krm

Lifetime Member

- Joined

- Apr 22, 2016

- Messages

- 859

- Reaction score

- 418

- Points

- 978

- Location

- ny

- Country

- USA

- Snowmobile

- sidewinder 850 mxz,850xrs 850xrs 900t22Mach Z

Daltons 76.3 gm BLK/BLUE drive spring b/o driven stk. 35 helix ,gates belt mod stk muffler 137 track with 1.45" triggersTD Power Trail?

Exhaust?

Whats your weight setup?

What track?

Thanks in advance

rbell14

TY 4 Stroke Guru

My Viper belt did the same thing while on a stand, however when I rode it in the yard the belt came back up to the proper spot int he secondary. I think you need to make your final adjustments trail side after a rolling stop.

I just replaced my belt last night with a new one. Settings on secondary was never adjusted. Belt didn't come back up to normal sport until drove the sled down the driveway. Now it's perfect again.

I just replaced my belt last night with a new one. Settings on secondary was never adjusted. Belt didn't come back up to normal sport until drove the sled down the driveway. Now it's perfect again.

actionjack

TY 4 Stroke God

- Joined

- Apr 9, 2005

- Messages

- 2,519

- Reaction score

- 623

- Points

- 1,483

- Location

- Westminster, Maryland

- Website

- www.inspectorjack.com

- Country

- USA

- Snowmobile

- 2017 SideWinder LTX-LE

Thank youDaltons 76.3 gm BLK/BLUE drive spring b/o driven stk. 35 helix ,gates belt mod stk muffler 137 track with 1.45" triggers

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,183

- Reaction score

- 701

- Points

- 1,308

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

I just got back from a trip in Maine testing my PT set up and the clutches are nice and cool.no blown belts ,and the sled revs 8900-9000 always .Using the OSP adjuster with no shim the clutch has some movement under load ,The Gates belt also works well As do the Dalton weights set up correct with the correct spring for how you ride ,with the stk.35 helix .One thing many need to learn to do is ,role to a stop ,don't slam on the breaks or it won't back shift correct .So far the thing rips and the btx seat is much better that the stk le seat .The sled also goes by my buds 850 like he pulled the shoot ,but the 850s are also a nice trail sled as are these spinegrinders .

I don't mean to start any crap here, but this isn't how a clutch should work on a high performance sled. Every other yamaha sled ever made you can slam the brakes and it will backshift correctly, so this should do the same.

Janne339

TY 4 Stroke Junkie

- Joined

- Oct 31, 2015

- Messages

- 559

- Reaction score

- 395

- Points

- 738

- Location

- Sweden

- Country

- Sweden

- Snowmobile

- 2021 Sidewinder LTX GT

60y weights are actually a good middle of the road between stock and clickers. They work well and are a good overall weight.

The stock club weights push very hard at the beginning of the shift, but use a lot of weight to keep pressure on the belt at high speeds. Clickers use a lot of curvature and weight placement to achieve the same goal. Since most of the weight is in the heal it it does not contribute very much at full shift.

Adding a gram in the tip of stock weights does virtually nothing compared to adding a gram in the tip of clickers or STMs.

The stock weights push so hard at the beginning of the shift if you were to use them with those higher helix angles they would bog the motor down unless you put a huge Spring in the primary. At full shift they really are crappy for tuning because adding weight has little affect.

It's all about the contact angle on the roller. Now if someone were to regrind the profile on the stock weight???

Naw just use them as bottom bouncers next time you walleye fishing in 50' of water.

Great info! It make sense!

