Kuzzy

Expert

- Joined

- Dec 6, 2020

- Messages

- 442

- Reaction score

- 234

- Points

- 408

- Location

- saskatchewan

- Country

- Canada

- Snowmobile

- 2020 yamaha sidewinder xtx se

2022 STX GT

2017 King Cat M9000

For better or worse, the engineers involved in this seem to want a loose fit. They hardened the Shaft so it doesn't wear away in the bearing, they lubed the shaft so if it spins in the bearing it does less damage, and the bearing itself is spec'd as a loose bearing. The engineers don't want to lock this up and are doing everything they can to not lock it up. They must have a reason, will something else blow up if it is locked? (Doesnt some like it with all of the savers out there.) Like I said in the beginning, for better or worse, don't crucify me for making observations lol

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,298

- Reaction score

- 3,345

- Points

- 1,603

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

Agree with your post. I can only add that locking it down had ZERO negative effects for thousands of miles. I know for sure mine was locked down for 2 seasons at around 270 hp. As we speak my 2022 is locked down. And certain I will need heat and the puller I made to get the bearing off shaft. BUT I don’t know until after this season that it will not spin.For better or worse, the engineers involved in this seem to want a loose fit. They hardened the Shaft so it doesn't wear away in the bearing, they lubed the shaft so if it spins in the bearing it does less damage, and the bearing itself is spec'd as a loose bearing. The engineers don't want to lock this up and are doing everything they can to not lock it up. They must have a reason, will something else blow up if it is locked? (Doesnt some like it with all of the savers out there.) Like I said in the beginning, for better or worse, don't crucify me for making observations lol

Are they afraid of the chassis flexing and bearing locked down?

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,444

- Reaction score

- 3,707

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

I said this before, if you lock that bearing to the shaft and have a bearing failure it is possible to have brake failure.

If that bearing locks , starts spinning in the caliper and tears it up you could be in for trouble.

Maybe that's why they want it to be able to move.

If that bearing locks , starts spinning in the caliper and tears it up you could be in for trouble.

Maybe that's why they want it to be able to move.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,858

- Reaction score

- 6,134

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

For better or worse, the engineers involved in this seem to want a loose fit. They hardened the Shaft so it doesn't wear away in the bearing, they lubed the shaft so if it spins in the bearing it does less damage, and the bearing itself is spec'd as a loose bearing. The engineers don't want to lock this up and are doing everything they can to not lock it up. They must have a reason, will something else blow up if it is locked? (Doesnt some like it with all of the savers out there.) Like I said in the beginning, for better or worse, don't crucify me for making observations lol

The only reason to allow it to easily slide on and off the shaft is its an easy way to assemble and take apart. The way it is engineered now makes it all but impossible to lock down without a new shaft with bolt on the end, and a shoulder inside for the bearing to lock down to, or to use the BOP shaft saver wedge to distort the shaft in three places to try to keep from spinning in the bearing, which works well and is an easy fix when you TQ it down properly and not get the bearing cocked on the shaft when you do lock it down. If it gets cocked when locked down on the shaft, it will flex the chassis and bearing holder. Easy to see when operating on the stand and looking at it.

It would be easy to make a shaft that lacks it all together like the old Yamahas had, but you chance that if the brake warps, it pulsates the brake. Easy fix is a floating brake disc on a hub, Its not rocket science. Ski-Doo also makes a setup that works well with the bearing having an interference fit on the shaft and a snug fit on the bearing holder, almost requiring a puller to get it apart. People even make pullers for them but it's not necessary. Ski-Doo has proven how it should be done, but Cat is too stupid to copy it or perhaps its a patent thing and they can't copy it. I'm guessing there is not a patent on fitting bearings though...

Any good builder or engineer could fix this inherent issue easily, but for whatever reason, Cat fails to fix it year after year and Yamaha could care less if it gets fixed. I just shake my head over all the little nagging problems that are easily fixed by the aftermarket, yet the factory fails to address with this chassis. Once you get the little issues addressed, its a bullet proof sled that works like it should, but it drives a lot of customers away as they don't want to work on this stuff and don't want a trip to the dealer all the time. It leaves the rest of us blown away by the stupidity of it all. I could fix and re-engineer this stuff back in high-school shop class as a kid! Hard to imagine they just seem to do the same crap year after year and expect to grow and gain market share, but we keep being them year after year... Textron/Cat needs to re-think how to stay in business and build quality if they want to succeed.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,806

- Reaction score

- 2,838

- Points

- 1,113

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

AMEN KA!

