The goal of this conversion is twofold.

#1 Increase Top End Performance

#2 Eliminate a Variable that MIGHT cause erratic idle and other engine running qualities

I have never understood why the ignition pickup on the Nytro and Vipers was placed on the Stubshaft our Primary clutch is attached too. This Stubshaft is splined and a loose spline to the crankshaft. I believe the stubshaft stock setup is way cheaper to manufacture than a Flywheel activated ignition. I believe a Flywheel activated system is also way more accurate since it is a direct connection to Crankshaft and there cannot be any play since the flywheel is keyed to the Crank rather than the Stubshaft splines which are also a big source of noise which confirms they are not tight.

The Sidewinder ditched the Stubshaft Ignition pickup and its on the Flywheel. Hurricane Performance has also come out with a weighted Stubshaft which is claimed to reduce the Stubshaft noise. I am not concerned about the noise but am interested in the added weight. I believe any added weight on the crankshaft will smooth out the engine and add Torque. I have long said this 3 cylinder acts more like a 2 stroke than my SRX. It does not like a load such as poor conditions. Dirtbikes and Quads are HUGELY affected by adding weight to flywheel or crank. Like Night and Day with very small amount. When the Flywheel/Pickup conversion has proven to work and has been proven to at least not harm performance then I will add the Hurricane Stubshaft to the Viper motor. Hope it all fits!

I want to Thank DC5 and Dave for sharing their little secrets that are insignificant to them but mean so much to me and others who appreciate the hard work,$ and frustration experimenting costs. I will not whine much if it doesnt work! LOL!

https://ty4stroke.com/threads/the-hurricane-clutch-noise-elimination-shaft.154029/

https://ty4stroke.com/threads/hurricane-clutch-noise-elimination-system.153680/#post-1436502

https://ty4stroke.com/threads/stub-shaft.154043/#post-1440985

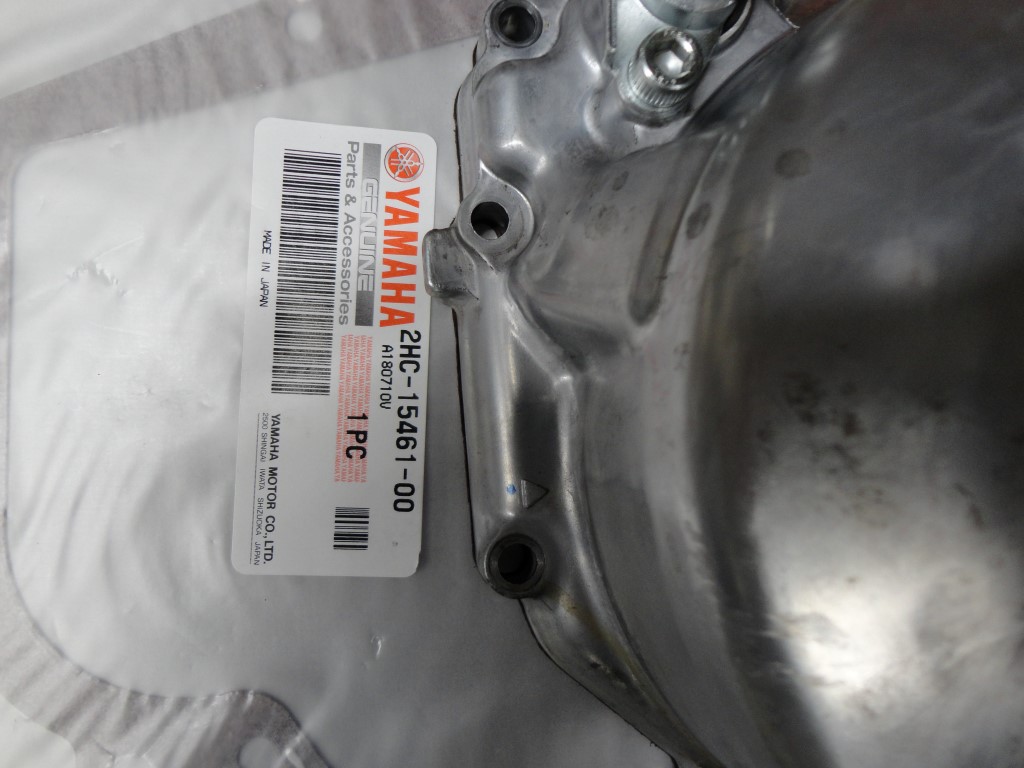

Parts needed:

Sidewinder Flywheel,Stator(Higher Output),Gasket and SideCover

Viper Sidecover Notice lower hose fitting on Sidewinder has a elbow so will have to deal with that.

