got 50 miles on a ltx deluxe, wow it sure is nice, go to check it over and those torx screws sure do suck, if the heads do not strip on some the threads are screwed on the others and wont come out at all, i am thinking over tightening on the line cause the threads are striped.

Phyxius74

Pro

I´ve been working in the automotive industy (truck manufacturing) for 19 years and never seen a stripped torx head if the correct bit and torque have been used! Must be bad quality of the screw.

the one that came with the sled did not work and the set of torx sockets i have did no better!!

Nytro40th

TY 4 Stroke God

- Joined

- Sep 19, 2007

- Messages

- 1,798

- Location

- Amherstview Ontario

- Country

- Canada

- Snowmobile

- 2014 SR Viper RTX SE

I use allen keys in the torx screws

wot-75

Expert

I told a dealer today.. "you know if someone were to come up with a bolt kit to replace every Cat torx bolt with a nice stainless Hex head kit (by model) they could stand to make a lot of money." They laughed and said I should get on that...

I am going over my Viper now. I did find one stripped screw. All were in very tight. Maybe too tight. Guys these are screws which means you use a screwdriver on them. Yes I know a torx but they make nice bits or buy a torks screwdriver and you wont have any issues. I did not strip a single one and you cannot even tell they were removed unlike a Phillips or Allenhead. I like them except for the two under the nose which were a bit of a pain. Could some be better designed and styles kept the same throughout? YES that is something the Japanese do best. But it is like complaining the snow is to slippery sometimes! Once you start the engine and hear the Yamaha sing and the hot looks your sled has these little annoyances are forgotten by me at least!

Nytro40th

TY 4 Stroke God

- Joined

- Sep 19, 2007

- Messages

- 1,798

- Location

- Amherstview Ontario

- Country

- Canada

- Snowmobile

- 2014 SR Viper RTX SE

I will not loose any sleep over it lol

Me either. As matter of fact I am more impressed with this sled and how it designed the further I go into it. So far very easy to work on and I really like how fast I can access everything.

Suckur

Pro

I agree. A good set of Torx bits and you're golden. I take a proper driver with me because the ones in the tool kit are cheesy. It's amazing how fast you can get into this sled compared to my Phazer. I can have all the bodywork including seat and tank shroud sitting in a pile in about 3 minutes.

billymx815

TY 4 Stroke Junkie

- Joined

- Nov 17, 2009

- Messages

- 521

- Location

- S. Berwick, Maine

- Country

- USA

- Snowmobile

- SXV Venom, RTX Nytro, SR Viper RTX SE

- LOCATION

- Maine

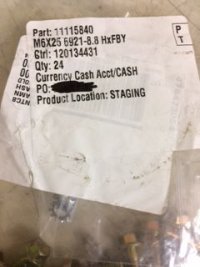

Does anyone know what the size of the Torx are that holds the front of the side panel? It's above the shock where the side panel locks into the black hood flange area. Looks to be roughly 3/4" long Torx on the other side.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,265

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

25Does anyone know what the size of the Torx are that holds the front of the side panel? It's above the shock where the side panel locks into the black hood flange area. Looks to be roughly 3/4" long Torx on the other side.

mike800

Veteran

- Joined

- Jan 20, 2022

- Messages

- 28

- Age

- 66

- Location

- Anoka County, Minnesota

- Country

- USA

- Snowmobile

- 137" Procross

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 21

- Views

- 36K

- Replies

- 25

- Views

- 48K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.