74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,357

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

They still use non-HYVO chain?Too many parts to this Cat case. I would bet if Yamaha designed it you would see something like this

Stubbs

TY 4 Stroke Master

- Joined

- Nov 7, 2006

- Messages

- 1,152

- Age

- 44

- Location

- Uxbridge, On, Can.

- Country

- Canada

- Snowmobile

- ‘16 Apex XTX with 137” Mono II

+ other gooodies

- LOCATION

- Uxbridge ON

......and is the cover still held on by self tapping screws?They still use non-HYVO chain?

Pstn head

TY 4 Stroke Master

is the forward gear on a spine ? Now that would be pretty good.

J & J Racing

Extreme

- Joined

- Jan 30, 2019

- Messages

- 119

- Age

- 44

- Location

- Stillman Valley IL

- Country

- USA

- Snowmobile

- 2019 AC TCAT

My reverse chain and gears almost look as heavy

Haha

Cat old chain case was fine. Changed to this with longer chain for whatever reason. Sell more parts I guess?

To be honest, I wish they had diamond drive still.

Very few failures and lighter, they worked

JMO

You could run a shoe and self adjuster that was in case from 2012 to 2016. Seemed to work well

Haha

Cat old chain case was fine. Changed to this with longer chain for whatever reason. Sell more parts I guess?

To be honest, I wish they had diamond drive still.

Very few failures and lighter, they worked

JMO

You could run a shoe and self adjuster that was in case from 2012 to 2016. Seemed to work well

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Well it was a whirlwind week last week for sure.....

Monday-Tore sled down, 2pm ordered parts

Wednesday-Drove back to NY, Dealer had parts by 2pm!- Picked up parts.

Thursday-Have Tensioner tack welded, Pickup Bearing Mount Compound- Drive back north to Ontario.

Friday-Wrench the sled back together...lots of work again!

This Weekend - RIDE!!!

What a week in the life of a Winder owner.....Doing it myself definitely got me back on the trail faster then taking sled home, waiting to get dealer to tear it down, order parts, and then get it back together and back to cottage. Likely would have been upwards of two weeks if not more. So it was worth all the wrenching. I just hope its the last time for awhile!

Getting back out on her, and realizing that weird vibration around 60mph is gone now made me feel better....I am now wondering how long my tensioner may have had one screw loose? Hard to say for sure. But the peace of mind of tack welded screws is priceless...

No more backing out the adjuster 1 turn for me(much less 1.5 as manual states), mine is now set at 1/2 turn out. With stock gears that chain can touch the case at post if any looser. So easy and nice to see it all with case open.

Sure is interesting installing new case to tunnel....the rear case is not threaded at the holes that attach it to tunnel when new. So you have to impact the 6 silver (self tapping) torx screws in from under the sled tunnel, and just bottom them out. Using the impact gun goes fast. Also makes me think this could be reason so many oil tanks leak when fairly new....I believe the factory is siliconing them, and impacting them together which squeezes the silicone out, since the holes that connect the oil tank to cover are also not pre-threaded.

What I did was.....impact the screws from Oil tank into cover DRY first...this threads the holes initially. Now take it apart clean out holes ect. Silicone it good(also silicone the plastic baffles at both end), set cases together but just so silicone touches both sides, just start screws but wait.....let silicone setup for an hour(thicken), then go back and tighten screws and then torque them down properly. I start around 8ft lbs, then work may way up to 10 to 12 max. If the factory is applying silicone AND impacting them all at once, there is no way to get a proper torque in them and not squeeze out all the silicone.

Sure is lots to put back together, but glad its all done. I do worry that I will likely need to use a puller next time I try to remove my brake rotor/caliper since that green bearing mount im told will really hold on bigtime.

Dan

Decided to add some around sight glass just incase(even though dealer claims new part number fixed this issue some have)

6 Self TAPPING need to be impacted in, then 4 gold at bottom are bolts/nuts.

All torqued down and then let set inside for 24hrs.

Permatex bearing mount

Belt Guard all back installed, coolant bottle ect.

Monday-Tore sled down, 2pm ordered parts

Wednesday-Drove back to NY, Dealer had parts by 2pm!- Picked up parts.

Thursday-Have Tensioner tack welded, Pickup Bearing Mount Compound- Drive back north to Ontario.