Step1 Modify Sidewinder Stator Harness to reach the Viper Pickup Coil plug. Use a scissor to cut the protective sleeve and separate the Pickup wires from the Stator wires. Then repair the sleeve over the stator wires and add a protective sleeve to the Pickup wires. The wires in Winder pickup plug need to be reversed in the plug. Use a pin to press tab inside and they come right out. Grey and white need to be in same spots in plug as Viper grey and white.Thats it.This allows you to plug Stator wire plug into the regulator since its identical and run the Pickup wires across to the existing plug on left side in Viper harness.

Black 2 wire plug on left side near steering pyramid above clutch cover. Plug With Green/White and Blue/White wires plugs right in.(The two white plugs in Pic are for my PCV Ignition Module)Male end of Black Plugs wont be used anymore but will stay till I know it all works.

Voltage Regulator Sidewinder Plug is Identical and plugs into the grey receptical on regulator

Completed Harness. Will be run alongside the reverse actuator wires which have foil heat barrier (DEI AutoZone)so I did same. Then over engine to Pickup plug on left side. Plenty of wire and no cutting or splicing. SideWinder Harness is way nicer than our Viper wiring. This is in between. I am happy with it.

Ok In we go.

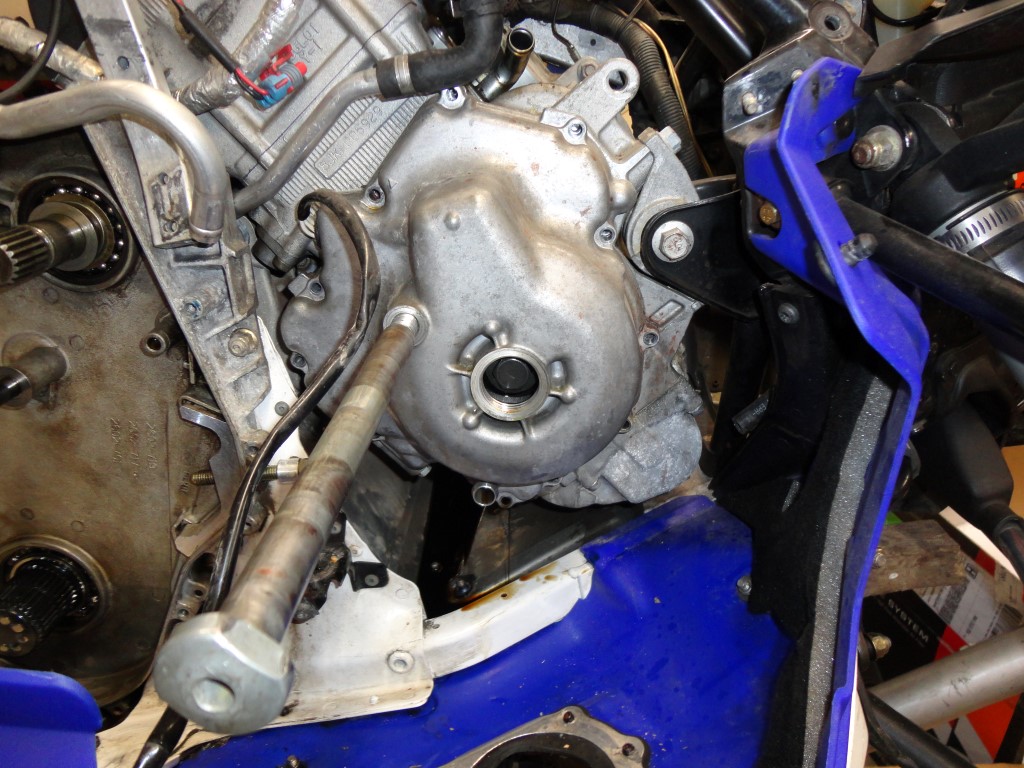

You can see the crossmember needs to be removed and all bolts. The Magnets of flywheel are strong so I threaded this old Swingarm bolt into timing hole to ease cover removal. If you have had a starter gear failure this is same procedure.

