- Joined

- Nov 29, 2009

- Messages

- 1,230

- Reaction score

- 992

- Points

- 1,578

- Location

- sabattus, maine

- Country

- USA

- Snowmobile

- 76 exciter, 87 phazer, 89 bravo, 00 srx x3, 01 srx, 02/04 viper, 06 ape

Now let's get back to the subject of the brake rotor

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,061

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Now let's get back to the subject of the brake rotor

Good point!

The non-locking bearing sucks!

So many here have re-engineered it so ALL should take notice...................except for Polaris, SkiDoo & real Yamaha owners

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,061

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Unfortunately since my sled was gone all summer getting a new tunnel, i did not get a chance to fasten this bearing, but it is new.

Hoping it makes the year......

Hoping it makes the year......

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,688

- Reaction score

- 4,292

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Steve, eventually the oil tanks leak on the Apex too.I love a good cat fight but let's hold the chest thumping for just a second.

Mr Knapp's writings sound grumpy, but he's a blunt honest person. In a grumpy kind of way.

He was a true Blue guy, but had great success with his Doo's. He loves this 'Winder, but let's face it, there are basic things that we are fixing that are driving some of us nuts. Like leaky oil tanks & bearings spinning & holes not drilled so chain case top bearings go bad.

Like the grumpy Knapp says, we are fixing basic engineering issues to make this sled AWSOME.

This bearing that spins causes premature brake rotor failure and driveshaft wear. I will pin mine next year.

In the meantime, i'm trying to teach Mr. Knapp how to come across with a smile on TY. It might be easier to fix this sled's engineering downfalls.

Go team Blue!

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,363

- Reaction score

- 4,061

- Points

- 1,753

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Steve, eventually the oil tanks leak on the Apex too.I've changed plenty. They start to crack at about 15000kms, on machines that have seen rough trails and hard riding.

I replaced one on my first Apex at 6,000 & one on my 2nd Apex at 17,000 miles.

My Sidewinder oil tank leaked in the garage with 1.6 miles on it. Then again at 700 miles. Then again at 2200 miles.

Been good since the KNAPP ROV replacement system. I think the Cat glue was junk.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,688

- Reaction score

- 4,292

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

I don't like the way they seal them. Should use an 0-ring or gasket.I replaced one on my first Apex at 6,000 & one on my 2nd Apex at 17,000 miles.

My Sidewinder oil tank leaked in the garage with 1.6 miles on it. Then again at 700 miles. Then again at 2200 miles.

Been good since the KNAPP ROV replacement system. I think the Cat glue was junk.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,984

- Reaction score

- 6,316

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

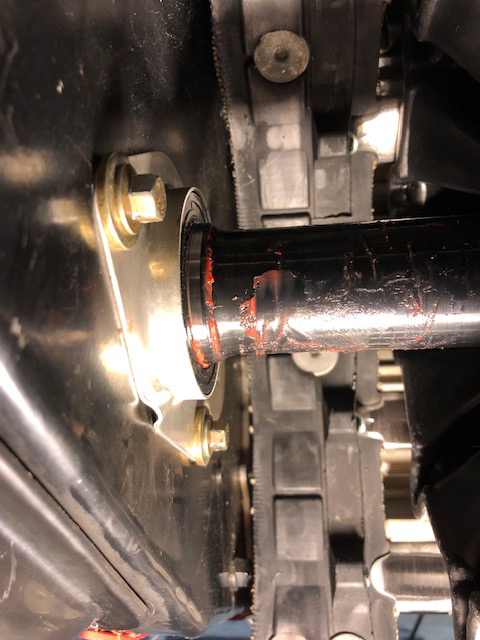

When I assembled my new shaft and bearing back together after just 2300 miles, I added a thin o-ring against the inner circlip to hold the whole assembly together in hopes of pinching the bearing to the disc. Doo has an o-ring between the disc to quiet the rotor down and prevent this wear. When the brake starts to rattle/chatter on the Doo after a couple thousand miles its time to replace the o-ring and put some anti-seize on the shaft to quiet it back down. With the doo the bearing is pressed on the shaft and a tighter slip fit on the outer race to disassemble this area. The problem with this Cat is the shaft fit is too loose on the bearing and the bearing spins on the shaft a certain percentage and wears the disc and shaft out, even if the bearing is perfectly good and full of grease. Actually, because it is filled with grease its harder to turn and slips even more on the shaft.

