KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,695

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

I'm trying to see the logic as to why a roller would last any longer in the older primary compared to the newer. I mean, they are the same rollers and pins....?

Are the entire clutch assemblies different weight? That could have an affect on harmonics possibly.

I don't get it either, and yes they are the same. The only thing I can think of is the rollers and weights are 3mm close to the shaft centerline putting less pressure on them. Or, the clutch does not flex as much being a slightly different design or construction makeup.

I'm serious when I say I really think Yamaha sourced the clutches and engines to China now. Since the untreated rods show up in the 1050 Viper engine I've thought this. That never would have happened in a Yamaha plant in Japan. The old clutches were built in Japan. Better metal or better design? Either way, many that have made the switch are claiming no more roller problems after years of roller wear in the winder primary, and I want to see it for myself to believe it. I had issue with bushings, roller wear and belts for years, I'll know if it works.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

I don't get it either, and yes they are the same. The only thing I can think of is the rollers and weights are 3mm close to the shaft centerline putting less pressure on them. Or, the clutch does not flex as much being a slightly different design or construction makeup.

I'm serious when I say I really think Yamaha sourced the clutches and engines to China now. Since the untreated rods show up in the 1050 Viper engine I've thought this. That never would have happened in a Yamaha plant in Japan. The old clutches were built in Japan. Better metal or better design? Either way, many that have made the switch are claiming no more roller problems after years of roller wear in the winder primary, and I want to see it for myself to believe it. I had issue with bushings, roller wear and belts for years, I'll know if it works.

Just a thought, I know one member here mentioned he switched his Winder to 15mm rollers, and has had success without issue ever since. Not sure who it was, but could just having a larger OD roller be the fix, at least for roller life?

Dan

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,265

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Maybe Dan.Just a thought, I know one member here mentioned he switched his Winder to 15mm rollers, and has had success without issue ever since. Not sure who it was, but could just having a larger OD roller be the fix, at least for roller life?

Dan

When you think about the difference in thickness in terms of percentage of the metal portion, it is substantial.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Even if true, I still like the results Mike is seeing in BELT TEMP and sheave temps....and lighter springs with less slippage means alot.Maybe Dan.

When you think about the difference in thickness in terms of percentage of the metal portion, it is substantial.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,265

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

It is very interesting for sure. Yamaha should have Mike or someone like him on payroll for testing and quality control.Even if true, I still like the results Mike is seeing in BELT TEMP and sheave temps....and lighter springs with less slippage means alot.

The thing is, I just don't think it is realistic to think that Winder owners are going to switch out their clutches.

I personally haven't had a huge amount of issues with the 8DN belt and have yet to try the XS. Maybe the lower gearing helps, I'm not sure. This sled will probably be replaced next year and I already spend enough on software which stays with the machine and must be bought again.

Lets not kid ourselves either that other manufacturers don't have issues. I just repaired an 850 Doo this week, The 4 bolts that hold the secondary together came loose, one was snapped off inside the helix leg. Judging by the mess in the clutch compartment area, this thing had shredded a few belts too.

On the bright side, it is SNOWing today!

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

One thing we need to always remember, the Winder if left stock for most works as it should. I would say alignment could be better but stock most do ok. Its the 270+ tunes where all the shortcomings are revealed.It is very interesting for sure. Yamaha should have Mike or someone like him on payroll for testing and quality control.

The thing is, I just don't think it is realistic to think that Winder owners are going to switch out their clutches.

I personally haven't had a huge amount of issues with the 8DN belt and have yet to try the XS. Maybe the lower gearing helps, I'm not sure. This sled will probably be replaced next year and I already spend enough on software which stays with the machine and must be bought again.

Lets not kid ourselves either that other manufacturers don't have issues. I just repaired an 850 Doo this week, The 4 bolts that hold the secondary together came loose, one was snapped off inside the helix leg. Judging by the mess in the clutch compartment area, this thing had shredded a few belts too.

On the bright side, it is SNOWing today!

Dan

I have a Razor belt temp gage installed on my 2019 SW XTX LE, Hurricane SM 240 flash. I am using an 8DN belt, stock Yamaha clutches, TP rollers in both with Dalton tuning components .

I raced a friends SW with a 280 hp flash and 3 inch muffler 8 times or so back to back the other day[only got beat twice] and my belt temps got up to 178'F which is well below the level of any concerns.

Also took the winder ice fishing the other day, towing a 200+lb sleigh, breaking trail through 8" of snow and slush and the belt temps never went above 177'F.

With my current setup the sled runs 114mph GPS on the hardpack.[Speedo said 122]

I had initially planned to install an Apex clutch on it, but so far I am very happy and for the time being I will leave well enough alone. If I start having issues I will probably take the same approach Mike is doing with an Apex primary and Viper Secondary, but I may do a roller conversion to it.

