Any pic’s of broken front arm ?

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

ViperRob

Veteran

- Joined

- Oct 16, 2016

- Messages

- 41

- Reaction score

- 12

- Points

- 358

- Location

- Boone

- Country

- USA

- Snowmobile

- 15 Viper

Notice a difference with that shock damper on the rear tunnel?

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

ViperRobNotice a difference with that shock damper on the rear tunnel?

I have one in the front also but no difference that I can feel. But who knows vibration harmonics

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

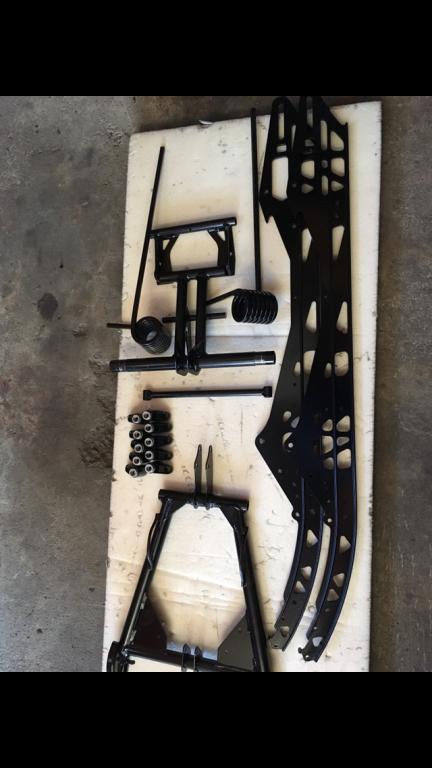

Rear skid Powder coated now to assemble.

Mike P

Lifetime Member

- Joined

- Nov 18, 2015

- Messages

- 564

- Reaction score

- 276

- Points

- 808

- Location

- Berlin CT

- Country

- USA

- Snowmobile

- Sr Viper R-TX SE

- LOCATION

- Berlin CT

Looks good.

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

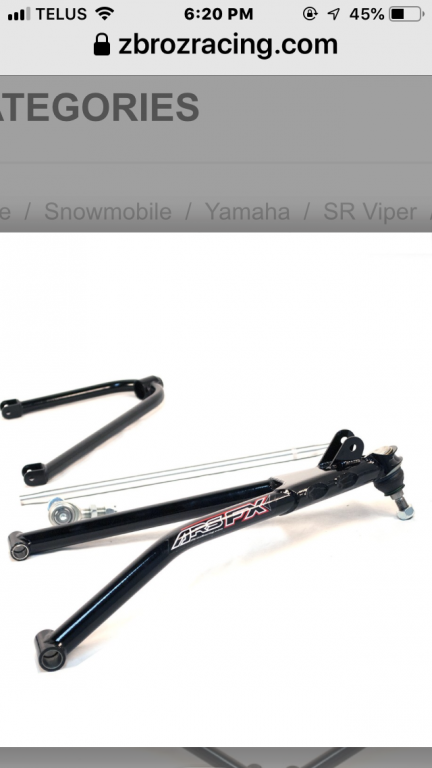

Seriously considering ordering a ZBroz front end for my Sr viper also there centre skid shock. The last kit I bought from them for my IQ 800 mod I built in 2007.

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,787

- Reaction score

- 620

- Points

- 1,228

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

View attachment 148068 Not trying to highjack here but noticed you just took these wheels off, the ones that are giving me a very hard time! Any tips or tricks to getting these 2 off?

You can take that upper part of the scissor off, and sandwich the shaft in a shop press and press the wheel off the shaft. Its a bit of a pain but it takes it off clean and smoothly. No hammering, banging etc.

MS

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

Last edited:

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

So I removed drive axel had a bit of wear measured a new yamaha bearing then the shaft.

Going to order a new SKF C3 bearings and as per ClutchMaster loctight 638.

Going to order a new SKF C3 bearings and as per ClutchMaster loctight 638.

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

My drive Axel measures the same.

Last edited:

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

View attachment 148554 New yamaha bearing measurement.

My drive Axel measures the same

Last edited:

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

Both bearings were fine. Going to replace anyway. Lower chaincase seal was a pain to install but got it in.

Replaced drive axel bearings with Fag bearings.

Last edited:

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

Last edited:

gpxsrx

Expert

- Joined

- Dec 15, 2009

- Messages

- 376

- Reaction score

- 162

- Points

- 788

- Location

- Ontario

- Country

- Canada

- Snowmobile

- way to many 2 strokes

Last edited:

Similar threads

- Replies

- 0

- Views

- 608

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.