Correct me if I am wrong but those o-rings behind the pucks did not even exist until a few years ago on this clutch?

Rich Kay

TY 4 Stroke Guru

- Joined

- Mar 29, 2006

- Messages

- 963

- Reaction score

- 279

- Points

- 1,058

- Location

- SE MI. Howell

- Country

- USA

- Snowmobile

- Yamaha apex rtx

I know they go back to 07 for sure .Correct me if I am wrong but those o-rings behind the pucks did not even exist until a few years ago on this clutch?

Allan

TY 4 Stroke Junkie

- Joined

- Oct 19, 2014

- Messages

- 719

- Reaction score

- 270

- Points

- 788

- Location

- Newfoundland

- Country

- Canada

- Snowmobile

- 2016 Sr Viper XTX

Did mine today and the small dremel bit worked very good.by no means am I a expert but a round file worked perfectly! not sure if a dremel bit will fit in the slot???

BFS

Extreme

- Joined

- Jan 26, 2015

- Messages

- 119

- Reaction score

- 49

- Points

- 463

- Country

- USA

- Snowmobile

- 2016 LTX-LE

Red/White

Cleaned up my casting flash today also, you could see where they tried cleaning it up but still had edge. Used a rat tail file, smooth windows now. Allan, how good/bad was your edge.

Allan

TY 4 Stroke Junkie

- Joined

- Oct 19, 2014

- Messages

- 719

- Reaction score

- 270

- Points

- 788

- Location

- Newfoundland

- Country

- Canada

- Snowmobile

- 2016 Sr Viper XTX

Mine was not that bad just had a edge you could feel.

birkebeiner

Lifetime Member

- Joined

- Jul 27, 2009

- Messages

- 895

- Reaction score

- 102

- Points

- 718

- Location

- Norway

- Country

- Norway

- Snowmobile

- 2015 Yamaha SR Viper X-TX

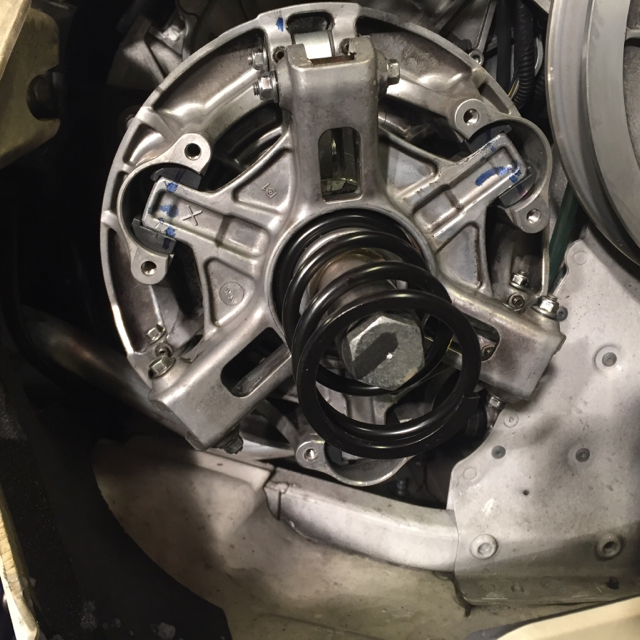

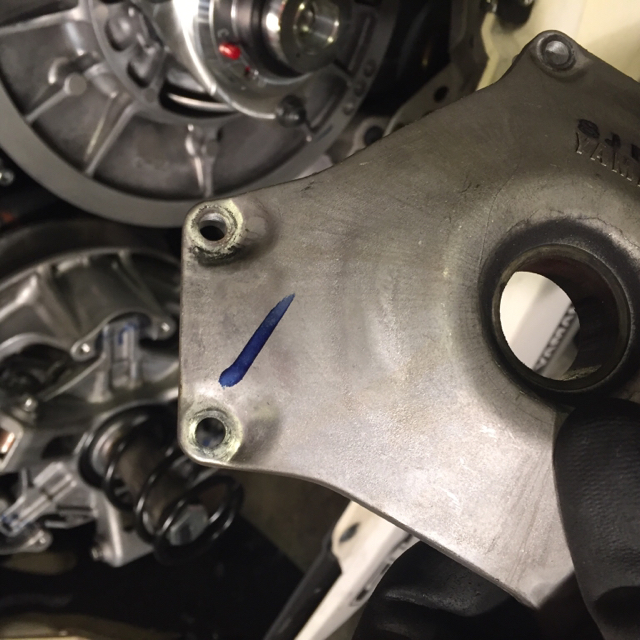

Reading through this made me check my clutches, especially for three things:

1) did I put the primary clutch cover back correctly after I installed the clutch kit.

