help, but shaft was already too far gone.

New driveshafts & bearings, for both machines will be coming shortly.

My thoughts are this...

-These driveshafts spin from day one

-Driveshaft Saver will only work on New Driveshafts & Bearings

-Driveshaft Saver May work at 1000 miles or less. Test, don't guess.

I feel the Barn of Parts Driveshaft Saver is a good solution to prevent the bearing from spinning on the shaft.

But the shaft has to be essentially new.

What are your experiences and observations?

https://www.barnofparts.com/driveshaft-saver-new

Here's mine...

Both machines received a Driveshaft Saver at seasons start.

Wedge installed flush at 40ftlbs.

I Did Not check to see if the bearing was actually locked onto the shaft.

Just torque and go.

Machine #1

At 4500 miles wedge was installed.

2900 miles since install.

Still spinning.

Machine #2

At 2400 miles wedge was installed.

150 miles since install. Wife did not get to ride due to a non-sled related injury.

We can see that the wedge was "trying" to help, but shaft was already too far gone.

New driveshafts & bearings, for both machines will be coming shortly.

My thoughts are this...

-These driveshafts spin from day one

-Driveshaft Saver will only work on New Driveshafts & Bearings

-Driveshaft Saver May work at 1000 miles or less. Test, don't guess.

I feel the Barn of Parts Driveshaft Saver is a good solution to prevent the bearing from spinning on the shaft.

But the shaft has to be essentially new.

What are your experiences and observations?

4strokes

Expert

- Joined

- Mar 13, 2018

- Messages

- 323

- Age

- 52

- Location

- charlemont ma

- Country

- USA

- Snowmobile

- 18 winder xtx 09 nytro xtx 06 apex gt

5000 miles and mine was shot. have a new axle and bearing with the wedge ready to install. that is my experience. I am glad I didn't procrastinate, It looks like yamaha is done handing them out

- Joined

- Feb 13, 2017

- Messages

- 188

- Age

- 69

- Location

- Amston,CT

- Country

- USA

- Snowmobile

- Renegade 900 ACE,XF 9000 Crosstour,2024 Skidoo Renegade XRS 900R

Looking at a track change after next season.Currently 5500 miles on sled,with drive shaft saver installed @3K .The Dealer in Essex jct. Vt.,Franks has a lower track drive shaft program in place,along with all drivetrain bearings being up graded,to NACHI,along with multiple chain case,and suspension upgrades,with track change.Please see dealer reply

Attachments

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,218

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

I am wondering if a bearing with less "drag" would help this situation? Take a new bearing. Cool it to 15 degrees. Try to turn it with your hands. Very hard to turn. This would make it more likely to turn on the shaft.

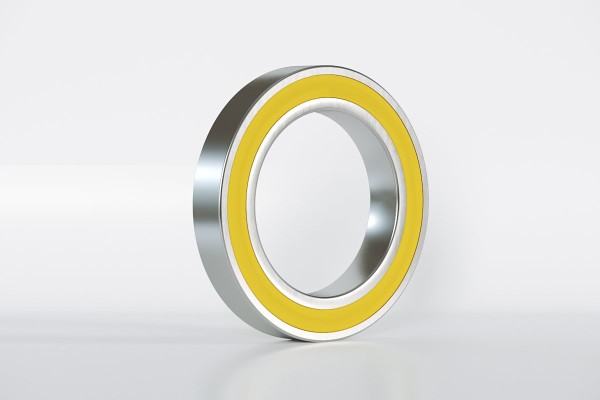

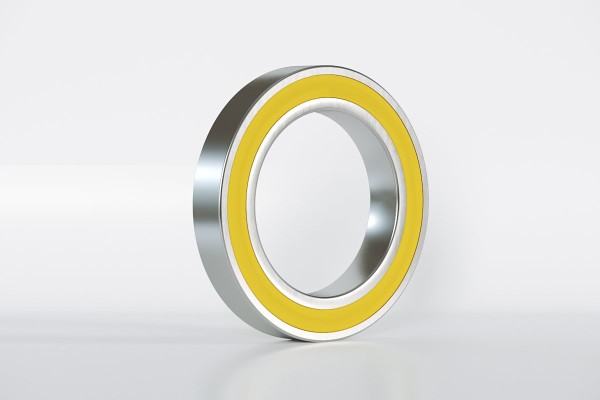

I know they are expensive but I found these ceramic bearings with some super low temp grease.

