ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,519

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

I'm running less weight for three reasons basically.

1. Way less secondary spring than I had been running. By a long shot!

2. Ultimax xs825 belt hooks the clutches better with less pressure. (also the reason I went to less spring pressure to start with).

3. Helix is WAY more aggressive. Even though its a nickel plated Advant edge @ 49/41, it compares to a Dalton at 53/45, which is actually pretty aggressive. Adtant-Edge cut their helixs with way different angles for whatever reason that is beyond me. Add 4 dergrees to them to compare to stock or Dalton. Another thing is it is pre-cut for OD just the way it comes.

I believe this combo is the reason I'm running way less weight in the arms without actually slipping the belt. I plan to test some things like heavier secondary springs and different belts along the way too, as soon as we get some more snow to test on. The biggest reason I installed the RX-1 drive clutch for was to prolong the roller life. Guys have stated that when switching to the old clutch it does not eat rollers any more. One thing I like about my current setup is it bites the belt way better down low as well as up top. I reminds me of my old TRA, where it bites, goes and grips the belt. Its nice and smooth with a lower engagement for trail use.

I was ready to drive over this sled with a dozer and crush the dang thing flat as a pancake, it was so frustrating to me! I now at least feel some hope that I'll be able to keep belts and rollers in it finally. I was considering adding a TAPP clutch, but who wants to put that much money into a machine you don't like without knowing if it too will even help with belt life? Maybe now I may come to like it anyway. Nothing worse that having issues you can't really fix decently. I hope this is the trick anyway I've tried nearly everything else I could think of, so far it looks real promising with the test in warm weather.

In time I'm betting I will end up with a bit heavier weight up front with cooler weather, a bit more secondary wrap pressure and a happy setup in ALL conditions!

I feel like I had to reduce the pressure on the belt on both ends to make it all work, but that was impossible for me using the roller secondary with the heavy spring setup to keep the belt clamped tight enough. Perhaps If I had reduced the top end helix down to 33 or less who knows, but I was at my whits end with the Winder stuff and had to make a wholesale change.

Mike your also running the older primary that generally takes more weight to equal the same force as the Winder primary.

Your at approx 75 grams and what tune?

That’s like a Winder primary @ 71~72 grams?

That’s crazy light weight for a 270 tune even with the XS belt.

I’m trying to reverse think this, what would need to be done to the Winder Secondary to allow it to run with your primary setup.....

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,965

- Reaction score

- 6,296

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Mike your also running the older primary that generally takes more weight to equal the same force as the Winder primary.

Your at approx 75 grams and what tune?

That’s like a Winder primary @ 71~72 grams?

That’s crazy light weight for a 270 tune even with the XS belt.

I’m trying to reverse think this, what would need to be done to the Winder Secondary to allow it to run with your primary setup.....

I hear you and agree Clutchmaster. I'm out this AM in the shop checking secondary pressures, and where I'm at in the viper secondary. What I have is the secondary is setup with VERY light secondary spring pressure. Actually 60 lbs. less on top end than a old stock Yamaha white set at 60 degrees! I wanted to start light to see the effect on this clutch package, I wanted to push the limit and try to slip the belt and go up from there. That is on a 300 HP tune, and lets face it, we know its not making an actual 300 HP, the old gas in the tank from last season and a brand new belt which we know always sticks good and RPM's less as well to begin with. Don't overthink the light weights just yet. Let me get some time on the new belt and see if it starts slipping first. I know I'll need to tighten up the secondary pressures and add weight at some point. It's just nice knowing I can get by with lighter and more normal pressures now.

The winder secondary would never, ever grip the belt set as light as it is under any conditions. I honestly don't even want to go back to it. I struggled with it for years as you know! One day it would be bang on, the next day burning the belts again.

race24x

TY 4 Stroke Master

- Joined

- Dec 29, 2003

- Messages

- 1,051

- Reaction score

- 47

- Points

- 988

- Location

- Belgrade, Maine

- Website

- www.r-scomputer.com

So are we talking about a Apex Primary with buttons and a Viper secondary with buttons instead of all the roller stuff?

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,519

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Apex/RX1 has rollers in the primary, they are just spaced further from the weights than the Sidewinder primary.So are we talking about a Apex Primary with buttons and a Viper secondary with buttons instead of all the roller stuff?

You’ve got me thinking, maybe some of these Winder clutches have runout? Either way I think your really on to something, ok I’ll shut up now.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,913

- Reaction score

- 2,926

- Points

- 1,113

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

No intention of getting off track here (I have a Cat) but I thought you all might find it interesting and much in parallel with Mike's testing and findings.

