jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,302

- Reaction score

- 3,347

- Points

- 1,603

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

Thanks for the belts. Got them. Ran xs last season for 1500 miles.XS will drop rpm by 5-600. Drop 4 grams and test.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,872

- Reaction score

- 6,168

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Yea that could be. Not on all set ups. Mine dropped around 300 rpm. Totally dependent on set up andweights. Especially weight profile.

Also would vary depending on secondary setup.

IMO you can greatly reduce the secondary pressure with this XS belt vs a 8DN or 8JP as well, which will help with primary roller and bushing issues as well. No reason to over pinch a belt when not needed.

Sledbrapping88

Pro

- Joined

- Oct 6, 2019

- Messages

- 147

- Reaction score

- 32

- Points

- 143

- Location

- Upstate NY

- Country

- USA

- Snowmobile

- Yamaha sidewinder ltx

As

As of right now it has stock primary spring dtay1 set 78.5 grams with stock helix and black/orange secondary wrapped 6-3

Yea that could be. Not on all set ups. Mine dropped around 300 rpm. Totally dependent on set up and weights. Especially weight profile.

As of right now it has stock primary spring dtay1 set 78.5 grams with stock helix and black/orange secondary wrapped 6-3

snow_rider

Lifetime Member

- Joined

- Apr 2, 2009

- Messages

- 63

- Reaction score

- 11

- Points

- 958

- Location

- Tawas City MI

- Country

- USA

- Snowmobile

- 2018 Sidewinder LTX-LE 50th

As all have said, great work and info Knapp!

I was also curious about clutch rattle noise with this setup? Same? Better? Gone?

Again thanks!

I was also curious about clutch rattle noise with this setup? Same? Better? Gone?

Again thanks!

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,872

- Reaction score

- 6,168

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

As all have said, great work and info Knapp!

I was also curious about clutch rattle noise with this setup? Same? Better? Gone?

Again thanks!

Rattle is the same using the RX-1 primary.

At some point this year I'll be going back to try the PB80 again. I need a different spring to make it work properly, but it runs rattle free on the 998, just like the TAPP clutch does.

snow_rider

Lifetime Member

- Joined

- Apr 2, 2009

- Messages

- 63

- Reaction score

- 11

- Points

- 958

- Location

- Tawas City MI

- Country

- USA

- Snowmobile

- 2018 Sidewinder LTX-LE 50th

Understood, was hoping maybe that was solved too...

Regards

Regards

Stubbs

TY 4 Stroke Master

- Joined

- Nov 7, 2006

- Messages

- 1,181

- Reaction score

- 688

- Points

- 1,378

- Location

- Uxbridge, On, Can.

- Country

- Canada

- Snowmobile

- ‘16 Apex XTX with 137” Mono II

+ other gooodies

- LOCATION

- Uxbridge ON

Gotta question or two Knapp......RX1 had 14.5mm rollers stock, did you go to the 15mm rollers by choice, or was that just a typo? If you did switch rollers, why? Yammy has always spec’d the 15.4mm rollers on all the triple motors with the old clutches until the Winder showed up with the new piece of garbage attached. Do you think there is anything to Yammy’s using larger rollers in the triples simply for increased longevity, and that’s why they used to last? or is the new clutch design just that shitty?

Here’s the reason for my question......I’m using the old style clutch, but need to re-bush my rollers and have both 14.5mm and 15.6mm in hand. Which way do you think I should go? Input from guys other than Mike also more than welcome here.......

Here’s the reason for my question......I’m using the old style clutch, but need to re-bush my rollers and have both 14.5mm and 15.6mm in hand. Which way do you think I should go? Input from guys other than Mike also more than welcome here.......

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,518

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Gotta question or two Knapp......RX1 had 14.5mm rollers stock, did you go to the 15mm rollers by choice, or was that just a typo? If you did switch rollers, why? Yammy has always spec’d the 15.4mm rollers on all the triple motors with the old clutches until the Winder showed up with the new piece of garbage attached. Do you think there is anything to Yammy’s using larger rollers in the triples simply for increased longevity, and that’s why they used to last? or is the new clutch design just that shitty?

Here’s the reason for my question......I’m using the old style clutch, but need to re-bush my rollers and have both 14.5mm and 15.6mm in hand. Which way do you think I should go? Input from guys other than Mike also more than welcome here.......

