Nikolai

TY 4 Stroke God

Looking for steering suggestions.

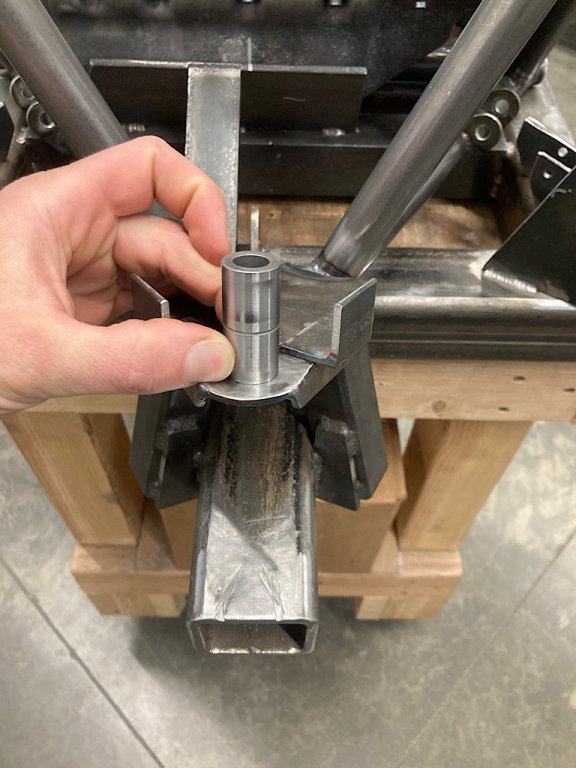

Couple pics of how steering is going to be setup. U-joint welded to steering arm and 1.125 x .058 post with 2 Polaris clamps.

The steering arm will have some kind of bushing in it and slide over a sleeve that is bolted to the frame. Frame has a 12mm hole but I could reduce it and use a 10mm bolt no problem and save some weight.

Some kind of sleeve will bolt to the frame and the steering arm with bushing pressed in will slide on and pivot on sleeve. Rings welded to the post on either side of the tube clamps will keep the post from moving vertically.

I have 2 options so far I’ve come up with and would like opinions on what you guys think would be better.

1. On left is the factory needle bearing and hardened steel sleeve setup from a Nytro. I can press the needle bearings into the arm and bolt the sleeve to frame. This would require using an M12 x 55mm bolt which is heavy.

2. I bought the correct size oil impregnated bronze bushing to press into the steering arm, the ID is 7/8. My lightest option here would be to bolt on a piece of 7/8 tube for the pivot. I would weld a cap on one end of the tube and use an M10 x 20mm bolt. Or I could make an aluminum sleeve and counterbore the hole to use an approx M10 x 40mm socket head with the nut on the bottom of the bracket . Oilite bushings are used in a-arms all the time with aluminum sleeves so wear doesn’t seem to be a problem.

The lightest setup I can think of is to bolt the 7/8 tube to the frame with a short 10mm bolt and have the oil lite bushing pivot on that but I don’t know if the chromo would wear out the bushing. Or if it would be as smooth as the needle bearings.

Thoughts?

Couple pics of how steering is going to be setup. U-joint welded to steering arm and 1.125 x .058 post with 2 Polaris clamps.

The steering arm will have some kind of bushing in it and slide over a sleeve that is bolted to the frame. Frame has a 12mm hole but I could reduce it and use a 10mm bolt no problem and save some weight.

Some kind of sleeve will bolt to the frame and the steering arm with bushing pressed in will slide on and pivot on sleeve. Rings welded to the post on either side of the tube clamps will keep the post from moving vertically.

I have 2 options so far I’ve come up with and would like opinions on what you guys think would be better.

1. On left is the factory needle bearing and hardened steel sleeve setup from a Nytro. I can press the needle bearings into the arm and bolt the sleeve to frame. This would require using an M12 x 55mm bolt which is heavy.

2. I bought the correct size oil impregnated bronze bushing to press into the steering arm, the ID is 7/8. My lightest option here would be to bolt on a piece of 7/8 tube for the pivot. I would weld a cap on one end of the tube and use an M10 x 20mm bolt. Or I could make an aluminum sleeve and counterbore the hole to use an approx M10 x 40mm socket head with the nut on the bottom of the bracket . Oilite bushings are used in a-arms all the time with aluminum sleeves so wear doesn’t seem to be a problem.

