ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

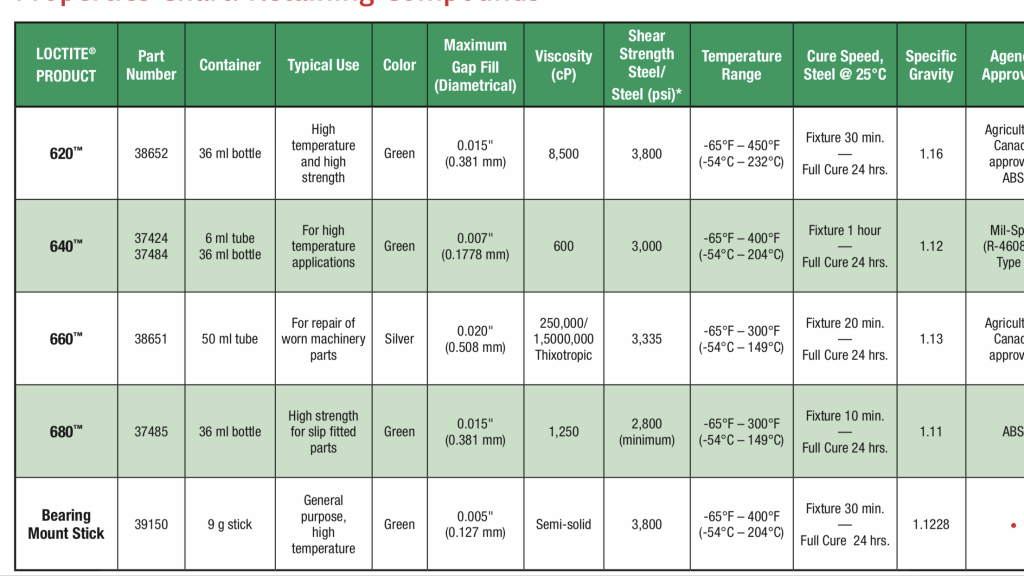

Mike...Ive been searching/reading specs on the loctite site. They offer at least 3 or 4 diff "Retaining Compounds" 635, 640,648,660,638,609,620 ect...pic below.Nope, there no better in the chassis dept. Better than in 2012, well most of it but not all of it. IMO if the slip fit is loose it will happen to all. If its tight slip fit, maybe not, but either way, the bearing should be locked to the shaft somehow, and its not from the factory.

No, they have not changed the driveline or brake setup in 19. It has been an issue on this side of the shaft since 12. Its a poor design to say the least and an engineering or bean counters problem from the Cat factory. Yamaha has nothing to do with the Cat chassis here. Wishful thinking though.

Seems some are better then others for OUR situation with slip fit....Some thinner/thicker ect. But it does seem like specs state these compounds will hold bigtime. So im wondering, will this stuff lock the bearing in for certain, even without a set screw?

And how do we know which one is best for locking this down?

Dan

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,861

- Reaction score

- 6,147

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Good question Dan. No one knows for sure till its tried over a period of time and miles. I used the loctite 638 on mine, but only in three areas on the shaft. along with one set screw and the o-ring.

No one really knows for certain if the set screw or o-ring will work over time either. I'm using all three and won't know it works until it's gone for thousands of miles.

No one really knows for certain if the set screw or o-ring will work over time either. I'm using all three and won't know it works until it's gone for thousands of miles.

Lonerider

Lifetime Member

- Joined

- Feb 26, 2010

- Messages

- 156

- Reaction score

- 26

- Points

- 853

- Location

- south west mi

- Country

- USA

- Snowmobile

- 04 rx1, 05 Warrior 06 Attak-w/yamacharger, 07 Attak-Supercharged, 17 Sidewinder TD power trail

Bearing mount specs

Lonerider

Lifetime Member

- Joined

- Feb 26, 2010

- Messages

- 156

- Reaction score

- 26

- Points

- 853

- Location

- south west mi

- Country

- USA

- Snowmobile

- 04 rx1, 05 Warrior 06 Attak-w/yamacharger, 07 Attak-Supercharged, 17 Sidewinder TD power trail

Loctite threadloc specs.Bearing mount specsView attachment 144222

Attachments

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,528

- Reaction score

- 4,186

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Maybe 680 is best suited....?Bearing mount specsView attachment 144222

Lonerider

Lifetime Member

- Joined

- Feb 26, 2010

- Messages

- 156

- Reaction score

- 26

- Points

- 853

- Location

- south west mi

- Country

- USA

- Snowmobile

- 04 rx1, 05 Warrior 06 Attak-w/yamacharger, 07 Attak-Supercharged, 17 Sidewinder TD power trail

I will be trying this. Loctite Bearing Mount item 39150. Come in a stick form. Need to look at its gap fill under specs and sheer strength

Last edited:

Lonerider

Lifetime Member

- Joined

- Feb 26, 2010

- Messages

- 156

- Reaction score

- 26

- Points

- 853

- Location

- south west mi

- Country

- USA

- Snowmobile

- 04 rx1, 05 Warrior 06 Attak-w/yamacharger, 07 Attak-Supercharged, 17 Sidewinder TD power trail

As to new deaveshafts. I asked about this in a another post with out much reply. I can get them. They are not cheep. 3 times as much as stock. Talked about adding a second bearing on the inside of tunnel also as a option. So you can picture this, take a brake caliper and use the bearing mount cutting away the braking parts. More to it than this but needs to be designed. Spacer between bearings, sealed inside tunnel. This option would only work on custom shaft. With option piece you could also attach it to the tunnel. Few more ideas are being kicked around. Adding plate to have room for circ clip in between rotor and bearing this piece would mounts to bearing option piece. What’s your thoughts?