Well here’s M2C,

If your running Dalton weights and have some room for more weight, then I would go with the 15.6mm rollers. If your running STM weights I would go with the 14.5mm rollers. STM weights are tucked more than the Dalton’s and would benefit from the increased force of the smaller roller. I would watch the smaller rollers for premature wear tho.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,872

- Reaction score

- 6,168

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Gotta question or two Knapp......RX1 had 14.5mm rollers stock, did you go to the 15mm rollers by choice, or was that just a typo? If you did switch rollers, why? Yammy has always spec’d the 15.4mm rollers on all the triple motors with the old clutches until the Winder showed up with the new piece of garbage attached. Do you think there is anything to Yammy’s using larger rollers in the triples simply for increased longevity, and that’s why they used to last? or is the new clutch design just that shitty?

Here’s the reason for my question......I’m using the old style clutch, but need to re-bush my rollers and have both 14.5mm and 15.6mm in hand. Which way do you think I should go? Input from guys other than Mike also more than welcome here.......

My clutch came off a very low mile 03 RX-1 I put a different clutch on. I just had it sitting on the shelf collecting dust and decided to put it back in action after a good cleanup. It came with 15mm rollers as I've never changed them. I used a low engagement 40kg ggg yamaha drive spring to compensate for the larger rollers, plus I have flexibility to add weight in my arms. Given your situation, I'd opt for the 14.5's over the 15.5's. I just stuck with the 15's for now until I saw how it reacted. Roller size is like shimming the spider on a normal Polaris or Comet type clutch, its just another tuning component option. Think of it this way, if you add 1 mm to roller size, only half that size has any effect on the "shimming effect", so only 1/2 mm of effect on the arms, that's only .020" which is nothing really. It won't effect much running wise unless you have a weight like Clutchmaster said are close to the tipping point and already tucked under a bit too far. Untucking the weight will bite the belt harder down low.

I'll add that looking at the clutches side by side you would think the Winder would be the stronger piece, but that does not seem to be the case. Just going by what I was told, the old clutch is supposed to be stronger and not wear out rollers, something I had issues with on the winder clutch package. That plus the fact I have been all over the board on setups with the winder clutches and was never happy with them in varying conditions, I felt the need to go away from them. I was very close to pulling the trigger on a TAPP, but thought why not try what I have on the shelf first, so here I am, and very glad I did so far. I could not run a light spring in the winder secondary to save my soul, and was forced to go to a heavy secondary spring as a band aid, which brought on other issues. Consistency in different conditions, eating up rollers in the primary, belt blowing and cording belts no matter what setup I installed. One day I had clutching Nirvana, the next day it was a clutching nightmare with the winder stuff. I couldn't keep going down that road myself and pulling my hair out. My belief is that Yamaha had the Winder clutches built in china, and that could be a factor.

We'll see if the old stuff will hold up, judging by the reports out there I suspect they will. They sure seem to have helped my ability to prevent belt slippage using a light secondary spring as I'm running an even light spring than the Black/Orange Dalton. My drill press scale tells me light springs in a old button driven has better/higher side pressure on the belt than the winders roller clutch using a heavier spring.

Now I need some SNOW!

Stubbs

TY 4 Stroke Master

- Joined

- Nov 7, 2006

- Messages

- 1,181

- Reaction score

- 688

- Points

- 1,378

- Location

- Uxbridge, On, Can.

- Country

- Canada

- Snowmobile

- ‘16 Apex XTX with 137” Mono II

+ other gooodies

- LOCATION

- Uxbridge ON

STM Weights, old school 60’s with lots of profile, not the newer/flatter cam arms. I was curious if anyone would mention the difference in tuck with other sized rollers. That isn’t on many guys radar.Well here’s M2C,

If your running Dalton weights and have some room for more weight, then I would go with the 15.6mm rollers. If your running STM weights I would go with the 14.5mm rollers. STM weights are tucked more than the Dalton’s and would benefit from the increased force of the smaller roller. I would watch the smaller rollers for premature wear tho.

Stubbs

TY 4 Stroke Master

- Joined

- Nov 7, 2006

- Messages

- 1,181

- Reaction score

- 688

- Points

- 1,378

- Location

- Uxbridge, On, Can.

