jaydaniels

TY 4 Stroke Junkie

- Joined

- Dec 10, 2008

- Messages

- 654

- Location

- Bedford NS Canada

- Country

- Canada

- Snowmobile

- 2017 Sidewinder RTX

msThe stock secondary allows float, after the sled is moving, outward not inward.

Up until recently everything I have read always suggested that 61mm was the number to strive for when measuring offset. Now it seems that this may not be the case. Seems to me that since the clutch can always float out if needed once it has started shifting it makes more sense to be closer to the 58mm measurement. If set at 61 it can never float in less than the 61mm measurement. Unless I’m missing something, which is very possible lol.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

True......

And more and more are finding 58-59mm offset to run cooler.

Ive just set mine up there, so will see.....prob not til next season tho unfortunately.

And more and more are finding 58-59mm offset to run cooler.

Ive just set mine up there, so will see.....prob not til next season tho unfortunately.

Soupy

Expert

- Joined

- Jan 10, 2017

- Messages

- 359

- Age

- 50

- Location

- West Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX-LE

Correct. This is why I started the "Why 61mm offset?" thread long ago, of course never got any good answers.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

I hear ya.....Been reading for near 2 seasons now how 61mm was the spot....and now all the sudden guys saying 58 is cooler....I sure hope it does something for belt life. I never felt like mine were hot to begin with tho.Correct. This is why I started the "Why 61mm offset?" thread long ago, of course never got any good answers.

How have you made out recently?

I keep hoping you get yours fixed as it seems to be the most extreme belt issue here.

Any snow left to test?

jaydaniels

TY 4 Stroke Junkie

- Joined

- Dec 10, 2008

- Messages

- 654

- Location

- Bedford NS Canada

- Country

- Canada

- Snowmobile

- 2017 Sidewinder RTX

Yeah I noticed that thread with no responses. I think I’ll try mine without the washer. With one washer I’m right at 61mm. Mine has been good on belts but I’m so worried about blowing one I never hold it open too long. I do notice my clutches run substantially hotter than anyone else in our group, including a viper.Correct. This is why I started the "Why 61mm offset?" thread long ago, of course never got any good answers.

sledding rocks

Expert

my 2017 came with no washer behind the secondary ,and have yet to brake a belt , offset is 60mmHad anyone tried no washer behind secondary? Did the bearing clip do anything to the hub?

No washers behind mine, and no belt issues 975 miles all on EVO stage 4 and 180 1.64 stingers. I did grenade 1 belt at 400 miles but figured out it was glazed and not broke in properly.

Soupy

Expert

- Joined

- Jan 10, 2017

- Messages

- 359

- Age

- 50

- Location

- West Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX-LE

I hear ya.....Been reading for near 2 seasons now how 61mm was the spot....and now all the sudden guys saying 58 is cooler....I sure hope it does something for belt life. I never felt like mine were hot to begin with tho.

How have you made out recently?

I keep hoping you get yours fixed as it seems to be the most extreme belt issue here.

Any snow left to test?

No good, blew another 8jp within about 100 miles. Clutches still hot at 58.5mm and even down to 56mm, trying to let it float. Got pissed and dropped it off to Priceless Performance. They're well known and have a chassis dyno so hopefully he can figure it out. 16 belts now in 3000 miles...

Trying to get to the Wawa area next wknd but no snow left in the lower and went fishing on my lake yesterday, sucks!

fourload

TY 4 Stroke Master

Been reading your posts. Can’t believe how many belts you have gone through. I would be so pissed I would drive to Quebec and have it stolen! Lol. Maybe it isn’t clutch related. How is the chassis? Does it coast well and run freely? Maybe twisted or deformed somehow. Let us know when you solve your problem. All of us are curious.

Soupy

Expert

- Joined

- Jan 10, 2017

- Messages

- 359

- Age

- 50

- Location

- West Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX-LE

Been reading your posts. Can’t believe how many belts you have gone through. I would be so pissed I would drive to Quebec and have it stolen! Lol. Maybe it isn’t clutch related. How is the chassis? Does it coast well and run freely? Maybe twisted or deformed somehow. Let us know when you solve your problem. All of us are curious.

With the exception of this issue, I love the sled so I keep at it. Track spins very freely by hand on the stand. Sled doesn't coast to a stop as well as I thought but I think different clutch springs change the engine braking amount. I agree possibly twisted or deformed but clutch alignment is good so maybe I'll learn something from the chassis dyno.

fourload

TY 4 Stroke Master

Yes the track dyno should tell you a lot. Too bad you have to spend all the time and money on the friggin thing. You are a very patient man!!With the exception of this issue, I love the sled so I keep at it. Track spins very freely by hand on the stand. Sled doesn't coast to a stop as well as I thought but I think different clutch springs change the engine braking amount. I agree possibly twisted or deformed but clutch alignment is good so maybe I'll learn something from the chassis dyno.

