Jacob Hinrichs

Veteran

- Joined

- Jan 14, 2019

- Messages

- 27

- Age

- 47

- Location

- Bonners ferry , idaho

- Country

- USA

- Snowmobile

- 18 sidewinder mtx

Set it up with the Hurricane bar. There will then be a dogleg outward. You can them use shims inside the driven to set deflection and use a washer the size of the hub to let it float outward a couple mm.

Dan, show him how. Sounds like he need pictures or videos and has no idea on the principle of how these clutches and belts work or line up.

ClutchMaster, someone help me out. I gotta tap out.

I am very mechanically inclined and thank you for all the help. Just want to get this right. Right now my secondary sets in( towards the motor causing a dog leg) the shins you are talking about are the arctic cat shims that sit between the sheaves to set belt deflection correct? I understand the washer the size of the driven shaft to get some float. But if I move my secondary in to where the hurricane bar tells me to even with the new float ( out ward) that I gained I will still be doglegged at initial engagement. But if I leave my secondary where it is now and allow it to float out a bit it will center upon engagement and then move in with the shift if you see what I am saying.

The dog leg created by adjusting to the hurricane bar is extreme

alpineviper

Pro

- Joined

- Aug 24, 2014

- Messages

- 155

- Age

- 41

- Country

- Canada

- Snowmobile

- Alpine Turbo Viper

I am very mechanically inclined as well....I was just stating that the hurricane bar doesnt help the belts on the MTX's if riding in the steep and deep. I was looking for some ideas to possibly fix. Not to be called down by some ignorant people who probably never spent a day riding in the mountains.

Jacob Hinrichs

Veteran

- Joined

- Jan 14, 2019

- Messages

- 27

- Age

- 47

- Location

- Bonners ferry , idaho

- Country

- USA

- Snowmobile

- 18 sidewinder mtx

Dude that is just plain rude!

Mike has been trying to help you guys understand the concept. He’s not getting anything for helping you, nothing!

Now you come out with this attitude, if you disagree then why are you so full of questions?

Plenty of info on here as to what Mikes talking about, just do a search and you’ll find it! instead your asking him to rehash stuff that’s all over this very site.

Silver platter.........

https://ty4stroke.com/threads/does-the-sidewinder-secondary-float.149944/

As for the dog leg in your belt at idle, well the belt isn’t even tight so yea it’s gonna look way off. Take the belt guard off put it on a stand and engage the clutches. You will see that when the belt is tight it’s much straighter.

Here I’ll dumb it down for ya..... look at your sheaves coloring, if the inside sheave of the driven is darker than the outside sheave then your offset is too high. You want them both the same finish and color, your close enough.

Still having issues, then look at you clutch setup it’s probably junk.

Have a little respect, 2win

I have my clutch cover off, and I understand pretty well how the clutches are supposed to run. You did give a good mental picture though, thank you. My sled is completely stock so what are the stock weights and springs for a stock 18 mtx sidewinder 162. I have blown 3 belts in 200 miles . Just trying to get er figured out

Alpineviper,

People are here to learn, improve and make this a more enjoyable sled for all to benefit. I don't know KnappAttack or Clutchmaster but their knowledge and experience are something we are lucky they share with us,they have forgotten more than you will ever know. Instead of taking it personal and lashing out ask questions. Oh and stop being an @sshole.

People are here to learn, improve and make this a more enjoyable sled for all to benefit. I don't know KnappAttack or Clutchmaster but their knowledge and experience are something we are lucky they share with us,they have forgotten more than you will ever know. Instead of taking it personal and lashing out ask questions. Oh and stop being an @sshole.

Last edited:

alpineviper

Pro

- Joined

- Aug 24, 2014

- Messages

- 155

- Age

- 41

- Country

- Canada

- Snowmobile

- Alpine Turbo Viper

All I said was no need for arrogance and calling someone down for asking some questions.

If I misread then I apologize. Onward we go....

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,361

- Age

- 57

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Beats Soupy

Soupy is definitely the winner/loser on belt breakage.