- Country

- Canada

- Snowmobile

- ‘16 Apex XTX with 137” Mono II

+ other gooodies

- LOCATION

- Uxbridge ON

Thanks for the reply Mike, appreciate it. I’m interested to see how these old clutches live long term on these sleds. I’m running a turned up 1049 like Clutchmaster, not a Winder, but I figured the roller questions kinda applied to both triples when using the same clutch. I’ve always been puzzled as to why Yammy put the larger rollers in the triples, but used the 14.5’s in virtually every other “performance” sled over the years.My clutch came off a very low mile 03 RX-1 I put a different clutch on. I just had it sitting on the shelf collecting dust and decided to put it back in action after a good cleanup. It came with 15mm rollers as I've never changed them. I used a low engagement 40kg ggg yamaha drive spring to compensate for the larger rollers, plus I have flexibility to add weight in my arms. Given your situation, I'd opt for the 14.5's over the 15.5's. I just stuck with the 15's for now until I saw how it reacted. Roller size is like shimming the spider on a normal Polaris or Comet type clutch, its just another tuning component option. Think of it this way, if you add 1 mm to roller size, only half that size has any effect on the "shimming effect", so only 1/2 mm of effect on the arms, that's only .020" which is nothing really. It won't effect much running wise unless you have a weight like Clutchmaster said are close to the tipping point and already tucked under a bit too far. Untucking the weight will bite the belt harder down low.

I'll add that looking at the clutches side by side you would think the Winder would be the stronger piece, but that does not seem to be the case. Just going by what I was told, the old clutch is supposed to be stronger and not wear out rollers, something I had issues with on the winder clutch package. That plus the fact I have been all over the board on setups with the winder clutches and was never happy with them in varying conditions, I felt the need to go away from them. I was very close to pulling the trigger on a TAPP, but thought why not try what I have on the shelf first, so here I am, and very glad I did so far. I could not run a light spring in the winder secondary to save my soul, and was forced to go to a heavy secondary spring as a band aid, which brought on other issues. Consistency in different conditions, eating up rollers in the primary, belt blowing and cording belts no matter what setup I installed. One day I had clutching Nirvana, the next day it was a clutching nightmare with the winder stuff. I couldn't keep going down that road myself and pulling my hair out. My belief is that Yamaha had the Winder clutches built in china, and that could be a factor.

We'll see if the old stuff will hold up, judging by the reports out there I suspect they will. They sure seem to have helped my ability to prevent belt slippage using a light secondary spring as I'm running an even light spring than the Black/Orange Dalton. My drill press scale tells me light springs in a old button driven has better/higher side pressure on the belt than the winders roller clutch using a heavier spring.

Now I need some SNOW!

ShootToThrill

VIP Member

Been running apex primary for 5000+ miles. Original rollers in it still with 260+ tune and loaded stm's

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,545

- Reaction score

- 4,195

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

I'm trying to see the logic as to why a roller would last any longer in the older primary compared to the newer. I mean, they are the same rollers and pins....?

Are the entire clutch assemblies different weight? That could have an affect on harmonics possibly.

Are the entire clutch assemblies different weight? That could have an affect on harmonics possibly.

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,484

- Reaction score

- 3,745

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

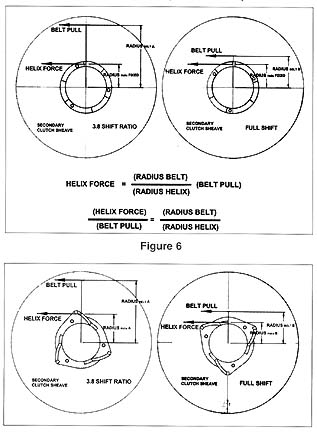

I have a theory as to why the Sidewinder clutches don't work well. It is not all my thinking and is a little long winded. It is actually do to the secondary.

I always go back and forth about secondary spring pressure vs. efficiency. Why do I need a 120-180 secondary spring to make my Sidewinder belts not slip in the secondary? This seems like a band aid for a different problem. Secondary spring pressure should only hold the belt, not control the primary clutch, or engine RPM. Huge secondary springs should not be needed, as evidenced by Knapps testing and previous high HP Apex clutching.