Checked fit of Sidewinder Cover. Perfect!

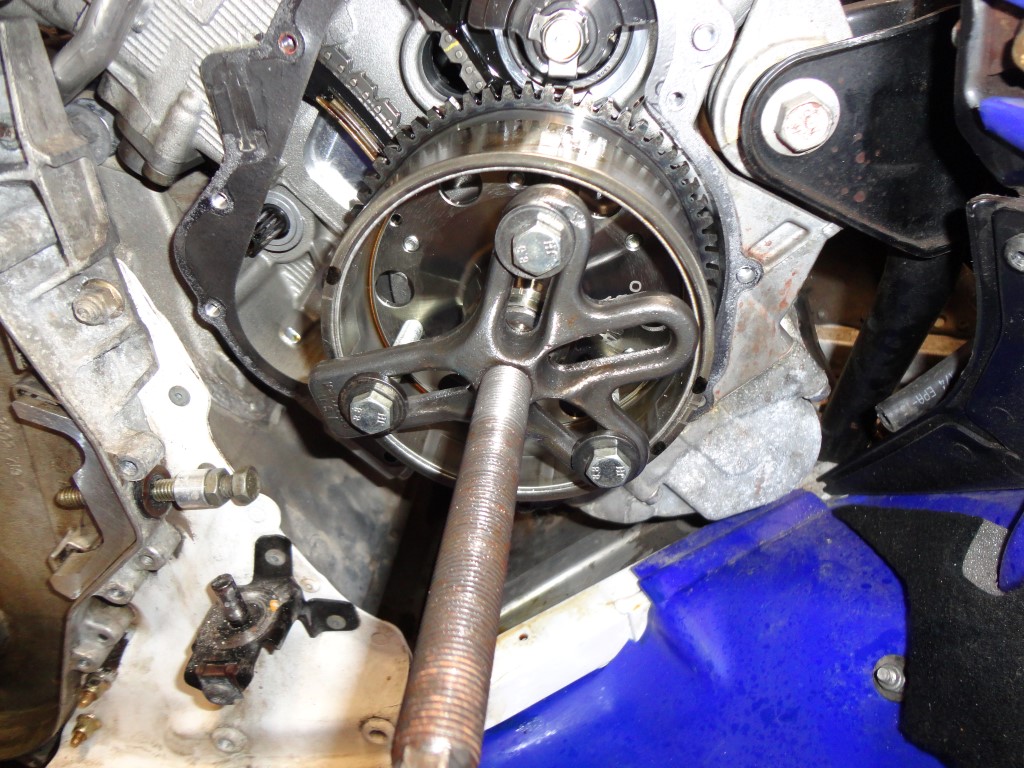

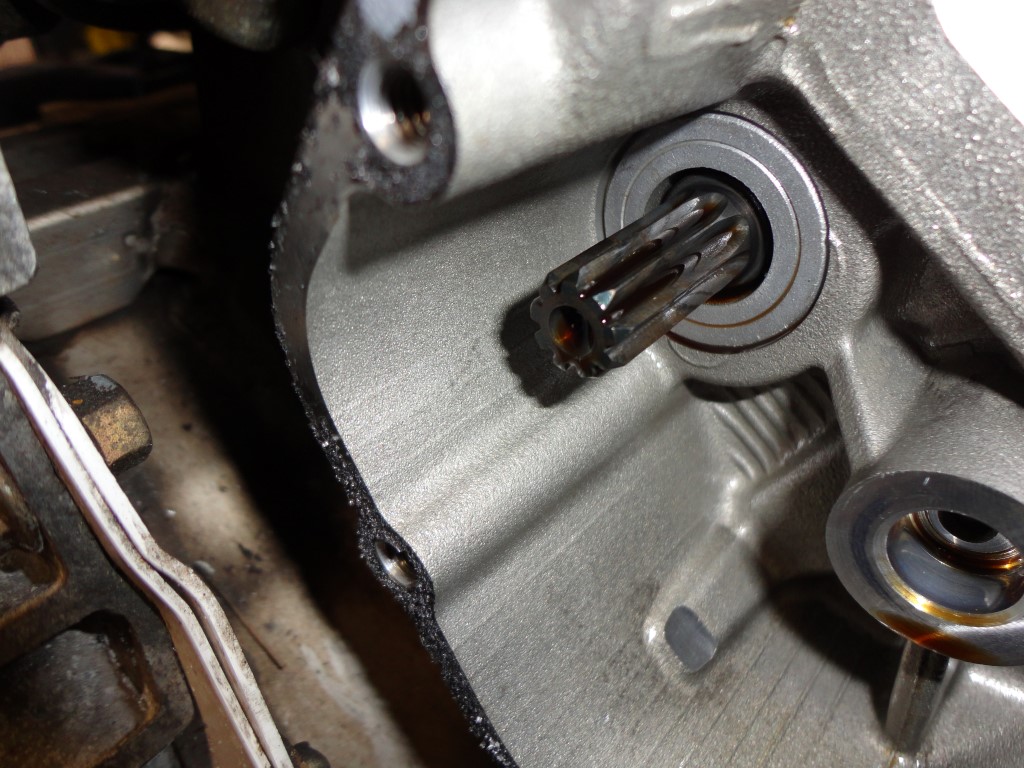

This is setup you use to remove Flywheel. Its both keyed and Tapered fit. I used a impact and came off easy.

Guys these motors are Jewels. Pleasure to see. This is all original never