The lightest setup I can think of is to bolt the 7/8 tube to the frame with a short 10mm bolt and have the oil lite bushing pivot on that but I don’t know if the chromo would wear out the bushing. Or if it would be as smooth as the needle bearings.

Thoughts?

I have same type steering on my nytro and I used original needle bearing boltet in gusset. Only problem is that it is very sensitive to frame movements and steering post need to be aligned very carefully. I dont think this would be issue in your build because of that frame, I have about stock frame and it connects kinda in two different parts of frame, so there is some movements. It sometimes feels tacky and needs cleaning and lubrication, upper bushing is stock plastic pieces and I have to use old worn pieces to keep steering untacky. I would use some light plastic bushings to avoid sticky steering. Steering post can have some slack without affecting too much driving.

Nikolai

TY 4 Stroke God

Do you think a UHMW bushing would be better? I have large enough round stock, I could make one similar to the oil lite out of UHMW.I have same type steering on my nytro and I used original needle bearing boltet in gusset. Only problem is that it is very sensitive to frame movements and steering post need to be aligned very carefully. I dont think this would be issue in your build because of that frame, I have about stock frame and it connects kinda in two different parts of frame, so there is some movements. It sometimes feels tacky and needs cleaning and lubrication, upper bushing is stock plastic pieces and I have to use old worn pieces to keep steering untacky. I would use some light plastic bushings to avoid sticky steering. Steering post can have some slack without affecting too much driving.

kennyspec

Expert

Heres what i did, i used one of the lower spherical ball joints from a nytro front a arm. Then i inserted a bolt in the spherical joint and welded the head to the top of the inner ball of the spherical joint. Then i inserted the joint into the steering shaft and welded it. You can then eliminate the universal joint and run the steering shaft straight to the mount and the spherical joint will take up the angle differences.

Nikolai

TY 4 Stroke God

I couldn’t run the steering post straight to the arm, it would lower it too much and get into my charge tube at the throttle bodies. I could have bent a steering post similar to the Ski-Doo revs and then that would have worked. If I build a version 2.0 I will try and figure out a way to get rid of the u-joint but I’m too late in the game to change it on this one.

What I do like about a steel chassis is the ability to change things down the road. If I ride this and it works good, then I can try and modify it with a different steering system and try it. I have a feeling this sled is going to see a few changes after riding it. I have a lot of ideas scribbled on notepads.

What I do like about a steel chassis is the ability to change things down the road. If I ride this and it works good, then I can try and modify it with a different steering system and try it. I have a feeling this sled is going to see a few changes after riding it. I have a lot of ideas scribbled on notepads.