Dont' know the percentage of slippage, but its enough to warrant a new shaft and bearing on my machine with just 2300 miles on the clock.

So I did three things to try and prevent bearing slip on the shaft again. I was lucky enough to get a new assembly from Yamaha that had just .001" slip fit from shaft to bearing, so that was more snug than some others have reported to be as high as .007".

1. I added a thin 0-ring to inside the bearing for bearing to set against and lessen the chance of spin on the shaft, without it, there is no pinch to hold the bearing, keep in mind I had to hammer the outer circlip back on the shaft as there is now pressure against that circlip. On my old assembly, the bearing wore away and it didn't set against this circlip but away from it about the

I'd feel better if I'd have installed a weldment inside the shaft and tightened down to a solid flange on the shaft to really clamp these things together, but that would have meant a new custom shaft to be built with a flange. I though about machining a spacer to go over the inside circlip, but didn't feel the circlip would be strong enough to hold the pressure needed to last long term. Also keep in mind my brake rotor was worn enough that I could hammer on the circlip on the shaft, others nay not be able to do this as clearance would be too tight.

2. I added a set screw from the shaft to bearing to hopefully lock it in place. My concern here is how long will this last before it wears the set screw down enough and the bearing just spins again. After all, there is a lot of pressure here with the power and the tight track, things move and flex even with a tighter .001" slip fit.

3. I added three areas of loctite 648 to the shaft on assembly. I know all the way around the shaft would have been better, but it would be a bugger to dis-assmemble next time it has to come apart.

My hope is all three of these things combined prevent bearing spin on the shaft and it lasts like it should. Only time and miles will tell. but this brake rotor, bearing and shaft wear and spinning is not acceptable and should not be happening in this day and age. It's a bad design that needs to be dealt with and re-engineered, the Cat guys might put up with it, but I don't want to be buying shafts, bearings, and brake rotors and changing them every few thousand miles like one would change belts.

Dont' know the percentage of slippage, but its enough to warrant a new shaft and bearing on my machine with just 2300 miles on the clock.

So I did three things to try and prevent bearing slip on the shaft again. I was lucky enough to get a new assembly from Yamaha that had just .001" slip fit from shaft to bearing, so that was more snug than some others have reported to be as high as .007".

1. I added a thin 0-ring to inside the bearing for bearing to set against and lessen the chance of spin on the shaft, without it, there is no pinch to hold the bearing, keep in mind I had to hammer the outer circlip back on the shaft as there is now pressure against that circlip. On my old assembly, the bearing wore away and it didn't set against this circlip but away from it about the

I'd feel better if I'd have installed a weldment inside the shaft and tightened down to a solid flange on the shaft to really clamp these things together, but that would have meant a new custom shaft to be built with a flange. I though about machining a spacer to go over the inside circlip, but didn't feel the circlip would be strong enough to hold the pressure needed to last long term. Also keep in mind my brake rotor was worn enough that I could hammer on the circlip on the shaft, others nay not be able to do this as clearance would be too tight.

2. I added a set screw from the shaft to bearing to hopefully lock it in place. My concern here is how long will this last before it wears the set screw down enough and the bearing just spins again. After all, there is a lot of pressure here with the power and the tight track, things move and flex even with a tighter .001" slip fit.

3. I added three areas of loctite 648 to the shaft on assembly. I know all the way around the shaft would have been better, but it would be a bugger to dis-assmemble next time it has to come apart.

My hope is all three of these things combined prevent bearing spin on the shaft and it lasts like it should. Only time and miles will tell. but this brake rotor, bearing and shaft wear and spinning is not acceptable and should not be happening in this day and age. It's a bad design that needs to be dealt with and re-engineered, the Cat guys might put up with it, but I don't want to be buying shafts, bearings, and brake rotors and changing them every few thousand miles like one would change belts.