been opened 13000mi motor. Starter drive very little wear.

The infamous Idler gear. Perfect

Oneway bearing perfect

Fun stuff

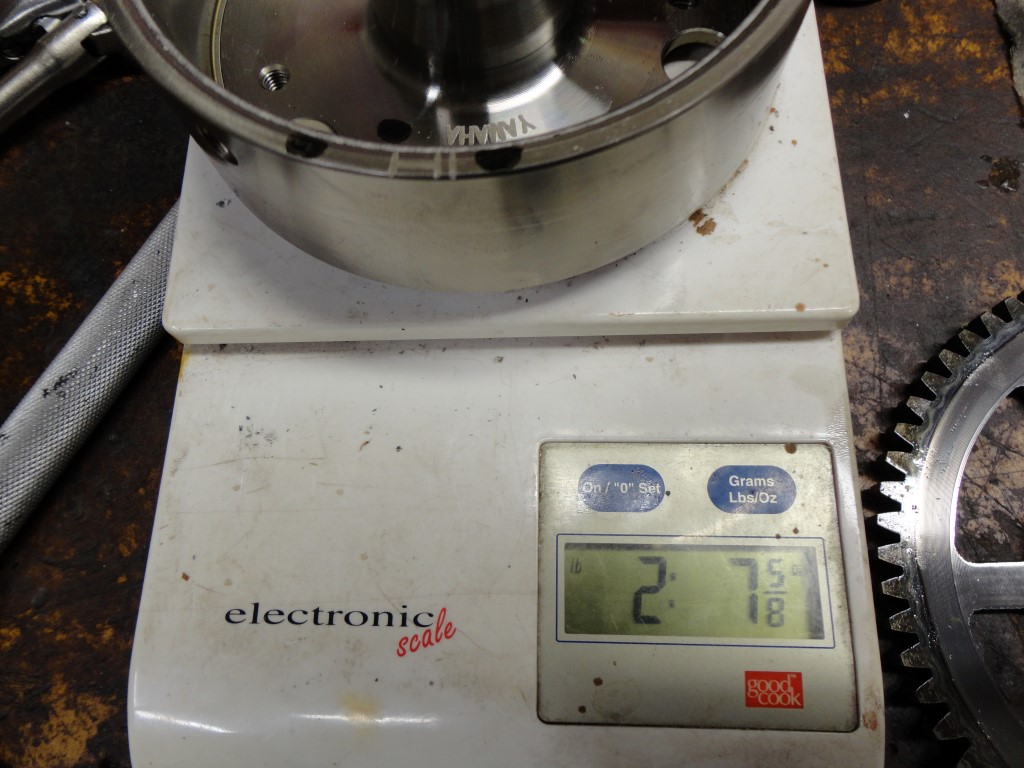

Flywheels Stock Viper

Sidewinder

Almost 7oz difference on outside of flywheel WILL without any doubt do something guaranteed! Excited to try.