He farted while asleep & when he awoke...................................................his brand new belt blew!

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

All I said was no need for arrogance and calling someone down for asking some questions.

I think Mike was more frustrated than arrogant.

There’s several threads that discussed how the float works on this new Winder clutch. Search the topic instead of expecting a personalized tutorial on the subject.

Alpineviper,

Don’t be so apathetic towards other people’s efforts and time to help you.

So Jacob,

your blowing belts before and after the Hurricane tool?

Jacob Hinrichs

Veteran

- Joined

- Jan 14, 2019

- Messages

- 27

- Age

- 47

- Location

- Bonners ferry , idaho

- Country

- USA

- Snowmobile

- 18 sidewinder mtx

I think Mike was more frustrated than arrogant.

There’s several threads that discussed how the float works on this new Winder clutch. Search the topic instead of expecting a personalized tutorial on the subject.

Alpineviper,

Don’t be so apathetic towards other people’s efforts and time to help you.

So Jacob,

your blowing belts before and after the Hurricane tool?

Yes, the first 2 belts I blew were on one day snow was deep and very heavy. (I rode about a 150 miles before this day of powder rides, not heavy snow). Then after i blew the 2 belts i bought the alignment tool and set up my clutches to it. I literally was no able to ride it more than 5 minutes off trail with out having to stop because my clutches were smoking hot.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

I have a feeling that they were smoking hot with or without the alignment tool in deep stuff. Riding slowly will only make matters worse, so yes a gear change would be something to consider to ease the torque the belt has to carry.

8jp belt?

Mountain machines generally need shallower helix angles and stiffer secondary springs to prevent overshifting in loose snow.

If your absolutely sure your alignment is correct (you are an alignment guy), I would start with a secondary spring change and smaller primary rollers. This is your cheapest option.

Are a majority of the MTX sleds having issues?

8jp belt?

Mountain machines generally need shallower helix angles and stiffer secondary springs to prevent overshifting in loose snow.

If your absolutely sure your alignment is correct (you are an alignment guy), I would start with a secondary spring change and smaller primary rollers. This is your cheapest option.

Are a majority of the MTX sleds having issues?

Shagnos

TY 4 Stroke Junkie

I did some offtrail riding through the trees. Didn’t like it neither did my sled, everything got hot crawling along at barely above engagement.

alpineviper

Pro

- Joined

- Aug 24, 2014

- Messages

- 155

- Age

- 41

- Country

- Canada

- Snowmobile

- Alpine Turbo Viper

Most of the mtx I ride with have all swapped driven springs over to epi purple or dalton black orange and the belt problems seem to have went away. The stock driven spring is way too soft. If we can get 1000km out of a belt in the steep and deep that’s good enough. Riding the mountains is torture for a sidewinder belt. You can’t really afford to gear em down anymore than they already are.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Im not sure if you want to remove float or add it? I believe you should already have float if its stock. The more you machine off secondary hub and push secondary inward, the more float you will have.