Lonerider

Lifetime Member

- Joined

- Feb 26, 2010

- Messages

- 156

- Reaction score

- 26

- Points

- 1,003

- Location

- south west mi

- Country

- USA

- Snowmobile

- 04 rx1, 05 Warrior 06 Attak-w/yamacharger, 07 Attak-Supercharged, 17 Sidewinder TD power trail

I think the race spinning would not be problem IF it didn’t touch the rotor. Therefor I will be milling down the rotor and installing harden shims 2 maybe 3 and the set screw will be into the rotor.

Sasquatch

Lifetime Member

- Joined

- Apr 17, 2004

- Messages

- 3,699

- Reaction score

- 974

- Points

- 1,733

- Location

- North Western Ontario

- Website

- www.dptc.com

- Country

- Canada

- Snowmobile

- Yamaha's

Please spend some time reading Mr Knapp’s posts and you will see that most are Doo friendly and Yamaha unfriendly. Is this a Doo or Yamaha site??

Well as an Apex rider I'm used to Yamaha unfreindly. We hated Cats for years and claimed them to be nothing but junk and now we can't say anything bad about them. We can however run the Apex down as an overweight pig and go on to list a hundred issues with it. Live with the taunts that the Apex is dead and buried, let it lie it was a pile of crap.

Knapp did more for the Apex in the years he owned and loved them but like all the guys riding Cats now, he wanted a new chassis that never came, you can't blame him anymore then you can the Cat riders. Careful with comparing cc sizes the 1049 Yamaha can't even come close to the Apex either and makes about the same hp as the 1170 Doo. So by your standard Yamaha engineering is not solid either otherwise the 1049 would have been 170 hp at least, not 130.

I love Apex and it sounds like you love yours, I'm glad your sled is the best handling quickest and fastest sled on the snow. Enjoy is they don't build them anymore.

Crossfire12

TY 4 Stroke Guru

- Joined

- Feb 13, 2017

- Messages

- 884

- Reaction score

- 543

- Points

- 858

- Location

- New York Adirondacks

- Country

- USA

- Snowmobile

- 2010 Z1 Turbo ,2017 zr9000, F1100 turbo, 700 srx

- LOCATION

- Sacandaga reservoir

Yamaha will fix what, reallyMike are you telling me if I modified my 08 Apex ( which is 170 cc smaller ), spend 6-8 grand (guessing the price) the 1200 would leave it in the dust ? I don't think so . If the 1200 was that good hurricane & turbo dynamics would be selling the kits & racing them . If u love skidoo that much , why are u riding a Yamaha ? & u should have kept your Apex because it was faster than your 1200 ...

sorry to get off topic...

Unfortunately Yamaha die hard s will have to live with kitty deficiencies until Yamaha fixes them next year

Stormbringer

Extreme

- Joined

- Jun 5, 2018

- Messages

- 109

- Reaction score

- 96

- Points

- 253

- Location

- Valparaiso Indiana

- Country

- USA

- Snowmobile

- 18 sidewinder rtx 15 viper rtx

Great information! Thanks, I now know what to look for before real problems start.When I assembled my new shaft and bearing back together after just 2300 miles, I added a thin o-ring against the inner circlip to hold the whole assembly together in hopes of pinching the bearing to the disc. Doo has an o-ring between the disc to quiet the rotor down and prevent this wear. When the brake starts to rattle/chatter on the Doo after a couple thousand miles its time to replace the o-ring and put some anti-seize on the shaft to quiet it back down. With the doo the bearing is pressed on the shaft and a tighter slip fit on the outer race to disassemble this area. The problem with this Cat is the shaft fit is too loose on the bearing and the bearing spins on the shaft a certain percentage and wears the disc and shaft out, even if the bearing is perfectly good and full of grease. Actually, because it is filled with grease its harder to turn and slips even more on the shaft.

Dont' know the percentage of slippage, but its enough to warrant a new shaft and bearing on my machine with just 2300 miles on the clock.

So I did three things to try and prevent bearing slip on the shaft again. I was lucky enough to get a new assembly from Yamaha that had just .001" slip fit from shaft to bearing, so that was more snug than some others have reported to be as high as .007".