I've been running the XS belt all last year but never really spent any time testing to see if I could achieve lower belt temps without losing performance/acceleration and/or blowing belts up. This past weekend I spent some time testing to see how much I could reduce my secondary spring pressure without slipping the belt. I know this is all different from Winder secondary stuff but relevant IMO. I was able to change to the lowest spring I had (compression secondary), reduce primary weight significantly without slipping belt. I went from 155/220 secondary spring down to 125/200 spring, reduced primary weight 2 grams per arm (total of 6 grams) and still pulled 8850-8900 RPM without slipping belt. Helix stayed same at 44/49. I have an IR belt temp gage. My belt temps came down about 30 degF from my previous setup (from around 170 down to about 140 on back to back WOT runs). The XS belt grips so good I don't need higher secondary pressures to prevent slippage with the bonus of reducing belt temps.

Sounds like what I found out is kind of similar to what Knapp is finding out. Still haven't blown an XS belt (knock on wood).

I've been running the XS belt all last year but never really spent any time testing to see if I could achieve lower belt temps without losing performance/acceleration and/or blowing belts up. This past weekend I spent some time testing to see how much I could reduce my secondary spring pressure without slipping the belt. I know this is all different from Winder secondary stuff but relevant IMO. I was able to change to the lowest spring I had (compression secondary), reduce primary weight significantly without slipping belt. I went from 155/220 secondary spring down to 125/200 spring, reduced primary weight 2 grams per arm (total of 6 grams) and still pulled 8850-8900 RPM without slipping belt. Helix stayed same at 44/49. I have an IR belt temp gage. My belt temps came down about 30 degF from my previous setup (from around 170 down to about 140 on back to back WOT runs). The XS belt grips so good I don't need higher secondary pressures to prevent slippage with the bonus of reducing belt temps.

Sounds like what I found out is kind of similar to what Knapp is finding out. Still haven't blown an XS belt (knock on wood).

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,965

- Reaction score

- 6,296

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

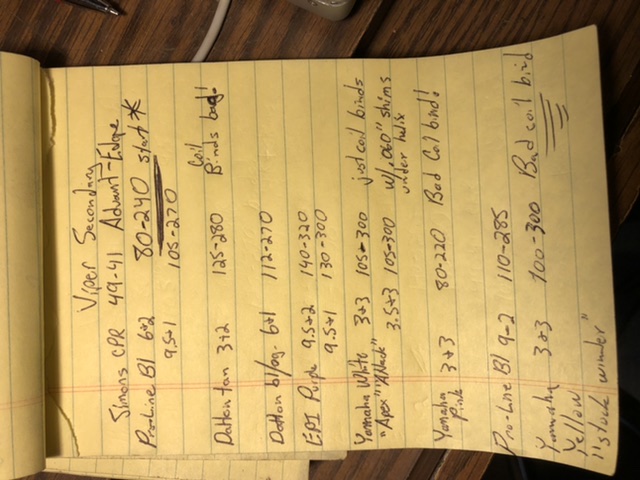

So messing around in the shop today, I did some spring testing in the Viper button secondary. I think most would agree that the old Yamaha white spring (was used in the 136" Attak and mountain sleds) was a fairly soft spring, most of the big turbo sleds ran it up to about 300 HP or so. Some guys found severe slippage using it and went to the Cat Green or EPI purple set at 0-1. So I tested most of the popular springs at different settings. I was quite surprised to see the Yamaha white at 105-300 set at 3.5+3, which is 65 degrees using .060" shims under my helix. I had to use the shims to prevent solid coil bind as it wanted to bind at 3+3 before shimming. The Yamaha Yellow spring coil bound bad in the Viper clutch! So did the Dalton tan. The white spring just bound at 3+3 and needed .060" shims behind the helix to prevent total binding and full travel of the stock RX-1 primary.

I had been running the ProLine black secondary spring, which is the same as the Dalton Red but tangs are off by 30*, so I have to wrap it up an additional 30* to equal the Dalton red secondary spring. I was running 80* wrap in it and it measured 80-240 on my scale which would be a 50* wrap in a Dalton red. Next time out, I'll try the Yamaha white set at 65* and add 5.5G to the primary arms to see how its reacts and what happens to belt temps. Running the White Yamaha Attak stock spring in the Viper secondary, is like running the Cat Green spring in the Winder secondary at 0-1 pressure wise on the scale for comparison! Thus requiring more weight in the primary arms. Lets see what happens. Pray for SNOW!!!