Nikolai

TY 4 Stroke God

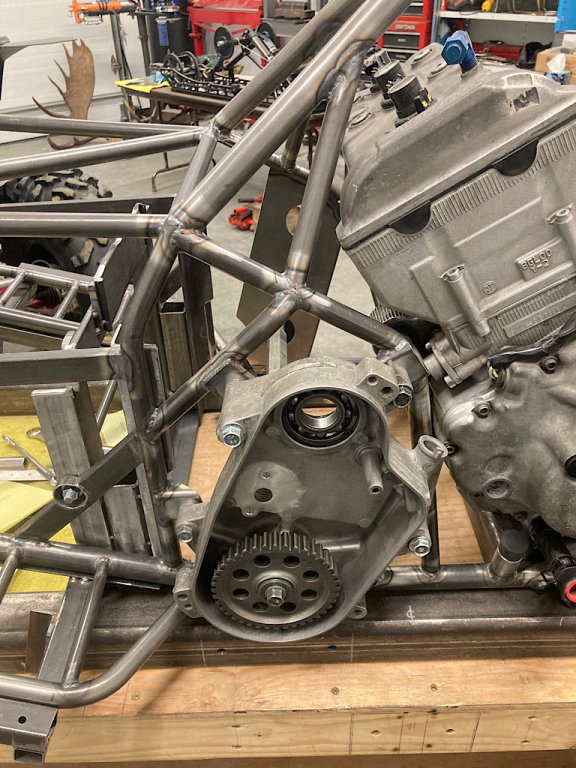

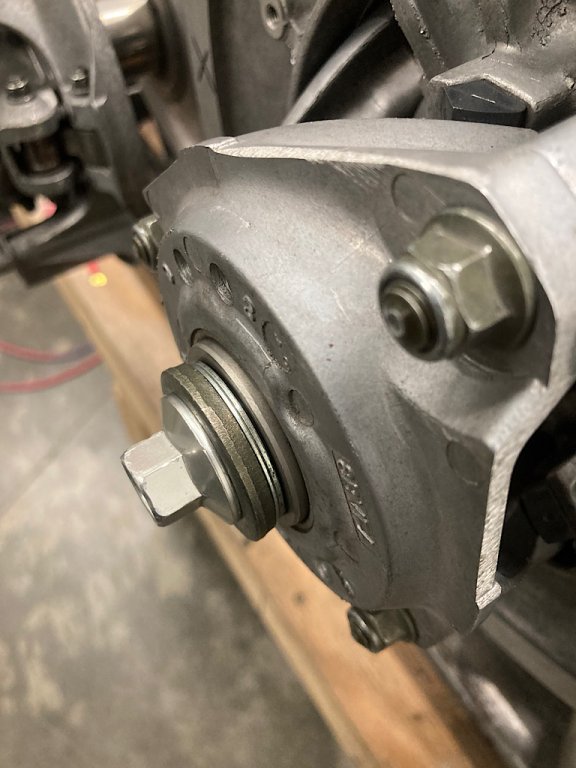

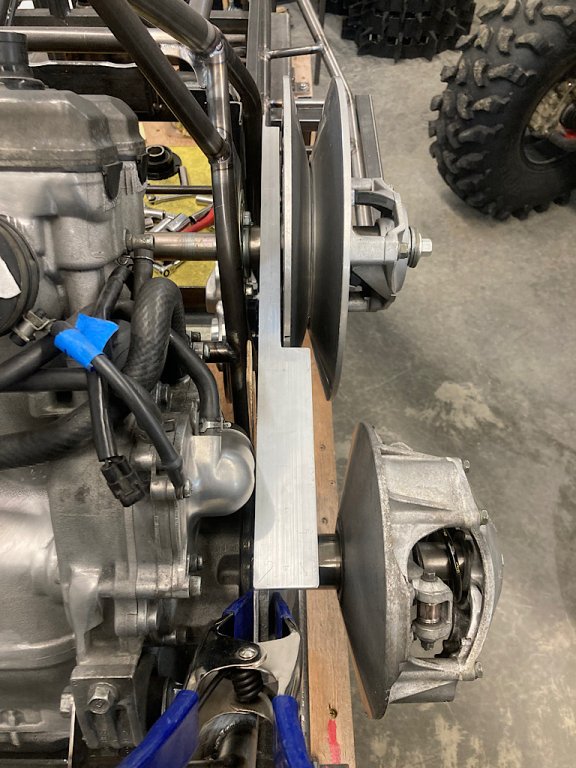

Changing gears for a minute. I have been working on the driveshaft the last few nights. Taking my time to get alignment perfect.

Bolted the chaincase in, there is a little movement in the chaincase holes and I have it positioned perfectly so I’m going to tack weld the nuts on the back of the tabs before removing the chaincase to keep the position set.