Janne339

TY 4 Stroke Junkie

- Joined

- Oct 31, 2015

- Messages

- 559

- Reaction score

- 395

- Points

- 738

- Location

- Sweden

- Country

- Sweden

- Snowmobile

- 2021 Sidewinder LTX GT

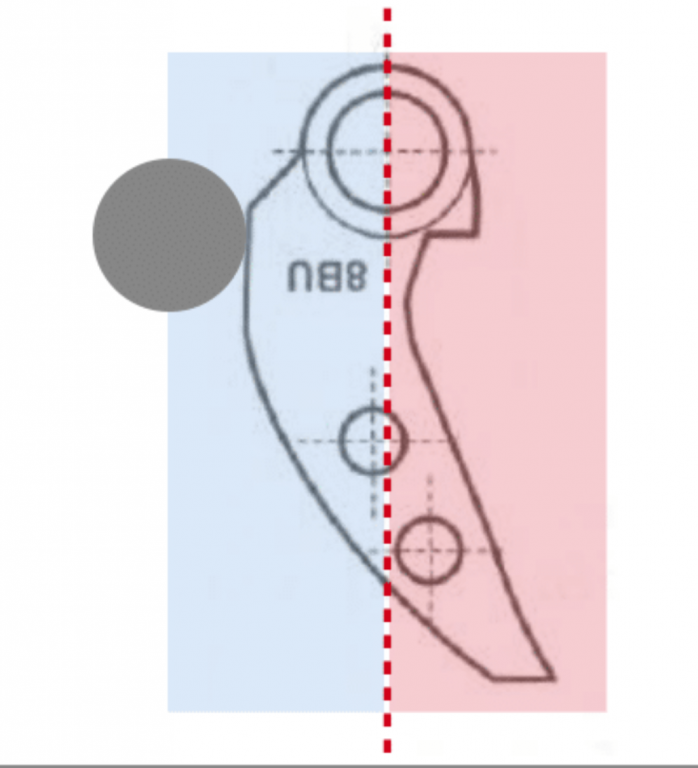

Blue area positive force. Red area negative force. The pic explain what ClutchMaster said about flat and curvature weights in the beginning of the shift.

Janne339

TY 4 Stroke Junkie

- Joined

- Oct 31, 2015

- Messages

- 559

- Reaction score

- 395

- Points

- 738

- Location

- Sweden

- Country

- Sweden

- Snowmobile

- 2021 Sidewinder LTX GT

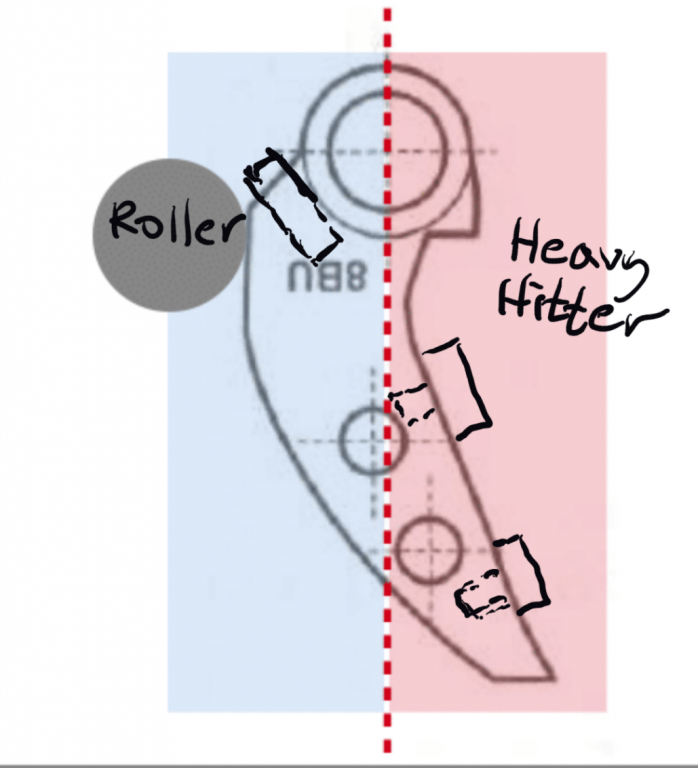

illustration of heavy hitter weight

When boost and power is comming like a hammer in my low compression turbo kit, the washers and bolts are in the blue area. And with smaller or wider rollers you are able to tune it perfect.

When boost and power is comming like a hammer in my low compression turbo kit, the washers and bolts are in the blue area. And with smaller or wider rollers you are able to tune it perfect.

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Reaction score

- 1,440

- Points

- 1,038

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

How is the belt going to go to the top when you hit the brakes hard stopping? Doesn't the secondary need to rotate for the belt to climb up? Just like when you change a belt. You open the secondary to install it and it will stay there and not move until you rotate it and make it climb to the top.I don't mean to start any crap here, but this isn't how a clutch should work on a high performance sled. Every other yamaha sled ever made you can slam the brakes and it will backshift correctly, so this should do the same.

Soupy

Expert

- Joined

- Jan 10, 2017

- Messages

- 359

- Reaction score

- 84

- Points

- 668

- Location

- West Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX-LE

Agreed. When the belt is clamped by a spring and the clutch is stationary, it's virtually impossible to downshift.How is the belt going to go to the top when you hit the brakes hard stopping? Doesn't the secondary need to rotate for the belt to climb up? Just like when you change a belt. You open the secondary to install it and it will stay there and not move until you rotate it and make it climb to the top.