I raced a friends SW with a 280 hp flash and 3 inch muffler 8 times or so back to back the other day[only got beat twice] and my belt temps got up to 178'F which is well below the level of any concerns.

Also took the winder ice fishing the other day, towing a 200+lb sleigh, breaking trail through 8" of snow and slush and the belt temps never went above 177'F.

With my current setup the sled runs 114mph GPS on the hardpack.[Speedo said 122]

I had initially planned to install an Apex clutch on it, but so far I am very happy and for the time being I will leave well enough alone. If I start having issues I will probably take the same approach Mike is doing with an Apex primary and Viper Secondary, but I may do a roller conversion to it.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,695

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

I have a Razor belt temp gage installed on my 2019 SW XTX LE, Hurricane SM 240 flash. I am using an 8DN belt, stock Yamaha clutches, TP rollers in both with Dalton tuning components .

I raced a friends SW with a 280 hp flash and 3 inch muffler 8 times or so back to back the other day[only got beat twice] and my belt temps got up to 178'F which is well below the level of any concerns.

Also took the winder ice fishing the other day, towing a 200+lb sleigh, breaking trail through 8" of snow and slush and the belt temps never went above 177'F.

With my current setup the sled runs 114mph GPS on the hardpack.[Speedo said 122]

I had initially planned to install an Apex clutch on it, but so far I am very happy and for the time being I will leave well enough alone. If I start having issues I will probably take the same approach Mike is doing with an Apex primary and Viper Secondary, but I may do a roller conversion to it.

Good feedback!

The 240 tune when properly clutched for is IMO the best out there. No worries about clutches, belt life, overheating the intake continually or octane level, not mention noise. And isn't that interesting it's just as fast as the big tunes... Seen this a time or two. Sure be nice to know what 280 tune you ran against...

When the big tune is beating up the intake air and overheating it, the 240 tune just runs along happily running fairly cool, never a worry about blowing belts or messing up anything. If I can't make the big tunes work on the trail I too was just going to go to the stock muffler tune bundle, clutch and run the 240 all the time. This dickin around trying to make the big tunes work gets frustrating. Sometimes I wonder if that power is actually there, (yes, it probably there when cold and not heat soaked, but we can't ride them that way on the trail) the 900t guys are finding this out now too on larger tunes. The heat just zaps the power away anyway.

Both Sidewinders are 2019 XTX LEs with the stock 1.75" x 141" tracks no studs. The 280hp sled has a Precision 280 Stage 3 with traction and launch control and a Hindle Exhaust. We raced from a dead stop up to 1000'. My Hurricane 240 SM sled was ahead the entire time in every race but 2 where I lost by a few feet. We were both surprised by the results because the Precision flashed sled is a strong runner.

Last edited:

snowbeast

TY 4 Stroke God

- Joined

- Apr 13, 2003

- Messages

- 5,498

- Age

- 69

- Location

- E waterboro,maine

- Country

- USA

- Snowmobile

- 2015 apex xtx traded for a 2017 sidewinder L-tx-le

- yes

- YOUTUBE

- yes

Hi Bob,i am not surprised to see that big spread between the gps and speedo,at times with the yamacats,both cat version and Yamaha version,i have seen that happen. Not sure what it is,at times have seen as close as 2 mph between the two,and at times 8-10 mph spread. Man that 240 sm tune sure runs good,i think I too would leave well enough along.I have a Razor belt temp gage installed on my 2019 SW XTX LE, Hurricane SM 240 flash. I am using an 8DN belt, stock Yamaha clutches, TP rollers in both with Dalton tuning components .

I raced a friends SW with a 280 hp flash and 3 inch muffler 8 times or so back to back the other day[only got beat twice] and my belt temps got up to 178'F which is well below the level of any concerns.

Also took the winder ice fishing the other day, towing a 200+lb sleigh, breaking trail through 8" of snow and slush and the belt temps never went above 177'F.

With my current setup the sled runs 114mph GPS on the hardpack.[Speedo said 122]

I had initially planned to install an Apex clutch on it, but so far I am very happy and for the time being I will leave well enough alone. If I start having issues I will probably take the same approach Mike is doing with an Apex primary and Viper Secondary, but I may do a roller conversion to it.