How can Knapp run softer springs in a 150 TRACK HP Apex Than his tuned Sidewinder and be the class of the field? How does Gagne Lassard run STOCK springs in his record setting Bonneville salt flats Apex? Why did my buddies Apex run faster speeds with SOFTER than stock secondary spring? As a former sponsor of this site said, it all about the upshift. The faster a sled upshifts while maintaining proper belt grip the faster it will go.

I have been thinking since the Winder came out, why is the helix at 35 degrees? Yamaha clutching, which had been at that time rock solid, has always been within +/- 2-3 degrees of 45 finishing angle, with 45 being the optimum. Now it is 35 degrees. Why? What changed? Well they went from a roller from a button for one. But they also increased the radius of the helix without increasing the radius of the secondary clutch. If you think of the contact points of the helix vs. the contact points of the belt in the secondary you will see that the lower the belt gets in the clutch the less of the mechanical advantage it has to squeeze the belt combined with the less surface area it has to work with. If you look at the old button clutch vs the roller clutch, that advantage is even worse.

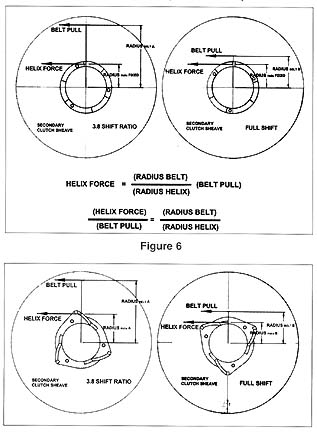

Button first, Winder second. Look at where the helix contact point is in relation to the belt at high ratio.

The belt in the button never gets to the contact point yet on the roller it is even. Huge loss in mechanical advantage.

What is the cure? Shallow helix. Adding more power? Need stiffer springs. Result? More heat, belts shredded.

Like I said not all my thinking. Check this picture out from almost 20 years ago to explain this theory.

This is from the Heel-X that Randy Nouis developed 20 years ago. I ran one on my F7 at the time . I proved it to work in back to back testing against a strong running ZR 800 at that time.

Can this be why the Winder has trouble at high shift ratios with belt life? Is the larger helix limiting belt squeeze at higher speeds making people run unheard of low helix angles and super high spring rates? Combine this with the over sensitive roller secondary which makes for wildly inconsistent RPM's?

Am I crazy? Do I need a different hobby? This is the chit that keeps me up at night.

It would really interesting to see a Viper secondary on a Winder with a stock primary and see what the results are.

I could also be totally wrong and overthinking this whole thing.

I always go back and forth about secondary spring pressure vs. efficiency. Why do I need a 120-180 secondary spring to make my Sidewinder belts not slip in the secondary? This seems like a band aid for a different problem. Secondary spring pressure should only hold the belt, not control the primary clutch, or engine RPM. Huge secondary springs should not be needed, as evidenced by Knapps testing and previous high HP Apex clutching.

How can Knapp run softer springs in a 150 TRACK HP Apex Than his tuned Sidewinder and be the class of the field? How does Gagne Lassard run STOCK springs in his record setting Bonneville salt flats Apex? Why did my buddies Apex run faster speeds with SOFTER than stock secondary spring? As a former sponsor of this site said, it all about the upshift. The faster a sled upshifts while maintaining proper belt grip the faster it will go.

I have been thinking since the Winder came out, why is the helix at 35 degrees? Yamaha clutching, which had been at that time rock solid, has always been within +/- 2-3 degrees of 45 finishing angle, with 45 being the optimum. Now it is 35 degrees. Why? What changed? Well they went from a roller from a button for one. But they also increased the radius of the helix without increasing the radius of the secondary clutch. If you think of the contact points of the helix vs. the contact points of the belt in the secondary you will see that the lower the belt gets in the clutch the less of the mechanical advantage it has to squeeze the belt combined with the less surface area it has to work with. If you look at the old button clutch vs the roller clutch, that advantage is even worse.

Button first, Winder second. Look at where the helix contact point is in relation to the belt at high ratio.

The belt in the button never gets to the contact point yet on the roller it is even. Huge loss in mechanical advantage.

What is the cure? Shallow helix. Adding more power? Need stiffer springs. Result? More heat, belts shredded.

Like I said not all my thinking. Check this picture out from almost 20 years ago to explain this theory.

This is from the Heel-X that Randy Nouis developed 20 years ago. I ran one on my F7 at the time . I proved it to work in back to back testing against a strong running ZR 800 at that time.