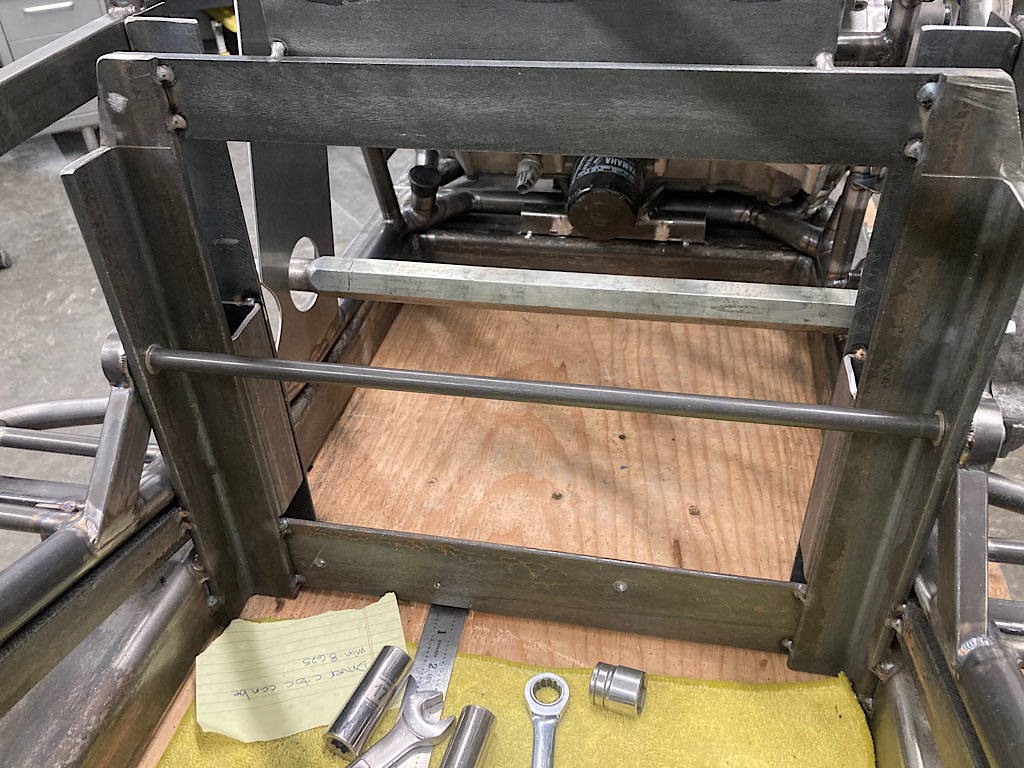

Bolted in a piece of chromoly tube over threaded rod to pull measurements off the suspension mounts.

Measured from the frame tube below motor to driveshaft, driveshaft to front arm of rear suspension and driveshaft to rear arm of rear suspension. Driveshaft is perfectly square to frame and parallel with the suspension mounts and frame tube. Can see chromo tube in line with hex of shaft.

Had to make my driveshaft jig removable to finish mounting the bearing housing. It is now held on with 3 5/16 bolts and threads tapped into the jig.

With the driveshaft set I traced out the bearing holder on the plate and finished opening up the hole, it is the exact size of the housing so there is no tolerance for it to be off. Then drilled the (3) 8mm holes. I will get nice button head bolts for final assembly.

The driveshaft spins incredibly easy. Next up was the brake caliper. I wanted the 10mm bolts equal distance from the bearing holder but I was not able to do this, I had to angle it a little for the bleeder to clear the frame enough to bleed the brakes. My OCD will have to live with it. Because of this I had to turn down the flange of the bolt in my lathe to clear the bearing holder. I will get some button head or socket head bolts for final assembly. If the driveshaft brake works decent and I did the same drivetrain on a second build I would simply move that 3/4 tube rearward about 1/4”.

The blue tape with “Gusset” that lives on the plate is there for a reason. I want to weld a small tube(will need to be 1/2 or 3/8 to clear secondary clutch) to the edge of the plate down to the frame to remove some flex in the plate but needed to finish the brake caliper first.

Going to be tight to the drivers but my math says the driver teeth should just clear the caliper.

I’m curious how well the brake works. I know snowbikes have issues with the brakes needing to be pumped due to constant exposure to snow and AC only did it for a year on the first model Firecat or SnoPro. If it is bad then I will make a carbon fiber shield for it and it if still sucks I can always buy a stock apex jackshaft and outer chaincase cover and go back to factory brake setup.

***As a side note, the brake caliper bleeder is upside down because I intended to run it on the front of the driveshaft but realized a long time ago it would not clear the track with 8-tooth 2.86 pitch drivers so I had to install it in the rear and flip it upside down. Wilwood makes the PS1 caliper in the correct orientation I need but didn’t want to spend another $100. I will unbolt the reservoir from the handlebars and tip the sled on its side when it comes time to bleed the brakes.