Tarzan

TY 4 Stroke Guru

- Joined

- Oct 28, 2009

- Messages

- 861

- Age

- 50

- Location

- Norway

- Website

- www.youtube.com

- Country

- Norway

- Snowmobile

- Yamaha Nytro and SideWinder BTX

Finaly one man (you) are saying this that i have been woundering about in many years now . I just cant understand why all this tuners are beating the #*$&@ out of this little turbo.All you are making is more heat and little hp with to much turbo psi on that little turbo. The first thing i did when i bought my 2017 Btx was to mount a bigger turbo that would be the correct sice to the hp i wanted.and a bigger intercooler. To me it looks like all the tuners are competing with itother whos is getting the biggest tunes out of this little turbo and not thinking about all the hp that gets lost in just heat and hurting prformance of other things.And now they are doing it with the 900 ace with 220 hp on that tiny little turbo,i just dont get it. Spot on KnappAttackI wished I knew the answers, but the only way to know is to test and re-test different components, which is what I intend to do, but I believe you have a spot on accurate description of the key issues. Were putting big secondary springs in the junk secondary roller clutch to make it work properly on large tunes.

Another thing to think about and ask is, (probably a topic of a different conversation) why does the Apex make 150 track HP with only 265 engine HP? Even talking with Allen Ulmer, he says the same thing, we made way more track HP with the Simons turbo Apexs, and they were faster in the field and held that power forever. These Winders just don't have the same jam for any length of time. The turbos are so small and beat the heii out of the intake change heating them up so quickly and zapping the power away, so we chase our tails there as well. The triple power pulses make it hard on belts and clutches, where the four-cylinders underdriven and cushioned PTO shaft made belt and clutch life just so easy on parts. The 998 has a lightened crank on it compared to the old 1050's making things even worse on belts and clutches. I've thought about adding a ring to the clutch to help with flywheel effect and clutch life.

That said the Doo 1200, is the same triple with the same power pulses, and it shows way better belt and clutch life with the proper clutch on it too. In all honesty, the Winder is not much to write home about when it comes to turbo power compared to what we have had previously, trail power anyway, because of the small puny turbo on the winder.

Cold shot racing is a different story than trying to trail ride these thing when it comes to intake heat management, IMO 240-250 max is about all you are going to get out of them efficiently without heat soaking the intercooler and dropping power anyway, so I'm not even sure why I keep beating my head against the wall trying to make these bigger tunes work with the puny small stock turbo. I guess just because I have them in the tune bundle and want to be able to use them for 10 seconds at a time before letting the intake cool for a while before using it again. And the harder you spool them, the worse the intake temps get. So at the point of diminishing return.

I never thought I'd say it, but I wished we had a good NA 200 HP four-stroke platform like a Apex's underdriven PTO output shaft, four-cylinder out there again, just not in that same tank of a chassis as the old Apex. Think about adding an aftermarket turbo to a platform like that!

And a whice choice of you to ditch the stock Sidewinder cluthces

And a whice choice of you to ditch the stock Sidewinder cluthces

Last edited:

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

I have a theory as to why the Sidewinder clutches don't work well. It is not all my thinking and is a little long winded. It is actually do to the secondary.

I always go back and forth about secondary spring pressure vs. efficiency. Why do I need a 120-180 secondary spring to make my Sidewinder belts not slip in the secondary? This seems like a band aid for a different problem. Secondary spring pressure should only hold the belt, not control the primary clutch, or engine RPM. Huge secondary springs should not be needed, as evidenced by Knapps testing and previous high HP Apex clutching.

How can Knapp run softer springs in a 150 TRACK HP Apex Than his tuned Sidewinder and be the class of the field? How does Gagne Lassard run STOCK springs in his record setting Bonneville salt flats Apex? Why did my buddies Apex run faster speeds with SOFTER than stock secondary spring? As a former sponsor of this site said, it all about the upshift. The faster a sled upshifts while maintaining proper belt grip the faster it will go.

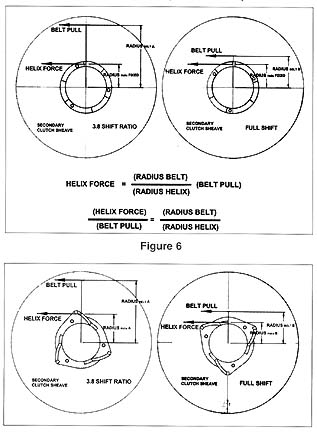

I have been thinking since the Winder came out, why is the helix at 35 degrees? Yamaha clutching, which had been at that time rock solid, has always been within +/- 2-3 degrees of 45 finishing angle, with 45 being the optimum. Now it is 35 degrees. Why? What changed? Well they went from a roller from a button for one. But they also increased the radius of the helix without increasing the radius of the secondary clutch. If you think of the contact points of the helix vs. the contact points of the belt in the secondary you will see that the lower the belt gets in the clutch the less of the mechanical advantage it has to squeeze the belt combined with the less surface area it has to work with. If you look at the old button clutch vs the roller clutch, that advantage is even worse.

Button first, Winder second. Look at where the helix contact point is in relation to the belt at high ratio.