And before you ask, the Advant-Edge helix has 5 degree increments on it too. So you can change by 5 degrees too rather than just 10 degree increments. The only reason for me using that helix is it came in a Simons CPR kit that I ran in my old 150 track HP (265 engine HP) turbo Attak back in the day. With the White spring and that helix, it now has the exact secondary setup in it my old turbo Attak had. Should be a good comparison. The difference is the Attak ran 86G HH primary arms in it with 14.5 mm rollers on a 8DN belt. Keep in mind my Attak turned 8900 RPM clutch speed too.

Why do my photos always turn sideways on here?

I had been running the ProLine black secondary spring, which is the same as the Dalton Red but tangs are off by 30*, so I have to wrap it up an additional 30* to equal the Dalton red secondary spring. I was running 80* wrap in it and it measured 80-240 on my scale which would be a 50* wrap in a Dalton red. Next time out, I'll try the Yamaha white set at 65* and add 5.5G to the primary arms to see how its reacts and what happens to belt temps. Running the White Yamaha Attak stock spring in the Viper secondary, is like running the Cat Green spring in the Winder secondary at 0-1 pressure wise on the scale for comparison! Thus requiring more weight in the primary arms. Lets see what happens. Pray for SNOW!!!

And before you ask, the Advant-Edge helix has 5 degree increments on it too. So you can change by 5 degrees too rather than just 10 degree increments. The only reason for me using that helix is it came in a Simons CPR kit that I ran in my old 150 track HP (265 engine HP) turbo Attak back in the day. With the White spring and that helix, it now has the exact secondary setup in it my old turbo Attak had. Should be a good comparison. The difference is the Attak ran 86G HH primary arms in it with 14.5 mm rollers on a 8DN belt. Keep in mind my Attak turned 8900 RPM clutch speed too.

Why do my photos always turn sideways on here?

Last edited:

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,555

- Reaction score

- 3,808

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

80 grams in the Dalton arms, 14.5 rollers, green Cat secondary spring at 0-1 is the EXACT set up I ended up in my Winder before going to the TAPP clutch. It was the best I got it go.wrap in a Dalton red. Next time out, I'll try the Yamaha white set at 65* and add 5.5G to the primary arms to see how its reacts and what happens to belt temps. Running the White Yamaha Attak stock spring in the Viper secondary, is like running the Cat Green spring in the Winder secondary at 0-1 pressure wise on the scale for comparison

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,965

- Reaction score

- 6,296

- Points

- 1,733

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

80 grams in the Dalton arms, 14.5 rollers, green Cat secondary spring at 0-1 is the EXACT set up I ended up in my Winder before going to the TAPP clutch. It was the best I got it go.

That's about the best I ended up with in my sled with winder clutches as well. Just wasn't consistent from day to day though when temps changed and ate rollers and still corded belts about 3-400 miles.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Reaction score

- 2,519

- Points

- 1,003

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

No intention of getting off track here (I have a Cat) but I thought you all might find it interesting and much in parallel with Mike's testing and findings.

I've been running the XS belt all last year but never really spent any time testing to see if I could achieve lower belt temps without losing performance/acceleration and/or blowing belts up. This past weekend I spent some time testing to see how much I could reduce my secondary spring pressure without slipping the belt. I know this is all different from Winder secondary stuff but relevant IMO. I was able to change to the lowest spring I had (compression secondary), reduce primary weight significantly without slipping belt. I went from 155/220 secondary spring down to 125/200 spring, reduced primary weight 2 grams per arm (total of 6 grams) and still pulled 8850-8900 RPM without slipping belt. Helix stayed same at 44/49. I have an IR belt temp gage. My belt temps came down about 30 degF from my previous setup (from around 170 down to about 140 on back to back WOT runs). The XS belt grips so good I don't need higher secondary pressures to prevent slippage with the bonus of reducing belt temps.

Sounds like what I found out is kind of similar to what Knapp is finding out. Still haven't blown an XS belt (knock on wood).

TFlash,

What primary weights are you running with your setup? I noticed your running a reverse cut helix, so I’m assuming your running a very flat profile weight? Oh I almost forgot, what tune do you run?

That setup with 140 temps sounds awsome! Guys running the Tapp are up around 180~190 degrees using finish helix angles in the mid to low 30’s trying to control the aggressive fast shift.

Could it be that an even flatter tip profile weight than the Dalton is needed to slow down the shift speed up top with these rollers?