- No, I didn't! :O

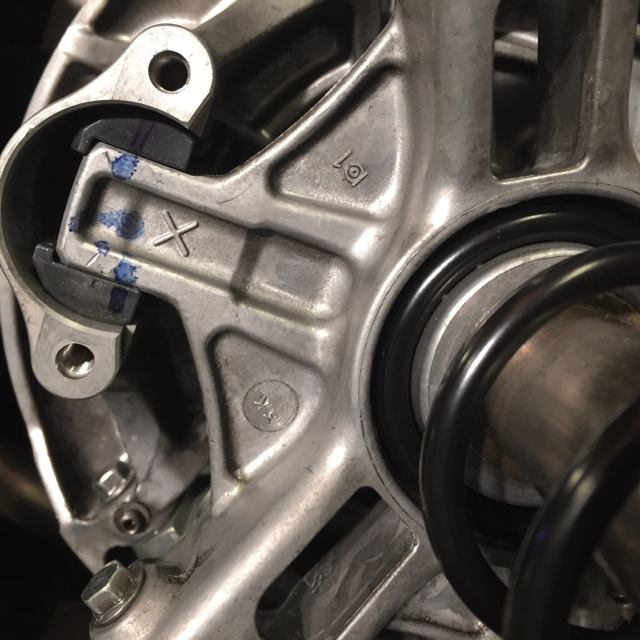

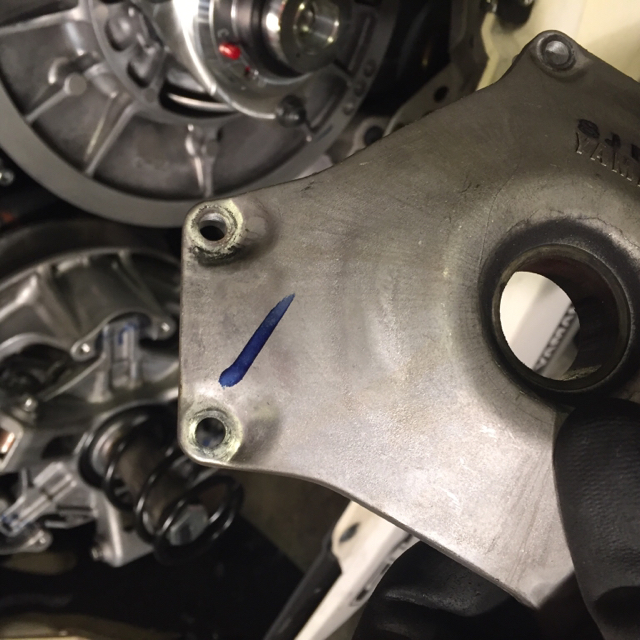

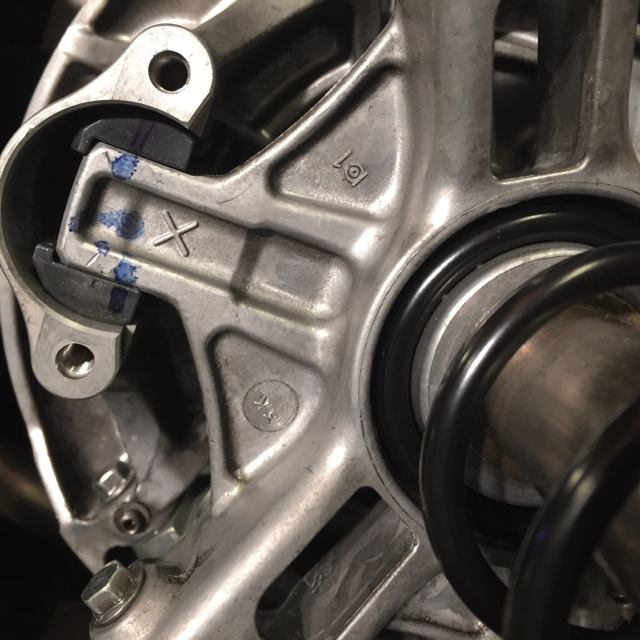

However, I'm not 100% sure what mark to look for. There is a X on both the clutch cover and the spider, but there are also pen marker marks, but they are all over the place so I went for the X

These are pen marker marks

2) belt dust and movement of the primary

- yeah, there was plenty... Surprisingly much for a sled with only 680 km / 425 miles

I don't yet have a clutch puller so wasn't able to take off the clutch so I had to blow it clean where it was. I also took some dishwasher soap and water and cleaned it the best I could. Blowed then wiped it dry. It felt a bit sticky, especially the first inch of movement but got a bit better after I cleaned it.

3) any binding issues in the secondary.

- luckily no issues here, plenty of clearance It looks like someone cleaned out the flashes already, either at the factory or my dealer.

It looks like someone cleaned out the flashes already, either at the factory or my dealer.

With everything back in I started up the sled to see how it works.