Next thing on the list is to get the jackshaft set parallel to the driveshaft and square to the frame so I can finish the jackshaft bearing flanges.

Bolted the chaincase in, there is a little movement in the chaincase holes and I have it positioned perfectly so I’m going to tack weld the nuts on the back of the tabs before removing the chaincase to keep the position set.

Bolted in a piece of chromoly tube over threaded rod to pull measurements off the suspension mounts.

Measured from the frame tube below motor to driveshaft, driveshaft to front arm of rear suspension and driveshaft to rear arm of rear suspension. Driveshaft is perfectly square to frame and parallel with the suspension mounts and frame tube. Can see chromo tube in line with hex of shaft.

Had to make my driveshaft jig removable to finish mounting the bearing housing. It is now held on with 3 5/16 bolts and threads tapped into the jig.

With the driveshaft set I traced out the bearing holder on the plate and finished opening up the hole, it is the exact size of the housing so there is no tolerance for it to be off. Then drilled the (3) 8mm holes. I will get nice button head bolts for final assembly.

The driveshaft spins incredibly easy. Next up was the brake caliper. I wanted the 10mm bolts equal distance from the bearing holder but I was not able to do this, I had to angle it a little for the bleeder to clear the frame enough to bleed the brakes. My OCD will have to live with it. Because of this I had to turn down the flange of the bolt in my lathe to clear the bearing holder. I will get some button head or socket head bolts for final assembly. If the driveshaft brake works decent and I did the same drivetrain on a second build I would simply move that 3/4 tube rearward about 1/4”.

The blue tape with “Gusset” that lives on the plate is there for a reason. I want to weld a small tube(will need to be 1/2 or 3/8 to clear secondary clutch) to the edge of the plate down to the frame to remove some flex in the plate but needed to finish the brake caliper first.

Going to be tight to the drivers but my math says the driver teeth should just clear the caliper.

I’m curious how well the brake works. I know snowbikes have issues with the brakes needing to be pumped due to constant exposure to snow and AC only did it for a year on the first model Firecat or SnoPro. If it is bad then I will make a carbon fiber shield for it and it if still sucks I can always buy a stock apex jackshaft and outer chaincase cover and go back to factory brake setup.

***As a side note, the brake caliper bleeder is upside down because I intended to run it on the front of the driveshaft but realized a long time ago it would not clear the track with 8-tooth 2.86 pitch drivers so I had to install it in the rear and flip it upside down. Wilwood makes the PS1 caliper in the correct orientation I need but didn’t want to spend another $100. I will unbolt the reservoir from the handlebars and tip the sled on its side when it comes time to bleed the brakes.

Next thing on the list is to get the jackshaft set parallel to the driveshaft and square to the frame so I can finish the jackshaft bearing flanges.

Last edited:

I think it would be better with some plastic bushings than metallic, also what Kennyspec said about ball joints, that was in my mind to modify my steering, just easier to make or use some stock plastic pieces. On my sled steering post goes between charge tubes, just barely fitted it and had to make narrower piece to not rub. I did same thing to my brothers apex but this time I machined center piece from solid axle and lightened it with center boring from both ends. It propably needs some more modifications because afterwards we found MPI supercharger set and it was fairly cheap, so it kinda moved in to my garage... Charger is coming just where I planned steering post end to be. Apex is whole lot different story than nytro, curious to see what your sled is going to be.Do you think a UHMW bushing would be better? I have large enough round stock, I could make one similar to the oil lite out of UHMW.

You have given me much inspiration to my sled builds and I will make some story from my builds too. Maybe it could give some inspiration and motivation to somebodys builds in future!

Nikolai

TY 4 Stroke God

I would love to see some other build threads get started, even if the progress is really slow like mine. I still read thru old build threads on here and Snowest all the time looking for ideas.

Nikolai

TY 4 Stroke God

Jackshaft is done.

Started with my alignment tool, had to egg out the mount holes in jig at bottom to lower it a fuzz to be perfectly parallel to driveshaft. Double checked it was parallel to suspension mounts and square with frame. Once it was set I traced around the bearing.

Zero tolerance in the bearing hole.