Keep in mind when you do Basic Cam Timing it is done by eye. So interested if marks on Winder Flywheel are same or close to same as Viper. I lined the crank key slots up and put straightedge across both. Sure looks to be identical. That saves some work in future if ever doing a valve adjustment or removing cams again.

Fits nicely and torqued. Old gasket material was cleaned off and all debris was Vacuumed out. Just tape a smaller hose onto shop vac hose end. Works great and no chance of contamination you would get blowing the crap around.

Continued on Page2

20 pics a post is max so final is here.

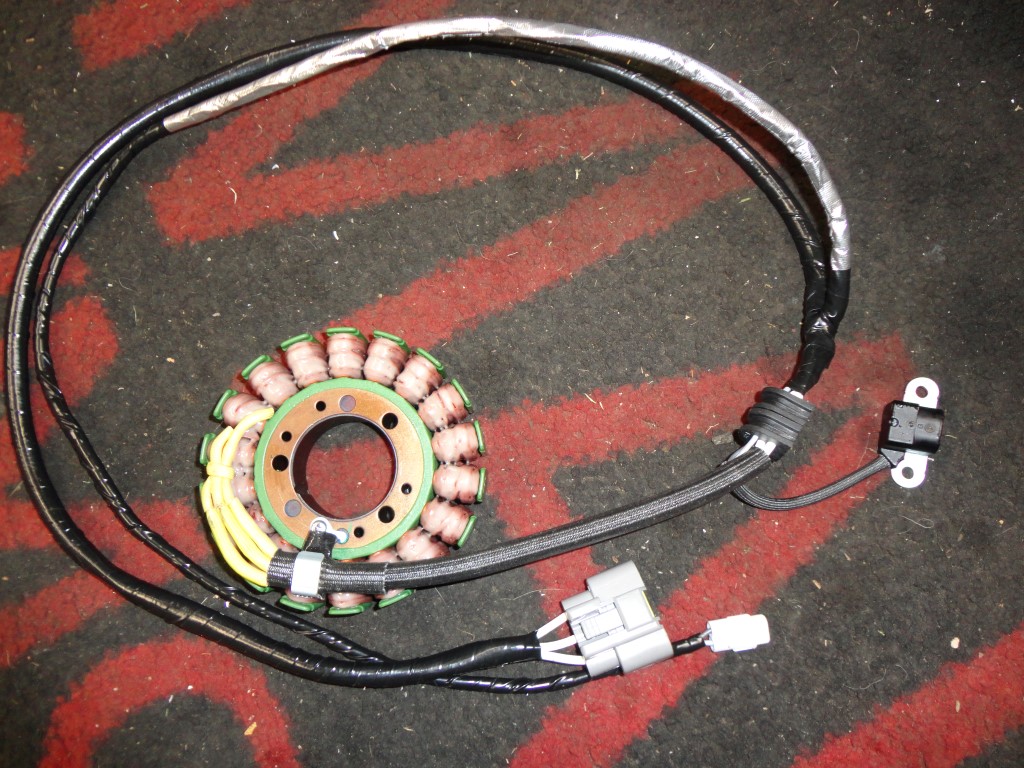

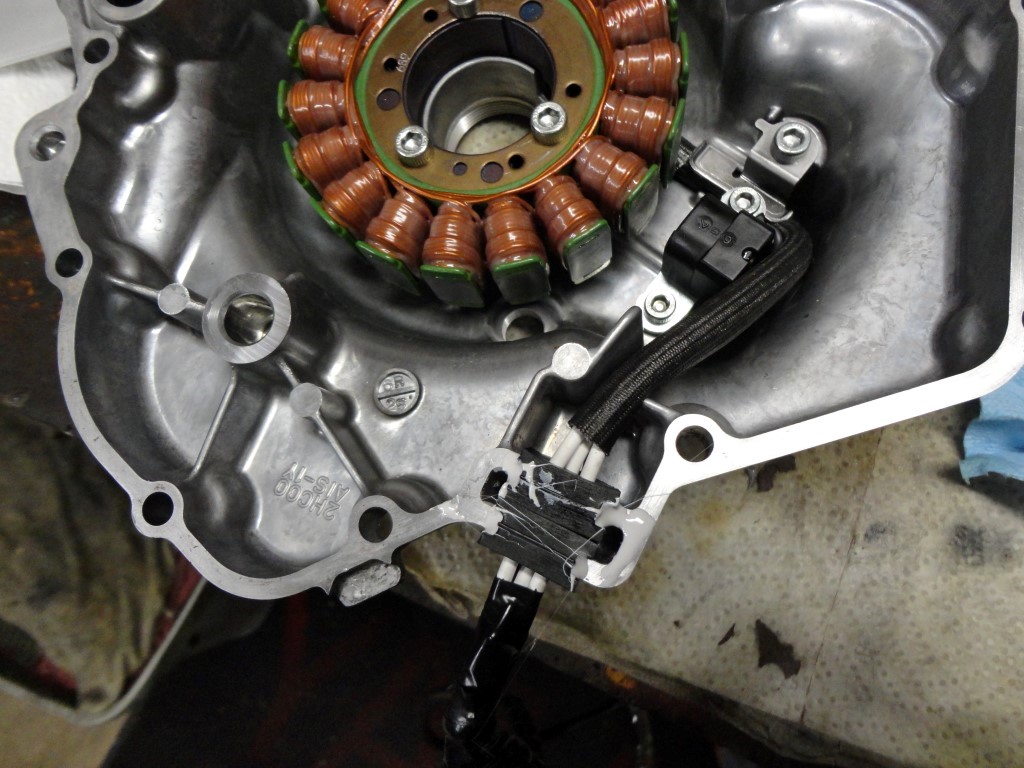

Stator and Pickup all mounted and Loctited and Torqued.

Gasket and Locating pins in. I put a dab of Yamabond where cases meet and grommet where Stator wires come out.

The two black screws go where arrows on cover are. They get Loctite and all get torqued

All Plugged in and Done. Just waiting on my Drivechain tensioner before I can add oil and see if this thing runs. I turned it over by hand and all seems good!

#1 Increase Top End Performance

#2 Eliminate a Variable that MIGHT cause erratic idle and other engine running qualities

I have never understood why the ignition pickup on the Nytro and Vipers was placed on the Stubshaft our Primary clutch is attached too. This Stubshaft is splined and a loose spline to the crankshaft. I believe the stubshaft stock setup is way cheaper to manufacture than a Flywheel activated ignition. I believe a Flywheel activated system is also way more accurate since it is a direct connection to Crankshaft and there cannot be any play since the flywheel is keyed to the Crank rather than the Stubshaft splines which are also a big source of noise which confirms they are not tight.