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Soupy be sure to check the vertical reading of each clutch. Some cats back in 12 were setting too low on PTO side so the primary sheave was not vertically equal to the secondary. That is the one thing that is harder to check for, but if the clutches are not both vertically equal, you will make heat fast. I assume you have checked it but this is one reading you really gotta check closely.

Yours if the most extreme blower for sure, and I give you credit for sticking with it. Mine is not nearly as bad and it pisses me off, so i feel your pain brother.

Dan

Yours if the most extreme blower for sure, and I give you credit for sticking with it. Mine is not nearly as bad and it pisses me off, so i feel your pain brother.

Dan

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

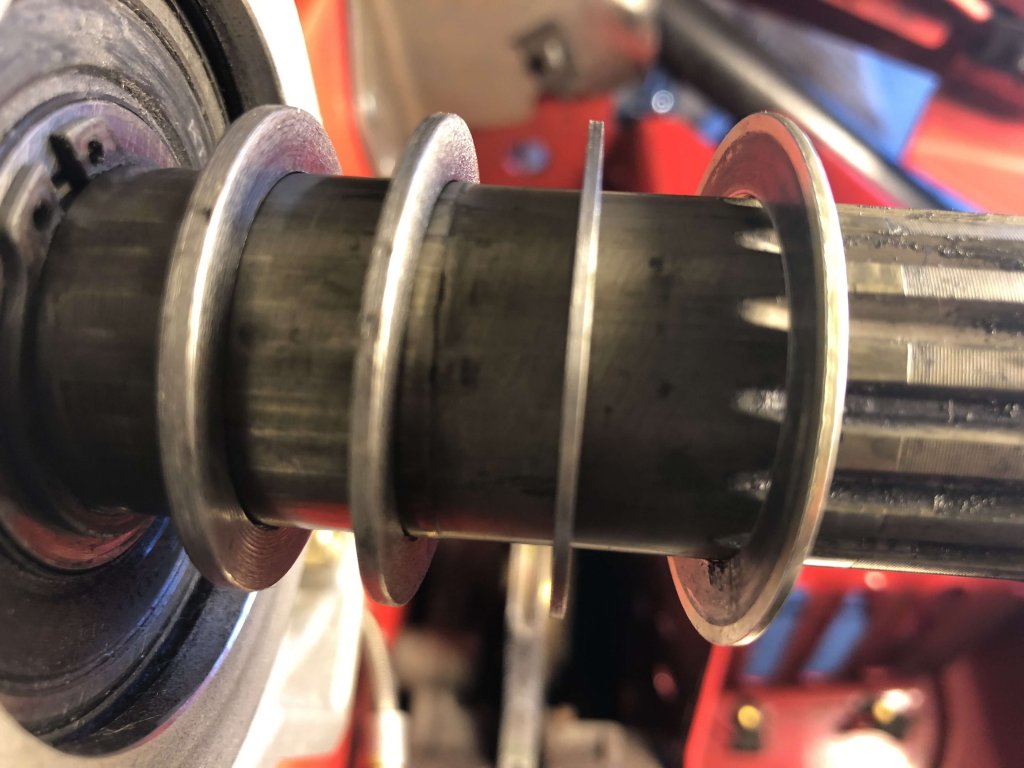

Got my stuff back from my machinist.....

Had him take off 4mm off hub, which makes it past flush when full shifted. And then I had him make me 3 shims, that are a slightly smaller OD then stock YAM shims. This way I can shim it wherever I want, and it will allow the shim to go inside if need be.

I had him make me a 2mm, 1.5mm, 1mm, shown in pic below....and then the stock 1mm which is larger OD.

I am now able to put my clutch anywhere from 58mm on up to 61. Where mine sits, I use the 1.5mm and end up right around 58.8mm or just under 59mm. Which I think is where I will put it now.

Dan

Had him take off 4mm off hub, which makes it past flush when full shifted. And then I had him make me 3 shims, that are a slightly smaller OD then stock YAM shims. This way I can shim it wherever I want, and it will allow the shim to go inside if need be.

I had him make me a 2mm, 1.5mm, 1mm, shown in pic below....and then the stock 1mm which is larger OD.

I am now able to put my clutch anywhere from 58mm on up to 61. Where mine sits, I use the 1.5mm and end up right around 58.8mm or just under 59mm. Which I think is where I will put it now.

Dan

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

You do need to mock it up without spring in helix, to full shift...and be certain the backside of secondary at full shift does not contact the main bearing bracket, as the bearing is set inward with circlip.

Mine ends up very close due to where my engine is set.

Dan

Mine ends up very close due to where my engine is set.

Dan

jayden84

Newbie

- Joined

- Jan 2, 2011

- Messages

- 18

- Location

- Nova Scotia

- Country

- Canada

- Snowmobile

- 2017 yamaha sidewinder xtx se

No shim in mine from factory, 59.6 offset , 4600 miles blew 1 belt at 2500 miles under multiple wot back to back running. High torque rollers in the secondary from new as well

Similar threads

- Replies

- 10

- Views

- 3K

- Replies

- 0

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.