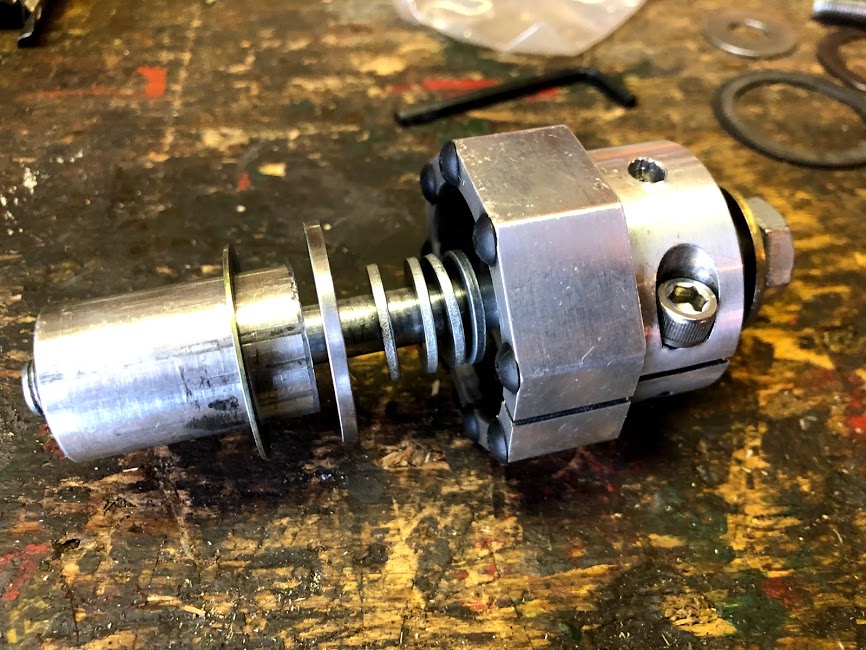

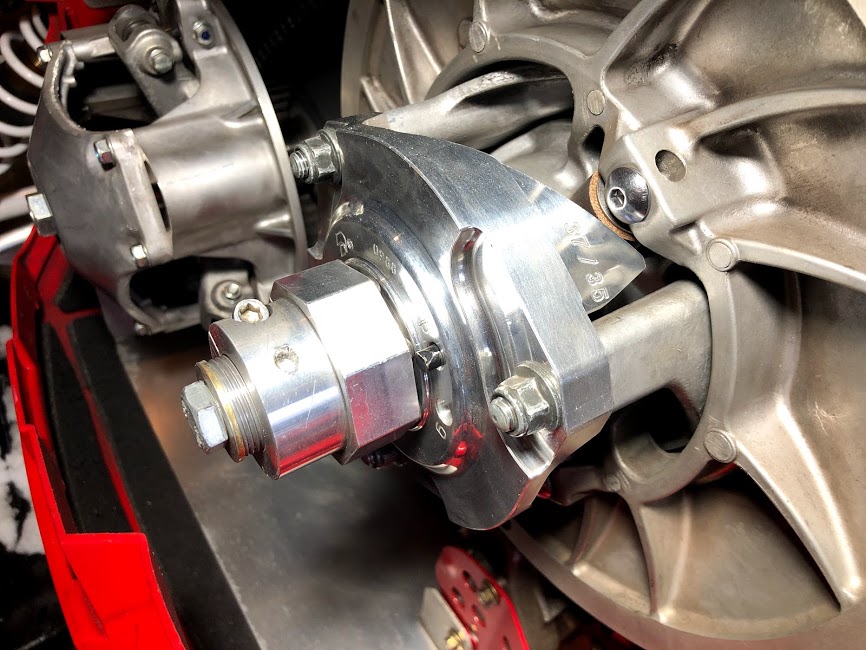

I can post these pics below(BTW all the pics I ever post are always in my build thread-SIG BELOW) which is how I REMOVED FLOAT entirely....I tend to like using the BOP adjuster so belt swaps are easier when I use alot of backpressure setting. --Dan

Here is the entire write-up I did:

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/page-34#post-1449153

Removing the float while using the BOP belt adjuster

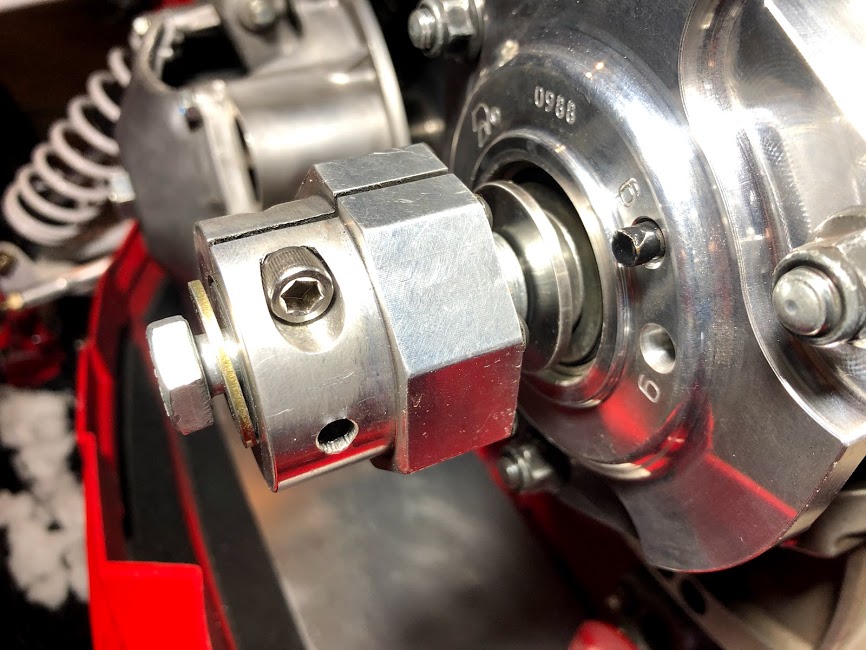

I was able to set up my BOP adjuster very nicely. Travis should like this! So anyone with the BOP adjuster, this is an easy setup with a few easy mods and a 35mm OD washer.

So anyone with the BOP adjuster, this is an easy setup with a few easy mods and a 35mm OD washer.

This setup will allow for belt deflection adjusting, and also removal/installing belts as we all love, and will remove the float fully or just the amount you want.

Lowering the offset as per the Hurricane alignment bar, Secondary hub backside gets machined down, and so the secondary slides inward approx 3 to 4mm. To reduce the massive amount of float that is produced afterwards, material needs to be cut off the stock aluminum float plug. So first get your secondary exactly where the Hurricane bar wants it.

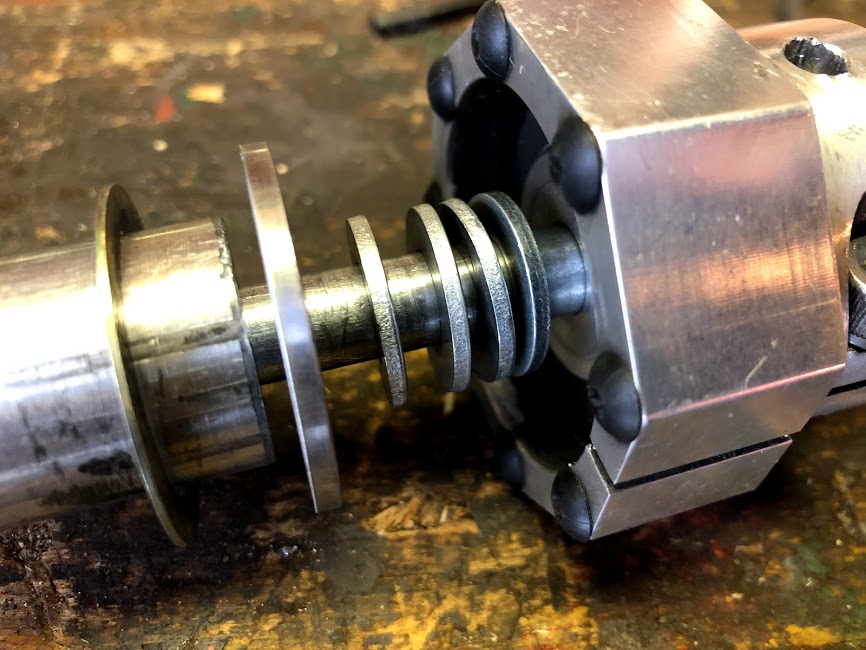

Once secondary is sitting perfect with Hurricane alignment bar, insert the stock alum float plug. The alum float plug will get cut down close to flush with outer hub..... When I cut mine, I left it a tad longer then flush, and used an old Apex shim OVERTOP of the Alum float plug to remove the float down to approx .2mm(Basically nothing). These shims are much larger and fit over the alum plug like the apex used to have(pics below).....I like to allow for this small spacing so there is no side loading when bolted tight.