I had junior engineering interns that could fix this in a day.

I had junior engineering interns that could fix this in a day.

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,250

- Reaction score

- 2,689

- Points

- 1,733

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Yes it makes me shake my head why they don't fix this issue.

Its an easy fix to lock that bearing down.

What gets me is why they went with a floating brake disc design and not a floating caliper design.

Its an easy fix to lock that bearing down.

What gets me is why they went with a floating brake disc design and not a floating caliper design.

Upstater57

Lifetime Member

- Joined

- Apr 25, 2021

- Messages

- 594

- Reaction score

- 577

- Points

- 778

- Location

- New York

- Country

- USA

- Snowmobile

- 2022 Tcat EPS,

2014 ZR9000 (sold)

1978,1979,1980 SRX (sold)

Just maybe is it designed like this on purpose as a cost measure. For years AC steering had a bunch of play built into it. The "play" kept the sled from being darting prone. it was not precision engineering, we did not like it, but it worked. Put 10's of thousands of miles on those chassis with no issues.

WinderFab

TY 4 Stroke God

- Joined

- Mar 1, 2009

- Messages

- 1,880

- Reaction score

- 1,129

- Points

- 1,478

- Location

- Woodbridge, ON

- Country

- Canada

- Snowmobile

- 2020 Sidewinder Ltx GT

I just checked the 2022 top gear part # and it the same part # as my 2020 gear, has it really been upgrade with better material?

rtx moose

VIP Member

- Joined

- Jul 31, 2014

- Messages

- 1,141

- Reaction score

- 550

- Points

- 1,308

- Location

- WATERTOWN,MN

- Country

- USA

- Snowmobile

- 2017 sidewinder LTX LE,2007 RTX,2000 SRX700

It's called broaching..they make keyway doing thisI am not a machinist so I dont know. How do they do it on the brake disc? Can't be too difficult.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,876

- Reaction score

- 2,752

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

I just checked the 2022 top gear part # and it the same part # as my 2020 gear, has it really been upgrade with better material?

Wow...i'm surprised the 22 fiche are even out! Will have to some part number checking myself. DId you happen to check driveshaft or secondary shaft part numbers from 22 against prior year?

WinderFab

TY 4 Stroke God

- Joined

- Mar 1, 2009

- Messages

- 1,880

- Reaction score

- 1,129

- Points

- 1,478

- Location

- Woodbridge, ON

- Country

- Canada

- Snowmobile

- 2020 Sidewinder Ltx GT

This is for a 2022, they just added the 2022 fiche, maybe it’s wrong but the part numbers are all the same.Wow...i'm surprised the 22 fiche are even out! Will have to some part number checking myself. DId you happen to check driveshaft or secondary shaft part numbers from 22 against prior year?

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,306

- Reaction score

- 1,491

- Points

- 1,583

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

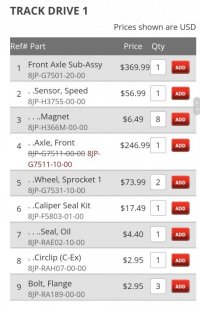

Port Yamaha also has the 2022 microfiche:

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,444

- Reaction score

- 3,707

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

could be a running change to the part with the number staying the same. I have seen it in the automotive world

Janne339

TY 4 Stroke Junkie

- Joined

- Oct 31, 2015

- Messages

- 559

- Reaction score

- 395

- Points

- 738

- Location

- Sweden

- Country

- Sweden

- Snowmobile

- 2021 Sidewinder LTX GT

WinderFab

TY 4 Stroke God

- Joined

- Mar 1, 2009

- Messages

- 1,880

- Reaction score

- 1,129

- Points

- 1,478

- Location

- Woodbridge, ON

- Country

- Canada

- Snowmobile

- 2020 Sidewinder Ltx GT

Ok, I guess than Yamaha Canada already switched out the old part numbers to all the new part numbers.This from a 2021 LTX. New driveshaft for 2022.

Similar threads

- Replies

- 24

- Views

- 4K

- Replies

- 23

- Views

- 44K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.