https://www.bocabearings.com/products/smr6009c-2ys-c3-3-mg2-8037

SMR6009C-2YS/C3 #3 MG2

45 x 75 x 16 Millimeters

0 Reviews

Description

Ceramic Lightning, yellow sealed bearings are specially designed for off-road or excessively dirty operating environments. These bearings are maintenance free and lubed for the life of the bearing. The heavy duty rubber seal provides extra protection against the harshest elements. These bearings have ceramic balls, with stainless steel races and retainers. Ceramic hybrids are lighter, capable of achieving higherRPMs and sustaining higher operating temperatures than traditional bearings. Bearings that are packed in grease will require a short break in period to loosen up. Grease can be removed before shipping upon request. C3 Fit, ABEC #3, (45x75x16)MM

I know they are expensive but I found these ceramic bearings with some super low temp grease.

https://www.bocabearings.com/products/smr6009c-2ys-c3-3-mg2-8037

SMR6009C-2YS/C3 #3 MG2

45 x 75 x 16 Millimeters

0 Reviews

Description

Ceramic Lightning, yellow sealed bearings are specially designed for off-road or excessively dirty operating environments. These bearings are maintenance free and lubed for the life of the bearing. The heavy duty rubber seal provides extra protection against the harshest elements. These bearings have ceramic balls, with stainless steel races and retainers. Ceramic hybrids are lighter, capable of achieving higherRPMs and sustaining higher operating temperatures than traditional bearings. Bearings that are packed in grease will require a short break in period to loosen up. Grease can be removed before shipping upon request. C3 Fit, ABEC #3, (45x75x16)MM

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,757

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

I found on mine torque had to be at least 55lbs to get it to grip. Even at that it was not bound on the shaft by any stretch.

Loctiting the shaft with the saver is not a bad combo but be sure to turn the shaft soon as you loctitite it together. I have had issues with the bearing and shaft 'not mating' and it not turning true.

Other misc thoughts: using a lower temp grease in that bearing, keeping your track tight and give everything in the am a chance to warm up and get more fluid. Run it a km or two at reasonable speed before goosing it.

When grease is cold it can be real stiff. I can only imagine cracking the throttle after a night of sitting the shaft will just spin on the bearing.

MS

Loctiting the shaft with the saver is not a bad combo but be sure to turn the shaft soon as you loctitite it together. I have had issues with the bearing and shaft 'not mating' and it not turning true.

Other misc thoughts: using a lower temp grease in that bearing, keeping your track tight and give everything in the am a chance to warm up and get more fluid. Run it a km or two at reasonable speed before goosing it.

When grease is cold it can be real stiff. I can only imagine cracking the throttle after a night of sitting the shaft will just spin on the bearing.

MS

If the shaft is new or barely worn the saver will work but you need to test and learn the correct torque setting for your shaft. Mine had some wear and it took 60-65ft lbs to get the fit tight. If you throw it on there and torque to 35 ft lbs and call it good it might not work. If you purchase a new shaft your better off taking it to a machine shop and having them weld it and turn it down to correct size for interference fit on bearing and then your done with it forever. The shop in town charged me $50 to do this and thats cheaper than the driveshaft saver. If you have a new sled and arent planning on removing shaft than the driveshaft saver is the way to go since it saves you all the labor of having to remove it. IMO if you have the shaft out for any reason at all then get it fixed correctly and your done with it for the life of the sled.