NOTE: Initially the amt left hanging out of my HUB was 7mm!(check yours as not all will be exact same). That large amount of float, is increased if using the belt adjuster, as hub may float inside the adjuster even further outward once into the shift. This is where the 35mm washer comes into play.

Next in line to the newly cut down float plug, you need a larger fender style washer, be sure its thick enough too. I found fastenal has 10mm X 35mm OD X 2.5mm thick.

Next we use the 4 small washers that Travis includes in his adjuster. This helps as the main bolt he gives you is very long, and also helps with adjuster to remove belts.

Next is the adjuster itself.

Next I use a large washer outside, i chose one that is a tad larger then BOP threaded adjuster diam, so if the adjuster ever came loose, it cannot spin off.

Now the adjuster works as a deflection tool and also a belt change tool too. Possibly Travis will include a 35mm large washer for guys who want no float

Remember, the '12 cats had this float setup with the helix, and they were belt killers, and now the new Cat 998s are locked down like the doos, and sure enough their belt life seems reasonable. Time will tell.

Dan

Notice the thin Apex shim on left, overtop of Alum float plug.

Float plug,Apex shim, 35mm fender washer, 4 washers came with BOP adjuster, BOP adjuster, large washer.

Apex shim sitting overtop of stock float plug,dials in perfect amt of float(.2mm now,so basically nothing)

All tightened up and deflection set where I want with Adjuster, also used for removing belts easily.

I can post these pics below(BTW all the pics I ever post are always in my build thread-SIG BELOW) which is how I REMOVED FLOAT entirely....I tend to like using the BOP adjuster so belt swaps are easier when I use alot of backpressure setting. --Dan

Here is the entire write-up I did:

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/page-34#post-1449153

Removing the float while using the BOP belt adjuster

I was able to set up my BOP adjuster very nicely. Travis should like this!

This setup will allow for belt deflection adjusting, and also removal/installing belts as we all love, and will remove the float fully or just the amount you want.

Lowering the offset as per the Hurricane alignment bar, Secondary hub backside gets machined down, and so the secondary slides inward approx 3 to 4mm. To reduce the massive amount of float that is produced afterwards, material needs to be cut off the stock aluminum float plug. So first get your secondary exactly where the Hurricane bar wants it.

Once secondary is sitting perfect with Hurricane alignment bar, insert the stock alum float plug. The alum float plug will get cut down close to flush with outer hub..... When I cut mine, I left it a tad longer then flush, and used an old Apex shim OVERTOP of the Alum float plug to remove the float down to approx .2mm(Basically nothing). These shims are much larger and fit over the alum plug like the apex used to have(pics below).....I like to allow for this small spacing so there is no side loading when bolted tight.

NOTE: Initially the amt left hanging out of my HUB was 7mm!(check yours as not all will be exact same). That large amount of float, is increased if using the belt adjuster, as hub may float inside the adjuster even further outward once into the shift. This is where the 35mm washer comes into play.

Next in line to the newly cut down float plug, you need a larger fender style washer, be sure its thick enough too. I found fastenal has 10mm X 35mm OD X 2.5mm thick.

Next we use the 4 small washers that Travis includes in his adjuster. This helps as the main bolt he gives you is very long, and also helps with adjuster to remove belts.

Next is the adjuster itself.

Next I use a large washer outside, i chose one that is a tad larger then BOP threaded adjuster diam, so if the adjuster ever came loose, it cannot spin off.

Now the adjuster works as a deflection tool and also a belt change tool too. Possibly Travis will include a 35mm large washer for guys who want no float

Remember, the '12 cats had this float setup with the helix, and they were belt killers, and now the new Cat 998s are locked down like the doos, and sure enough their belt life seems reasonable. Time will tell.

Dan

Notice the thin Apex shim on left, overtop of Alum float plug.

Float plug,Apex shim, 35mm fender washer, 4 washers came with BOP adjuster, BOP adjuster, large washer.