To me it looks like there is an issue with the back shift?? Once I come of the throttle the secondary doesn't close all the way in. Don't know whether this is normal or not. Have a look at the vid

Birkebeiner

1) did I put the primary clutch cover back correctly after I installed the clutch kit.

- No, I didn't! :O

However, I'm not 100% sure what mark to look for. There is a X on both the clutch cover and the spider, but there are also pen marker marks, but they are all over the place so I went for the X

These are pen marker marks

2) belt dust and movement of the primary

- yeah, there was plenty... Surprisingly much for a sled with only 680 km / 425 miles

I don't yet have a clutch puller so wasn't able to take off the clutch so I had to blow it clean where it was. I also took some dishwasher soap and water and cleaned it the best I could. Blowed then wiped it dry. It felt a bit sticky, especially the first inch of movement but got a bit better after I cleaned it.

3) any binding issues in the secondary.

- luckily no issues here, plenty of clearance

With everything back in I started up the sled to see how it works.

To me it looks like there is an issue with the back shift?? Once I come of the throttle the secondary doesn't close all the way in. Don't know whether this is normal or not. Have a look at the vid

Birkebeiner

- Joined

- Apr 14, 2003

- Messages

- 6,539

- Reaction score

- 3,171

- Points

- 1,983

- Location

- Hessel, Michigan

- Country

- USA

- Snowmobile

- Sidewinder, SR Viper XTX, SR Viper XTX, 2016 Apex XTX and Pro-Line Pro Stock 1000

birkebeiner - The secondary will not close all the way when running on the stand if #1, the track tension is too tight and the slides get hot ... #2, the secondary clutch spring is wrapped wrong.... #3, the parking brake is on...... or #4, there is something binding in the chain case.

I see by the weights, you must have STM weights, check your weights and see if they are setup correctly.

Try a little water on the slides or what I like to use is some tire shine....smells good and lubricates for that short time

I see by the weights, you must have STM weights, check your weights and see if they are setup correctly.

Try a little water on the slides or what I like to use is some tire shine....smells good and lubricates for that short time

birkebeiner

Lifetime Member

- Joined

- Jul 27, 2009

- Messages

- 895

- Reaction score

- 102

- Points

- 718

- Location

- Norway

- Country

- Norway

- Snowmobile

- 2015 Yamaha SR Viper X-TX

#1 the track could be too tight but it didn't look like it, and the slides couldn't get hot enough to make a difference by the short amount of time I let her run; max 1 minute.

#2 that could be the case, the Ulmer kit instructions said 3-3, and it's in 3-3. I turned the helix clockwise until it fitted on the inner shave's towers. It felt correct when I put the belt back on, but it could still be wrong.

#3 it was initially but not in the video.

but not in the video.

#4 oh man, I hope that's not the case.

The bad thing is that I didn't check the clutches before I installed the Ulmer kit.

Birkebeiner

#2 that could be the case, the Ulmer kit instructions said 3-3, and it's in 3-3. I turned the helix clockwise until it fitted on the inner shave's towers. It felt correct when I put the belt back on, but it could still be wrong.

#3 it was initially

#4 oh man, I hope that's not the case.

The bad thing is that I didn't check the clutches before I installed the Ulmer kit.

Birkebeiner

aquaticlaker

Extreme

- Joined

- Feb 21, 2009

- Messages

- 80

- Reaction score

- 47

- Points

- 843

- Location

- Green Lake WI

- Country

- USA

- Snowmobile

- SIDEWINDER L‑TX LE 50TH

- LOCATION

- Green Lake Wi

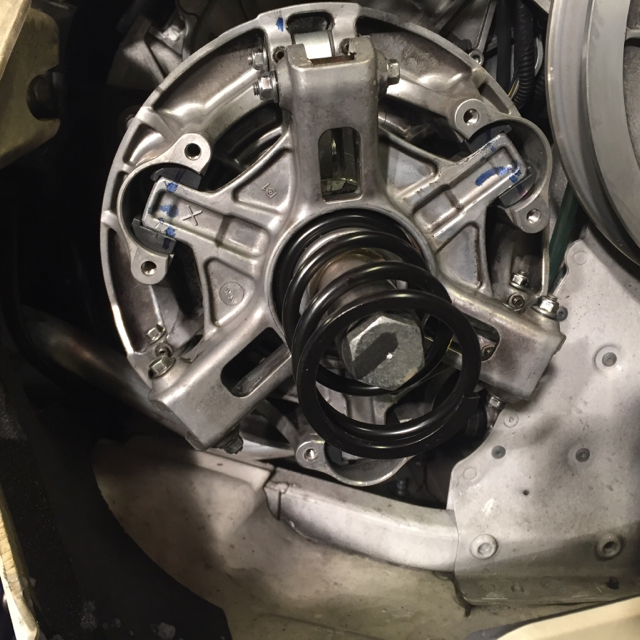

I have not been able to ride the sled sense the changes do to lack of snow. i was able to ride yesterday I Grand Lake, Co and what a difference in clutching so much better.View attachment 107491 View attachment 107490

Here are 2 pics of aquaticlaker's primary clutch before cleaning. Notice the belt residue by the sliders on the spider. This is actually less than most I see, I've seen some that you don't even see the aluminum. His sled has run the 8DN belt since brand new, but because his secondary was binding up and not shifting open enough from the casting flash, his belt was slipping and causing his clutching to do crazy stuff. This was why his COTC setup was hitting the rev limiter no matter how much weight (rivets) we put in his primary weights.