1. I added a thin 0-ring to inside the bearing for bearing to set against and lessen the chance of spin on the shaft, without it, there is no pinch to hold the bearing, keep in mind I had to hammer the outer circlip back on the shaft as there is now pressure against that circlip. On my old assembly, the bearing wore away and it didn't set against this circlip but away from it about the

I'd feel better if I'd have installed a weldment inside the shaft and tightened down to a solid flange on the shaft to really clamp these things together, but that would have meant a new custom shaft to be built with a flange. I though about machining a spacer to go over the inside circlip, but didn't feel the circlip would be strong enough to hold the pressure needed to last long term. Also keep in mind my brake rotor was worn enough that I could hammer on the circlip on the shaft, others nay not be able to do this as clearance would be too tight.

2. I added a set screw from the shaft to bearing to hopefully lock it in place. My concern here is how long will this last before it wears the set screw down enough and the bearing just spins again. After all, there is a lot of pressure here with the power and the tight track, things move and flex even with a tighter .001" slip fit.

3. I added three areas of loctite 648 to the shaft on assembly. I know all the way around the shaft would have been better, but it would be a bugger to dis-assmemble next time it has to come apart.

My hope is all three of these things combined prevent bearing spin on the shaft and it lasts like it should. Only time and miles will tell. but this brake rotor, bearing and shaft wear and spinning is not acceptable and should not be happening in this day and age. It's a bad design that needs to be dealt with and re-engineered, the Cat guys might put up with it, but I don't want to be buying shafts, bearings, and brake rotors and changing them every few thousand miles like one would change belts.

View attachment 144047

View attachment 144048

View attachment 144049

Mototown

TY 4 Stroke Guru

- Joined

- Sep 11, 2018

- Messages

- 871

- Reaction score

- 744

- Points

- 728

- Location

- Ontario

- Country

- Canada

- Snowmobile

- Apex 40 th

First it will be a new chassis , so we will see how far Yamaha has developed ( what I believe) has been sitting on the drawing boards for a while .Yamaha will fix what, really

Short list

Brakes , 19s have been updated already with better units

Oil tank leaks

No chain case drain or to access to add oil

Below grade bolts ( rust or oxidize)

Self tapping screws

Cheap track adjusting mounts

Motor mounted to high in chassis, could be lowered 2-3 inches

Crap digital display ( compared to stuff they have on street bikes )

Cheap electrical connections on seat heater & accessories

Better clutch mounting

Better quality chassis & steering stem suports

Better quality metal ,chain case , oil tank frame supports that don't oxidize or stain

Better quality side panels & stickers that stay on ....

But I question if some of these quality issues being made in America , unless they ship more Yamaha parts from japan...

Last edited:

SPM

Pro

- Joined

- Nov 18, 2018

- Messages

- 155

- Reaction score

- 79

- Points

- 383

- Location

- so. mn

- Country

- USA

- Snowmobile

- 2018 Sidewinder L-TX LE

I'm not sure I have room on my "list" for all that. Being new to yammi this year I've had start two lists titled "That would be nice" and "will it get me home"??First it will be a new chassis , so we will see how far Yamaha has developed ( what I believe) has been sitting on the drawing boards for a while .

Short list

Brakes , 19s have been updated already with better units

Oil tank leaks

No chain case drain or to access to add oil

Below grade bolts ( rust or oxidize)

Self tapping screws

Cheap track adjusting mounts

Motor mounted to high in chassis, could be lowered 2-3 inches

Crap digital display ( compared to stuff they have on street bikes )

Cheap electrical connections on seat heater & accessories

Better clutch mounting

Better quality chassis & steering stem suports

Better quality metal ,chain case , oil tank frame supports that don't oxidize or stain

Better quality side panels & stickers that stay on ....

But I question if some of these quality issues being made in America , unless they ship more Yamaha parts from japan...

The one thing I am going to question you on for this set screw mod is what if the shaft breaks now? We have all seen it. Apex was real common. I 100% agree something needs to be done to avoid yearly shaft replacement. Personally on my low powered Viper Peening a GOOD shaft has been enough. If wore Loctite and Peening has been enough. I hope the set screw fix proves to be reliable and I have learned alot from you. Just worried and frustrated that everyone doesnt turn these in for warranty so they fix for everyone in future.When I assembled my new shaft and bearing back together after just 2300 miles, I added a thin o-ring against the inner circlip to hold the whole assembly together in hopes of pinching the bearing to the disc. Doo has an o-ring between the disc to quiet the rotor down and prevent this wear. When the brake starts to rattle/chatter on the Doo after a couple thousand miles its time to replace the o-ring and put some anti-seize on the shaft to quiet it back down. With the doo the bearing is pressed on the shaft and a tighter slip fit on the outer race to disassemble this area. The problem with this Cat is the shaft fit is too loose on the bearing and the bearing spins on the shaft a certain percentage and wears the disc and shaft out, even if the bearing is perfectly good and full of grease. Actually, because it is filled with grease its harder to turn and slips even more on the shaft.