Clamped flange over to mark bolt holes. Bolt holes positioned opposite of driveshaft bearing holder.

Very careful drilling to make sure all holes are exact size so there’s no movement in anything.

And done! Hex flange Ti bolts will be used on final assembly. Needed to get bolt length before ordering, these will be M8-1.25x14 with K-nuts.

I thought the yamaha flanges were spaced .090 apart but it turned out my old ones were just deformed from being used. The new ones I ordered appear to be meant to sandwich .100 material. I used .090 for my plate but there didn’t seem to be any issue sucking down the flanges, only talking .005 extra per flange.

Glad to have all that behind me. Another huge project done getting the shafts dealt with. Next will be motor alignment and rear motor mounts along with the gusset.

Started with my alignment tool, had to egg out the mount holes in jig at bottom to lower it a fuzz to be perfectly parallel to driveshaft. Double checked it was parallel to suspension mounts and square with frame. Once it was set I traced around the bearing.

Zero tolerance in the bearing hole.

Clamped flange over to mark bolt holes. Bolt holes positioned opposite of driveshaft bearing holder.

Very careful drilling to make sure all holes are exact size so there’s no movement in anything.

And done! Hex flange Ti bolts will be used on final assembly. Needed to get bolt length before ordering, these will be M8-1.25x14 with K-nuts.

I thought the yamaha flanges were spaced .090 apart but it turned out my old ones were just deformed from being used. The new ones I ordered appear to be meant to sandwich .100 material. I used .090 for my plate but there didn’t seem to be any issue sucking down the flanges, only talking .005 extra per flange.

Glad to have all that behind me. Another huge project done getting the shafts dealt with. Next will be motor alignment and rear motor mounts along with the gusset.