Friday-Wrench the sled back together...lots of work again!

This Weekend - RIDE!!!

What a week in the life of a Winder owner.....Doing it myself definitely got me back on the trail faster then taking sled home, waiting to get dealer to tear it down, order parts, and then get it back together and back to cottage. Likely would have been upwards of two weeks if not more. So it was worth all the wrenching. I just hope its the last time for awhile!

Getting back out on her, and realizing that weird vibration around 60mph is gone now made me feel better....I am now wondering how long my tensioner may have had one screw loose? Hard to say for sure. But the peace of mind of tack welded screws is priceless...

No more backing out the adjuster 1 turn for me(much less 1.5 as manual states), mine is now set at 1/2 turn out. With stock gears that chain can touch the case at post if any looser. So easy and nice to see it all with case open.

Sure is interesting installing new case to tunnel....the rear case is not threaded at the holes that attach it to tunnel when new. So you have to impact the 6 silver (self tapping) torx screws in from under the sled tunnel, and just bottom them out. Using the impact gun goes fast. Also makes me think this could be reason so many oil tanks leak when fairly new....I believe the factory is siliconing them, and impacting them together which squeezes the silicone out, since the holes that connect the oil tank to cover are also not pre-threaded.

What I did was.....impact the screws from Oil tank into cover DRY first...this threads the holes initially. Now take it apart clean out holes ect. Silicone it good(also silicone the plastic baffles at both end), set cases together but just so silicone touches both sides, just start screws but wait.....let silicone setup for an hour(thicken), then go back and tighten screws and then torque them down properly. I start around 8ft lbs, then work may way up to 10 to 12 max. If the factory is applying silicone AND impacting them all at once, there is no way to get a proper torque in them and not squeeze out all the silicone.

Sure is lots to put back together, but glad its all done. I do worry that I will likely need to use a puller next time I try to remove my brake rotor/caliper since that green bearing mount im told will really hold on bigtime.

Dan

Decided to add some around sight glass just incase(even though dealer claims new part number fixed this issue some have)

6 Self TAPPING need to be impacted in, then 4 gold at bottom are bolts/nuts.

All torqued down and then let set inside for 24hrs.

Permatex bearing mount

Belt Guard all back installed, coolant bottle ect.

Last edited:

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Rest of it going together....BTW the only holes that ARE pre-threaded are the cover to rear case holes, which use the black machine torx screws. So these are installed normally and torqued sequentially in a similar fashion. I start at 8 ft lbs working way up to 12 ft lbs.

Dan

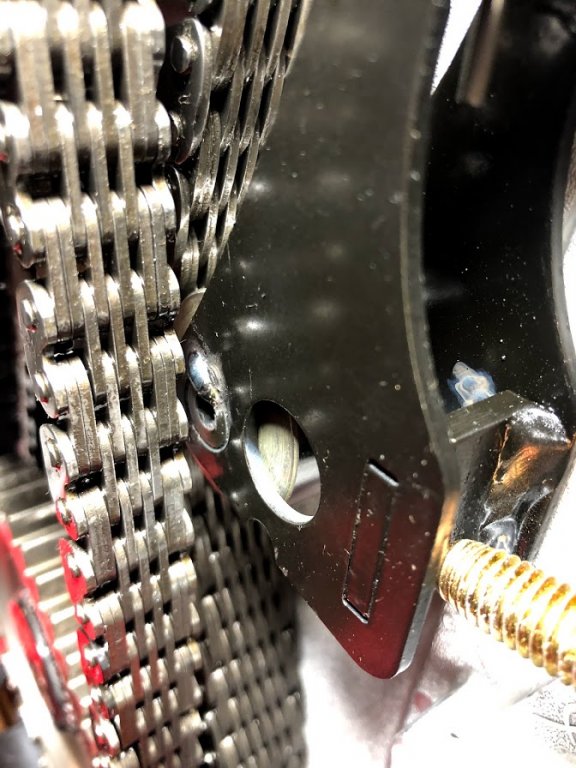

Notice how close the chain rides to the case at post, with 1.5 turns out the chain can slap it!

Be sure the rear screw weld is not too large of a tack/bead. It will hit rear case/rub. I ground mine down some. Front tack has more room next to reverse chain(shown)

Not much adjustment left at all with stock gears, this is with 1/2 turn out only.