OK, back to the primary..... Look for evidence of large amounts of powder from the belt, if its in your bellypan....it's stuck in your clutching also. I know for a fact that aquaticlaker cleaned his clutches a couple times and still had problems with engagement, hitting the rev limiter all the time and couldn't pull anymore mph no matter what we did to the clutching. This is with over 2,000 miles on the sled.

1) Take the primary clutch off of the sled (if you have the correct Yamaha clutch puller), this is the best way to clean the clutching is outside cause you WILL have a black cloud if you do it indoors.....especially in the sled.

2) Take the top cover off of your primary (6 10mm bolts) and start your air compressor. Under high pressure, blow the snot out of the clutch, getting into every nook and cranny. Yes, that is all belt dust!!!!

This is a good time to check your rollers and weights to see if they move freely, if not....the whole weight and rollers need to come out and get cleaned, but most will be ok.

3) take a rag and wipe out the pockets where the spider pads ride. This is where the gunk really gets trapped. Blow out once again and check for binding or to see if the clutch moves freely. If not, more cleaning is needed.

4) when putting the primary back together, look for the "x" inside the cover and on the spider, they must match up as this is how the clutch was machined so you want it back that way for balancing.

Here is a video of how the clutch was before cleaning and after....much more free.

If your having issue like I was the above will fix it!

Mike

- Joined

- Apr 14, 2003

- Messages

- 6,539

- Reaction score

- 3,171

- Points

- 1,983

- Location

- Hessel, Michigan

- Country

- USA

- Snowmobile

- Sidewinder, SR Viper XTX, SR Viper XTX, 2016 Apex XTX and Pro-Line Pro Stock 1000

This will work for any Yamaha clutch

Mills

Lifetime Member

- Joined

- Dec 4, 2007

- Messages

- 800

- Reaction score

- 321

- Points

- 1,228

- Location

- Elk Mound, Wisconsin

- Country

- USA

- Snowmobile

- '21 SRX, '14 Viper RTX, '06 Apex, '99 SX 600, '74 TL433F,

Now I know why no matter how I load my primary weights it hits the rev limiter. The clutches will be coming off before the sled goes into storage for the summer and the flashing removed and both throughly cleaned. I have cleaned the primary several times and no matter how clean I get it, it seems to be "sticky" when I slide it together and back out by hand without the spring and cover on it. Is there any flashing removal or machining that can correct this issue with the primary?

Last edited:

Not as far as I know but there is little tricks to getting it to slide nice. I have even been known to wax the sliders surface. Probably Just some crap somewhere Mills. If you dont have the tools just send it to Thunder and let them take it all apart and go through everything. Well worth it in my opinion and you know its done right.Now I know why no matter how I load my primary weights it hits the rev limiter. The clutches will be coming off before the sled goes into storage for the summer and the flashing removed and both throughly cleaned. I have cleaned the primary several times and no matter how clean I get it, it seems to be "sticky" when I sled it together and back out by hand without the sitting and cover on it. Is there any flashing removal or machining that can correct this issue with the primary?

Mills

Lifetime Member

- Joined

- Dec 4, 2007

- Messages

- 800

- Reaction score

- 321

- Points

- 1,228

- Location

- Elk Mound, Wisconsin

- Country

- USA

- Snowmobile

- '21 SRX, '14 Viper RTX, '06 Apex, '99 SX 600, '74 TL433F,

Thunder products it is.

- Joined

- Nov 11, 2016

- Messages

- 548

- Reaction score

- 961

- Points

- 1,018

- Location

- Cedarville, MI

- Country

- USA

- Snowmobile

- Yamaha, Polaris, AC and Ski-Doo

- LOCATION

- Cedarville, MI

- WEBSITE

- www.thunderproductsclutching.com

Clutches are coming in from owners with Vipers. Receiving 1-2 sets of clutches everyday now and can't believe the flash issues and sticking problems due to poor deburring.

Thank you to all who put your trust in us to work on your clutches

Thunder Products Clutching

Thank you to all who put your trust in us to work on your clutches

Thunder Products Clutching

Similar threads

- Replies

- 74

- Views

- 40K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.