Farmer 73

Lifetime Member

- Joined

- Feb 20, 2015

- Messages

- 411

- Age

- 65

- Country

- USA

- Snowmobile

- 2010 NYTRO RTX SE, 2012 VECTOR, 2001 SXR 600, 2001 PHAZER, 2000 PHAZER, 1983 ENTICER EXCELL III

I know, Hey Yamaha design and build a retrofit chain case that will address the drive shaft and upper gear bushing problem! Then the Yamaha loyalists could buy or order as an option when new! This will also build some credibility back into the Yamaha Snowmobile scene! I know I'm dreaming again! By the way please don't wake me up, I like good dreams!

Farmer 73

Lifetime Member

- Joined

- Feb 20, 2015

- Messages

- 411

- Age

- 65

- Country

- USA

- Snowmobile

- 2010 NYTRO RTX SE, 2012 VECTOR, 2001 SXR 600, 2001 PHAZER, 2000 PHAZER, 1983 ENTICER EXCELL III

Oh I forgot this bearing and drive shaft problem is on the other side of the sled, well, just include that in the retrofit fix too!

- Joined

- Apr 13, 2003

- Messages

- 21,535

- Age

- 54

- Location

- Schofield, WI

- Website

- www.totallyamaha.com

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

I have had one slip as well but I did the same thing and never made sure the torque at 40# was actually holding it. I had the shaft machined and spray metaled for size on size with used a NEW FAG bearing. Do not use the junk that comes from cat. Ever machine that we have done between the bearing and shaft the tolerance is all over the place. This to me is the true fix, then you can add the BOP shaft saver at #30 and your good. Also it never hurts to keep the track tight as well. We found #40 will bring it up .001, at #50 it goes to .002 and at #60 it will not go any more then .0025 without wrecking the locker. Each sled needs to be check. If you dont you are just wasting money and time.

Winderallday!

VIP Member

New drive shaft and Nachi bearing here. Bearing to shaft fit was a nice slip fit. (maybe .001" clearance).

Tested on the bench with BOP saver, and at around 16 ft/lb the shaft to bearing was snug could not move by hand.

Knowing this, when re-assembling, I torqued to 20-25 ft/lb knowing this should be more than enough.

My old drive axle was worn down by as much as .012-.015", no way will the Shaft Saver take up that much slack, torqued the Saver to 60 ft/lbs on the bench, no dice.

Torquing that much compromises the shaft saver tapers and threads, could see the compression marks in the tapered wedge fingers from the excessive force/torque

As others have noted in this thread and elsewhere, seems the max the Saver will take up safely is about .002-.003" wear, so if you catch yours in time by measuring the OD, you may have a chance.

Also agree that a better tool steel grade, say 4140 vs cold rolled steel would make the Shaft Saver and threads more robust, but I'm sure BOP is trying to keep the price point in check.

Cheers

Tested on the bench with BOP saver, and at around 16 ft/lb the shaft to bearing was snug could not move by hand.

Knowing this, when re-assembling, I torqued to 20-25 ft/lb knowing this should be more than enough.

My old drive axle was worn down by as much as .012-.015", no way will the Shaft Saver take up that much slack, torqued the Saver to 60 ft/lbs on the bench, no dice.

Torquing that much compromises the shaft saver tapers and threads, could see the compression marks in the tapered wedge fingers from the excessive force/torque

As others have noted in this thread and elsewhere, seems the max the Saver will take up safely is about .002-.003" wear, so if you catch yours in time by measuring the OD, you may have a chance.

Also agree that a better tool steel grade, say 4140 vs cold rolled steel would make the Shaft Saver and threads more robust, but I'm sure BOP is trying to keep the price point in check.

Cheers

Similar threads

- Replies

- 6

- Views

- 3K

- Replies

- 5

- Views

- 498

- Replies

- 36

- Views

- 6K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.