12oz as per manual.

Oil lines back installed....clamped.

Skid going back in....

Ready for tensioning....

Even got to take quick test run before sunset....

Got out for a nice 130 miles today...all working well.

Total miles to date.

Dan

Notice how close the chain rides to the case at post, with 1.5 turns out the chain can slap it!

Be sure the rear screw weld is not too large of a tack/bead. It will hit rear case/rub. I ground mine down some. Front tack has more room next to reverse chain(shown)

Not much adjustment left at all with stock gears, this is with 1/2 turn out only.

12oz as per manual.

Oil lines back installed....clamped.

Skid going back in....

Ready for tensioning....

Even got to take quick test run before sunset....

Got out for a nice 130 miles today...all working well.

Total miles to date.

Last edited:

SumpBuster

TY 4 Stroke God

- Joined

- Jul 18, 2003

- Messages

- 2,358

- Location

- Carlisle, NY .

- Country

- USA

- Snowmobile

- 18 sidewinder; 06 Apex RTX

I still like the yammy case where the gear that freewheels when in reverse is on the bottom, in the oil. JMO.Too many parts to this Cat case. I would bet if Yamaha designed it you would see something like this

Funny you should mention about running the tensioner that tight Dan. When putting mine back together i went finger tight and backed off a turn and a half while the case was open and the chain was just flopping around in there! I snugged it up and it looked about right a 3/4 turn out. And that was finger tight as in it would need a wrench to get it tighter

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

I totally agree.....1.5 turns will slap the center post with chain period, those specs need to be updated in manual by YAM for 21 gear.Funny you should mention about running the tensioner that tight Dan. When putting mine back together i went finger tight and backed off a turn and a half while the case was open and the chain was just flopping around in there! I snugged it up and it looked about right a 3/4 turn out. And that was finger tight as in it would need a wrench to get it tighter

With my 22 gear its a non-issue. If my chain stretches anymore, ill have to either get a new chain or go to 22 gear. Thinking with this much power a new chain would be smart.

Love the big power for trail riding but I can easily see how this sled will need constant attention in the drivetrain EVERY SEASON easily. Originally I was thinking tracks would need faster replacement but I think its gonna be drivetrain items from chains to gears to driveshaft bearing,clutch items ect ect ect.

Its very hard to step down in HP though, I swap often with buds sleds and the big power is gone. Maybe YAM will start to upgrade certain things as warranty adds up for them, but I doubt it. Looks like you need to be a wrencher to own one of these, which I don't mind.....but middle of season downtime sure can suck.

Dan

Fast

TY 4 Stroke Guru

- Joined

- Sep 25, 2018

- Messages

- 992

- Age

- 57

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

WTFDear Newbie Davis:

Welcome to the site!

I'm glad you were able to gain immediate success here on TY on saving your "bacon".

An Avatar will help your cause and so would complete sentences because besides for bacon i'm not exactly sure what the hell you said, but i did understand it.

P.S: Try not to mention BACON after 8pm on a testosterone filled website. Now i have to go make a BLT

Couldn't agree moreI totally agree.....1.5 turns will slap the center post with chain period, those specs need to be updated in manual by YAM for 21 gear.

With my 22 gear its a non-issue. If my chain stretches anymore, ill have to either get a new chain or go to 22 gear. Thinking with this much power a new chain would be smart.

Love the big power for trail riding but I can easily see how this sled will need constant attention in the drivetrain EVERY SEASON easily. Originally I was thinking tracks would need faster replacement but I think its gonna be drivetrain items from chains to gears to driveshaft bearing,clutch items ect ect ect.

Its very hard to step down in HP though, I swap often with buds sleds and the big power is gone. Maybe YAM will start to upgrade certain things as warranty adds up for them, but I doubt it. Looks like you need to be a wrencher to own one of these, which I don't mind.....but middle of season downtime sure can suck.

Dan

lilrez

Expert

nice job

theewarrior

Expert

I can’t seem to remember how to put the adjuster spring back in?

The short arm of the spring is the top of the spring. It's sprung down to the right away from the gears. The long arm of the tensioner is down and away from the gears on the right side of the tesionerI can’t seem to remember how to put the adjuster spring back in?

Similar threads

- Replies

- 11

- Views

- 2K

- Replies

- 12

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.