The belt in the button never gets to the contact point yet on the roller it is even. Huge loss in mechanical advantage.

What is the cure? Shallow helix. Adding more power? Need stiffer springs. Result? More heat, belts shredded.

Like I said not all my thinking. Check this picture out from almost 20 years ago to explain this theory.

This is from the Heel-X that Randy Nouis developed 20 years ago. I ran one on my F7 at the time . I proved it to work in back to back testing against a strong running ZR 800 at that time.

Can this be why the Winder has trouble at high shift ratios with belt life? Is the larger helix limiting belt squeeze at higher speeds making people run unheard of low helix angles and super high spring rates? Combine this with the over sensitive roller secondary which makes for wildly inconsistent RPM's?

Am I crazy? Do I need a different hobby? This is the chit that keeps me up at night.

It would really interesting to see a Viper secondary on a Winder with a stock primary and see what the results are.

I could also be totally wrong and overthinking this whole thing.

Absolutely positive your thinking is correct here. The larger diameter helix looses belt pinch on the big end. Less torque feedback to control the shift and more spring twist due to the lower helix angles. Rollers get forced open easier than Buttons especially @ full shift out, combine that with the fact the Winder secondary has a larger diameter helix = low belt pinch at 1:1 ratio. Same #*$&@ with the big helix Cat secondary.

Plucked from the same article you read, look at how much easier the secondary is to open at 1:1 ratio. Why can some sleds run 135 mph while others with the same horsepower and same clutch setup struggle to get 125 mph and burn belts? Why is it the Hurricane alignment bar shoots for perfect alignment at full shift? My point is these big power machines move the motor around causing havoc with finicky roller secondarys.

I’m just glad Mike has a working setup now!

No more Moriarty!!!!

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Maybe we need to rethink this? Mike is running less weight in the primary, so is the secondary actually pinching the belt more or less?

Why did Yamaha choose to use a reverse 35/39 helix in the SRX and remove weight from the arms?

Why did Yamaha choose to use a reverse 35/39 helix in the SRX and remove weight from the arms?

fourload

TY 4 Stroke Master

???? And the lighter pink Apex secondary spring?Maybe we need to rethink this? Mike is running less weight in the primary, so is the secondary actually pinching the belt more or less?

Why did Yamaha choose to use a reverse 35/39 helix in the SRX and remove weight from the arms?

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,695

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Maybe we need to rethink this? Mike is running less weight in the primary, so is the secondary actually pinching the belt more or less?

Why did Yamaha choose to use a reverse 35/39 helix in the SRX and remove weight from the arms?

I'm running less weight for three reasons basically.

1. Way less secondary spring than I had been running. By a long shot!

2. Ultimax xs825 belt hooks the clutches better with less pressure. (also the reason I went to less spring pressure to start with).

3. Helix is WAY more aggressive. Even though its a nickel plated Advant edge @ 49/41, it compares to a Dalton at 53/45, which is actually pretty aggressive. Adtant-Edge cut their helixs with way different angles for whatever reason that is beyond me. Add 4 dergrees to them to compare to stock or Dalton. Another thing is it is pre-cut for OD just the way it comes.

I believe this combo is the reason I'm running way less weight in the arms without actually slipping the belt. I plan to test some things like heavier secondary springs and different belts along the way too, as soon as we get some more snow to test on. The biggest reason I installed the RX-1 drive clutch for was to prolong the roller life. Guys have stated that when switching to the old clutch it does not eat rollers any more. One thing I like about my current setup is it bites the belt way better down low as well as up top. I reminds me of my old TRA, where it bites, goes and grips the belt. Its nice and smooth with a lower engagement for trail use.

I was ready to drive over this sled with a dozer and crush the dang thing flat as a pancake, it was so frustrating to me! I now at least feel some hope that I'll be able to keep belts and rollers in it finally. I was considering adding a TAPP clutch, but who wants to put that much money into a machine you don't like without knowing if it too will even help with belt life? Maybe now I may come to like it anyway. Nothing worse that having issues you can't really fix decently. I hope this is the trick anyway I've tried nearly everything else I could think of, so far it looks real promising with the test in warm weather.

In time I'm betting I will end up with a bit heavier weight up front with cooler weather, a bit more secondary wrap pressure and a happy setup in ALL conditions!

I feel like I had to reduce the pressure on the belt on both ends to make it all work, but that was impossible for me using the roller secondary with the heavy spring setup to keep the belt clamped tight enough. Perhaps If I had reduced the top end helix down to 33 or less who knows, but I was at my whits end with the Winder stuff and had to make a wholesale change.

Similar threads

- Replies

- 10

- Views

- 4K

- Replies

- 3

- Views

- 1K

- Replies

- 16

- Views

- 1K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.