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,913

- Reaction score

- 2,926

- Points

- 1,113

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

TFlash,

What primary weights are you running with your setup? I noticed your running a reverse cut helix, so I’m assuming your running a very flat profile weight? Oh I almost forgot, what tune do you run?

That setup with 140 temps sounds awsome! Guys running the Tapp are up around 180~190 degrees using finish helix angles in the mid to low 30’s trying to control the aggressive fast shift.

Could it be that an even flatter tip profile weight than the Dalton is needed to slow down the shift speed up top with these rollers?

Test sled (belongs to my brother) was 2017 Tcat 137" with Precision EFI Stage 3 (280HP) tune. 192 Lake Racer 1.50" studs. XS827 belt.

Primary is stock Team with D&D MagnaForce "standard" profile Team weight (3-hole). It's pretty close to stock Team profile. Weight started at 80.3 gms and by the end of the test session, we had it down to 78, still holding RPM @ 8850-8900. Primary spring is D&D tan yielding engagement of 3000. We were trying to find out if we could reduce secondary pinch (lighter spring) without slipping belt. Answer was 'yes' and belt temps came down too. Clutching seemed smoother and happier with less secondary pressure. All the previous higher pressure was doing was making heat, and trying to prevent belt from entering, exiting, and shifting up & down.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,913

- Reaction score

- 2,926

- Points

- 1,113

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

Test sled (belongs to my brother) was 2017 Tcat 137" with Precision EFI Stage 3 (280HP) tune. 192 Lake Racer 1.50" studs. XS827 belt.

Primary is stock Team with D&D MagnaForce "standard" profile Team weight (3-hole). It's pretty close to stock Team profile. Weight started at 80.3 gms and by the end of the test session, we had it down to 78, still holding RPM @ 8850-8900. Primary spring is D&D tan yielding engagement of 3000. We were trying to find out if we could reduce secondary pinch (lighter spring) without slipping belt. Answer was 'yes' and belt temps came down too. Clutching seemed smoother and happier with less secondary pressure. All the previous higher pressure was doing was making heat, and trying to prevent belt from entering, exiting, and shifting up & down.

BTW- we (reluctantly) tried a Cat belt at the end of the test. It slipped bad past about 1/2 throttle and all the way up. It needs higher side pressure/pinch to not slip. Proves the XS belt is much better at gripping clutch faces.

DooZ

TY 4 Stroke Junkie

- Joined

- Feb 26, 2007

- Messages

- 625

- Reaction score

- 405

- Points

- 1,128

- Location

- Minocqua, WI

- Country

- USA

- Snowmobile

- ZR9000RR

Doo 1200

Was there any change in holeshot with the lighter secondary spring? I'm probably preaching to the choir, but it's a fine line easing up on the spring and not having the belt pulled deeper into the secondary with good traction on a holeshot.Test sled (belongs to my brother) was 2017 Tcat 137" with Precision EFI Stage 3 (280HP) tune. 192 Lake Racer 1.50" studs. XS827 belt.

Primary is stock Team with D&D MagnaForce "standard" profile Team weight (3-hole). It's pretty close to stock Team profile. Weight started at 80.3 gms and by the end of the test session, we had it down to 78, still holding RPM @ 8850-8900. Primary spring is D&D tan yielding engagement of 3000. We were trying to find out if we could reduce secondary pinch (lighter spring) without slipping belt. Answer was 'yes' and belt temps came down too. Clutching seemed smoother and happier with less secondary pressure. All the previous higher pressure was doing was making heat, and trying to prevent belt from entering, exiting, and shifting up & down.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,612

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Here ya go Mike...keep up the good work in this thread guys.So messing around in the shop today, I did some spring testing in the Viper button secondary. I think most would agree that the old Yamaha white spring (was used in the 136" Attak and mountain sleds) was a fairly soft spring, most of the big turbo sleds ran it up to about 300 HP or so. Some guys found severe slippage using it and went to the Cat Green or EPI purple set at 0-1. So I tested most of the popular springs at different settings. I was quite surprised to see the Yamaha white at 105-300 set at 3.5+3, which is 65 degrees using .060" shims under my helix. I had to use the shims to prevent solid coil bind as it wanted to bind at 3+3 before shimming. The Yamaha Yellow spring coil bound bad in the Viper clutch! So did the Dalton tan. The white spring just bound at 3+3 and needed .060" shims behind the helix to prevent total binding and full travel of the stock RX-1 primary.