I used 638 and after 3000mi track let loose so had to remove driveshaft in a hurry for next ride so could not use heat. It was a bugger and had to use a puller. No way that race was spinning. Have been peening now and seems to be enough but I admit it’s borderline and the peens need to be renewed every time I have serviced the bearing since. Hard to tell if it still spun but tight fit from peening did loosen up. I put 3 dots of Loctite on this time with the peening. I also see a lot of evidence of tunnel flex so maybe that’s why they don’t make that bearing tight?

WVTurboLTX

TY 4 Stroke Guru

- Joined

- Nov 9, 2014

- Messages

- 878

- Reaction score

- 464

- Points

- 978

- Country

- USA

- Snowmobile

- 2009 Nytro XTX

2017 Sidewinder LTX LE

My thoughts exactly. Maybe that play needs to be there due to tunnel flex. I was thinking of using the same setup I used on the viper when the outer circlip failed and bolting everything tight instead of letting the caliper float but am worried about side stress on the bearings if the chassis flexes.I used 638 and after 3000mi track let loose so had to remove driveshaft in a hurry for next ride so could not use heat. It was a bugger and had to use a puller. No way that race was spinning. Have been peening now and seems to be enough but I admit it’s borderline and the peens need to be renewed every time I have serviced the bearing since. Hard to tell if it still spun but tight fit from peening did loosen up. I put 3 dots of Loctite on this time with the peening. I also see a lot of evidence of tunnel flex so maybe that’s why they don’t make that bearing tight?

www.ty4stroke.com/threads/drive-shaft-ring-groove-gone.150374/

If the dang shaft was hard enough under that race it could spin all it wanted and not hurt a thing. May even be a spot to use a DLC coating. That would solve the issue of wear. Its all the dang Cat shafts. You guys should see some of the wear on Jackshafts in early years. Way too soft. NosPro had one that happened too. So they do pop up even now. They just plain cant hit the numbers or find the rejects.

Sasquatch

Lifetime Member

- Joined

- Apr 17, 2004

- Messages

- 3,699

- Reaction score

- 974

- Points

- 1,733

- Location

- North Western Ontario

- Website

- www.dptc.com

- Country

- Canada

- Snowmobile

- Yamaha's

I don't think it has anything to do with that set screw. Those hex collars were there to prevent the outer wheels from moving outward. I've changed plenty driveshafts and they all broke flush with that black outer guide wheel, not where the set screw was. The reason for breaking imo was from harmonic type twisting on the shaft. That is why Yamaha came up with the fix they did of supporting the shaft in the cover also. Never saw any of them break.

Well mine and others I saw broke right under the set screw in the collar right beside the drive sprocket chaincase side. I agree they broke because of the twist on the throttle off the throttle produced.

Mototown

TY 4 Stroke Guru

- Joined

- Sep 11, 2018

- Messages

- 871

- Reaction score

- 744

- Points

- 728

- Location

- Ontario

- Country

- Canada

- Snowmobile

- Apex 40 th

Winder s are not the only ones with problems, my buddies Polaris 850 warped his brake rotor on the weekend less than 600km . Had to pump the brakes to stop

Attachments

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,861

- Reaction score

- 6,147

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Winder s are not the only ones with problems, my buddies Polaris 850 warped his brake rotor on the weekend less than 600km . Had to pump the brakes to stop

Hayes brakes = Junk!

My 2012 Cat was like this too, but had no warp on the disc at all, go figure. Had to pump the brake like 2-3 times to get it to work. My Winder to this point has not done this, but I have a hunch the outboard piston is stuck too.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Yeah hearing new POO 850 engine is having big issues.....Winder s are not the only ones with problems, my buddies Polaris 850 warped his brake rotor on the weekend less than 600km . Had to pump the brakes to stop

BTW, nice pics...where is that at?

Mototown

TY 4 Stroke Guru

- Joined

- Sep 11, 2018

- Messages

- 871

- Reaction score

- 744

- Points

- 728

- Location

- Ontario

- Country

- Canada

- Snowmobile

- Apex 40 th

We went from new leskeard into Quebec, south to temiscaming trails really good for this early. Not all the trails finished yet . Trails north to rouyn-noranda were 70 % percent finished.

Similar threads

- Replies

- 19

- Views

- 6K

- Replies

- 48

- Views

- 15K

- Replies

- 166

- Views

- 16K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.