Nikolai

TY 4 Stroke God

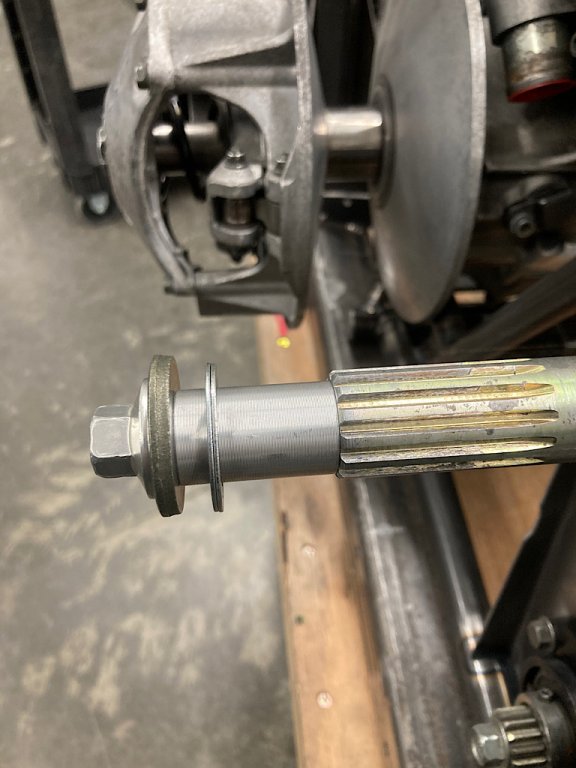

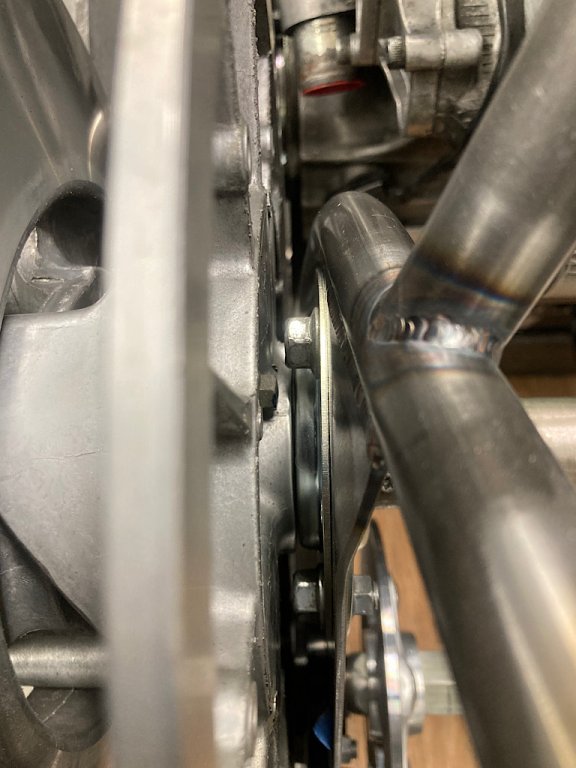

Secondary is done. It has been a lot of extra work building this as narrow as possible since the Yamaha Apex drivetrain is meant for a much wider chassis.

Finished shaving down the back of the secondary flush with the bushing to get all available clearance from the bearing flange.

Had to notch my plate to clear the sheave when fully open.

Had to grind out some threads from the jackshaft so I could thread the bolt further in as the shank was stopping at the threads. There is a 2.00mm shim against the bearing which is just enough to get the clutch to clear the bearing flange.

Turned down the aluminum spacer to correct length. With (2) 1.00 mm shims there is a 0.5mm free play. I did not want to grind out any more jackshaft threads hence the 2 shims.

With the sheave fully open there is about 0.5mm clearance from sheave to bearing flange. Just enough to not rub. Offset is right about 15.5mm which is as close as I could get it, I can’t get the clutch any further in. I was shooting for 15mm to be center of Yamaha’s 13.5-16.5 spec but it ain’t going to happen, 15.5mm will have to suffice.

My clutches are not perfectly parallel, I know the secondary is good so I’m going to pull the motor back out tomorrow and open the front motor mount holes a fuzz so I can twist the motor and get the primary parallel to the secondary before doing the rear motor mounts.

Finished shaving down the back of the secondary flush with the bushing to get all available clearance from the bearing flange.

Had to notch my plate to clear the sheave when fully open.

Had to grind out some threads from the jackshaft so I could thread the bolt further in as the shank was stopping at the threads. There is a 2.00mm shim against the bearing which is just enough to get the clutch to clear the bearing flange.

Turned down the aluminum spacer to correct length. With (2) 1.00 mm shims there is a 0.5mm free play. I did not want to grind out any more jackshaft threads hence the 2 shims.

With the sheave fully open there is about 0.5mm clearance from sheave to bearing flange. Just enough to not rub. Offset is right about 15.5mm which is as close as I could get it, I can’t get the clutch any further in. I was shooting for 15mm to be center of Yamaha’s 13.5-16.5 spec but it ain’t going to happen, 15.5mm will have to suffice.

My clutches are not perfectly parallel, I know the secondary is good so I’m going to pull the motor back out tomorrow and open the front motor mount holes a fuzz so I can twist the motor and get the primary parallel to the secondary before doing the rear motor mounts.

Nikolai

TY 4 Stroke God

Would like some opinion on how parallel the clutches need to be. I added a shim to the secondary to take the play out so it would be tight for measuring offset. Had a couple clutch alignment bars that weren’t totally flat(these were throwing me off last night) so I ended up modifying a piece of extruded aluminum which is flatter than anything else I have. I have it notched for the jackshaft to get it lower for measuring as close to the center of secondary as possible.

I pulled 5 measurements at front and 5 rear, then removed the tool, rotated both clutches and did 5 more measurements front and rear than got the averages. Used a caliper for measurements.

Averages

Front of secondary clutch offset 15.72mm

Rear of secondary clutch offset 15.89mm

Difference 0.178mm or 0.007”

It’s super close and the difference may even be in my alignment tool. I can’t imagine these engines twist much with their 4 motor mounts, but I’m wondering if I’m going to be good and can leave it alone? I haven’t touched any of the front motor mount holes yet so I can egg them out if need be.

Thanks

I pulled 5 measurements at front and 5 rear, then removed the tool, rotated both clutches and did 5 more measurements front and rear than got the averages. Used a caliper for measurements.

Averages

Front of secondary clutch offset 15.72mm

Rear of secondary clutch offset 15.89mm

Difference 0.178mm or 0.007”

It’s super close and the difference may even be in my alignment tool. I can’t imagine these engines twist much with their 4 motor mounts, but I’m wondering if I’m going to be good and can leave it alone? I haven’t touched any of the front motor mount holes yet so I can egg them out if need be.

