Derek Turnbull

Extreme

- Joined

- Apr 7, 2017

- Messages

- 79

- Age

- 43

- Location

- Maine

- Country

- USA

- Snowmobile

- 2018 Yamaha Sidewinder LTX-LE

Racing Blue

Just ordered 192 1.6 lake racers for my winder!

Blue Dave

Lifetime Member

- Joined

- Jan 7, 2008

- Messages

- 2,888

- Age

- 61

- Location

- Ham Lake, MN

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX DX

Tear outs has as much to do with too long of stud as it does quantity, and for that matter the quality of the base you ride on....I agree more penetration kicks butt for hook, but for trail riding when you start running over 1.450, you are asking for PUSH on hard trails, and more tearouts, and the outers are more vulnerable to tearouts and increase push on twistys.

Running the radar track in NB vs drag racing in fields, vs trail riding tight trails...Guys reading this who are novice need to understand that you really need to ask yourself what type of riding you do MOST, and what do you want from your sled. Prioritize your needs too. Then take all this good info on here and you should get your answer.

You can see this any weekend when a trail studded sled is brought to the track, and watch him barely hookup at take off...I would want a totally different stud to run NB track, vs what I run on trail. As Saber showed, the trigger(or other lake/ice stud) is what you want for serious penetration on ice. But I can guarantee you that design wont be the best bang for buck on longevity and remaining sharp on trail riding. Its all about what you want out of your sled.

Dan

Exactly! Great summary Dan. I will probably put 144 of the 1.500" length Fast Tac Top Gun II studs ( I have had excellent experience with these studs over the years on multiple sleds) down the middle with none on the outsides to avoid push on the twisty trails that I ride most of the time. I also don't want to risk pull outs on the outsides. I am a 90 % groomed trail rider, mostly the tight twisty trails. I sometimes like to line up with others on the lake for a 1/4 mile race but do not plan to do radar runs or official races on shaved ice. Most of my riding is from 30 - 80 mph on the trails (yes, I know that the speed limit in MN is 50 mph LOL!) so I am not concerned about top speed. I want the killer holeshot and the crazy arm stretching ski lifting corner to corner midrange pull.

Blue Dave

Lifetime Member

- Joined

- Jan 7, 2008

- Messages

- 2,888

- Age

- 61

- Location

- Ham Lake, MN

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX DX

OK, it is time for to make up my mind here and get studs installed since the trails are open and the lakes are freezing. Fast Trac Top Gun II advertised stud lengths (1.375", 1.500", & 1.625") have an actual overall length that is 0.375" more than that (1.750", 1.875", & 2.00" respectively) I am not sure how this compares to the other brands but with these studs I will receive penetration of 0.375", 0.500" or 0.625" respectively when installed in my track (heads pulled flush with inside of track).

So here is my question on length. I have the STM tunnel & heat exchanger protectors and it seems that the consensus is that I can run the 1.625" length with no fear of damage as long as I do not run my track too loose. I would use the tall nuts (1/2" nuts for the 1.500 studs or 5/8" nuts for the 1.625" studs) however I am concerned that studs that extend beyond the track too far will be more likely to "fold over" or bend because of the extra leverage that is being applied which also makes me concerned about the longer length studs being more likely to tear out for the same reason.

What is the ideal penetration amount for aggressive trail riding with the TD Powertrail tune? (I am not an ice drag racer).

Obviously the number of studs also needs to be considered as well since more studs means less stress on each individual stud. I am beginning to think that I may want to go with 192 up the middle rather than 144.

I know that this has been debated many times before and perhaps I am beating a dead horse here but I do value all of your opinions and experience which will be helpful in making my decision. Thanks in advance for the help!

So here is my question on length. I have the STM tunnel & heat exchanger protectors and it seems that the consensus is that I can run the 1.625" length with no fear of damage as long as I do not run my track too loose. I would use the tall nuts (1/2" nuts for the 1.500 studs or 5/8" nuts for the 1.625" studs) however I am concerned that studs that extend beyond the track too far will be more likely to "fold over" or bend because of the extra leverage that is being applied which also makes me concerned about the longer length studs being more likely to tear out for the same reason.

What is the ideal penetration amount for aggressive trail riding with the TD Powertrail tune? (I am not an ice drag racer).

Obviously the number of studs also needs to be considered as well since more studs means less stress on each individual stud. I am beginning to think that I may want to go with 192 up the middle rather than 144.