The Sidewinder ditched the Stubshaft Ignition pickup and its on the Flywheel. Hurricane Performance has also come out with a weighted Stubshaft which is claimed to reduce the Stubshaft noise. I am not concerned about the noise but am interested in the added weight. I believe any added weight on the crankshaft will smooth out the engine and add Torque. I have long said this 3 cylinder acts more like a 2 stroke than my SRX. It does not like a load such as poor conditions. Dirtbikes and Quads are HUGELY affected by adding weight to flywheel or crank. Like Night and Day with very small amount. When the Flywheel/Pickup conversion has proven to work and has been proven to at least not harm performance then I will add the Hurricane Stubshaft to the Viper motor. Hope it all fits!

I want to Thank DC5 and Dave for sharing their little secrets that are insignificant to them but mean so much to me and others who appreciate the hard work,$ and frustration experimenting costs. I will not whine much if it doesnt work! LOL!

https://ty4stroke.com/threads/the-hurricane-clutch-noise-elimination-shaft.154029/

https://ty4stroke.com/threads/hurricane-clutch-noise-elimination-system.153680/#post-1436502

https://ty4stroke.com/threads/stub-shaft.154043/#post-1440985

Parts needed:

Sidewinder Flywheel,Stator(Higher Output),Gasket and SideCover

Viper Sidecover Notice lower hose fitting on Sidewinder has a elbow so will have to deal with that.