Thanks

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,048

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Measure off of the two fixed sheaves on both clutches. The outer is fixed on the secondary.

Nikolai

TY 4 Stroke God

Ok, so round 2.

Borrowed a bar from Dad for checking flatness of cylinder heads. The piece of aluminum I was using was not perfectly flat. Went to the store and bought a piece of 1.5”x1.5”x1/8 aluminum angle and made an alignment tool that fits good and is perfectly flat.

Checked against bar

Clamped at the front and a couple wood shims very lightly pressed in between the bar and water pump to hold it against the sheave.

Measured this time from the outside of secondary fix sheave to the back of the aluminum angle. I did the front 5 times, rear 5 times and took averages.

Front: 63.75mm

Rear: 63.50mm

Difference: 0.25mm (.0098”)

Pulled the clutches and made sure center to center was still spot on.

Reinstalled the clutches in different positions and rechecked alignment. Again 5 times and took averages

Front: 63.65mm

Rear: 63.42mm

Difference: 0.23mm (0.0090”)

Offset from measured from back of secondary sheave is real close to 15mm

So, they are dang close. Ever so slightly out of parallel but it’s such a small amount and in the proper direction where as the motor pulls back under power it would be parallel I think I’m going to leave it. Splitting hairs at this point.

Borrowed a bar from Dad for checking flatness of cylinder heads. The piece of aluminum I was using was not perfectly flat. Went to the store and bought a piece of 1.5”x1.5”x1/8 aluminum angle and made an alignment tool that fits good and is perfectly flat.

Checked against bar

Clamped at the front and a couple wood shims very lightly pressed in between the bar and water pump to hold it against the sheave.

Measured this time from the outside of secondary fix sheave to the back of the aluminum angle. I did the front 5 times, rear 5 times and took averages.

Front: 63.75mm

Rear: 63.50mm

Difference: 0.25mm (.0098”)

Pulled the clutches and made sure center to center was still spot on.

Reinstalled the clutches in different positions and rechecked alignment. Again 5 times and took averages

Front: 63.65mm

Rear: 63.42mm

Difference: 0.23mm (0.0090”)

Offset from measured from back of secondary sheave is real close to 15mm

So, they are dang close. Ever so slightly out of parallel but it’s such a small amount and in the proper direction where as the motor pulls back under power it would be parallel I think I’m going to leave it. Splitting hairs at this point.

Nikolai

TY 4 Stroke God

Spent tonight rechecking alignment. In addition to clutches being parallel I put bolts in the rear motor mounts and measured the distance to the jackshaft. I tweaked the motor position just a little and was able to tighten up all the numbers. Measured probably a hundred times to try and get accurate averages.

Rear motor mount, edge of bolt to edge of jackshaft

- Chaincase side distance 61.34mm

- Clutch side distance 61.31mm

Clutch offset from front of fixed sheave

- Front of secondary 63.65mm

- Rear of secondary 63.61mm

I have been putting off doing my summer prep to the RZR for the last 3 months trying to get to this point but summer is approaching fast and I need to switch projects for a couple weeks. Finally at the spot I wanted to be at in order to put the sled in the corner for a bit. Hopefully in about 2 weeks I’ll be back at it to finish the motor mounts.

Rear motor mount, edge of bolt to edge of jackshaft

- Chaincase side distance 61.34mm

- Clutch side distance 61.31mm

Clutch offset from front of fixed sheave

- Front of secondary 63.65mm

- Rear of secondary 63.61mm

I have been putting off doing my summer prep to the RZR for the last 3 months trying to get to this point but summer is approaching fast and I need to switch projects for a couple weeks. Finally at the spot I wanted to be at in order to put the sled in the corner for a bit. Hopefully in about 2 weeks I’ll be back at it to finish the motor mounts.

kennyspec

Expert

You are going way overkill on the clutch alignment lol. Im sure mine is further off and i havent blown a belt yet!!!

Similar threads

- Replies

- 4

- Views

- 4K

- Replies

- 32

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.