Can this be why the Winder has trouble at high shift ratios with belt life? Is the larger helix limiting belt squeeze at higher speeds making people run unheard of low helix angles and super high spring rates? Combine this with the over sensitive roller secondary which makes for wildly inconsistent RPM's?

Am I crazy? Do I need a different hobby? This is the chit that keeps me up at night.

It would really interesting to see a Viper secondary on a Winder with a stock primary and see what the results are.

I could also be totally wrong and overthinking this whole thing.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,872

- Reaction score

- 6,168

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

I wished I knew the answers, but the only way to know is to test and re-test different components, which is what I intend to do, but I believe you have a spot on accurate description of the key issues. Were putting big secondary springs in the junk secondary roller clutch to make it work properly on large tunes.

Another thing to think about and ask is, (probably a topic of a different conversation) why does the Apex make 150 track HP with only 265 engine HP? Even talking with Allen Ulmer, he says the same thing, we made way more track HP with the Simons turbo Apexs, and they were faster in the field and held that power forever. These Winders just don't have the same jam for any length of time. The turbos are so small and beat the heii out of the intake change heating them up so quickly and zapping the power away, so we chase our tails there as well. The triple power pulses make it hard on belts and clutches, where the four-cylinders underdriven and cushioned PTO shaft made belt and clutch life just so easy on parts. The 998 has a lightened crank on it compared to the old 1050's making things even worse on belts and clutches. I've thought about adding a ring to the clutch to help with flywheel effect and clutch life.

That said the Doo 1200, is the same triple with the same power pulses, and it shows way better belt and clutch life with the proper clutch on it too. In all honesty, the Winder is not much to write home about when it comes to turbo power compared to what we have had previously, trail power anyway, because of the small puny turbo on the winder.

Cold shot racing is a different story than trying to trail ride these thing when it comes to intake heat management, IMO 240-250 max is about all you are going to get out of them efficiently without heat soaking the intercooler and dropping power anyway, so I'm not even sure why I keep beating my head against the wall trying to make these bigger tunes work with the puny small stock turbo. I guess just because I have them in the tune bundle and want to be able to use them for 10 seconds at a time before letting the intake cool for a while before using it again. And the harder you spool them, the worse the intake temps get. So at the point of diminishing return.

I never thought I'd say it, but I wished we had a good NA 200 HP four-stroke platform like a Apex's underdriven PTO output shaft, four-cylinder out there again, just not in that same tank of a chassis as the old Apex. Think about adding an aftermarket turbo to a platform like that!

Another thing to think about and ask is, (probably a topic of a different conversation) why does the Apex make 150 track HP with only 265 engine HP? Even talking with Allen Ulmer, he says the same thing, we made way more track HP with the Simons turbo Apexs, and they were faster in the field and held that power forever. These Winders just don't have the same jam for any length of time. The turbos are so small and beat the heii out of the intake change heating them up so quickly and zapping the power away, so we chase our tails there as well. The triple power pulses make it hard on belts and clutches, where the four-cylinders underdriven and cushioned PTO shaft made belt and clutch life just so easy on parts. The 998 has a lightened crank on it compared to the old 1050's making things even worse on belts and clutches. I've thought about adding a ring to the clutch to help with flywheel effect and clutch life.

That said the Doo 1200, is the same triple with the same power pulses, and it shows way better belt and clutch life with the proper clutch on it too. In all honesty, the Winder is not much to write home about when it comes to turbo power compared to what we have had previously, trail power anyway, because of the small puny turbo on the winder.

Cold shot racing is a different story than trying to trail ride these thing when it comes to intake heat management, IMO 240-250 max is about all you are going to get out of them efficiently without heat soaking the intercooler and dropping power anyway, so I'm not even sure why I keep beating my head against the wall trying to make these bigger tunes work with the puny small stock turbo. I guess just because I have them in the tune bundle and want to be able to use them for 10 seconds at a time before letting the intake cool for a while before using it again. And the harder you spool them, the worse the intake temps get. So at the point of diminishing return.

I never thought I'd say it, but I wished we had a good NA 200 HP four-stroke platform like a Apex's underdriven PTO output shaft, four-cylinder out there again, just not in that same tank of a chassis as the old Apex. Think about adding an aftermarket turbo to a platform like that!

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.