Dont' know the percentage of slippage, but its enough to warrant a new shaft and bearing on my machine with just 2300 miles on the clock.

So I did three things to try and prevent bearing slip on the shaft again. I was lucky enough to get a new assembly from Yamaha that had just .001" slip fit from shaft to bearing, so that was more snug than some others have reported to be as high as .007".

1. I added a thin 0-ring to inside the bearing for bearing to set against and lessen the chance of spin on the shaft, without it, there is no pinch to hold the bearing, keep in mind I had to hammer the outer circlip back on the shaft as there is now pressure against that circlip. On my old assembly, the bearing wore away and it didn't set against this circlip but away from it about the

I'd feel better if I'd have installed a weldment inside the shaft and tightened down to a solid flange on the shaft to really clamp these things together, but that would have meant a new custom shaft to be built with a flange. I though about machining a spacer to go over the inside circlip, but didn't feel the circlip would be strong enough to hold the pressure needed to last long term. Also keep in mind my brake rotor was worn enough that I could hammer on the circlip on the shaft, others nay not be able to do this as clearance would be too tight.

2. I added a set screw from the shaft to bearing to hopefully lock it in place. My concern here is how long will this last before it wears the set screw down enough and the bearing just spins again. After all, there is a lot of pressure here with the power and the tight track, things move and flex even with a tighter .001" slip fit.

3. I added three areas of loctite 648 to the shaft on assembly. I know all the way around the shaft would have been better, but it would be a bugger to dis-assmemble next time it has to come apart.

My hope is all three of these things combined prevent bearing spin on the shaft and it lasts like it should. Only time and miles will tell. but this brake rotor, bearing and shaft wear and spinning is not acceptable and should not be happening in this day and age. It's a bad design that needs to be dealt with and re-engineered, the Cat guys might put up with it, but I don't want to be buying shafts, bearings, and brake rotors and changing them every few thousand miles like one would change belts.

View attachment 144047

View attachment 144048

View attachment 144049

XP123

TY 4 Stroke Master

- Joined

- Dec 25, 2016

- Messages

- 1,494

- Reaction score

- 1,440

- Points

- 1,038

- Location

- Chautauqua NY

- Country

- USA

- Snowmobile

- Sidewinder XTX LE 137

Take it easy on Mike Knapp. He knows his stuff and he is brutally honest most of the time. I really liked my Sidewinder and it treated me well but all the things Mike has mentioned are true. I found that I was always ill at ease going on long saddlebag trips with my Winder because of all the things I was constantly worried about. If I were a rider who mostly rode from home everyday I wouldn't worry but when you are days away from your truck it is very uncomfortable.Why does it seem every time I read a post from Knapp there is a huge bias for BRP. You only have to work on one CanAm atv to figure out the there is very little good engineering going on at BRP. I can’t say anything about Cat cause I don’t know them, but all of my Yamaha sleds have been light years ahead of BRP IMO. Why are we comparing non stock sleds. In stock form the Apex is awesome and the engineering is solid so to compete BRP owners must spend money and time to modify their well engineered sleds, ya right! Mike Knapp come to my neck of the woods and bring your absolutely stock 1200 or 850 or turbo 900, and I’ll let my stock Apex xtx with 20k on the belt walk by you.

The Winder is awesome and the engine is rock solid but all the Cat engineering is very troublesome and that's why Knapp says what he says. I prefer honest opinions rather than just sticking your head in the sand and ignoring the facts.

I and many others have owned an Apex and you must have a magical one because mine never out handled the sleds you claim yours does.

Similar threads

- Replies

- 19

- Views

- 7K

- Replies

- 48

- Views

- 16K

- Replies

- 166

- Views

- 17K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.