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Reaction score

- 1,440

- Points

- 1,038

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

Back in 2012 I was on a trip with my brand new 1200 and my sled would not move once stopped. It would just sit there and burn the belt. After checking it out I found the secondary spring broke at the first turn of the spring. The good news was the Doo uses a compression spring not a torsion spring. The problem was I had to make sure I coasted to all my stops or the secondary would remain open because of lack of spring pressure. When I had no choice and did hit the brake when stopping I had members of my group hold the rear of my sled in the air while I tried to get the belt to climb up the secondary. There were times where I had to run along side my sled to get it going and then jump on it on the fly. I did this for two days and 400 miles! For the belt to climb up the secondary two things need to happen. One the secondary spring needs to be stiff enough to close the sheaves and 2 the secondary needs to rotate.

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,183

- Reaction score

- 701

- Points

- 1,308

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

How is the belt going to go to the top when you hit the brakes hard stopping? Doesn't the secondary need to rotate for the belt to climb up? Just like when you change a belt. You open the secondary to install it and it will stay there and not move until you rotate it and make it climb to the top.

Watch the videos in the first post of this thread. The second video is my turbo Nytro. It comes to the top when I jam the brakes. The brake wont lock up instantly, its going to turn a revolution or 2 before it comes to a complete stop. That sled ran 12psi on the trails for over 10000kms and never blew a belt. I always assumed a roller secondary would backshift better/easier than a button one, but maybe not.

Brian Friebel

Extreme

- Joined

- Jan 3, 2016

- Messages

- 70

- Reaction score

- 3

- Points

- 98

- Location

- Neenah Wi

- Country

- USA

- Snowmobile

- 2015 Yamaha Apex

My sled does the same thing. 2017 with the new updated Dalton black orange secondary spring. 33/35 Dalton Helix. Rollers are good. When I let off and coast or even using break it does it. It stays down about 3/16ths. But after it stops and I just quickly bump throttle enough to engage and let off quick it goes back to top where it should be. This is on a stand. Never checked it riding. Talked to dealer about it yesterday as its being gone thru getting ready for the season If we ever have a season in Wisconsin this year.Ya, I wasnt trying to say im right and your wrong or anything, just that many sleds seem to have this problem with snapping belts. My sidewinder and my brothers, the secondary clutches both dont snap closed. Does every sidewinder do this? I have heard of many having the exact same issue. One tuner told me to try a stiffer secondary spring as well, and I will once theres more snow. If every sled does this, theres needs to be a fix or a recall from Yamaha, if its just my sled, then Yamaha should step up and fix my problem under warranty.

This is just frustrating because I bought this sled to have less of a headache than my Nytro. So far its been the same crap, ive spend way too much time tinkering with it, driving back and forth to the dealer, etc etc.

Now Im out $400 worth of belts, have a sled with a broken side panel, and some clown from Yamaha telling me I cant drive my 19 grand high performance snowmobile fast and hard.

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,183

- Reaction score

- 701

- Points

- 1,308

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

My sled does the same thing. 2017 with the new updated Dalton black orange secondary spring. 33/35 Dalton Helix. Rollers are good. When I let off and coast or even using break it does it. It stays down about 3/16ths. But after it stops and I just quickly bump throttle enough to engage and let off quick it goes back to top where it should be. This is on a stand. Never checked it riding. Talked to dealer about it yesterday as its being gone thru getting ready for the season If we ever have a season in Wisconsin this year.

Ya. I’m not sure the dalton black/orange has enough torsional force to close the secondary quick enough. I have a whole bunch of springs that I will try out this year, I’m sure I will find something that will work better.

Doowithblue

TY 4 Stroke Guru

- Joined

- Mar 17, 2016

- Messages

- 865

- Reaction score

- 568

- Points

- 1,128

- Location

- Waterloo ON

- Country

- Canada

- Snowmobile

- 07 Mach z x (sold)

18- RTX LE

Not sure i agree with that. You can make pretty much any spring have torsional force just twist it up to desired poundage and go. Don't be so concerned with 60deg 70deg and this and that. I have a cat red/white twisted at 100. So does that mean its got super duty torsional poundage? No. Because tang locations are all dif and wire dia etc.

Brian Friebel

Extreme

- Joined

- Jan 3, 2016

- Messages

- 70

- Reaction score

- 3

- Points

- 98

- Location

- Neenah Wi

- Country

- USA

- Snowmobile

- 2015 Yamaha Apex

So the new updated dalton black orange says to wrap at 6/2 so i should try 9/1Not sure i agree with that. You can make pretty much any spring have torsional force just twist it up to desired poundage and go. Don't be so concerned with 60deg 70deg and this and that. I have a cat red/white twisted at 100. So does that mean its got super duty torsional poundage? No. Because tang locations are all dif and wire dia etc.

Last edited:

Similar threads

- Replies

- 105

- Views

- 13K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.