Step1 Modify Sidewinder Stator Harness to reach the Viper Pickup Coil plug. Use a scissor to cut the protective sleeve and separate the Pickup wires from the Stator wires. Then repair the sleeve over the stator wires and add a protective sleeve to the Pickup wires. The wires in Winder pickup plug need to be reversed in the plug. Use a pin to press tab inside and they come right out. Grey and white need to be in same spots in plug as Viper grey and white.Thats it.This allows you to plug Stator wire plug into the regulator since its identical and run the Pickup wires across to the existing plug on left side in Viper harness.

Black 2 wire plug on left side near steering pyramid above clutch cover. Plug With Green/White and Blue/White wires plugs right in.(The two white plugs in Pic are for my PCV Ignition Module)Male end of Black Plugs wont be used anymore but will stay till I know it all works.

Voltage Regulator Sidewinder Plug is Identical and plugs into the grey receptical on regulator

Completed Harness. Will be run alongside the reverse actuator wires which have foil heat barrier (DEI AutoZone)so I did same. Then over engine to Pickup plug on left side. Plenty of wire and no cutting or splicing. SideWinder Harness is way nicer than our Viper wiring. This is in between. I am happy with it.

Ok In we go.

You can see the crossmember needs to be removed and all bolts. The Magnets of flywheel are strong so I threaded this old Swingarm bolt into timing hole to ease cover removal. If you have had a starter gear failure this is same procedure.

Checked fit of Sidewinder Cover. Perfect!

This is setup you use to remove Flywheel. Its both keyed and Tapered fit. I used a impact and came off easy.

Guys these motors are Jewels. Pleasure to see. This is all original never been opened 13000mi motor. Starter drive very little wear.

The infamous Idler gear. Perfect

Oneway bearing perfect

Fun stuff

Flywheels Stock Viper

Sidewinder

Almost 7oz difference on outside of flywheel WILL without any doubt do something guaranteed! Excited to try.

Keep in mind when you do Basic Cam Timing it is done by eye. So interested if marks on Winder Flywheel are same or close to same as Viper. I lined the crank key slots up and put straightedge across both. Sure looks to be identical. That saves some work in future if ever doing a valve adjustment or removing cams again.

Fits nicely and torqued. Old gasket material was cleaned off and all debris was Vacuumed out. Just tape a smaller hose onto shop vac hose end. Works great and no chance of contamination you would get blowing the crap around.

Continued on Page2

20 pics a post is max so final is here.

Stator and Pickup all mounted and Loctited and Torqued.

Gasket and Locating pins in. I put a dab of Yamabond where cases meet and grommet where Stator wires come out.

The two black screws go where arrows on cover are. They get Loctite and all get torqued

All Plugged in and Done. Just waiting on my Drivechain tensioner before I can add oil and see if this thing runs. I turned it over by hand and all seems good!

You nailed it! I feel like a idiot. the colors were even right but the wires in Winder plug were reversed. Runs like a top! Very happy.Could it be something as simple as reversing the leads on the sensor.

Last edited:

Clyder6R

Extreme

- Joined

- Dec 24, 2015

- Messages

- 99

- Age

- 34

- Location

- Atlantic Canada

- Country

- Canada

- Snowmobile

- 2015 Yamaha Viper MTX 153 McXpress 190 kit

you are the man! thanks for all you do. I haven't even ridden my new sled yet and i have done a bunch of mods, maintenance and just getting familiar with it. All thanks to guys like you!

RTX

TY 4 Stroke God

- Joined

- Mar 31, 2005

- Messages

- 1,796

- Location

- massachusetts / maine

- Country

- USA

- Snowmobile

- 2014 viper rtx

2006 apex rtx

Curious to see the results.

Keep us posted

Keep us posted

DennyTuna

RIP-Logan-Dylan-Never forgotten!

- Joined

- Jan 28, 2017

- Messages

- 705

- Age

- 62

- Location

- Ohio

- Country

- USA

- Snowmobile

- 18 Winder LTX 50th

16 SR Viper RTX (red)

02 SX Viper ER (red)

97 SX Vmax 600 (red)

Very interesting Steve, will be watching this very closely.