Apex shim sitting overtop of stock float plug,dials in perfect amt of float(.2mm now,so basically nothing)

All tightened up and deflection set where I want with Adjuster, also used for removing belts easily.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,695

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

I am very mechanically inclined and thank you for all the help. Just want to get this right. Right now my secondary sets in( towards the motor causing a dog leg) the shins you are talking about are the arctic cat shims that sit between the sheaves to set belt deflection correct? I understand the washer the size of the driven shaft to get some float. But if I move my secondary in to where the hurricane bar tells me to even with the new float ( out ward) that I gained I will still be doglegged at initial engagement. But if I leave my secondary where it is now and allow it to float out a bit it will center upon engagement and then move in with the shift if you see what I am saying.

The dog leg created by adjusting to the hurricane bar is extreme

Hurricane bar is accurate for belt alignment at 1:1. Set it up like this and let the driven float outward 1.5mm and it will line up at engagement. Pull the clutch guard off and look at how it all works. You will see. If you are inclined, line it all up without springs or at least a very soft spring in the driven and mock it up and line it all up. You will understand it all better.

The problem you are having is severe slippage at engagement speed now, and fighting how the factory belt deflection operates with the large washer pushing the driven completely inward at low speed on the helix.

Eliminate the factory style deflection adjustment pushing on the helix, set it up for old style Cat reverse deflection washers in between the secondary sheaves for belt deflection, float the driven a couple mm so it lines up at engagement after setting it up with the Hurricane bar. It also has to line up at 1:1 shift ratio too. Here is the problem with floating though. If the driven sticks outward and does not float inward under power and 1:1 or full shift, it will still pop belts from misalignment if it sticks outward under power from the float outwards.

Keep in mind a winder is not made to go slow and idle around slipping the clutch and belt either. They are geared way to high for that slow speed stuff. There is no difference on how this works, whether its a mountain sled or a trail sled. Its all the same mechanically.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

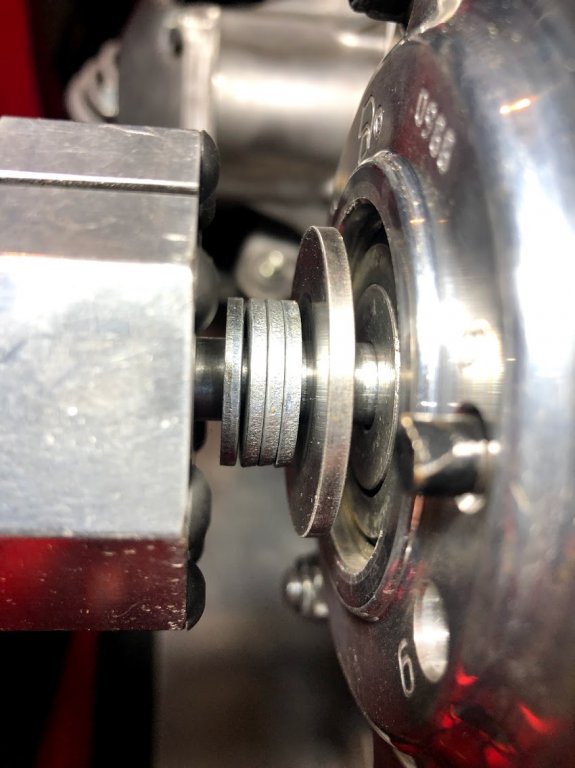

Adding in float for low speed running, as Mike said.....you DO NOT want to run an adjuster like my above pics, and you need to remove the factory way of setting deflection as Mike mentions.

So the large cat shims(in between sheaves) is the way to achieve deflection settings, while not having anything against helix.

Here are the large cat shims you need....

Dan

So the large cat shims(in between sheaves) is the way to achieve deflection settings, while not having anything against helix.

Here are the large cat shims you need....

Dan

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 5

- Views

- 1K

- Replies

- 36

- Views

- 9K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.