I had been running the ProLine black secondary spring, which is the same as the Dalton Red but tangs are off by 30*, so I have to wrap it up an additional 30* to equal the Dalton red secondary spring. I was running 80* wrap in it and it measured 80-240 on my scale which would be a 50* wrap in a Dalton red. Next time out, I'll try the Yamaha white set at 65* and add 5.5G to the primary arms to see how its reacts and what happens to belt temps. Running the White Yamaha Attak stock spring in the Viper secondary, is like running the Cat Green spring in the Winder secondary at 0-1 pressure wise on the scale for comparison! Thus requiring more weight in the primary arms. Lets see what happens. Pray for SNOW!!!

And before you ask, the Advant-Edge helix has 5 degree increments on it too. So you can change by 5 degrees too rather than just 10 degree increments. The only reason for me using that helix is it came in a Simons CPR kit that I ran in my old 150 track HP (265 engine HP) turbo Attak back in the day. With the White spring and that helix, it now has the exact secondary setup in it my old turbo Attak had. Should be a good comparison. The difference is the Attak ran 86G HH primary arms in it with 14.5 mm rollers on a 8DN belt. Keep in mind my Attak turned 8900 RPM clutch speed too.

View attachment 151966

Why do my photos always turn sideways on here?

snowbeast

TY 4 Stroke God

- Joined

- Apr 13, 2003

- Messages

- 5,498

- Reaction score

- 780

- Points

- 1,883

- Location

- E waterboro,maine

- Country

- USA

- Snowmobile

- 2015 apex xtx traded for a 2017 sidewinder L-tx-le

- yes

- YOUTUBE

- yes

Mike,are you talking about shimming the 3 bolts that hold the helix to the sheave? Put the washer/shim under the nut,that tightens the helix to hub? To relieve spring bind?So messing around in the shop today, I did some spring testing in the Viper button secondary. I think most would agree that the old Yamaha white spring (was used in the 136" Attak and mountain sleds) was a fairly soft spring, most of the big turbo sleds ran it up to about 300 HP or so. Some guys found severe slippage using it and went to the Cat Green or EPI purple set at 0-1. So I tested most of the popular springs at different settings. I was quite surprised to see the Yamaha white at 105-300 set at 3.5+3, which is 65 degrees using .060" shims under my helix. I had to use the shims to prevent solid coil bind as it wanted to bind at 3+3 before shimming. The Yamaha Yellow spring coil bound bad in the Viper clutch! So did the Dalton tan. The white spring just bound at 3+3 and needed .060" shims behind the helix to prevent total binding and full travel of the stock RX-1 primary.

I had been running the ProLine black secondary spring, which is the same as the Dalton Red but tangs are off by 30*, so I have to wrap it up an additional 30* to equal the Dalton red secondary spring. I was running 80* wrap in it and it measured 80-240 on my scale which would be a 50* wrap in a Dalton red. Next time out, I'll try the Yamaha white set at 65* and add 5.5G to the primary arms to see how its reacts and what happens to belt temps. Running the White Yamaha Attak stock spring in the Viper secondary, is like running the Cat Green spring in the Winder secondary at 0-1 pressure wise on the scale for comparison! Thus requiring more weight in the primary arms. Lets see what happens. Pray for SNOW!!!

And before you ask, the Advant-Edge helix has 5 degree increments on it too. So you can change by 5 degrees too rather than just 10 degree increments. The only reason for me using that helix is it came in a Simons CPR kit that I ran in my old 150 track HP (265 engine HP) turbo Attak back in the day. With the White spring and that helix, it now has the exact secondary setup in it my old turbo Attak had. Should be a good comparison. The difference is the Attak ran 86G HH primary arms in it with 14.5 mm rollers on a 8DN belt. Keep in mind my Attak turned 8900 RPM clutch speed too.

View attachment 151966

Why do my photos always turn sideways on here?

twyztid

VIP Member

- Joined

- Feb 14, 2011

- Messages

- 1,027

- Reaction score

- 517

- Points

- 1,478

- Location

- Middleville, MI

- Country

- USA

- Snowmobile

- 2025 Sidewinder LTX LE EPS

2017 Sidewinder LTX SE

2012 Apex XTX

2012 RS Vector LTX

- LOCATION

- Middleville, MI

Mike,are you talking about shimming the 3 bolts that hold the helix to the sheave? Put the washer/shim under the nut,that tightens the helix to hub? To relieve spring bind?

I am guessing he is referring to putting the shim washers on the studs before putting the helix on. This would put the helix a little further out than the original position.

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.