09nytro

TY 4 Stroke God

These things won’t start sometimes with the clutch off and won’t take throttle, all of what you are doing Steve make sense, I have never look at what the big differences are between viper and a sidewinder, up a turbo on a viper that has about the same HP as the sidewinder and the viper still doesn’t have the top end as the winder

I hope this will make a difference. If not about only thing left is the ECU itself. Never knew there was a issue with clutch off. Thats interesting. Really busy with shocks and overtime at work so moving slow on my sleds. It will happen.These things won’t start sometimes with the clutch off and won’t take throttle, all of what you are doing Steve make sense, I have never look at what the big differences are between viper and a sidewinder, up a turbo on a viper that has about the same HP as the sidewinder and the viper still doesn’t have the top end as the winder

09nytro

TY 4 Stroke God

I found it out teo years ago , had clutch off and tried to start it and wouldn’t , mess around trying to figure out why and got it to start then gave it throttle and stalled and wouldn’t restart , put clutch on and started right up !

My try the Hurricane stub shaft to see if that makes a difference in idle but 499 to just try Wowza

My try the Hurricane stub shaft to see if that makes a difference in idle but 499 to just try Wowza

Right! Wow I never tried that. Promising then. Will have to deal with it being longer for Winder clutch alignment also. Wish he wouldnt have done that.I found it out teo years ago , had clutch off and tried to start it and wouldn’t , mess around trying to figure out why and got it to start then gave it throttle and stalled and wouldn’t restart , put clutch on and started right up !

My try the Hurricane stub shaft to see if that makes a difference in idle but 499 to just try Wowza

snowfever27

VIP Member

- Joined

- Jan 7, 2015

- Messages

- 235

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2015 Arctic Cat XF7000

2009 Yamaha Nytro XTX (sold)

2007 Yamaha Phazer FX (sold)

2005 Ski-Doo MZX 800 Adrenaline (sold)

2003 Arctic Cat F7 EFI (sold)

2007 Yamaha Attack

2009 Polaris 600 Dragon SP

- LOCATION

- Vermont

I can’t wait to see if this makes a difference!! Steve, when do you think you’ll be able to start / ride your sled with the mods and see if it makes a difference? Very exciting!

I havent even started it since the Valve adjustment. I have to do chaincase yet. Shooting for starting engine during Thanksgiving weekend and testing on river or trail by Jan.I can’t wait to see if this makes a difference!! Steve, when do you think you’ll be able to start / ride your sled with the mods and see if it makes a difference? Very exciting!

RTX

TY 4 Stroke God

- Joined

- Mar 31, 2005

- Messages

- 1,796

- Location

- massachusetts / maine

- Country

- USA

- Snowmobile

- 2014 viper rtx

2006 apex rtx

I havent even started it since the Valve adjustment. I have to do chaincase yet. Shooting for starting engine during Thanksgiving weekend and testing on river or trail by Jan.

sorry to go off track

Did you do your own valve adjustment?

Were any out

Yes. 5 of 6 exhaust were out of spec. Tight side.sorry to go off track

Did you do your own valve adjustment?

Were any out

https://ty4stroke.com/threads/valve-check.153094/#post-1428183

Holy, keep up the great work and cool project! As others and you have said, will be very interesting for your findings!

Studroes144

TY 4 Stroke God

Very interesting stuff steve! Out of curiosity have you ever heard one of these engine on an engine dyno? As mentioned, starting can be hard and once they’re running it’s very hard to get them to come off of idle, they rattle very hard! I’ll see if I have any videos saved of when mine was on, they rattle bad enough that it’ll kill the engine about half the time when coming off idle.

Geeze! Never knew that. I did suspect that when I added 911 cover it smoothed out some and less noise. That cover is definitely heavier than stock. I will be interested to find out if the winder flywheel is also heavier than Viper. 11 nubs of steel (Reluctor teeth pickup reads) on outside of Winder flywheel has got to make a difference. Just need to catch up on shocks so I can get at this!Very interesting stuff steve! Out of curiosity have you ever heard one of these engine on an engine dyno? As mentioned, starting can be hard and once they’re running it’s very hard to get them to come off of idle, they rattle very hard! I’ll see if I have any videos saved of when mine was on, they rattle bad enough that it’ll kill the engine about half the time when coming off idle.

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 6

- Views

- 540

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.