I know that this has been debated many times before and perhaps I am beating a dead horse here but I do value all of your opinions and experience which will be helpful in making my decision. Thanks in advance for the help!

Last edited:

You have the protection... If you want to hook up..1.6xx.... And no plastic backers... Run over sized aluminum backers and standard nuts

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,182

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

I have 1.62 extreme max studs. They are 1.92 oal. 9/16th penetration.

400 kms so far of riding, no marks in the tunnel from hitting anything and I just have the Yamaha tunnel protectors at the back.

400 kms so far of riding, no marks in the tunnel from hitting anything and I just have the Yamaha tunnel protectors at the back.

I have 1.62 extreme max studs. They are 1.92 oal. 9/16th penetration.

400 kms so far of riding, no marks in the tunnel from hitting anything and I just have the Yamaha tunnel protectors at the back.

are you in the middle? if so...shine a light way up front into the tunnel and take a pic

Blue Dave

Lifetime Member

- Joined

- Jan 7, 2008

- Messages

- 2,888

- Age

- 61

- Location

- Ham Lake, MN

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX DX

are you in the middle? if so...shine a light way up front into the tunnel and take a pic

SJ, I am assuming that you are concerned about the header vent?

Big_Phil, please also reply with the number of studs you are running.

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,182

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

SJ, I am assuming that you are concerned about the header vent?

Big_Phil, please also reply with the number of studs you are running.

Ill take a pic when I get home. 135 studs. Middle bar only.

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,182

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

Don't mind the grass and mud. Not much of a base yet across the farmers fields.

And the center protector on the rear was in the sled when I got it, and is epoxied in or something. So that's been hit by a couple of studs, but nowhere near the actual exchanger in the rear. I might try and use the dremel to get it out, or might just leave it. Haven't decided yet.

get further into the tunnel towards the front

Doc Harley

TY 4 Stroke God

- Joined

- Oct 17, 2016

- Messages

- 3,695

- Age

- 56

- Location

- Here & there

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX SE

Big Phil, you say you go 250lbs & stud length is 1.6.

He'd be the perfect candidate to tear up the front vents.

He'd be the perfect candidate to tear up the front vents.

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,182

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

get further into the tunnel towards the front

Maybe later if you really want, but there is no stud contact anywhere. These are slightly shorter than a 1.575 woodys.

My track was even rather loose the last ride I took out because it stretched a bit. Over an inch of sag when lifting the back and still no contact. I just turned it up to 270hp from 240 tune before the last ride, added clutch weight and was making sure the Rpms were good. I did several antilag launches up to over 100mph, and did a 20 km bumpy trail ride at high speeds.

Blue Dave

Lifetime Member

- Joined

- Jan 7, 2008

- Messages

- 2,888

- Age

- 61

- Location

- Ham Lake, MN

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX DX

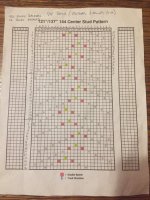

OK guys. I have about 600 miles now on my 144 Fast-Trac 1.500" Top Gun II studs. I used the CB Performance template for a 25 scratch line pattern between the rails utilizing 132 single backers & 12 double backers for a combination of 2, 3, & 4 studs per row in a 16 row pattern that repeats 3 times on my 137" track.

I installed the STM Powersports heat exchanger and tunnel protectors which are thicker and cover more area than the Yamaha protectors. I try to keep a tight track (1.5" sag with 20 # pulling in the center) but the track has stretched a lot and has twice become loose enough to ratchet under full power (285 hp TD set-up). Even with the track loose enough to ratchet under full power, plus many 120+ mph lake runs, and many miles of high speed bumpy trails, I do not have any stud damage anywhere in the tunnel except for a few very slight "nicks" at the very ends of a few of the front heat exchanger fins.

Last edited:

Studs on the outside KILL handling of the sled period! to many studs slow you down on top speed rotating mass. Unless you are drag racing everyday 144 down the middle for stopping and ice roads will do the trick. Studs on snow covered trails don't do a dam thing anyway

Blue Dave

Lifetime Member

- Joined

- Jan 7, 2008

- Messages

- 2,888

- Age

- 61

- Location

- Ham Lake, MN

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX DX

To each his own I guess. We all have our opinions. I found 144 in the middle to be a good compromise between a great handling sled (I like to get the rear end loose in the corners) and hooking up decent on acceleration with good stopping ability.

Similar threads

- Replies

- 7

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.